air filter JAGUAR S TYPE 2005 1.G Technical Guide Update

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2005, Model line: S TYPE, Model: JAGUAR S TYPE 2005 1.GPages: 133, PDF Size: 3.48 MB

Page 21 of 133

JAGUARS-TYPEBody

16

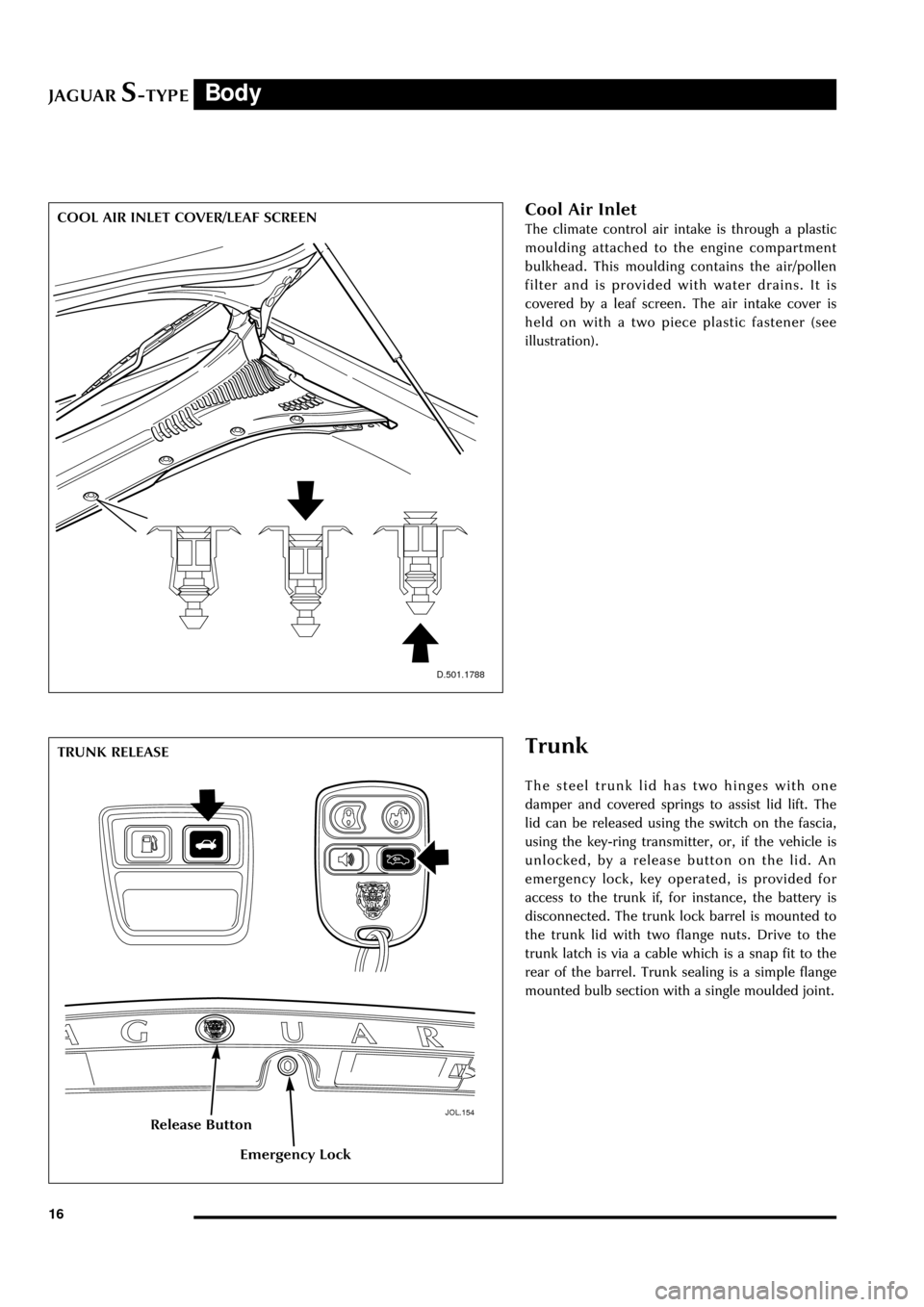

Cool Air Inlet

The climate control air intake is through a plastic

moulding attached to the engine compartment

bulkhead. This moulding contains the air/pollen

filter and is provided with water drains. It is

covered by a leaf screen. The air intake cover is

held on with a two piece plastic fastener (see

illustration).

