service JAGUAR S TYPE 2005 1.G Technical Guide Update

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2005, Model line: S TYPE, Model: JAGUAR S TYPE 2005 1.GPages: 133, PDF Size: 3.48 MB

Page 53 of 133

JAGUARS-TYPE

D.204.400

Chassis

48

D.204.440

VERTICAL FRONT KNUCKLE UPPER CONTROL ARM

D.204.440

D.204.400

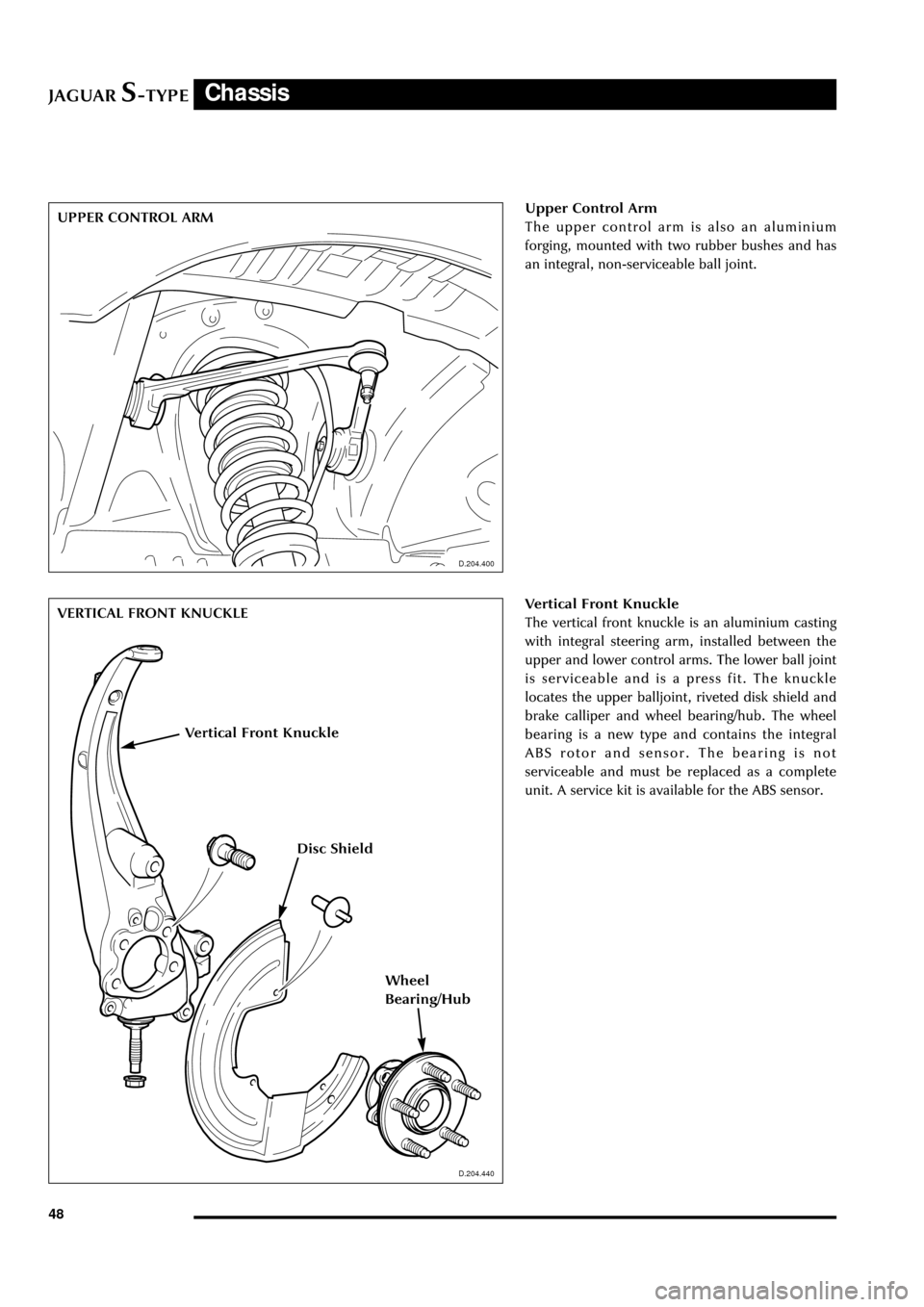

Upper Control Arm

The upper control arm is also an aluminium

forging, mounted with two rubber bushes and has

an integral, non-serviceable ball joint.

