steering JAGUAR S TYPE 2005 1.G Technical Guide Update

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2005, Model line: S TYPE, Model: JAGUAR S TYPE 2005 1.GPages: 133, PDF Size: 3.48 MB

Page 53 of 133

JAGUARS-TYPE

D.204.400

Chassis

48

D.204.440

VERTICAL FRONT KNUCKLE UPPER CONTROL ARM

D.204.440

D.204.400

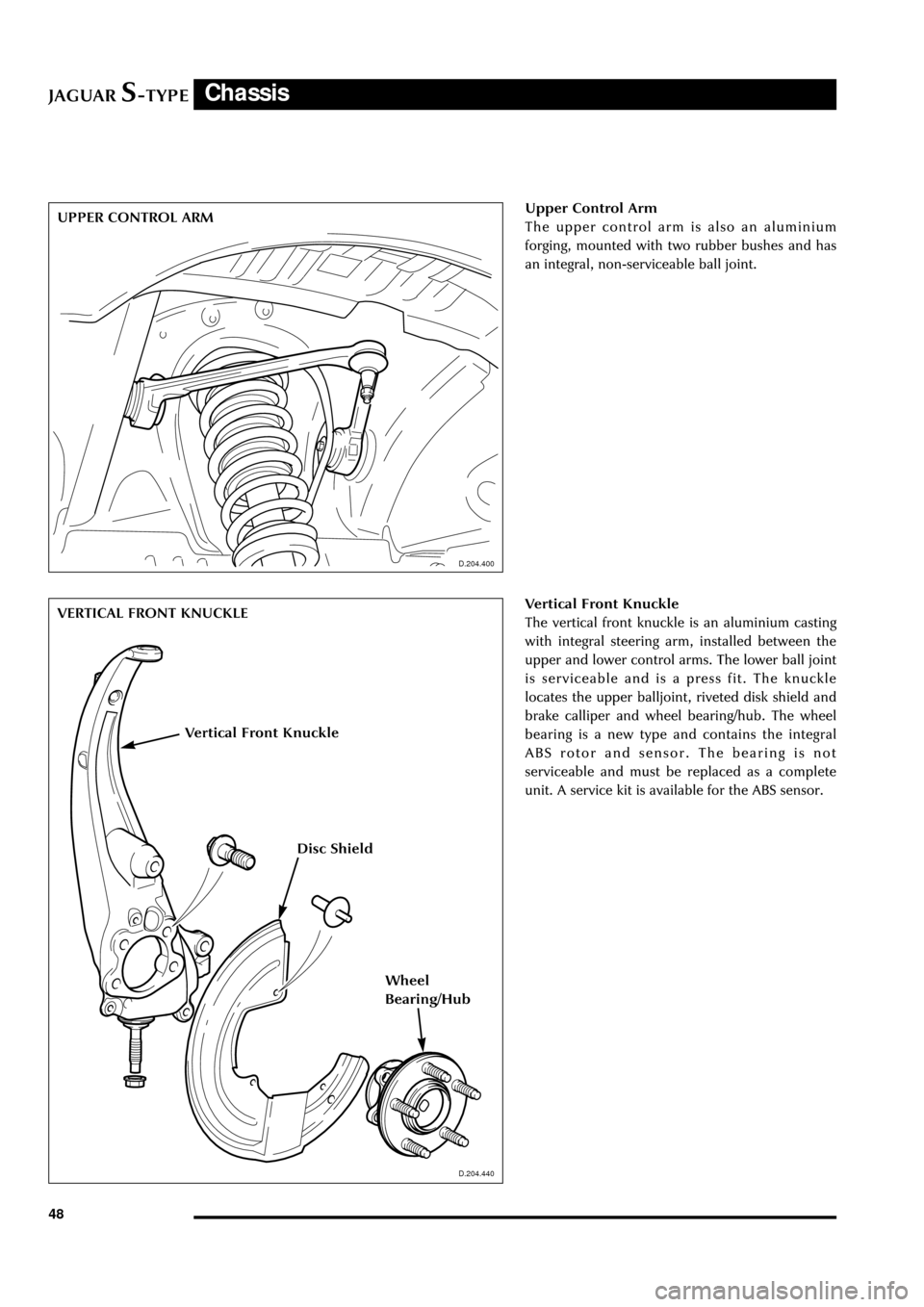

Upper Control Arm

The upper control arm is also an aluminium

forging, mounted with two rubber bushes and has

an integral, non-serviceable ball joint.

