service JAGUAR S TYPE 2005 1.G Technical Guide Update

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2005, Model line: S TYPE, Model: JAGUAR S TYPE 2005 1.GPages: 133, PDF Size: 3.48 MB

Page 2 of 133

Published by Service CommunicationsJaguar Cars LimitedPublication Part No JJM 10 15 16/92 February 1999

Page 4 of 133

Technical Guide

Jaguar S-TYPE

Sports Sedan

Introduction

Published by Service CommunicationsJaguar Cars LimitedPublication Part No JJM 10 15 16/92 February 1999

Page 5 of 133

JAGUARS-TYPEPreface

This Technical Guide introduces the Jaguar S-TYPE sports sedan which is a new addition to the Jaguar

range. It is intended to give Jaguar Dealer workshop personnel an overview of their construction and

operation, and is for information purposes only. The contents of this Technical Guide must not be used

as a reference source for servicing procedures; all servicing procedures must be in accordance with the

appropriate Service Manual.

This Technical Guide will not be updated. While every effort is made to ensure accuracy, changes may

occur between going to press and the equipment being introduced to the market. Once the equipment is

in service, details of changes can be obtained from Service Bulletins and revisions to the Service

Manuals.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or

transmitted, in any form, electronic, mechanical, photocopying, recording or other means without prior

written permission from the Service Division of Jaguar Cars Limited.

Page 25 of 133

JAGUARS-TYPEBody

20system mirrors. A clear patch in the darkened

area at the bottom left of the windshield gives

external visible access to the VIN.

There are three types of windshield variants:

¥ Rain sensing, with electrochromic mirror

(NAS markets have the option of a compass

fitted to the mirror head).

¥ Non-rain sensing with electrochromic mirror

(NAS markets have the option of a compass

fitted to the mirror head).

¥ Non-rain sensing with prismatic mirror.

Windshields are available as heated or non-

heated and the rain sensing versions have a

unique mirror mounting system.

Backlight

The backlight is direct glazed to body. All

backlights are heated and have solar control tint,

integral radio and telephone antenna. The

backlight heater is timed on for 10 minutes.

Door glass

Each front door window is single curvature glass,

5mm thick, and operated by a twin guide cable

and drum assembly with five stud fixing points.

The glass is clamped to the regulator slide blocks.

Access holes are provided in the inner door when

the glass is raised. There are no adjustable end of

travel stops.

Rear door glass is also a single curvature glass,

4mm thick, with a single guide cable and drum

assembly and three stud fixing points. The glass

drops fully to the door roll. The glass is located to

the slider blocks by pins and has no adjustable

end of travel stops.

Each front and rear cable and drum mechanisms

must be replaced as individual complete units,

they have no serviceable parts.

Quarter lights

Quarter lights are 4mm thick with three fixings,

one is a lower bracket to the door inner.

Perimeter foam and butyl rubber seals are fitted

to the door outer.