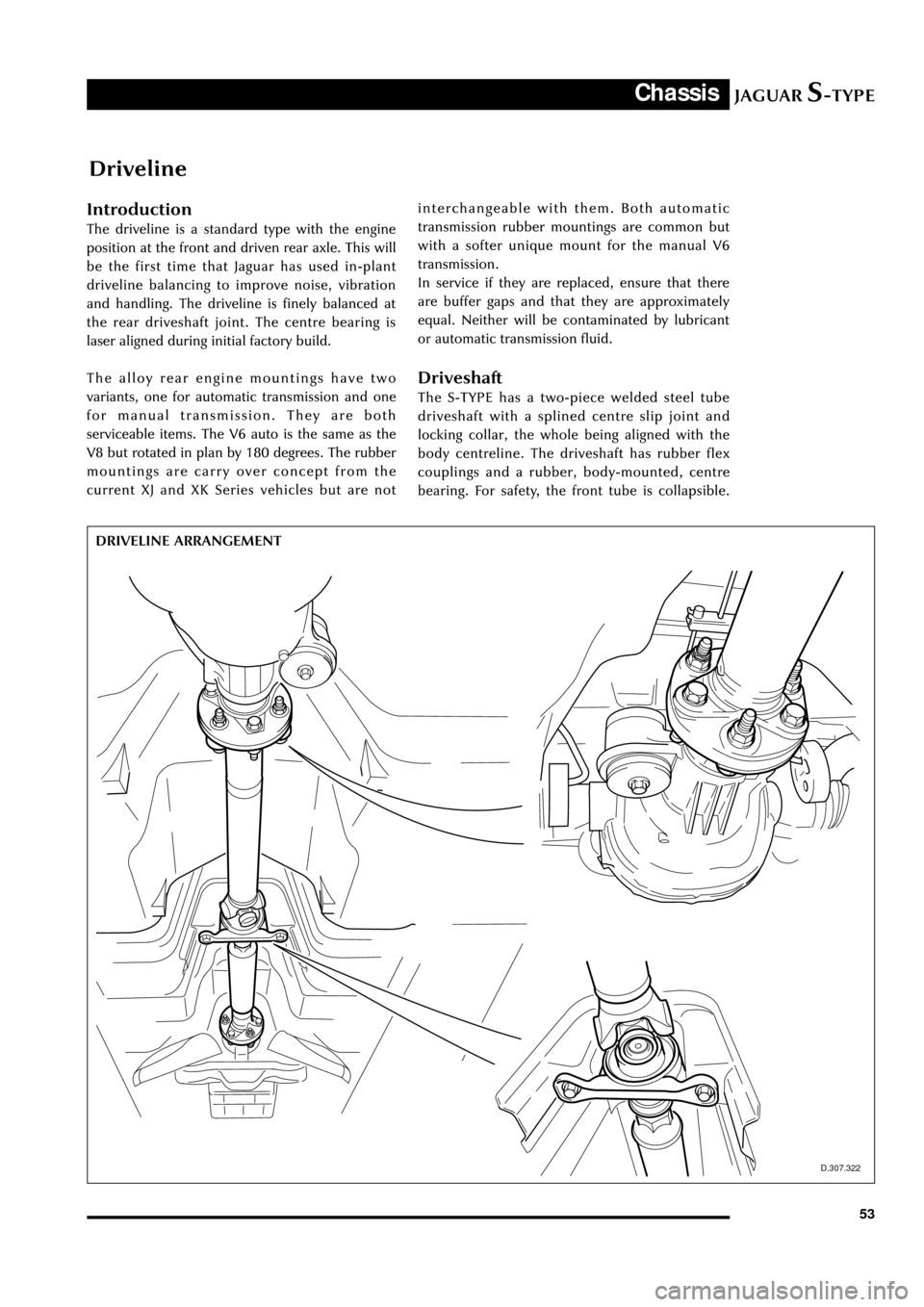

Vertical Front Knuckle

The vertical front knuckle is an aluminium casting

with integral steering arm, installed between the

upper and lower control arms. The lower ball joint

is serviceable and is a press fit. The knuckle

locates the upper balljoint, riveted disk shield and

brake calliper and wheel bearing/hub. The wheel

bearing is a new type and contains the integral

ABS rotor and sensor. The bearing is not

serviceable and must be replaced as a complete

unit. A service kit is available for the ABS sensor.

Vertical Front Knuckle

Disc Shield

Wheel

Bearing/Hub

Page 58 of 133

JAGUARS-TYPEChassis

53

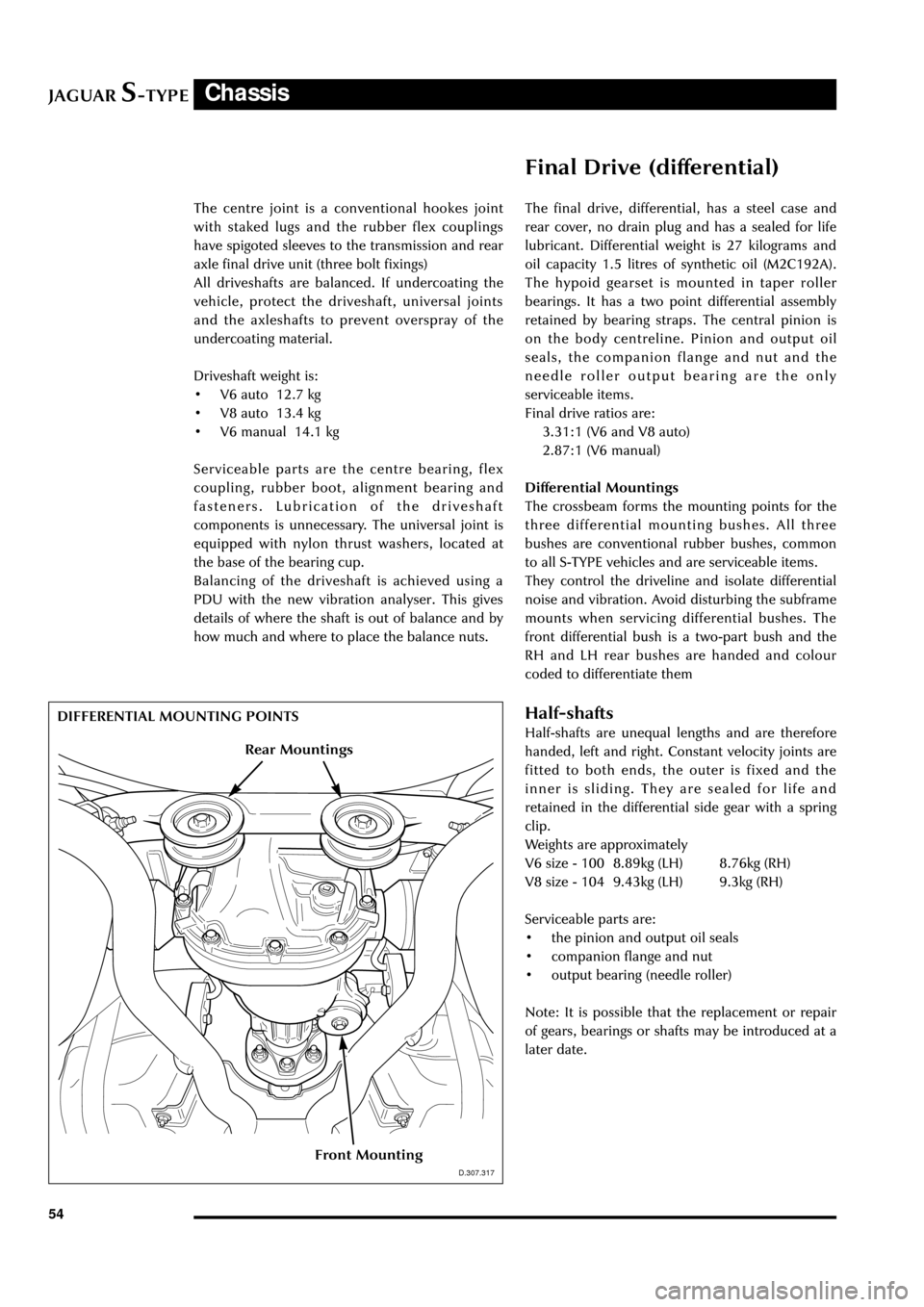

Driveline

Introduction

The driveline is a standard type with the engine

position at the front and driven rear axle. This will

be the first time that Jaguar has used in-plant

driveline balancing to improve noise, vibration

and handling. The driveline is finely balanced at

the rear driveshaft joint. The centre bearing is

laser aligned during initial factory build.