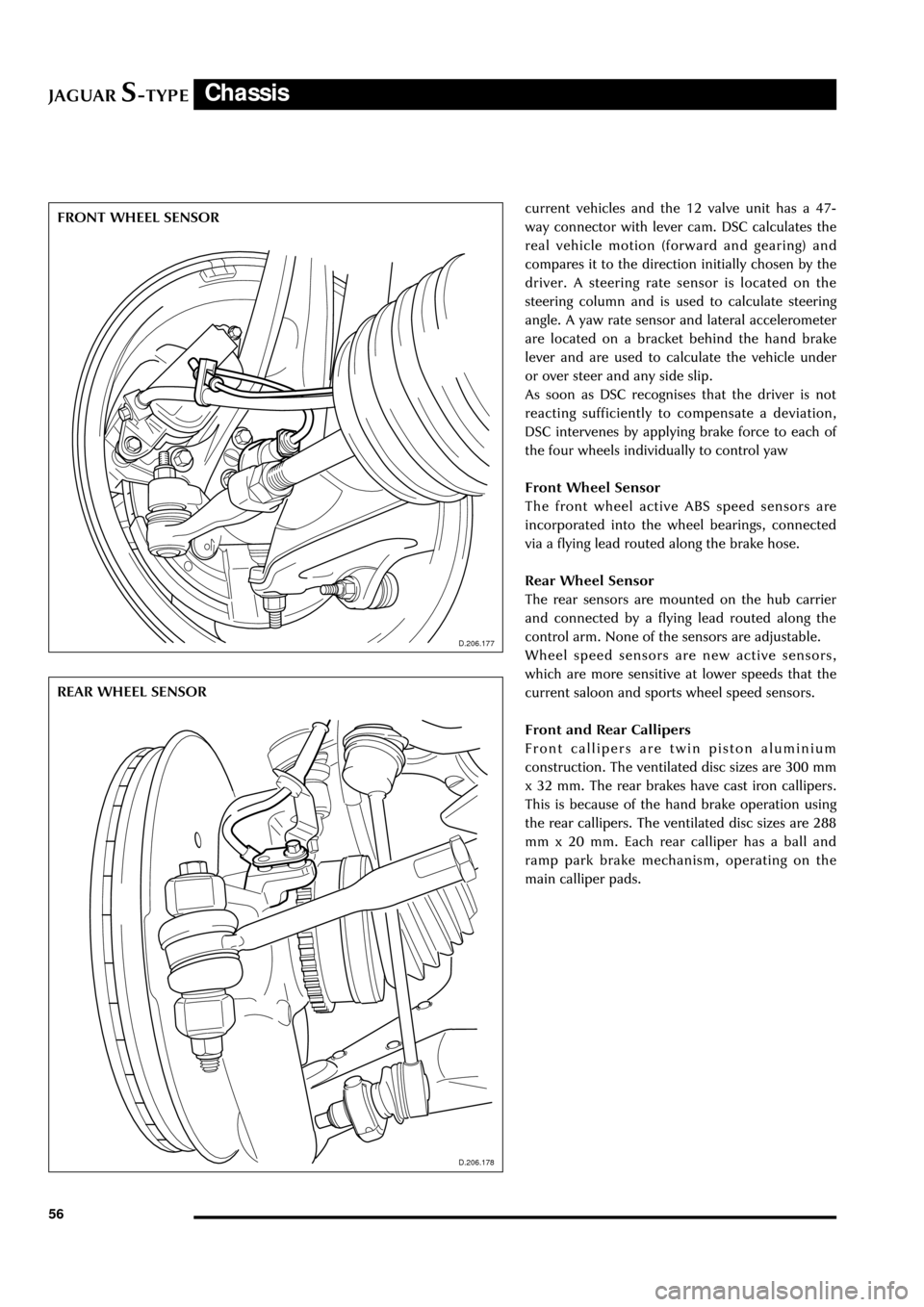

Vertical Front Knuckle

The vertical front knuckle is an aluminium casting

with integral steering arm, installed between the

upper and lower control arms. The lower ball joint

is serviceable and is a press fit. The knuckle

locates the upper balljoint, riveted disk shield and

brake calliper and wheel bearing/hub. The wheel

bearing is a new type and contains the integral

ABS rotor and sensor. The bearing is not

serviceable and must be replaced as a complete

unit. A service kit is available for the ABS sensor.

Vertical Front Knuckle

Disc Shield

Wheel

Bearing/Hub

Page 61 of 133

JAGUARS-TYPEChassis

56

D.206.177

current vehicles and the 12 valve unit has a 47-

way connector with lever cam. DSC calculates the

real vehicle motion (forward and gearing) and

compares it to the direction initially chosen by the

driver. A steering rate sensor is located on the

steering column and is used to calculate steering

angle. A yaw rate sensor and lateral accelerometer

are located on a bracket behind the hand brake

lever and are used to calculate the vehicle under

or over steer and any side slip.

As soon as DSC recognises that the driver is not

reacting sufficiently to compensate a deviation,

DSC intervenes by applying brake force to each of

the four wheels individually to control yaw

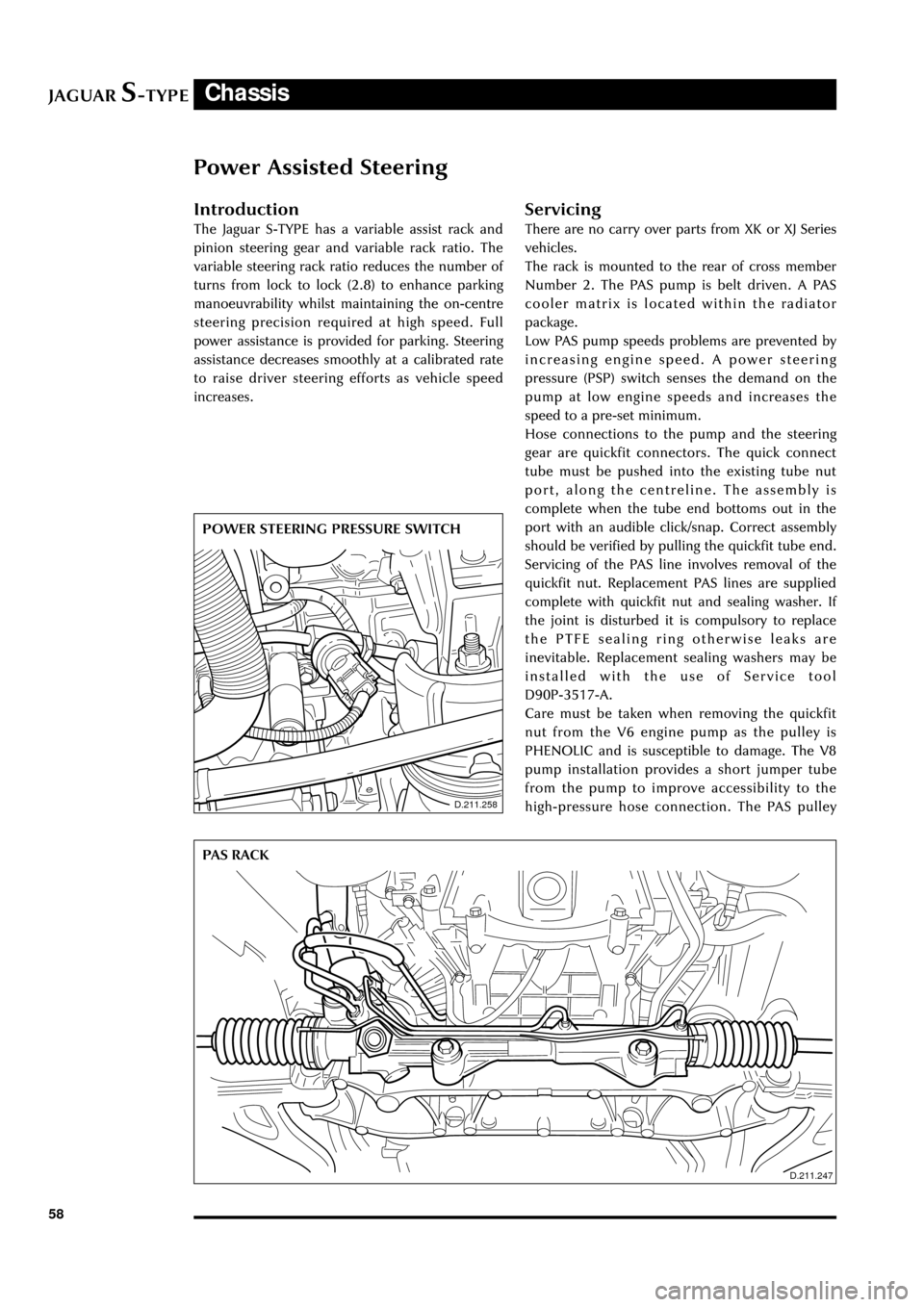

Front Wheel Sensor

The front wheel active ABS speed sensors are

incorporated into the wheel bearings, connected

via a flying lead routed along the brake hose.