D.501.1788

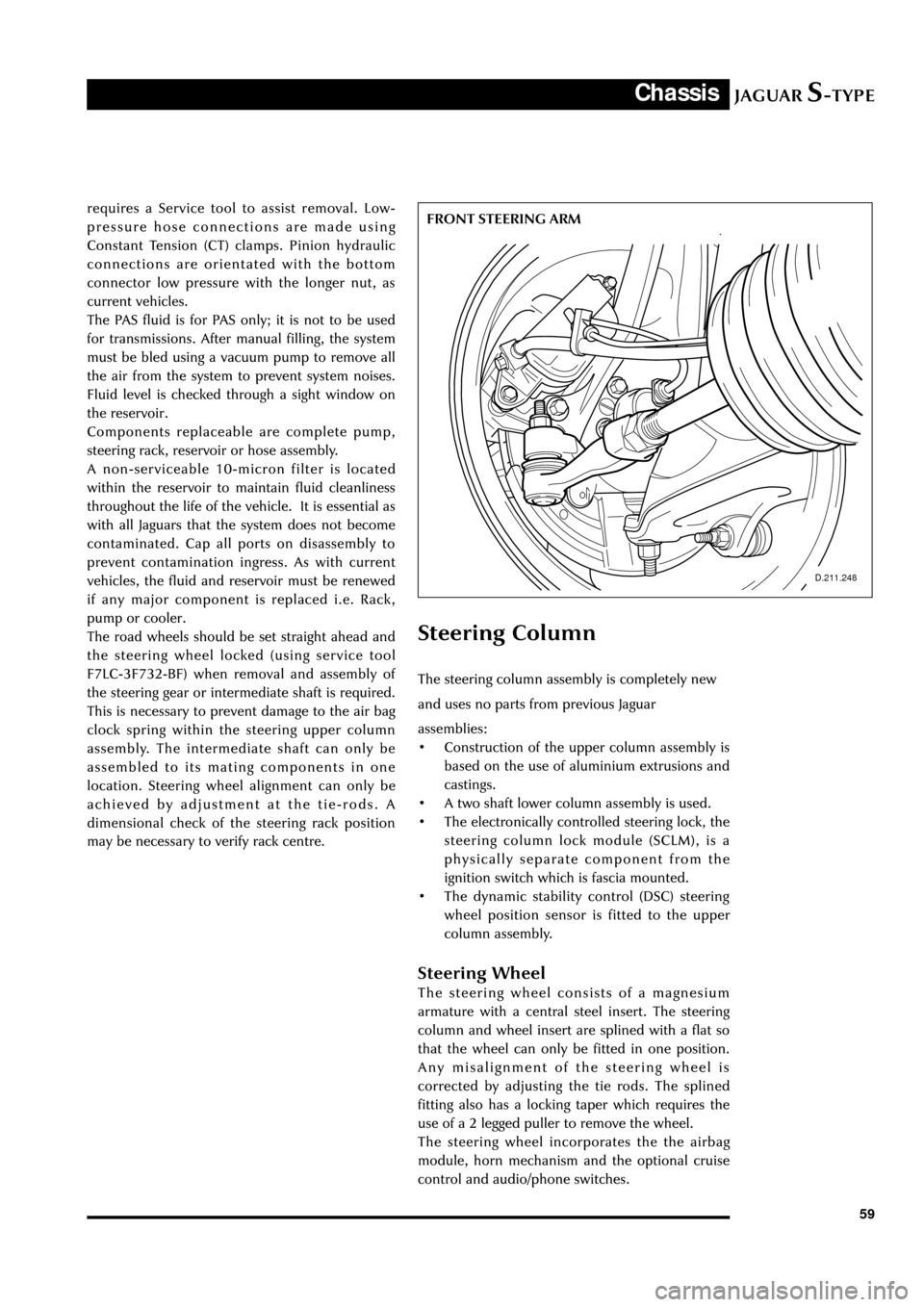

Trunk

The steel trunk lid has two hinges with one

damper and covered springs to assist lid lift. The

lid can be released using the switch on the fascia,

using the key-ring transmitter, or, if the vehicle is

unlocked, by a release button on the lid. An

emergency lock, key operated, is provided for

access to the trunk if, for instance, the battery is

disconnected. The trunk lock barrel is mounted to

the trunk lid with two flange nuts. Drive to the

trunk latch is via a cable which is a snap fit to the

rear of the barrel. Trunk sealing is a simple flange

mounted bulb section with a single moulded joint.