The alloy rear engine mountings have two

variants, one for automatic transmission and one

for manual transmission. They are both

serviceable items. The V6 auto is the same as the

V8 but rotated in plan by 180 degrees. The rubber

mountings are carry over concept from the

current XJ and XK Series vehicles but are not

D.307.322

DRIVELINE ARRANGEMENTinterchangeable with them. Both automatic

transmission rubber mountings are common but

with a softer unique mount for the manual V6

transmission.

In service if they are replaced, ensure that there

are buffer gaps and that they are approximately

equal. Neither will be contaminated by lubricant

or automatic transmission fluid.

Driveshaft

The S-TYPE has a two-piece welded steel tube

driveshaft with a splined centre slip joint and

locking collar, the whole being aligned with the

body centreline. The driveshaft has rubber flex

couplings and a rubber, body-mounted, centre

bearing. For safety, the front tube is collapsible.

Page 59 of 133

JAGUARS-TYPEChassis

54The centre joint is a conventional hookes joint

with staked lugs and the rubber flex couplings

have spigoted sleeves to the transmission and rear

axle final drive unit (three bolt fixings)

All driveshafts are balanced. If undercoating the

vehicle, protect the driveshaft, universal joints

and the axleshafts to prevent overspray of the

undercoating material.

Driveshaft weight is:

¥ V6 auto 12.7 kg

¥ V8 auto 13.4 kg

¥ V6 manual 14.1 kg

Serviceable parts are the centre bearing, flex

coupling, rubber boot, alignment bearing and

fasteners. Lubrication of the driveshaft

components is unnecessary. The universal joint is

equipped with nylon thrust washers, located at

the base of the bearing cup.

Balancing of the driveshaft is achieved using a

PDU with the new vibration analyser. This gives

details of where the shaft is out of balance and by

how much and where to place the balance nuts.

Final Drive (differential)

The final drive, differential, has a steel case and

rear cover, no drain plug and has a sealed for life

lubricant. Differential weight is 27 kilograms and

oil capacity 1.5 litres of synthetic oil (M2C192A).

The hypoid gearset is mounted in taper roller

bearings. It has a two point differential assembly

retained by bearing straps. The central pinion is

on the body centreline. Pinion and output oil

seals, the companion flange and nut and the

needle roller output bearing are the only

serviceable items.

Final drive ratios are:

3.31:1 (V6 and V8 auto)

2.87:1 (V6 manual)

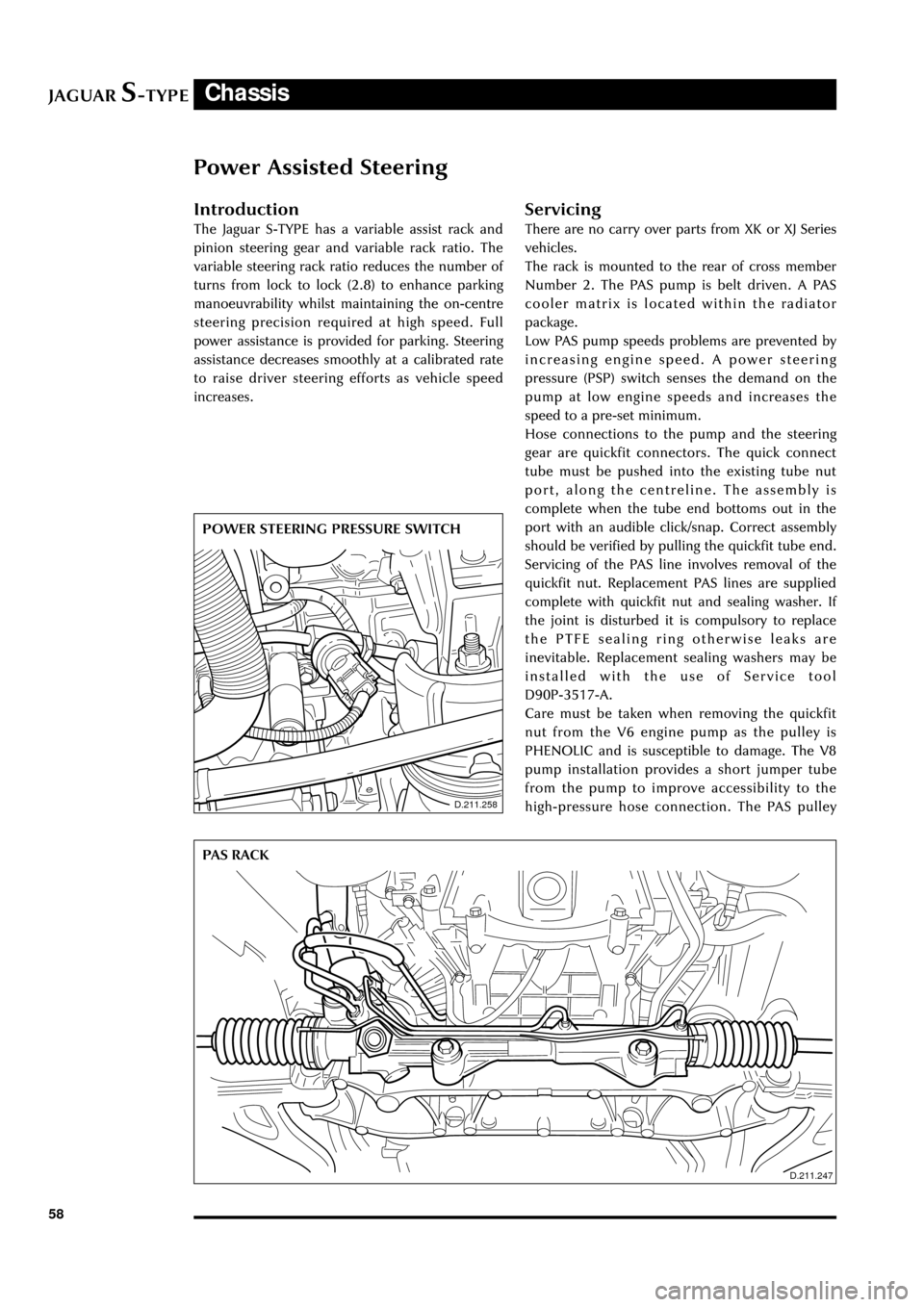

Differential Mountings

The crossbeam forms the mounting points for the

three differential mounting bushes. All three

bushes are conventional rubber bushes, common

to all S-TYPE vehicles and are serviceable items.