Rear Wheel Sensor

The rear sensors are mounted on the hub carrier

and connected by a flying lead routed along the

control arm. None of the sensors are adjustable.

Wheel speed sensors are new active sensors,

which are more sensitive at lower speeds that the

current saloon and sports wheel speed sensors.

Front and Rear Callipers

Front callipers are twin piston aluminium

construction. The ventilated disc sizes are 300 mm

x 32 mm. The rear brakes have cast iron callipers.

This is because of the hand brake operation using

the rear callipers. The ventilated disc sizes are 288

mm x 20 mm. Each rear calliper has a ball and

ramp park brake mechanism, operating on the

main calliper pads.

D.206.178

D.206.177

FRONT WHEEL SENSOR

REAR WHEEL SENSOR

D.206.178

Page 63 of 133

JAGUARS-TYPEChassis

58

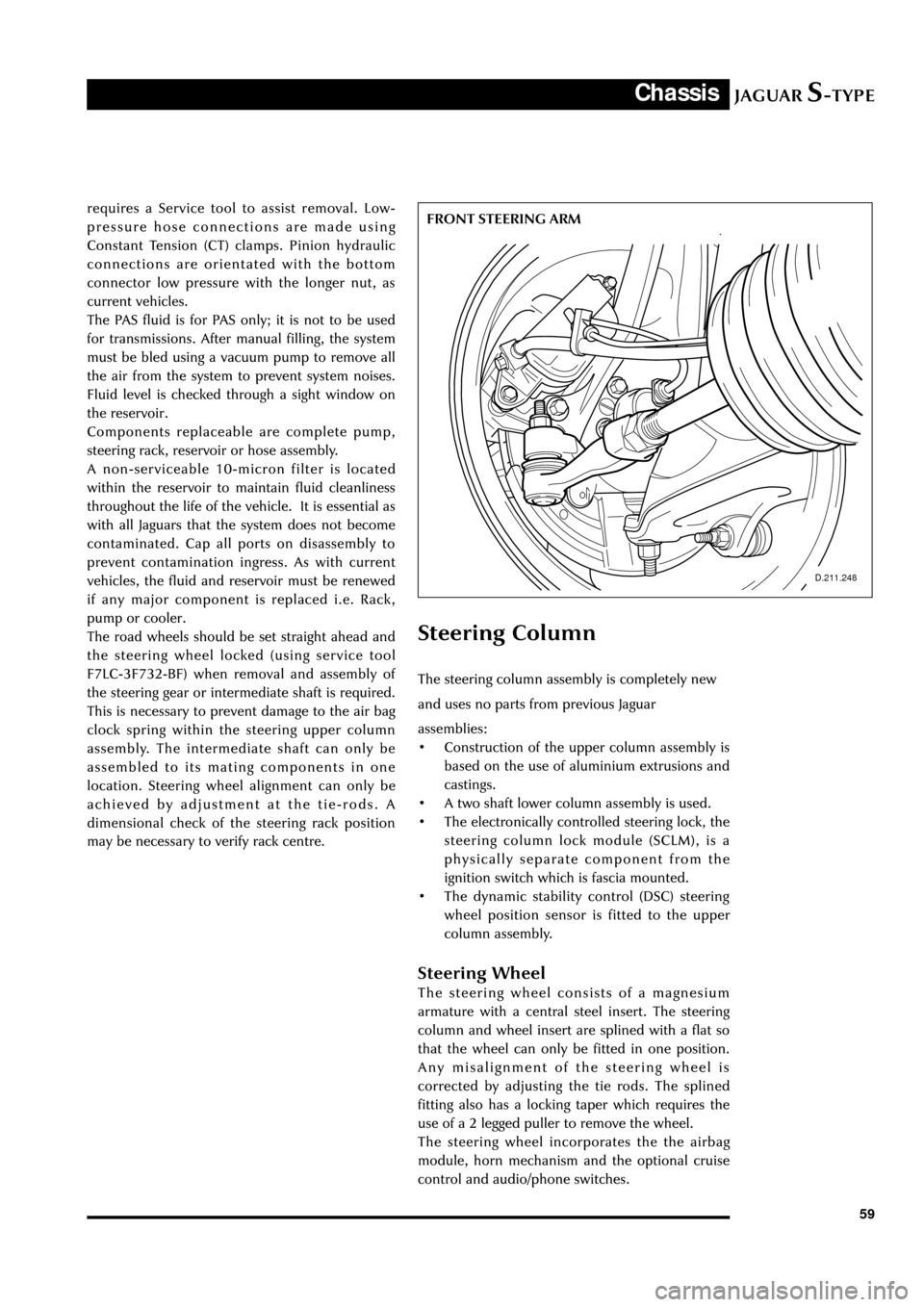

Power Assisted Steering

Introduction

The Jaguar S-TYPE has a variable assist rack and

pinion steering gear and variable rack ratio. The

variable steering rack ratio reduces the number of

turns from lock to lock (2.8) to enhance parking

manoeuvrability whilst maintaining the on-centre

steering precision required at high speed. Full

power assistance is provided for parking. Steering

assistance decreases smoothly at a calibrated rate

to raise driver steering efforts as vehicle speed

increases.

Servicing

There are no carry over parts from XK or XJ Series

vehicles.

The rack is mounted to the rear of cross member

Number 2. The PAS pump is belt driven. A PAS

cooler matrix is located within the radiator

package.

Low PAS pump speeds problems are prevented by

increasing engine speed. A power steering

pressure (PSP) switch senses the demand on the

pump at low engine speeds and increases the

speed to a pre-set minimum.

Hose connections to the pump and the steering

gear are quickfit connectors. The quick connect

tube must be pushed into the existing tube nut

port, along the centreline. The assembly is

complete when the tube end bottoms out in the

port with an audible click/snap. Correct assembly

should be verified by pulling the quickfit tube end.