Page 26 of 133

JAGUARS-TYPEBody

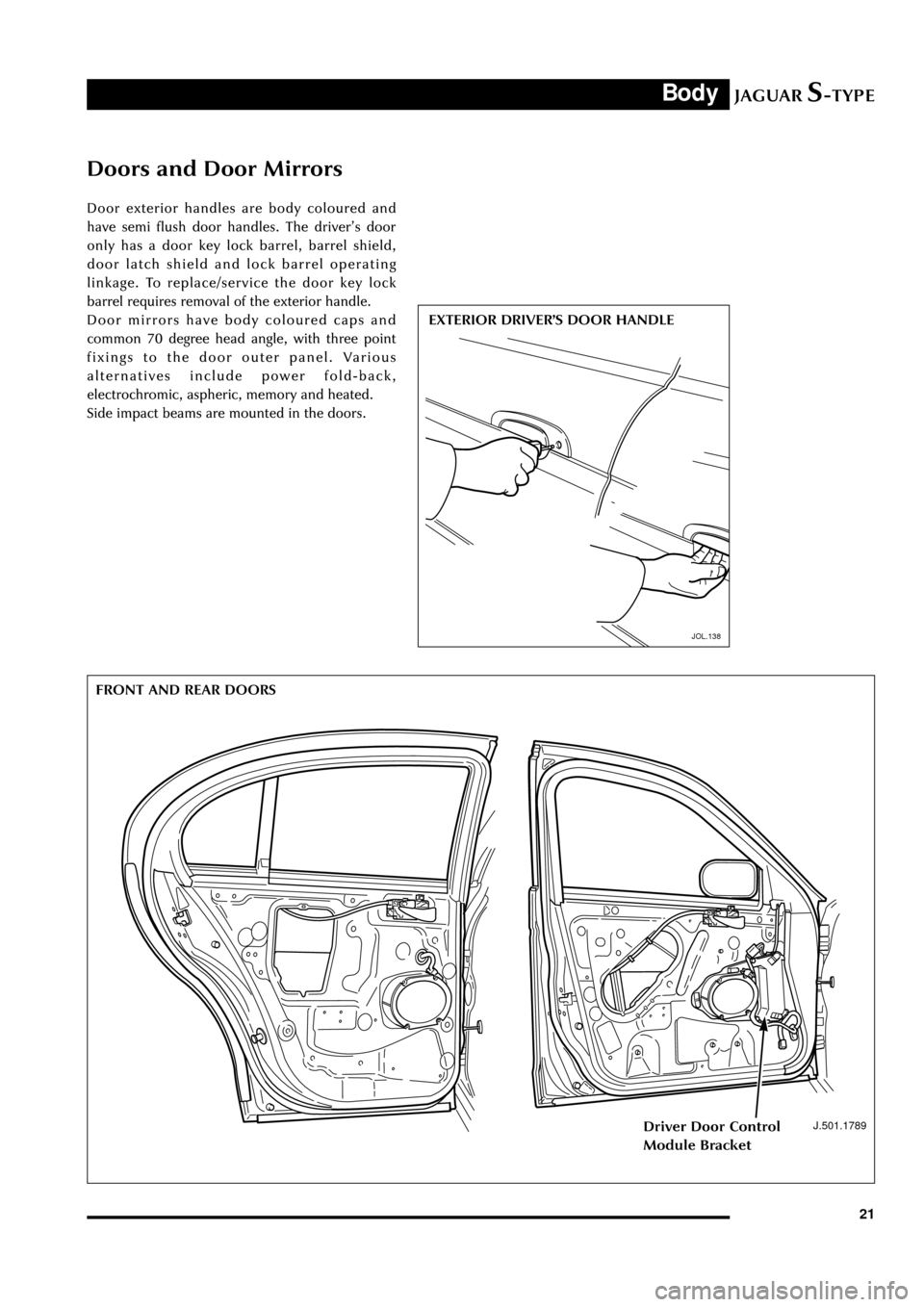

21 Door exterior handles are body coloured and

have semi flush door handles. The driverÕs door

only has a door key lock barrel, barrel shield,

door latch shield and lock barrel operating

linkage. To replace/service the door key lock

barrel requires removal of the exterior handle.

Door mirrors have body coloured caps and

common 70 degree head angle, with three point

fixings to the door outer panel. Various

alternatives include power fold-back,

electrochromic, aspheric, memory and heated.

Side impact beams are mounted in the doors.