They control the driveline and isolate differential

noise and vibration. Avoid disturbing the subframe

mounts when servicing differential bushes. The

front differential bush is a two-part bush and the

RH and LH rear bushes are handed and colour

coded to differentiate them

Half-shafts

Half-shafts are unequal lengths and are therefore

handed, left and right. Constant velocity joints are

fitted to both ends, the outer is fixed and the

inner is sliding. They are sealed for life and

retained in the differential side gear with a spring

clip.

Weights are approximately

V6 size - 100 8.89kg (LH) 8.76kg (RH)

V8 size - 104 9.43kg (LH) 9.3kg (RH)

Serviceable parts are:

¥ the pinion and output oil seals

¥ companion flange and nut

¥ output bearing (needle roller)

Note: It is possible that the replacement or repair

of gears, bearings or shafts may be introduced at a

later date.

D.307.317

DIFFERENTIAL MOUNTING POINTS

D.307.317

Front Mounting

Rear Mountings

Page 63 of 133

JAGUARS-TYPEChassis

58

Power Assisted Steering

Introduction

The Jaguar S-TYPE has a variable assist rack and

pinion steering gear and variable rack ratio. The

variable steering rack ratio reduces the number of

turns from lock to lock (2.8) to enhance parking

manoeuvrability whilst maintaining the on-centre

steering precision required at high speed. Full

power assistance is provided for parking. Steering

assistance decreases smoothly at a calibrated rate

to raise driver steering efforts as vehicle speed

increases.

Servicing

There are no carry over parts from XK or XJ Series

vehicles.

The rack is mounted to the rear of cross member

Number 2. The PAS pump is belt driven. A PAS

cooler matrix is located within the radiator

package.

Low PAS pump speeds problems are prevented by

increasing engine speed. A power steering

pressure (PSP) switch senses the demand on the

pump at low engine speeds and increases the

speed to a pre-set minimum.

Hose connections to the pump and the steering

gear are quickfit connectors. The quick connect

tube must be pushed into the existing tube nut

port, along the centreline. The assembly is

complete when the tube end bottoms out in the

port with an audible click/snap. Correct assembly

should be verified by pulling the quickfit tube end.

Servicing of the PAS line involves removal of the

quickfit nut. Replacement PAS lines are supplied

complete with quickfit nut and sealing washer. If

the joint is disturbed it is compulsory to replace

the PTFE sealing ring otherwise leaks are

inevitable. Replacement sealing washers may be

installed with the use of Service tool

D90P-3517-A.

Care must be taken when removing the quickfit

nut from the V6 engine pump as the pulley is

PHENOLIC and is susceptible to damage. The V8

pump installation provides a short jumper tube

from the pump to improve accessibility to the

high-pressure hose connection. The PAS pulley

D.211.247

PA S R AC K

D.211.258

POWER STEERING PRESSURE SWITCH

Page 64 of 133

JAGUARS-TYPEChassis

59

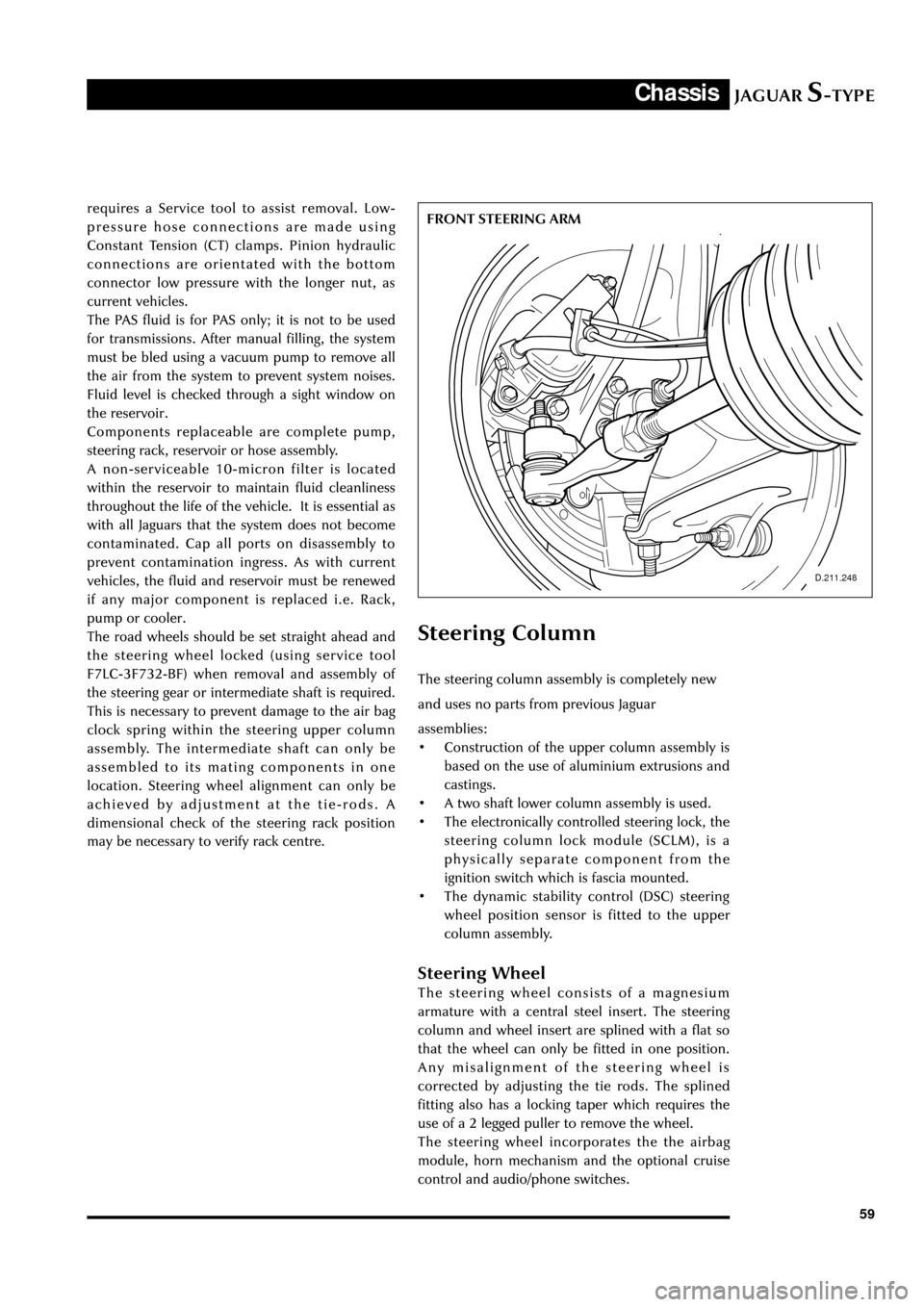

D.211.248

FRONT STEERING ARM requires a Service tool to assist removal. Low-

pressure hose connections are made using

Constant Tension (CT) clamps. Pinion hydraulic

connections are orientated with the bottom

connector low pressure with the longer nut, as

current vehicles.