Servicing of the PAS line involves removal of the

quickfit nut. Replacement PAS lines are supplied

complete with quickfit nut and sealing washer. If

the joint is disturbed it is compulsory to replace

the PTFE sealing ring otherwise leaks are

inevitable. Replacement sealing washers may be

installed with the use of Service tool

D90P-3517-A.

Care must be taken when removing the quickfit

nut from the V6 engine pump as the pulley is

PHENOLIC and is susceptible to damage. The V8

pump installation provides a short jumper tube

from the pump to improve accessibility to the

high-pressure hose connection. The PAS pulley

D.211.247

PA S R AC K

D.211.258

POWER STEERING PRESSURE SWITCH

Page 64 of 133

JAGUARS-TYPEChassis

59

D.211.248

FRONT STEERING ARM requires a Service tool to assist removal. Low-

pressure hose connections are made using

Constant Tension (CT) clamps. Pinion hydraulic

connections are orientated with the bottom

connector low pressure with the longer nut, as

current vehicles.

The PAS fluid is for PAS only; it is not to be used

for transmissions. After manual filling, the system

must be bled using a vacuum pump to remove all

the air from the system to prevent system noises.

Fluid level is checked through a sight window on

the reservoir.

Components replaceable are complete pump,

steering rack, reservoir or hose assembly.

A non-serviceable 10-micron filter is located

within the reservoir to maintain fluid cleanliness

throughout the life of the vehicle. It is essential as

with all Jaguars that the system does not become

contaminated. Cap all ports on disassembly to

prevent contamination ingress. As with current

vehicles, the fluid and reservoir must be renewed

if any major component is replaced i.e. Rack,

pump or cooler.

The road wheels should be set straight ahead and

the steering wheel locked (using service tool

F7LC-3F732-BF) when removal and assembly of

the steering gear or intermediate shaft is required.

This is necessary to prevent damage to the air bag

clock spring within the steering upper column

assembly. The intermediate shaft can only be

assembled to its mating components in one

location. Steering wheel alignment can only be

achieved by adjustment at the tie-rods. A

dimensional check of the steering rack position

may be necessary to verify rack centre.

Steering Column

The steering column assembly is completely new

and uses no parts from previous Jaguar

assemblies:

¥ Construction of the upper column assembly is

based on the use of aluminium extrusions and

castings.

¥ A two shaft lower column assembly is used.

¥ The electronically controlled steering lock, the

steering column lock module (SCLM), is a

physically separate component from the

ignition switch which is fascia mounted.

¥ The dynamic stability control (DSC) steering

wheel position sensor is fitted to the upper

column assembly.

Steering Wheel

The steering wheel consists of a magnesium

armature with a central steel insert. The steering

column and wheel insert are splined with a flat so

that the wheel can only be fitted in one position.

Any misalignment of the steering wheel is

corrected by adjusting the tie rods. The splined

fitting also has a locking taper which requires the

use of a 2 legged puller to remove the wheel.

The steering wheel incorporates the the airbag

module, horn mechanism and the optional cruise

control and audio/phone switches.

Page 65 of 133

JAGUARS-TYPEChassis

60

D.211.255

ELECTRICALLY ADJUSTABLE STEERING COLUMN

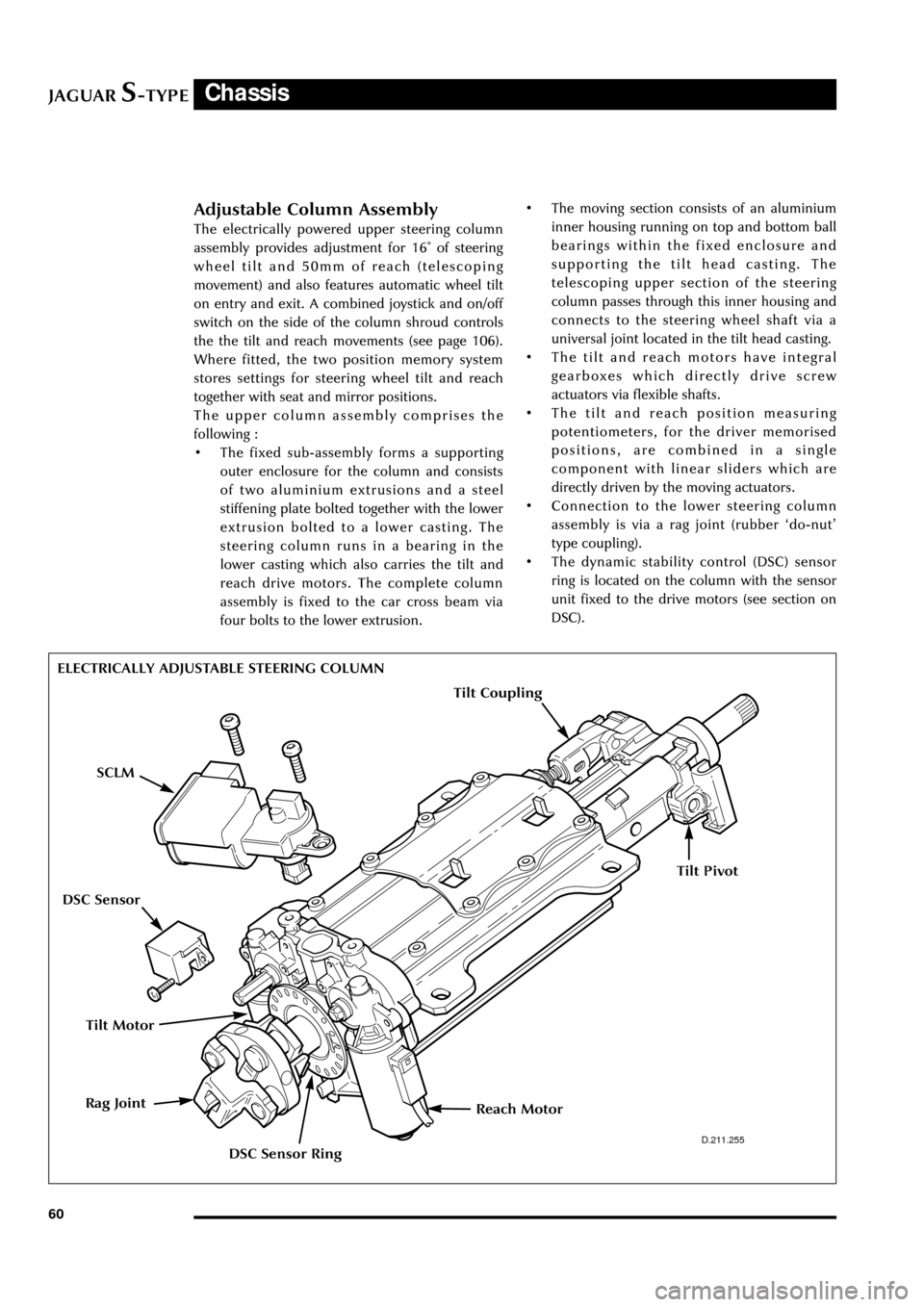

Adjustable Column Assembly

The electrically powered upper steering column

assembly provides adjustment for 16û of steering

wheel tilt and 50mm of reach (telescoping

movement) and also features automatic wheel tilt

on entry and exit. A combined joystick and on/off

switch on the side of the column shroud controls

the the tilt and reach movements (see page 106).