Doors and Door Mirrors

EXTERIOR DRIVERÕS DOOR HANDLE

JOL.138

J.501.1789

FRONT AND REAR DOORS

Driver Door Control

Module Bracket

Page 37 of 133

JAGUARS-TYPEOccupant Protection

32

Seatbelts

D.501.1777

REAR SEAT BELT RETRACTOR ASSEMBLIES

D.501.1465

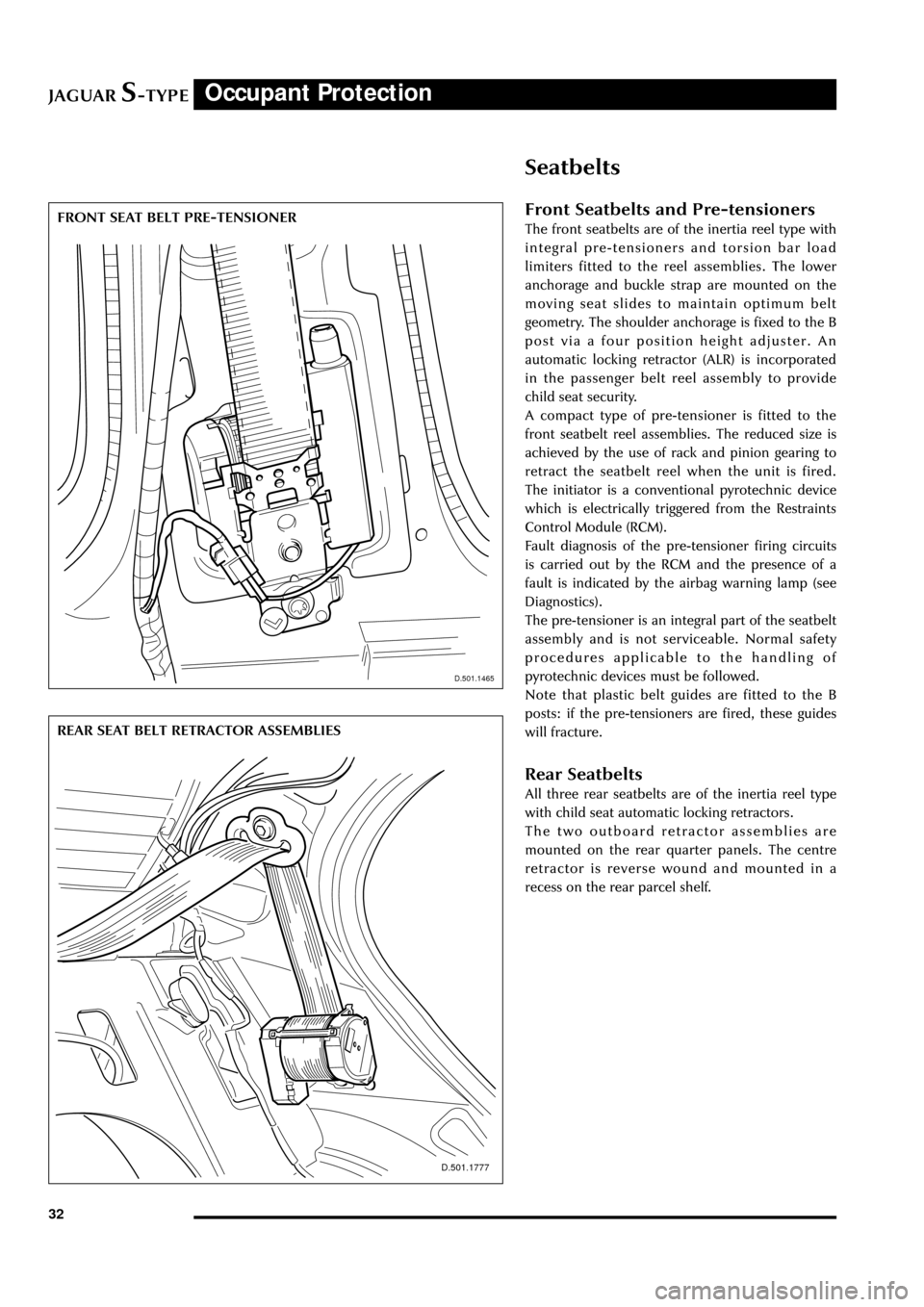

FRONT SEAT BELT PRE-TENSIONERFront Seatbelts and Pre-tensioners

The front seatbelts are of the inertia reel type with

integral pre-tensioners and torsion bar load

limiters fitted to the reel assemblies. The lower

anchorage and buckle strap are mounted on the

moving seat slides to maintain optimum belt

geometry. The shoulder anchorage is fixed to the B

post via a four position height adjuster. An

automatic locking retractor (ALR) is incorporated

in the passenger belt reel assembly to provide

child seat security.

A compact type of pre-tensioner is fitted to the

front seatbelt reel assemblies. The reduced size is

achieved by the use of rack and pinion gearing to

retract the seatbelt reel when the unit is fired.

The initiator is a conventional pyrotechnic device

which is electrically triggered from the Restraints

Control Module (RCM).

Fault diagnosis of the pre-tensioner firing circuits

is carried out by the RCM and the presence of a

fault is indicated by the airbag warning lamp (see

Diagnostics).

The pre-tensioner is an integral part of the seatbelt

assembly and is not serviceable. Normal safety

procedures applicable to the handling of

pyrotechnic devices must be followed.

Note that plastic belt guides are fitted to the B

posts: if the pre-tensioners are fired, these guides

will fracture.

Rear Seatbelts

All three rear seatbelts are of the inertia reel type

with child seat automatic locking retractors.

The two outboard retractor assemblies are

mounted on the rear quarter panels. The centre

retractor is reverse wound and mounted in a

recess on the rear parcel shelf.