The PAS fluid is for PAS only; it is not to be used

for transmissions. After manual filling, the system

must be bled using a vacuum pump to remove all

the air from the system to prevent system noises.

Fluid level is checked through a sight window on

the reservoir.

Components replaceable are complete pump,

steering rack, reservoir or hose assembly.

A non-serviceable 10-micron filter is located

within the reservoir to maintain fluid cleanliness

throughout the life of the vehicle. It is essential as

with all Jaguars that the system does not become

contaminated. Cap all ports on disassembly to

prevent contamination ingress. As with current

vehicles, the fluid and reservoir must be renewed

if any major component is replaced i.e. Rack,

pump or cooler.

The road wheels should be set straight ahead and

the steering wheel locked (using service tool

F7LC-3F732-BF) when removal and assembly of

the steering gear or intermediate shaft is required.

This is necessary to prevent damage to the air bag

clock spring within the steering upper column

assembly. The intermediate shaft can only be

assembled to its mating components in one

location. Steering wheel alignment can only be

achieved by adjustment at the tie-rods. A

dimensional check of the steering rack position

may be necessary to verify rack centre.

Steering Column

The steering column assembly is completely new

and uses no parts from previous Jaguar

assemblies:

¥ Construction of the upper column assembly is

based on the use of aluminium extrusions and

castings.

¥ A two shaft lower column assembly is used.

¥ The electronically controlled steering lock, the

steering column lock module (SCLM), is a

physically separate component from the

ignition switch which is fascia mounted.

¥ The dynamic stability control (DSC) steering

wheel position sensor is fitted to the upper

column assembly.

Steering Wheel

The steering wheel consists of a magnesium

armature with a central steel insert. The steering

column and wheel insert are splined with a flat so

that the wheel can only be fitted in one position.

Any misalignment of the steering wheel is

corrected by adjusting the tie rods. The splined

fitting also has a locking taper which requires the

use of a 2 legged puller to remove the wheel.

The steering wheel incorporates the the airbag

module, horn mechanism and the optional cruise

control and audio/phone switches.

Page 67 of 133

JAGUARS-TYPEChassis

62

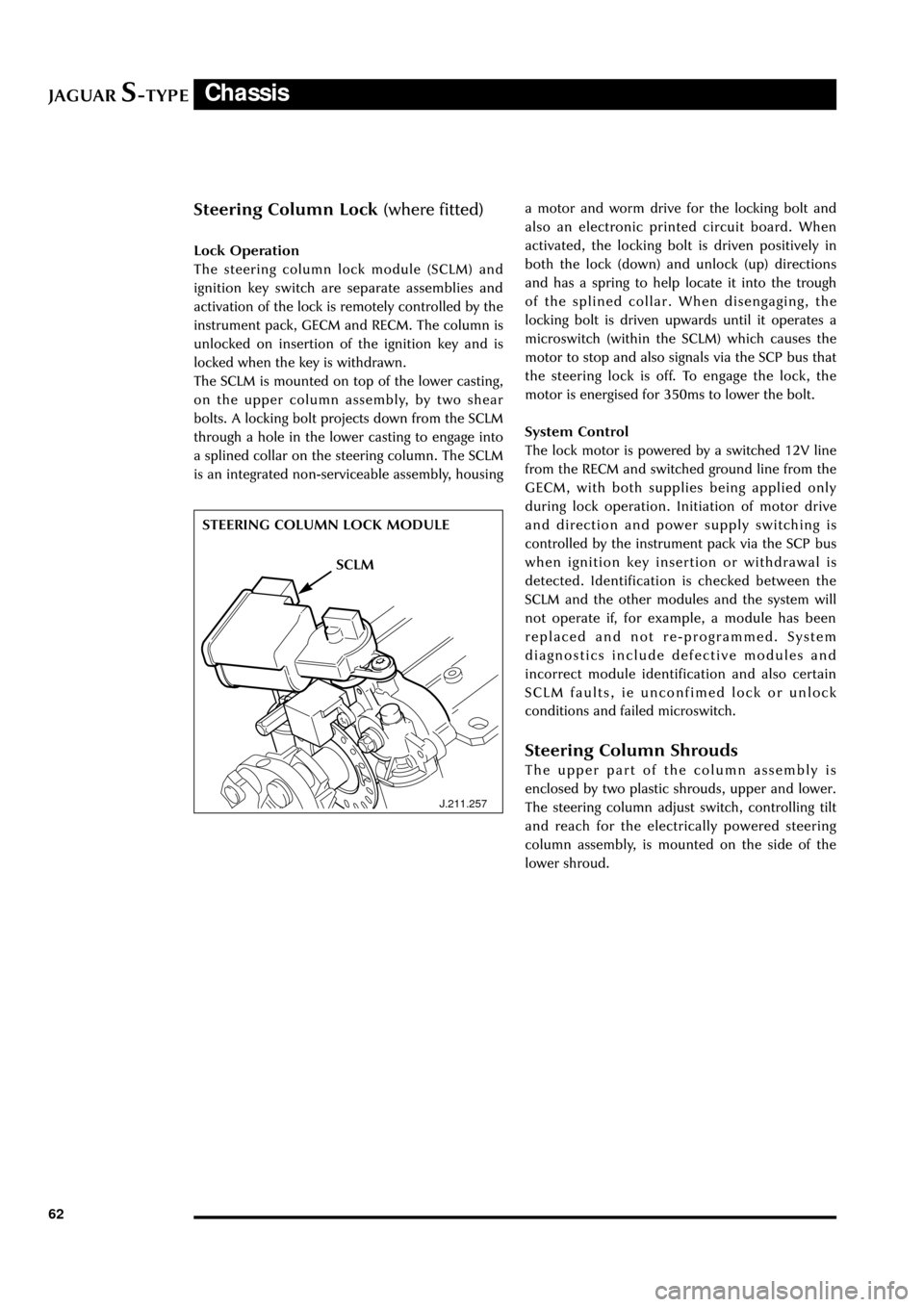

J.211.257

STEERING COLUMN LOCK MODULE

Steering Column Lock (where fitted)

Lock Operation

The steering column lock module (SCLM) and

ignition key switch are separate assemblies and

activation of the lock is remotely controlled by the

instrument pack, GECM and RECM. The column is

unlocked on insertion of the ignition key and is

locked when the key is withdrawn.