Where fitted, the two position memory system

stores settings for steering wheel tilt and reach

together with seat and mirror positions.

The upper column assembly comprises the

following :

¥ The fixed sub-assembly forms a supporting

outer enclosure for the column and consists

of two aluminium extrusions and a steel

stiffening plate bolted together with the lower

extrusion bolted to a lower casting. The

steering column runs in a bearing in the

lower casting which also carries the tilt and

reach drive motors. The complete column

assembly is fixed to the car cross beam via

four bolts to the lower extrusion.¥ The moving section consists of an aluminium

inner housing running on top and bottom ball

bearings within the fixed enclosure and

supporting the tilt head casting. The

telescoping upper section of the steering

column passes through this inner housing and

connects to the steering wheel shaft via a

universal joint located in the tilt head casting.

¥ The tilt and reach motors have integral

gearboxes which directly drive screw

actuators via flexible shafts.

¥ The tilt and reach position measuring

potentiometers, for the driver memorised

positions, are combined in a single

component with linear sliders which are

directly driven by the moving actuators.

¥ Connection to the lower steering column

assembly is via a rag joint (rubber Ôdo-nutÕ

type coupling).

¥ The dynamic stability control (DSC) sensor

ring is located on the column with the sensor

unit fixed to the drive motors (see section on

DSC).

Tilt Motor

Reach MotorRag Joint

SCLM

DSC Sensor Ring

DSC Sensor

Tilt Coupling

Tilt Pivot

Page 66 of 133

JAGUARS-TYPEChassis

61

D.211.253

LOWER STEERING COLUMN

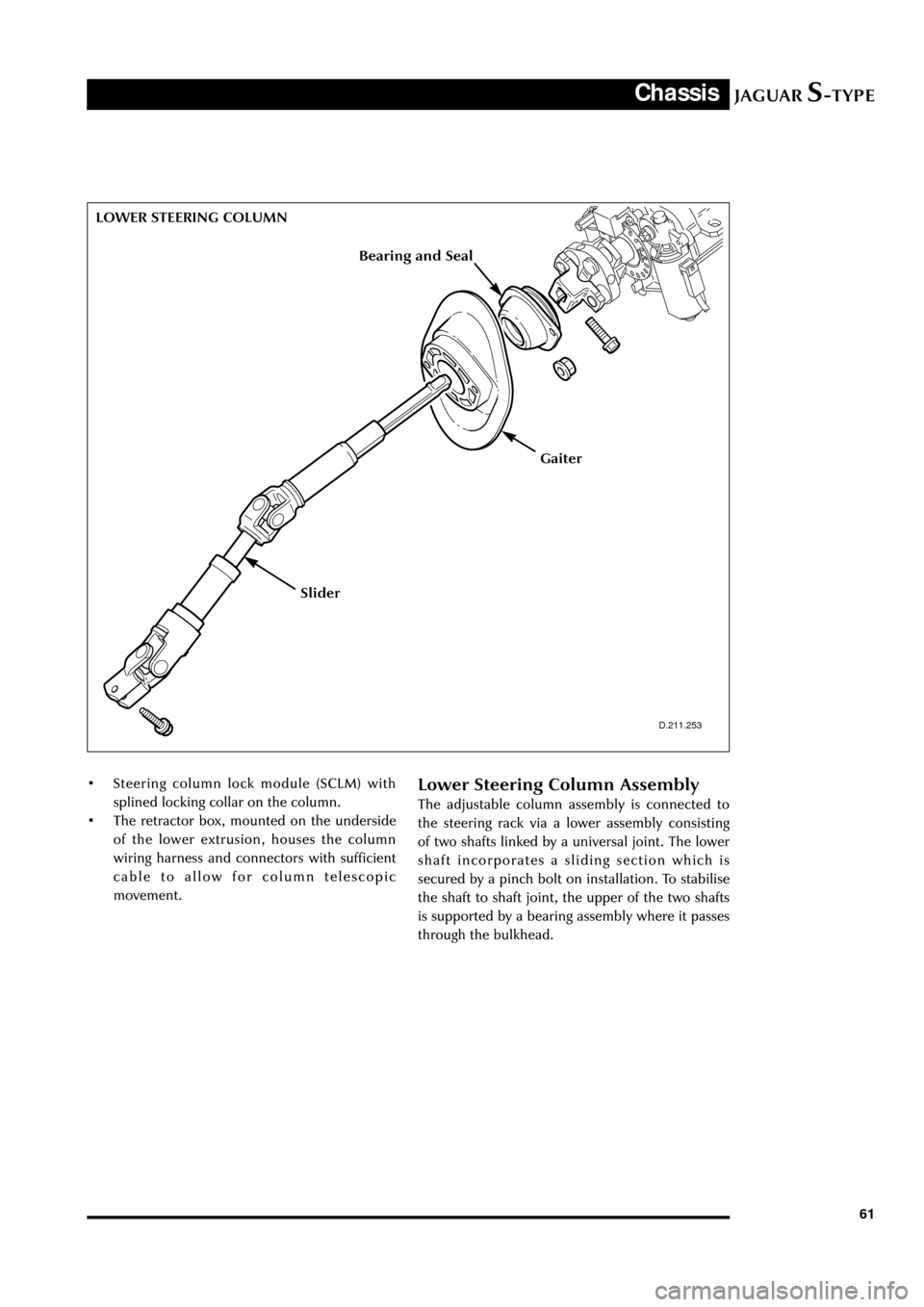

Lower Steering Column Assembly

The adjustable column assembly is connected to

the steering rack via a lower assembly consisting

of two shafts linked by a universal joint. The lower

shaft incorporates a sliding section which is

secured by a pinch bolt on installation. To stabilise

the shaft to shaft joint, the upper of the two shafts

is supported by a bearing assembly where it passes

through the bulkhead.