D.501.1465

Page 41 of 133

JAGUARS-TYPE

D.418.233

Occupant Protection

36

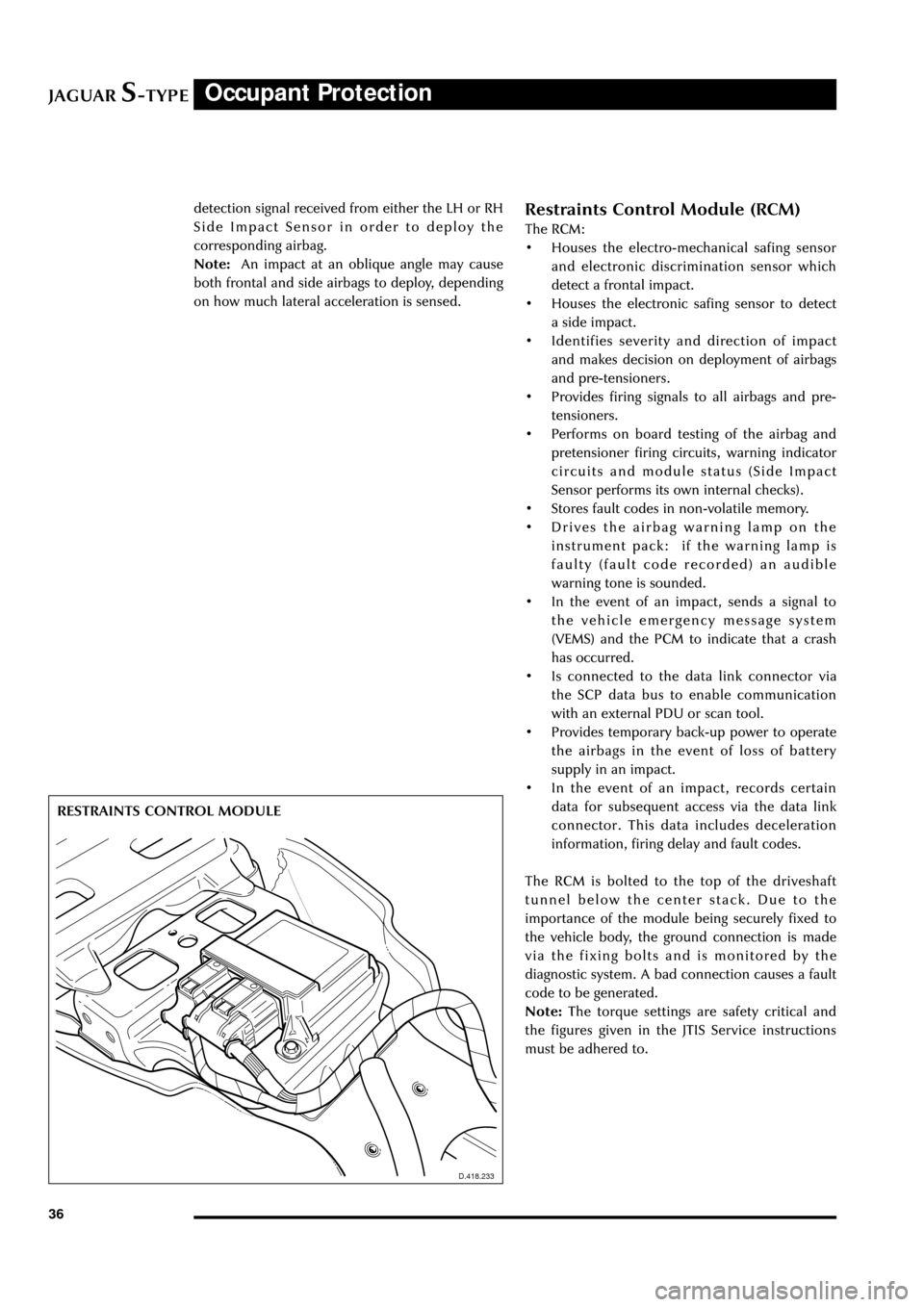

Restraints Control Module (RCM)

The RCM:

¥ Houses the electro-mechanical safing sensor

and electronic discrimination sensor which

detect a frontal impact.

¥ Houses the electronic safing sensor to detect

a side impact.

¥ Identifies severity and direction of impact

and makes decision on deployment of airbags

and pre-tensioners.

¥ Provides firing signals to all airbags and pre-

tensioners.

¥ Performs on board testing of the airbag and

pretensioner firing circuits, warning indicator

circuits and module status (Side Impact

Sensor performs its own internal checks).

¥ Stores fault codes in non-volatile memory.

¥ Drives the airbag warning lamp on the

instrument pack: if the warning lamp is

faulty (fault code recorded) an audible

warning tone is sounded.