The SCLM is mounted on top of the lower casting,

on the upper column assembly, by two shear

bolts. A locking bolt projects down from the SCLM

through a hole in the lower casting to engage into

a splined collar on the steering column. The SCLM

is an integrated non-serviceable assembly, housinga motor and worm drive for the locking bolt and

also an electronic printed circuit board. When

activated, the locking bolt is driven positively in

both the lock (down) and unlock (up) directions

and has a spring to help locate it into the trough

of the splined collar. When disengaging, the

locking bolt is driven upwards until it operates a

microswitch (within the SCLM) which causes the

motor to stop and also signals via the SCP bus that

the steering lock is off. To engage the lock, the

motor is energised for 350ms to lower the bolt.

System Control

The lock motor is powered by a switched 12V line

from the RECM and switched ground line from the

GECM, with both supplies being applied only

during lock operation. Initiation of motor drive

and direction and power supply switching is

controlled by the instrument pack via the SCP bus

when ignition key insertion or withdrawal is

detected. Identification is checked between the

SCLM and the other modules and the system will

not operate if, for example, a module has been

replaced and not re-programmed. System

diagnostics include defective modules and

incorrect module identification and also certain

SCLM faults, ie unconfimed lock or unlock

conditions and failed microswitch.

Steering Column Shrouds

The upper part of the column assembly is

enclosed by two plastic shrouds, upper and lower.

The steering column adjust switch, controlling tilt

and reach for the electrically powered steering

column assembly, is mounted on the side of the

lower shroud.

SCLM

Page 112 of 133

JAGUARS-TYPEElectrical/Electronic

107

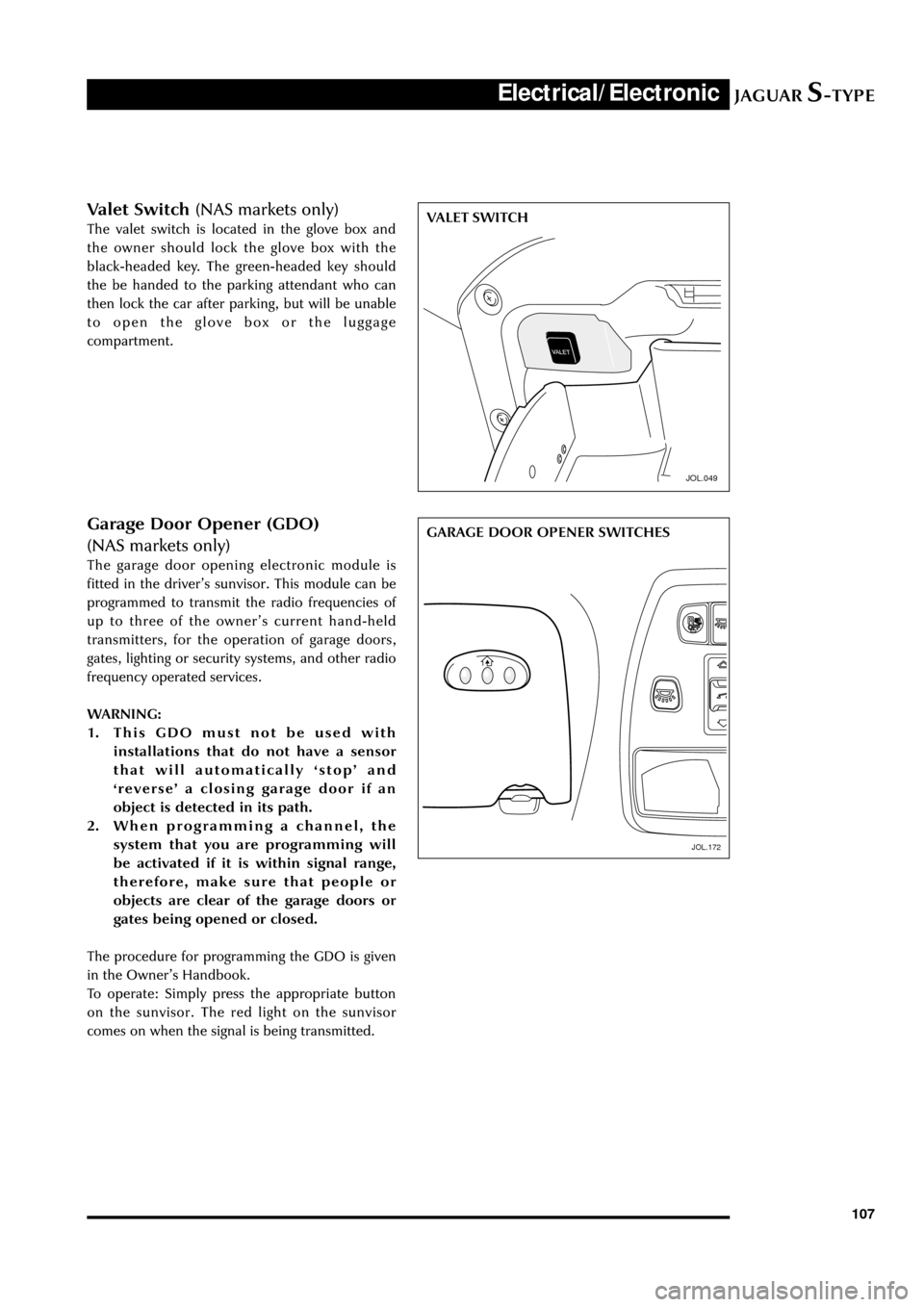

Valet Switch (NAS markets only)

The valet switch is located in the glove box and

the owner should lock the glove box with the

black-headed key. The green-headed key should

the be handed to the parking attendant who can

then lock the car after parking, but will be unable

to open the glove box or the luggage

compartment.

JOL.049

VALET SWITCH

JOL.172

GARAGE DOOR OPENER SWITCHESGarage Door Opener (GDO)

(NAS markets only)

The garage door opening electronic module is

fitted in the driverÕs sunvisor. This module can be

programmed to transmit the radio frequencies of

up to three of the ownerÕs current hand-held

transmitters, for the operation of garage doors,

gates, lighting or security systems, and other radio

frequency operated services.