Gaiter

Bearing and Seal

Slider

¥ Steering column lock module (SCLM) with

splined locking collar on the column.

¥ The retractor box, mounted on the underside

of the lower extrusion, houses the column

wiring harness and connectors with sufficient

cable to allow for column telescopic

movement.

Page 67 of 133

JAGUARS-TYPEChassis

62

J.211.257

STEERING COLUMN LOCK MODULE

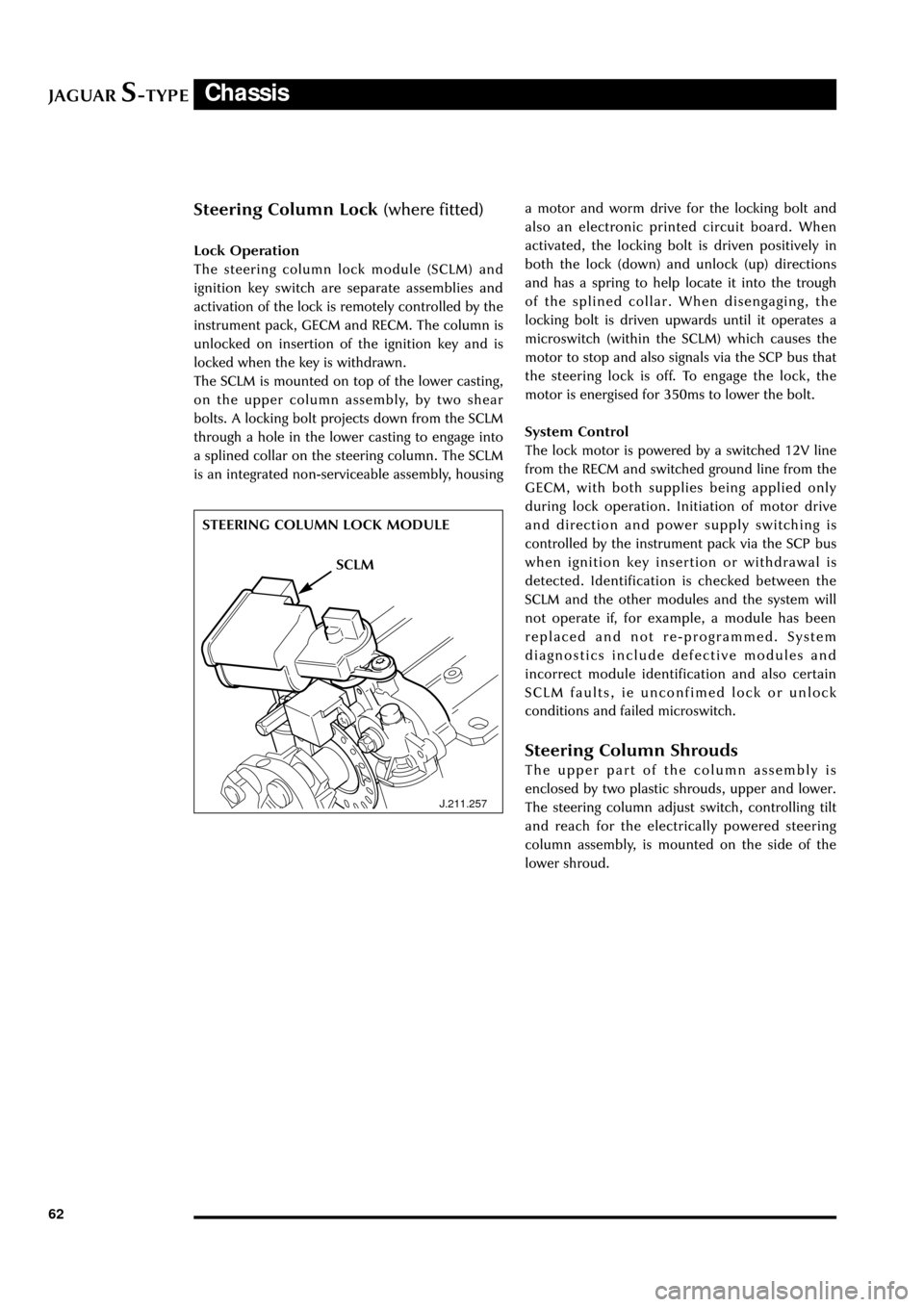

Steering Column Lock (where fitted)

Lock Operation

The steering column lock module (SCLM) and

ignition key switch are separate assemblies and

activation of the lock is remotely controlled by the

instrument pack, GECM and RECM. The column is

unlocked on insertion of the ignition key and is

locked when the key is withdrawn.

The SCLM is mounted on top of the lower casting,

on the upper column assembly, by two shear

bolts. A locking bolt projects down from the SCLM

through a hole in the lower casting to engage into

a splined collar on the steering column. The SCLM

is an integrated non-serviceable assembly, housinga motor and worm drive for the locking bolt and

also an electronic printed circuit board. When

activated, the locking bolt is driven positively in

both the lock (down) and unlock (up) directions

and has a spring to help locate it into the trough

of the splined collar. When disengaging, the

locking bolt is driven upwards until it operates a

microswitch (within the SCLM) which causes the

motor to stop and also signals via the SCP bus that

the steering lock is off. To engage the lock, the

motor is energised for 350ms to lower the bolt.

System Control

The lock motor is powered by a switched 12V line

from the RECM and switched ground line from the

GECM, with both supplies being applied only

during lock operation. Initiation of motor drive

and direction and power supply switching is

controlled by the instrument pack via the SCP bus

when ignition key insertion or withdrawal is

detected. Identification is checked between the

SCLM and the other modules and the system will

not operate if, for example, a module has been

replaced and not re-programmed. System

diagnostics include defective modules and

incorrect module identification and also certain

SCLM faults, ie unconfimed lock or unlock

conditions and failed microswitch.

Steering Column Shrouds

The upper part of the column assembly is

enclosed by two plastic shrouds, upper and lower.

The steering column adjust switch, controlling tilt

and reach for the electrically powered steering

column assembly, is mounted on the side of the

lower shroud.

SCLM

Page 72 of 133

JAGUARS-TYPEClimate Control

67 Pipework

The suction hose and liquid line are a one-piece

assembly. A single screw connects them to the air

conditioning unit manifold at the bulkhead. A

further screw fixing and push-in clip secures them

at the side of the engine bay. The liquid line fixed

to the cooling module then joins with a block

fitting and the suction hose connects with a quick

connect fitting and routes across the underneath

of the cooling module to the compressor. The

compressor suction and discharge hoses are also a

one piece assembly.