JOL.154

TRUNK RELEASE

Release Button

Emergency Lock

COOL AIR INLET COVER/LEAF SCREEN

Page 64 of 133

JAGUARS-TYPEChassis

59

D.211.248

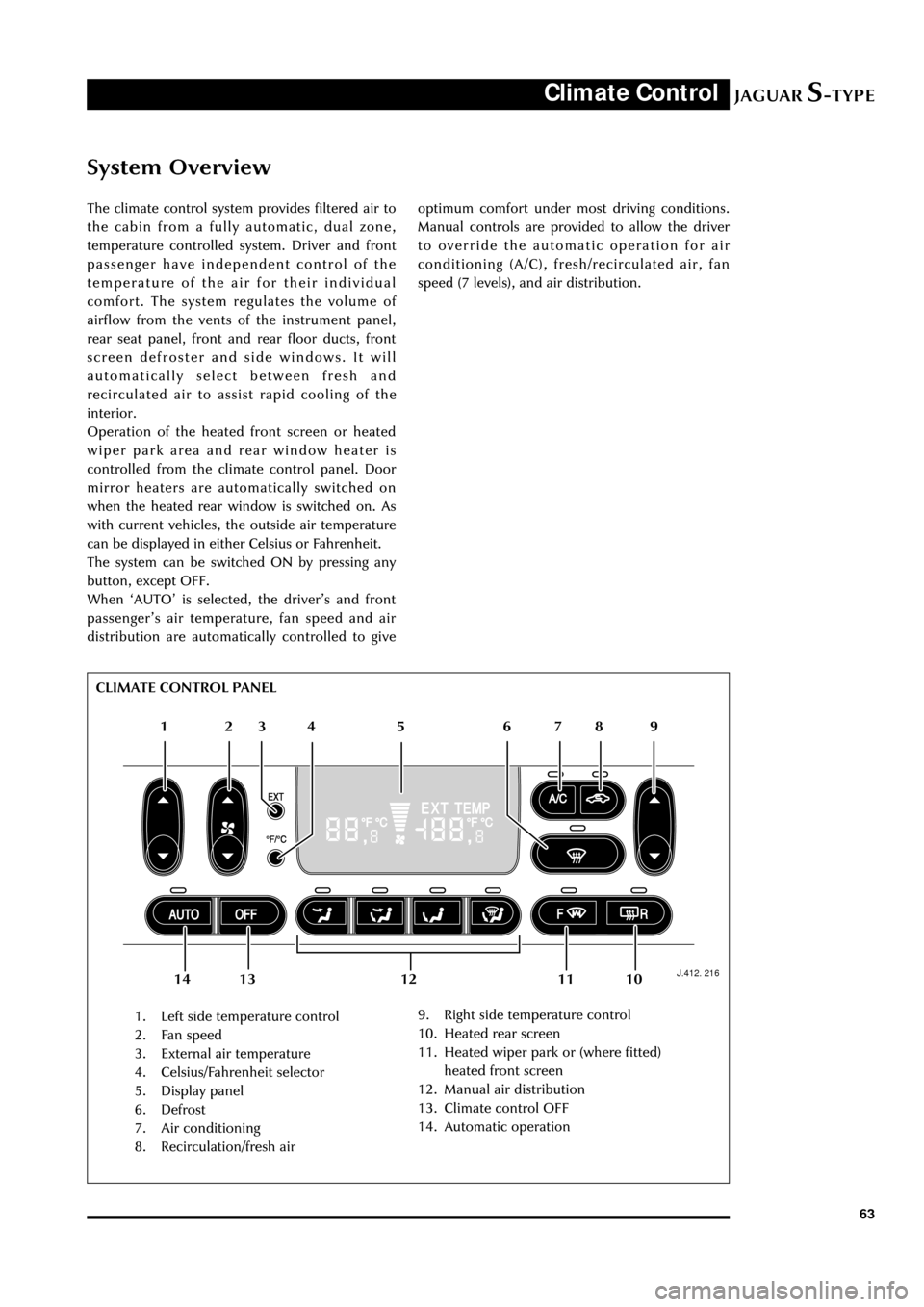

FRONT STEERING ARM requires a Service tool to assist removal. Low-

pressure hose connections are made using

Constant Tension (CT) clamps. Pinion hydraulic

connections are orientated with the bottom

connector low pressure with the longer nut, as

current vehicles.