WARNING:

1. This GDO must not be used with

installations that do not have a sensor

that will automatically ÔstopÕ and

ÔreverseÕ a closing garage door if an

object is detected in its path.

2. When programming a channel, the

system that you are programming will

be activated if it is within signal range,

therefore, make sure that people or

objects are clear of the garage doors or

gates being opened or closed.

The procedure for programming the GDO is given

in the OwnerÕs Handbook.

To operate: Simply press the appropriate button

on the sunvisor. The red light on the sunvisor

comes on when the signal is being transmitted.

JOL.172

Page 121 of 133

JAGUARS-TYPEElectrical/Electronic

116

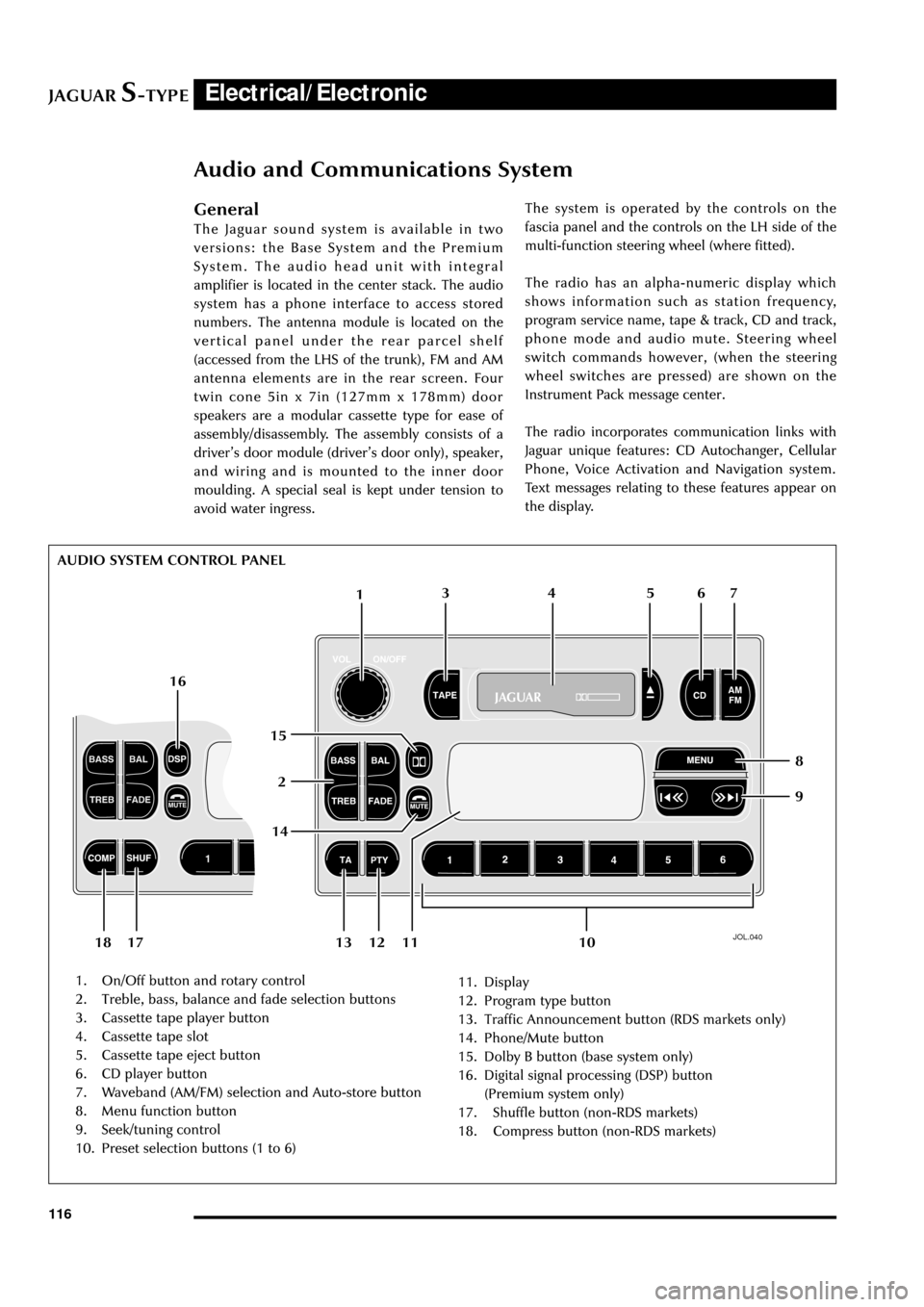

Audio and Communications System

General

The Jaguar sound system is available in two

versions: the Base System and the Premium

System. The audio head unit with integral

amplifier is located in the center stack. The audio

system has a phone interface to access stored

numbers. The antenna module is located on the

vertical panel under the rear parcel shelf

(accessed from the LHS of the trunk), FM and AM

antenna elements are in the rear screen. Four

twin cone 5in x 7in (127mm x 178mm) door

speakers are a modular cassette type for ease of

assembly/disassembly. The assembly consists of a

driverÕs door module (driverÕs door only), speaker,

and wiring and is mounted to the inner door

moulding. A special seal is kept under tension to

avoid water ingress.

JOL.040

1. On/Off button and rotary control

2. Treble, bass, balance and fade selection buttons

3. Cassette tape player button

4. Cassette tape slot

5. Cassette tape eject button

6. CD player button

7. Waveband (AM/FM) selection and Auto-store button

8. Menu function button

9. Seek/tuning control

10. Preset selection buttons (1 to 6)11. Display

12. Program type button

13. Traffic Announcement button (RDS markets only)

14. Phone/Mute button

15. Dolby B button (base system only)

16. Digital signal processing (DSP) button

(Premium system only)

17. Shuffle button (non-RDS markets)

18. Compress button (non-RDS markets)The system is operated by the controls on the

fascia panel and the controls on the LH side of the

multi-function steering wheel (where fitted).

The radio has an alpha-numeric display which

shows information such as station frequency,

program service name, tape & track, CD and track,

phone mode and audio mute. Steering wheel

switch commands however, (when the steering

wheel switches are pressed) are shown on the

Instrument Pack message center.

The radio incorporates communication links with

Jaguar unique features: CD Autochanger, Cellular

Phone, Voice Activation and Navigation system.

Text messages relating to these features appear on

the display.