A pressure transducer is fitted to the discharge

hose as it connects to the rear of the condenser.

The high side charge port is situated on the

manifold connecting to the receiver drier whilst

the low side is adjacent to the compressor behind

the LH front wheel.

The compressor is a 9Occ scroll, which is variable

from 100% to 30%. Compressor is standard

specification to all vehicles although package

makes them unique to V6 and V8.

Air Distribution

Air distribution is as follows:

¥ Defrost duct integral with the fascia.

¥ Face vents, plenum, manifold, centre face

duct, side face duct, side window demist duct

are all sub-assembled into the fascia.

¥ Driver and front seat passenger foot ducts are

installed in the fascia after it has been fitted

to the vehicle.

¥ Rear foot ducts are fitted to the underframe.

¥ Rear face duct fitted to transmission tunnel.

¥ Rear face vent fitted to console.

¥ Extractor boxes fitted in rear quarter panels.

All flaps are electric servo controlled and

comprise:

¥ Fresh/recirculation - heater/evaporator unit.

¥ Cold air bypass - heater/evaporator unit.

¥ Foot flap - mounted on plenum.

¥ Defrost flap - mounted on plenum.

¥ Face flap - mounted on plenum.

Sensors, for operation of the system, are:

¥ Ambient temperature sensor - located behind

the lower front grille.

¥ Solar sensor - fitted to the top centre of the

fascia at the defrost grille

¥ In-car sensor - aspirated from the plenum

venturi sensor mounted inboard of the

steering column.¥ Two heater air outlet sensors

¥ One evaporator air outlet sensor

Servicing

Routine servicing consists of particle filter

replacement.

Replaceable items on the climate control system

are:

¥ Servo complete with linkages

¥ Sensors

¥ Evaporator and seals

¥ Heater core and seals

¥ Blower motor

¥ Impeller/blower motor wheel

¥ Hoses

¥ Registers/vents

¥ Ducts, except the defrost

¥ Defrost and side window demist grilles

¥ Control unit

¥ Compressor

¥ Water pump

¥ Water valve

¥ Receiver/drier

¥ Condenser

There are no panel diagnostics but PDU facility is

available with extensive capability, similar to

current XJ and XK Series.

System refrigerant is R134a. Vehicle charge weight

is 800 gms and charging is through the high side

charge port only.

Oil type is WSH-MIC231-B and refill quantity is

180 cc -220 cc.

Special tools are hose clamp pliers and air-

conditioning hoses spring lock de-coupler.

General information

Ensure that the grille at the base of the windshield

is kept clear of leaves, snow or other obstructions.

A solar sensor is mounted on top of the fascia, in

the centre of the defrost grille, and this should not

be covered.

The air conditioning system should be run briefly

at least once each week with a cold setting to

prevent the seals from drying out with subsequent

refrigerant leaks.

When the engine and vehicle interior are cold the

fan speed may be low until the engine has warmed

up, this avoids excessively cold air being blown

into the cabin.

Page 77 of 133

JAGUARS-TYPEElectrical/Electronic

72

Module Communications Network

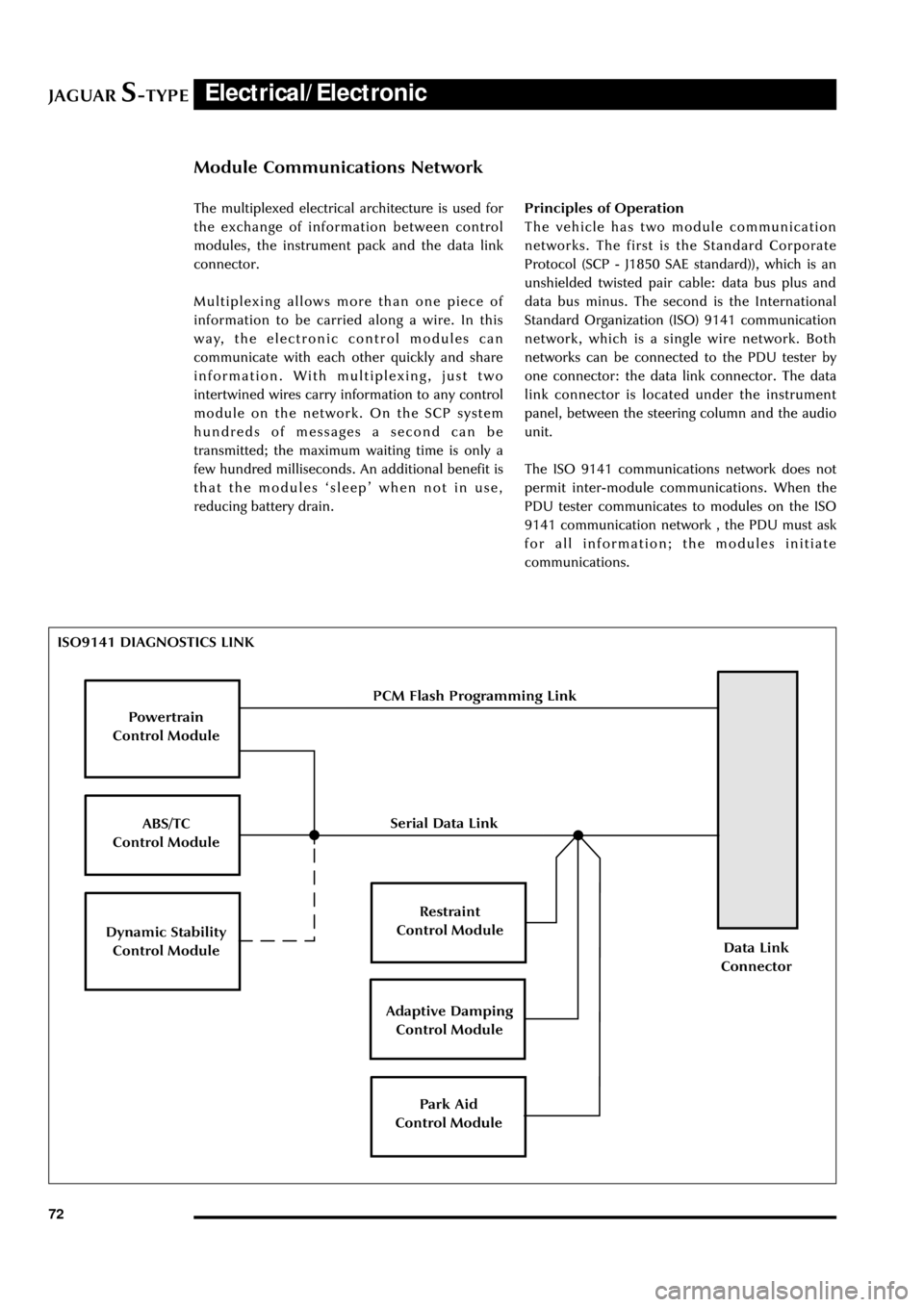

ISO9141 DIAGNOSTICS LINK

Powertrain

Control Module

ABS/TC

Control Module

Dynamic Stability

Control Module

Restraint

Control Module

Adaptive Damping

Control Module

Park Aid

Control Module

Data Link

Connector

PCM Flash Programming Link

Serial Data Link The multiplexed electrical architecture is used for

the exchange of information between control

modules, the instrument pack and the data link

connector.