The PAS fluid is for PAS only; it is not to be used

for transmissions. After manual filling, the system

must be bled using a vacuum pump to remove all

the air from the system to prevent system noises.

Fluid level is checked through a sight window on

the reservoir.

Components replaceable are complete pump,

steering rack, reservoir or hose assembly.

A non-serviceable 10-micron filter is located

within the reservoir to maintain fluid cleanliness

throughout the life of the vehicle. It is essential as

with all Jaguars that the system does not become

contaminated. Cap all ports on disassembly to

prevent contamination ingress. As with current

vehicles, the fluid and reservoir must be renewed

if any major component is replaced i.e. Rack,

pump or cooler.

The road wheels should be set straight ahead and

the steering wheel locked (using service tool

F7LC-3F732-BF) when removal and assembly of

the steering gear or intermediate shaft is required.

This is necessary to prevent damage to the air bag

clock spring within the steering upper column

assembly. The intermediate shaft can only be

assembled to its mating components in one

location. Steering wheel alignment can only be

achieved by adjustment at the tie-rods. A

dimensional check of the steering rack position

may be necessary to verify rack centre.

Steering Column

The steering column assembly is completely new

and uses no parts from previous Jaguar

assemblies:

¥ Construction of the upper column assembly is

based on the use of aluminium extrusions and

castings.

¥ A two shaft lower column assembly is used.

¥ The electronically controlled steering lock, the

steering column lock module (SCLM), is a

physically separate component from the

ignition switch which is fascia mounted.

¥ The dynamic stability control (DSC) steering

wheel position sensor is fitted to the upper

column assembly.

Steering Wheel

The steering wheel consists of a magnesium

armature with a central steel insert. The steering

column and wheel insert are splined with a flat so

that the wheel can only be fitted in one position.

Any misalignment of the steering wheel is

corrected by adjusting the tie rods. The splined

fitting also has a locking taper which requires the

use of a 2 legged puller to remove the wheel.

The steering wheel incorporates the the airbag

module, horn mechanism and the optional cruise

control and audio/phone switches.