¥ In the event of an impact, sends a signal to

the vehicle emergency message system

(VEMS) and the PCM to indicate that a crash

has occurred.

¥ Is connected to the data link connector via

the SCP data bus to enable communication

with an external PDU or scan tool.

¥ Provides temporary back-up power to operate

the airbags in the event of loss of battery

supply in an impact.

¥ In the event of an impact, records certain

data for subsequent access via the data link

connector. This data includes deceleration

information, firing delay and fault codes.

The RCM is bolted to the top of the driveshaft

tunnel below the center stack. Due to the

importance of the module being securely fixed to

the vehicle body, the ground connection is made

via the fixing bolts and is monitored by the

diagnostic system. A bad connection causes a fault

code to be generated.

Note:The torque settings are safety critical and

the figures given in the JTIS Service instructions

must be adhered to. RESTRAINTS CONTROL MODULE

D.418.233

detection signal received from either the LH or RH

Side Impact Sensor in order to deploy the

corresponding airbag.

Note:An impact at an oblique angle may cause

both frontal and side airbags to deploy, depending

on how much lateral acceleration is sensed.

Page 47 of 133

JAGUARS-TYPEFuel System

42

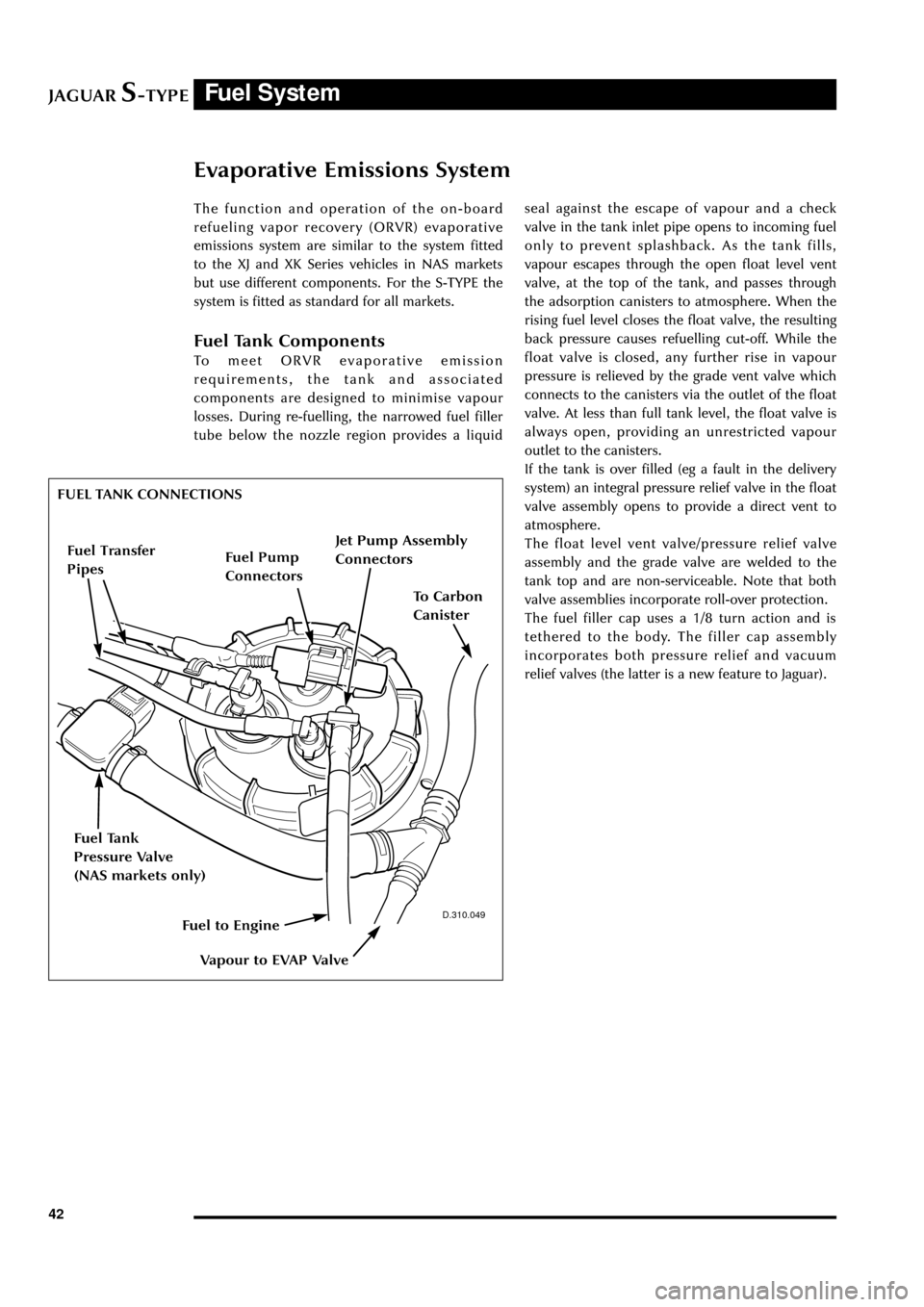

Evaporative Emissions System

The function and operation of the on-board

refueling vapor recovery (ORVR) evaporative

emissions system are similar to the system fitted

to the XJ and XK Series vehicles in NAS markets

but use different components. For the S-TYPE the

system is fitted as standard for all markets.

Fuel Tank Components

To meet ORVR evaporative emission

requirements, the tank and associated