Multiplexing allows more than one piece of

information to be carried along a wire. In this

way, the electronic control modules can

communicate with each other quickly and share

information. With multiplexing, just two

intertwined wires carry information to any control

module on the network. On the SCP system

hundreds of messages a second can be

transmitted; the maximum waiting time is only a

few hundred milliseconds. An additional benefit is

that the modules ÔsleepÕ when not in use,

reducing battery drain.Principles of Operation

The vehicle has two module communication

networks. The first is the Standard Corporate

Protocol (SCP - J1850 SAE standard)), which is an

unshielded twisted pair cable: data bus plus and

data bus minus. The second is the International

Standard Organization (ISO) 9141 communication

network, which is a single wire network. Both

networks can be connected to the PDU tester by

one connector: the data link connector. The data

link connector is located under the instrument

panel, between the steering column and the audio

unit.

The ISO 9141 communications network does not

permit inter-module communications. When the

PDU tester communicates to modules on the ISO

9141 communication network , the PDU must ask

for all information; the modules initiate

communications.

Page 78 of 133

JAGUARS-TYPEElectrical/Electronic

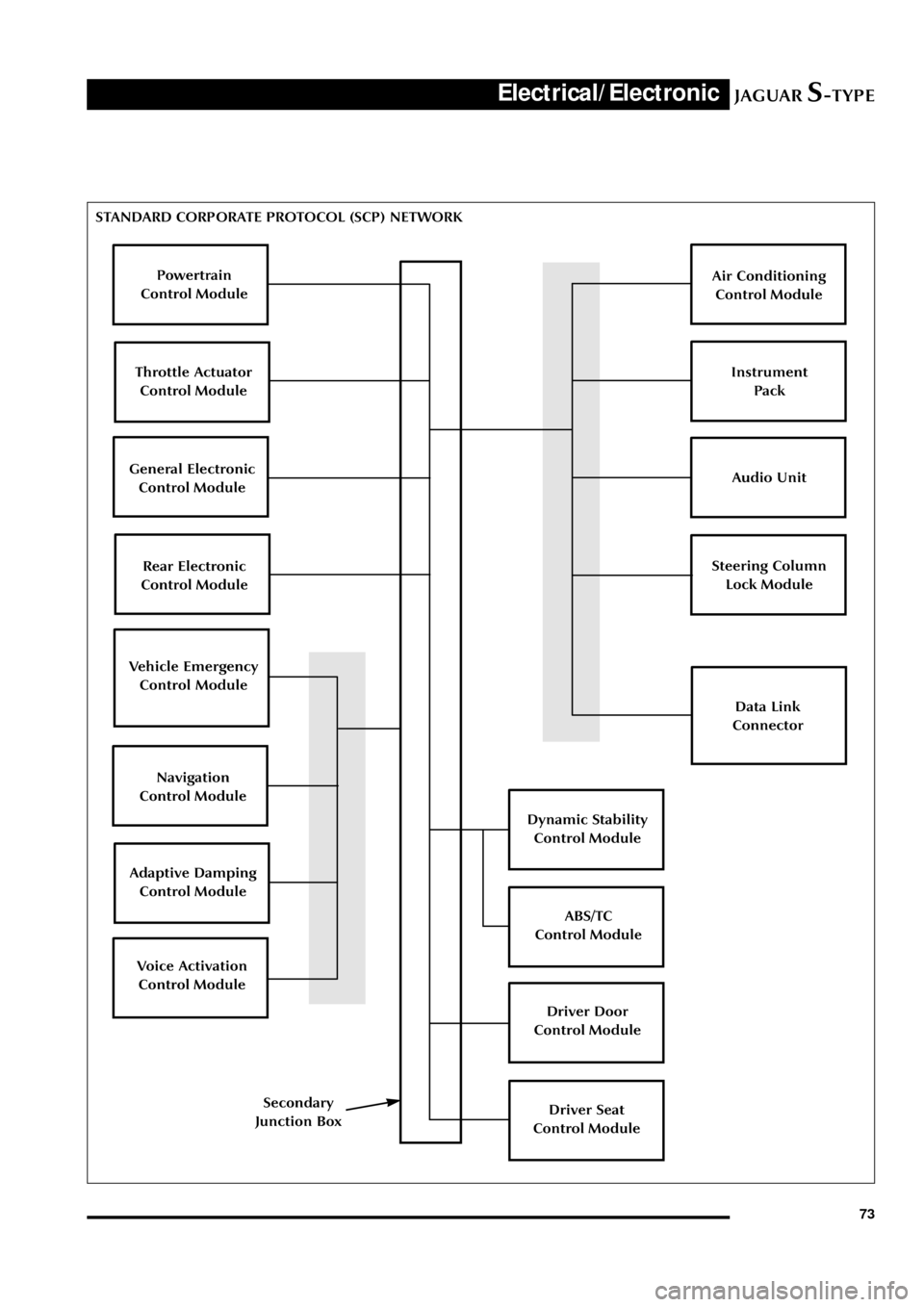

73 STANDARD CORPORATE PROTOCOL (SCP) NETWORK

Powertrain

Control Module

Vehicle Emergency

Control Module

Throttle Actuator

Control Module

General Electronic

Control Module

Rear Electronic

Control Module

Navigation

Control Module

Adaptive Damping

Control Module

Voice Activation

Control Module

Air Conditioning

Control Module

Data Link

Connector

Instrument

Pack

Audio Unit

Steering Column

Lock Module

Dynamic Stability

Control Module

Secondary

Junction BoxDriver Seat

Control Module

Driver Door

Control Module

ABS/TC

Control Module