Page 68 of 133

JAGUARS-TYPEClimate Control

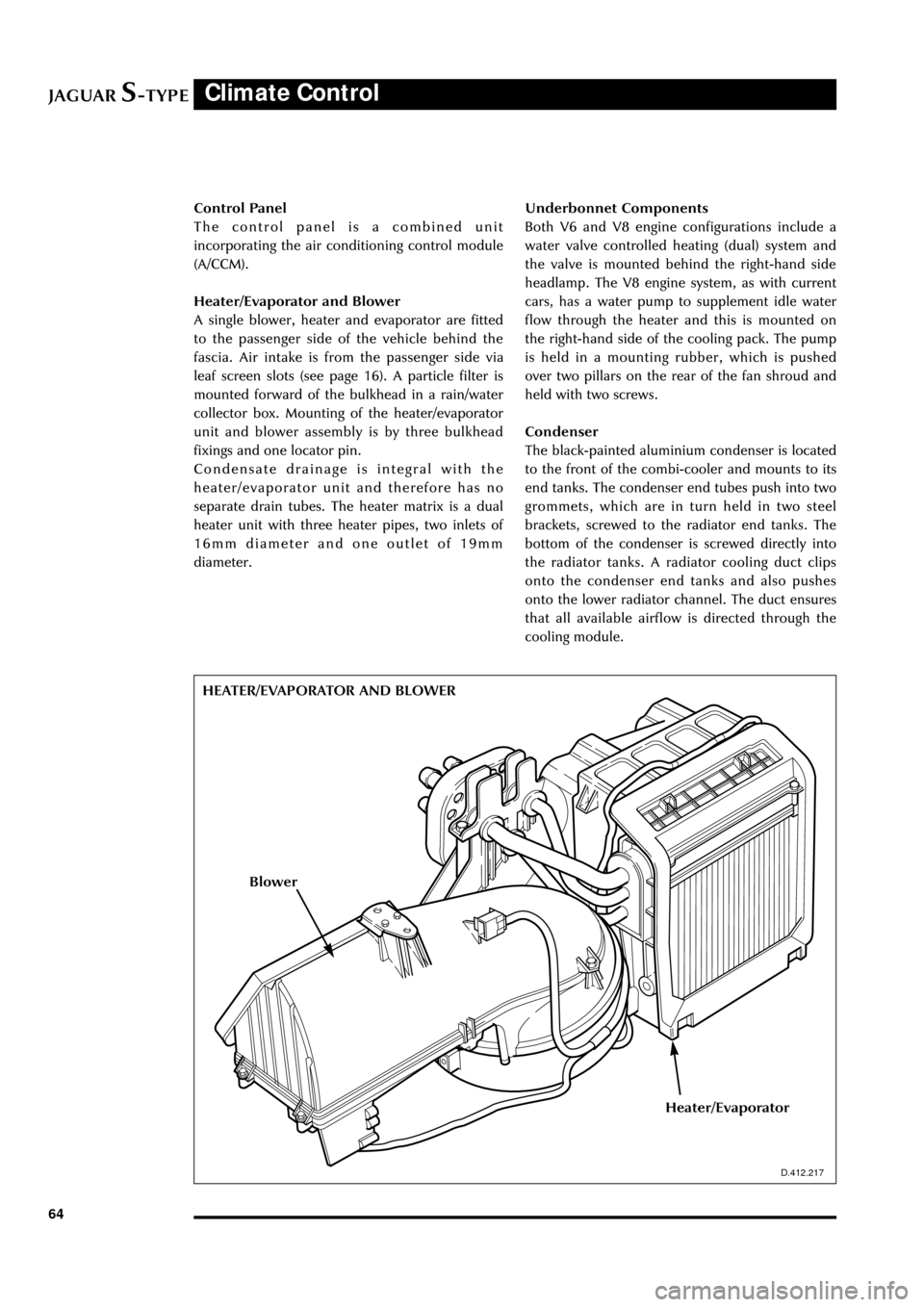

63

System Overview

The climate control system provides filtered air to

the cabin from a fully automatic, dual zone,

temperature controlled system. Driver and front

passenger have independent control of the

temperature of the air for their individual

comfort. The system regulates the volume of

airflow from the vents of the instrument panel,

rear seat panel, front and rear floor ducts, front

screen defroster and side windows. It will

automatically select between fresh and

recirculated air to assist rapid cooling of the

interior.

Operation of the heated front screen or heated

wiper park area and rear window heater is

controlled from the climate control panel. Door

mirror heaters are automatically switched on

when the heated rear window is switched on. As

with current vehicles, the outside air temperature

can be displayed in either Celsius or Fahrenheit.

The system can be switched ON by pressing any

button, except OFF.

When ÔAUTOÕ is selected, the driverÕs and front

passengerÕs air temperature, fan speed and air

distribution are automatically controlled to give

J.412. 216

1. Left side temperature control

2. Fan speed

3. External air temperature

4. Celsius/Fahrenheit selector

5. Display panel

6. Defrost

7. Air conditioning

8. Recirculation/fresh air9. Right side temperature control

10. Heated rear screen

11. Heated wiper park or (where fitted)

heated front screen

12. Manual air distribution

13. Climate control OFF

14. Automatic operation optimum comfort under most driving conditions.

Manual controls are provided to allow the driver

to override the automatic operation for air

conditioning (A/C), fresh/recirculated air, fan

speed (7 levels), and air distribution.

12 65 4 3

109 8 7

11 13 12 14 CLIMATE CONTROL PANEL

Page 69 of 133

JAGUARS-TYPEClimate Control

64Control Panel

The control panel is a combined unit

incorporating the air conditioning control module

(A/CCM).

Heater/Evaporator and Blower

A single blower, heater and evaporator are fitted

to the passenger side of the vehicle behind the

fascia. Air intake is from the passenger side via

leaf screen slots (see page 16). A particle filter is

mounted forward of the bulkhead in a rain/water

collector box. Mounting of the heater/evaporator

unit and blower assembly is by three bulkhead

fixings and one locator pin.

Condensate drainage is integral with the

heater/evaporator unit and therefore has no

separate drain tubes. The heater matrix is a dual

heater unit with three heater pipes, two inlets of

16mm diameter and one outlet of 19mm

diameter.