components are designed to minimise vapour

losses. During re-fuelling, the narrowed fuel filler

tube below the nozzle region provides a liquidseal against the escape of vapour and a check

valve in the tank inlet pipe opens to incoming fuel

only to prevent splashback. As the tank fills,

vapour escapes through the open float level vent

valve, at the top of the tank, and passes through

the adsorption canisters to atmosphere. When the

rising fuel level closes the float valve, the resulting

back pressure causes refuelling cut-off. While the

float valve is closed, any further rise in vapour

pressure is relieved by the grade vent valve which

connects to the canisters via the outlet of the float

valve. At less than full tank level, the float valve is

always open, providing an unrestricted vapour

outlet to the canisters.

If the tank is over filled (eg a fault in the delivery

system) an integral pressure relief valve in the float

valve assembly opens to provide a direct vent to

atmosphere.

The float level vent valve/pressure relief valve

assembly and the grade valve are welded to the

tank top and are non-serviceable. Note that both

valve assemblies incorporate roll-over protection.

The fuel filler cap uses a 1/8 turn action and is

tethered to the body. The filler cap assembly

incorporates both pressure relief and vacuum

relief valves (the latter is a new feature to Jaguar).

D.310.049

FUEL TANK CONNECTIONS

Fuel Tank

Pressure Valve

(NAS markets only)

Jet Pump Assembly

Connectors

Fuel Pump

Connectors

To Carbon

Canister

Vapour to EVAP Valve

Fuel to Engine

Fuel Transfer

Pipes

Page 50 of 133

JAGUARS-TYPETransmission

45

Introduction

The automatic and manual transmission units are

described in the ÔS-TYPE Sports Sedan Powertrain

IntroductionÕ Technical Guide.