1

26 5 4 3

109 8 7

11 13 12 1814 16

15

17 AUDIO SYSTEM CONTROL PANEL

Page 128 of 133

JAGUARS-TYPEElectrical/Electronic

123

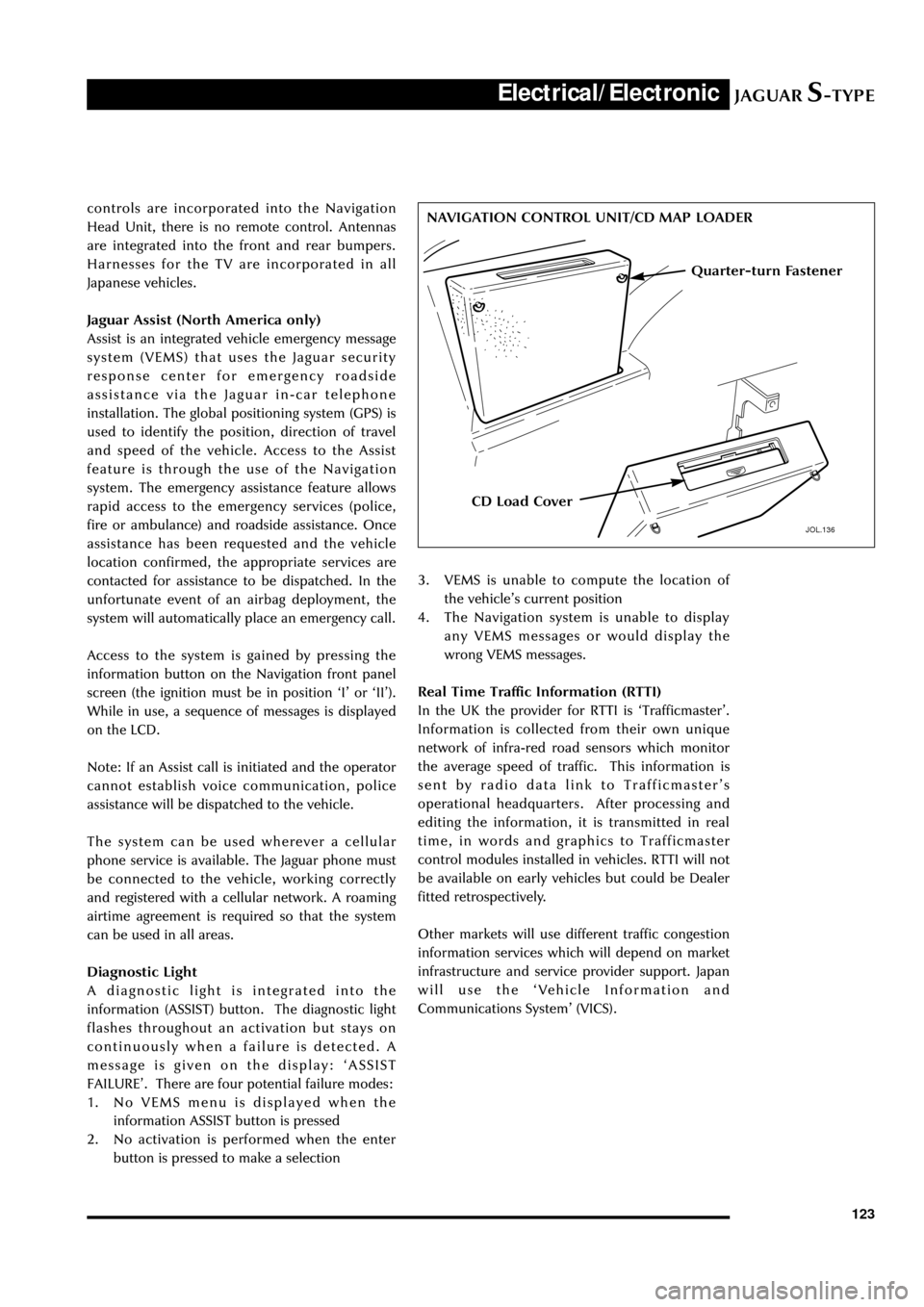

JOL.136

Quarter-turn Fastener

CD Load Cover

NAVIGATION CONTROL UNIT/CD MAP LOADER controls are incorporated into the Navigation

Head Unit, there is no remote control. Antennas

are integrated into the front and rear bumpers.

Harnesses for the TV are incorporated in all

Japanese vehicles.

Jaguar Assist (North America only)

Assist is an integrated vehicle emergency message

system (VEMS) that uses the Jaguar security

response center for emergency roadside

assistance via the Jaguar in-car telephone

installation. The global positioning system (GPS) is

used to identify the position, direction of travel

and speed of the vehicle. Access to the Assist

feature is through the use of the Navigation

system. The emergency assistance feature allows

rapid access to the emergency services (police,

fire or ambulance) and roadside assistance. Once

assistance has been requested and the vehicle

location confirmed, the appropriate services are

contacted for assistance to be dispatched. In the

unfortunate event of an airbag deployment, the

system will automatically place an emergency call.

Access to the system is gained by pressing the

information button on the Navigation front panel

screen (the ignition must be in position ÔIÕ or ÔIIÕ).

While in use, a sequence of messages is displayed

on the LCD.

Note: If an Assist call is initiated and the operator

cannot establish voice communication, police

assistance will be dispatched to the vehicle.

The system can be used wherever a cellular

phone service is available. The Jaguar phone must

be connected to the vehicle, working correctly

and registered with a cellular network. A roaming

airtime agreement is required so that the system

can be used in all areas.

Diagnostic Light

A diagnostic light is integrated into the

information (ASSIST) button. The diagnostic light

flashes throughout an activation but stays on

continuously when a failure is detected. A

message is given on the display: ÔASSIST

FAILUREÕ. There are four potential failure modes:

1. No VEMS menu is displayed when the

information ASSIST button is pressed

2. No activation is performed when the enter

button is pressed to make a selection3. VEMS is unable to compute the location of

the vehicleÕs current position

4. The Navigation system is unable to display

any VEMS messages or would display the

wrong VEMS messages.

Real Time Traffic Information (RTTI)

In the UK the provider for RTTI is ÔTrafficmasterÕ.

Information is collected from their own unique

network of infra-red road sensors which monitor

the average speed of traffic. This information is

sent by radio data link to TrafficmasterÕs

operational headquarters. After processing and

editing the information, it is transmitted in real

time, in words and graphics to Trafficmaster

control modules installed in vehicles. RTTI will not

be available on early vehicles but could be Dealer

fitted retrospectively.

Other markets will use different traffic congestion

information services which will depend on market

infrastructure and service provider support. Japan

will use the ÔVehicle Information and

Communications SystemÕ (VICS).