D.412.217

Underbonnet Components

Both V6 and V8 engine configurations include a

water valve controlled heating (dual) system and

the valve is mounted behind the right-hand side

headlamp. The V8 engine system, as with current

cars, has a water pump to supplement idle water

flow through the heater and this is mounted on

the right-hand side of the cooling pack. The pump

is held in a mounting rubber, which is pushed

over two pillars on the rear of the fan shroud and

held with two screws.

Condenser

The black-painted aluminium condenser is located

to the front of the combi-cooler and mounts to its

end tanks. The condenser end tubes push into two

grommets, which are in turn held in two steel

brackets, screwed to the radiator end tanks. The

bottom of the condenser is screwed directly into

the radiator tanks. A radiator cooling duct clips

onto the condenser end tanks and also pushes

onto the lower radiator channel. The duct ensures

that all available airflow is directed through the

cooling module.

HEATER/EVAPORATOR AND BLOWER

Blower

Heater/Evaporator

Page 72 of 133

JAGUARS-TYPEClimate Control

67 Pipework

The suction hose and liquid line are a one-piece

assembly. A single screw connects them to the air

conditioning unit manifold at the bulkhead. A

further screw fixing and push-in clip secures them

at the side of the engine bay. The liquid line fixed

to the cooling module then joins with a block

fitting and the suction hose connects with a quick

connect fitting and routes across the underneath

of the cooling module to the compressor. The

compressor suction and discharge hoses are also a

one piece assembly.

A pressure transducer is fitted to the discharge

hose as it connects to the rear of the condenser.

The high side charge port is situated on the

manifold connecting to the receiver drier whilst

the low side is adjacent to the compressor behind

the LH front wheel.

The compressor is a 9Occ scroll, which is variable

from 100% to 30%. Compressor is standard

specification to all vehicles although package

makes them unique to V6 and V8.

Air Distribution

Air distribution is as follows:

¥ Defrost duct integral with the fascia.

¥ Face vents, plenum, manifold, centre face

duct, side face duct, side window demist duct

are all sub-assembled into the fascia.

¥ Driver and front seat passenger foot ducts are

installed in the fascia after it has been fitted

to the vehicle.

¥ Rear foot ducts are fitted to the underframe.

¥ Rear face duct fitted to transmission tunnel.

¥ Rear face vent fitted to console.

¥ Extractor boxes fitted in rear quarter panels.

All flaps are electric servo controlled and

comprise:

¥ Fresh/recirculation - heater/evaporator unit.

¥ Cold air bypass - heater/evaporator unit.

¥ Foot flap - mounted on plenum.

¥ Defrost flap - mounted on plenum.

¥ Face flap - mounted on plenum.

Sensors, for operation of the system, are:

¥ Ambient temperature sensor - located behind

the lower front grille.

¥ Solar sensor - fitted to the top centre of the

fascia at the defrost grille

¥ In-car sensor - aspirated from the plenum

venturi sensor mounted inboard of the

steering column.¥ Two heater air outlet sensors

¥ One evaporator air outlet sensor

Servicing

Routine servicing consists of particle filter

replacement.

Replaceable items on the climate control system

are:

¥ Servo complete with linkages

¥ Sensors

¥ Evaporator and seals

¥ Heater core and seals

¥ Blower motor

¥ Impeller/blower motor wheel

¥ Hoses

¥ Registers/vents

¥ Ducts, except the defrost

¥ Defrost and side window demist grilles

¥ Control unit

¥ Compressor

¥ Water pump

¥ Water valve

¥ Receiver/drier

¥ Condenser

There are no panel diagnostics but PDU facility is

available with extensive capability, similar to

current XJ and XK Series.

System refrigerant is R134a. Vehicle charge weight

is 800 gms and charging is through the high side

charge port only.

Oil type is WSH-MIC231-B and refill quantity is

180 cc -220 cc.

Special tools are hose clamp pliers and air-

conditioning hoses spring lock de-coupler.

General information

Ensure that the grille at the base of the windshield

is kept clear of leaves, snow or other obstructions.

A solar sensor is mounted on top of the fascia, in

the centre of the defrost grille, and this should not

be covered.

The air conditioning system should be run briefly

at least once each week with a cold setting to

prevent the seals from drying out with subsequent

refrigerant leaks.

When the engine and vehicle interior are cold the

fan speed may be low until the engine has warmed

up, this avoids excessively cold air being blown

into the cabin.