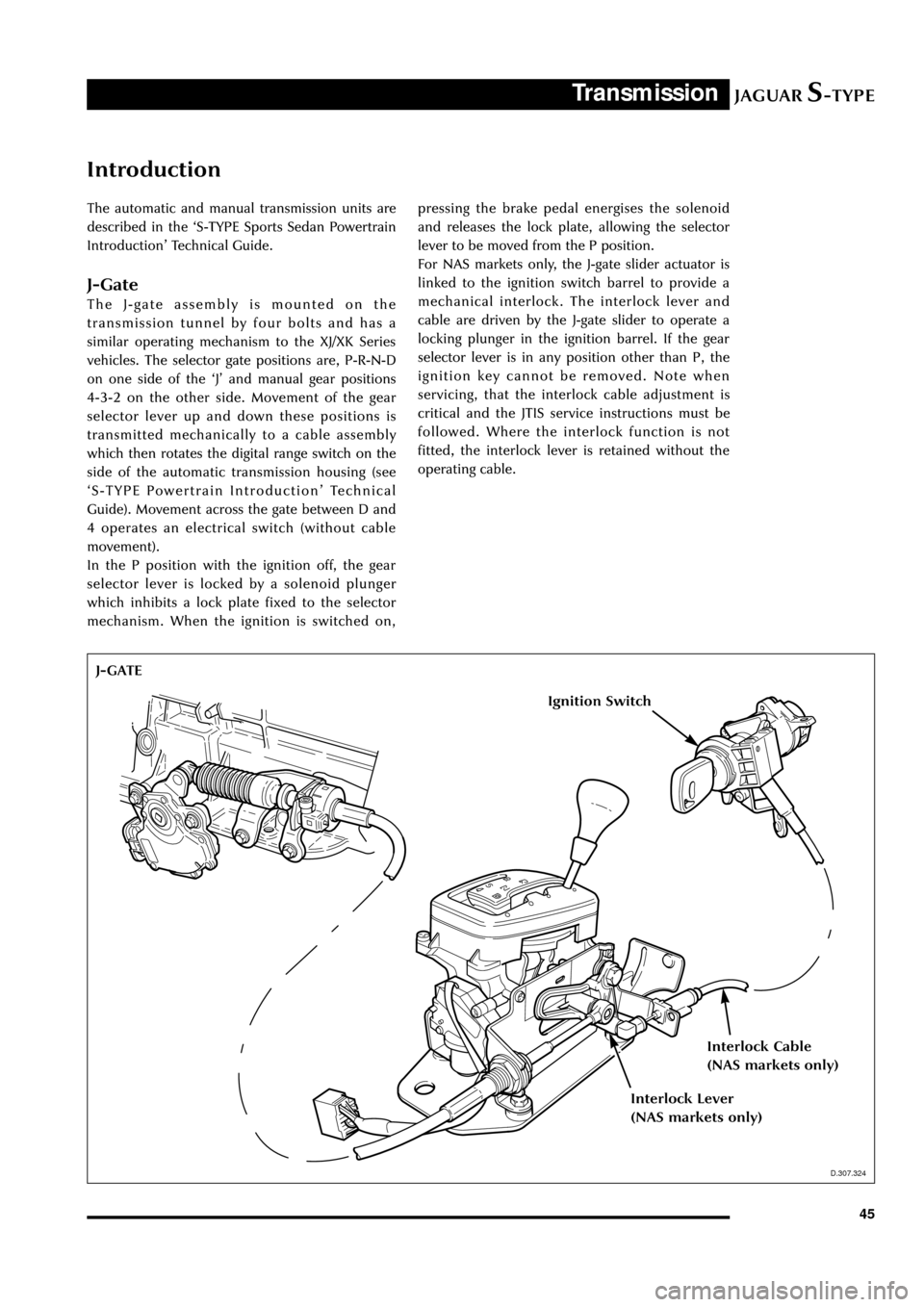

J-Gate

The J-gate assembly is mounted on the

transmission tunnel by four bolts and has a

similar operating mechanism to the XJ/XK Series

vehicles. The selector gate positions are, P-R-N-D

on one side of the ÔJÕ and manual gear positions

4-3-2 on the other side. Movement of the gear

selector lever up and down these positions is

transmitted mechanically to a cable assembly

which then rotates the digital range switch on the

side of the automatic transmission housing (see

ÔS-TYPE Powertrain IntroductionÕ Technical

Guide). Movement across the gate between D and

4 operates an electrical switch (without cable

movement).

In the P position with the ignition off, the gear

selector lever is locked by a solenoid plunger

which inhibits a lock plate fixed to the selector

mechanism. When the ignition is switched on,pressing the brake pedal energises the solenoid

and releases the lock plate, allowing the selector

lever to be moved from the P position.

For NAS markets only, the J-gate slider actuator is

linked to the ignition switch barrel to provide a

mechanical interlock. The interlock lever and

cable are driven by the J-gate slider to operate a

locking plunger in the ignition barrel. If the gear

selector lever is in any position other than P, the

ignition key cannot be removed. Note when

servicing, that the interlock cable adjustment is

critical and the JTIS service instructions must be

followed. Where the interlock function is not

fitted, the interlock lever is retained without the

operating cable.

D.307.324

J-GATE

Ignition Switch

Interlock Cable

(NAS markets only)

Interlock Lever

(NAS markets only)

D.307.324

Page 52 of 133

JAGUARS-TYPEChassis

47

Front Suspension

The independent front wheel suspension is a

double wishbone axle arrangement with

aluminium control arms. The two arms are of

different lengths, which minimises the changes in

track and camber. Inclination of the upper control

arm axis provides anti-dive front suspension

action. There are two front cross members,

known as Number 1 and Number 2.

Number 1, the forward cross member, is a steel

fabrication, non-isolated, which locates the lower

control arm front mounting, the anti-roll bar and

the cooling module.

The rear cross member, Number 2, is an

aluminium casting, non-isolated and it locates the

lower control arm rear mounting, the power

steering rack and the engine hydro-mounts.

WARNING: No attempt must be made to

weld or repair the aluminium cross

member. If it is damaged, a new one must

be installed.

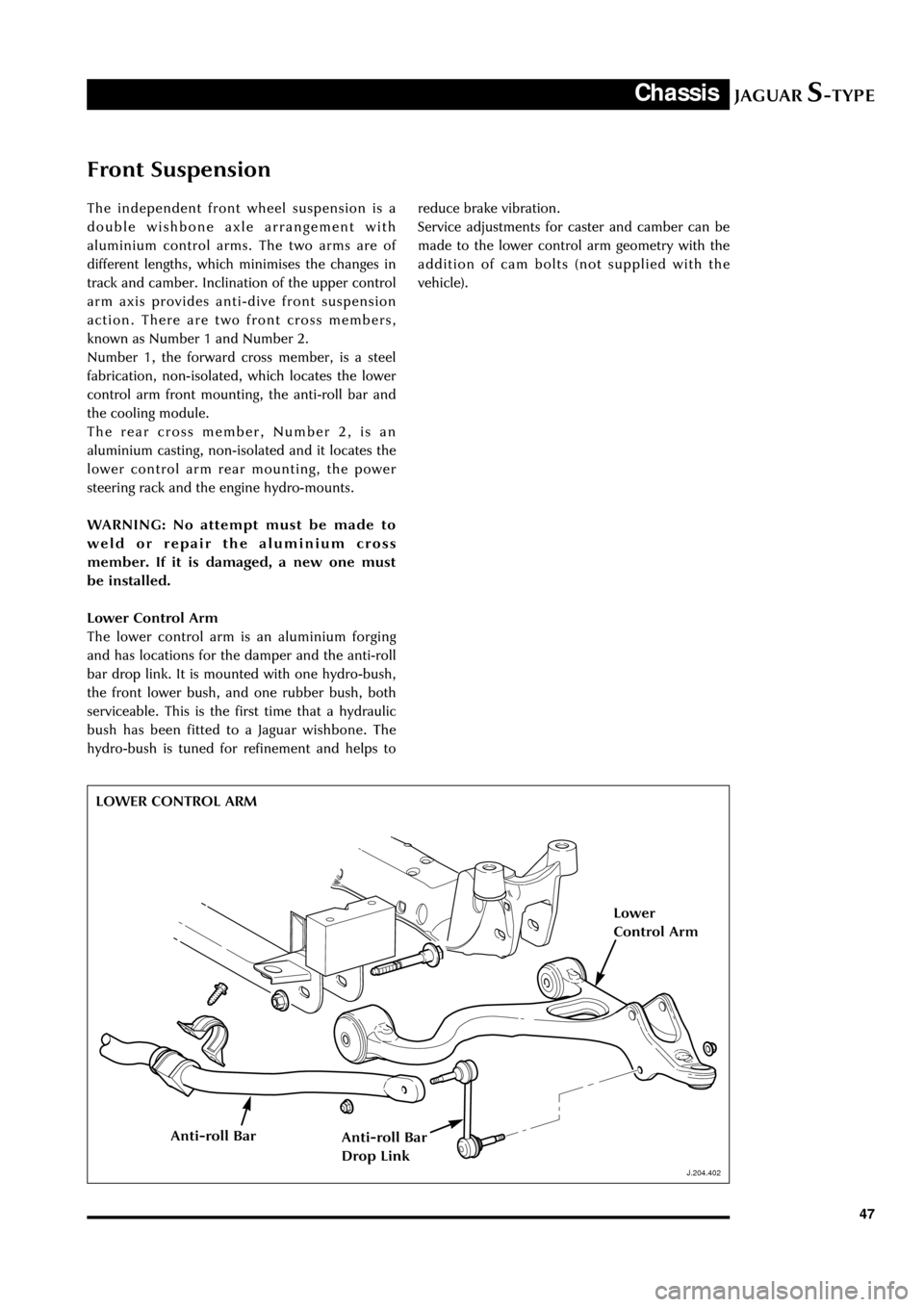

Lower Control Arm

The lower control arm is an aluminium forging

and has locations for the damper and the anti-roll

bar drop link. It is mounted with one hydro-bush,

the front lower bush, and one rubber bush, both

serviceable. This is the first time that a hydraulic

bush has been fitted to a Jaguar wishbone. The

hydro-bush is tuned for refinement and helps to

J.204.402

reduce brake vibration.

Service adjustments for caster and camber can be

made to the lower control arm geometry with the

addition of cam bolts (not supplied with the

vehicle).

LOWER CONTROL ARM

J.204.402

Lower

Control Arm

Anti-roll BarAnti-roll Bar

Drop Link