height JAGUAR S TYPE 2005 1.G Technical Guide Update

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2005, Model line: S TYPE, Model: JAGUAR S TYPE 2005 1.GPages: 133, PDF Size: 3.48 MB

Page 10 of 133

JAGUARS-TYPEIntroduction

5

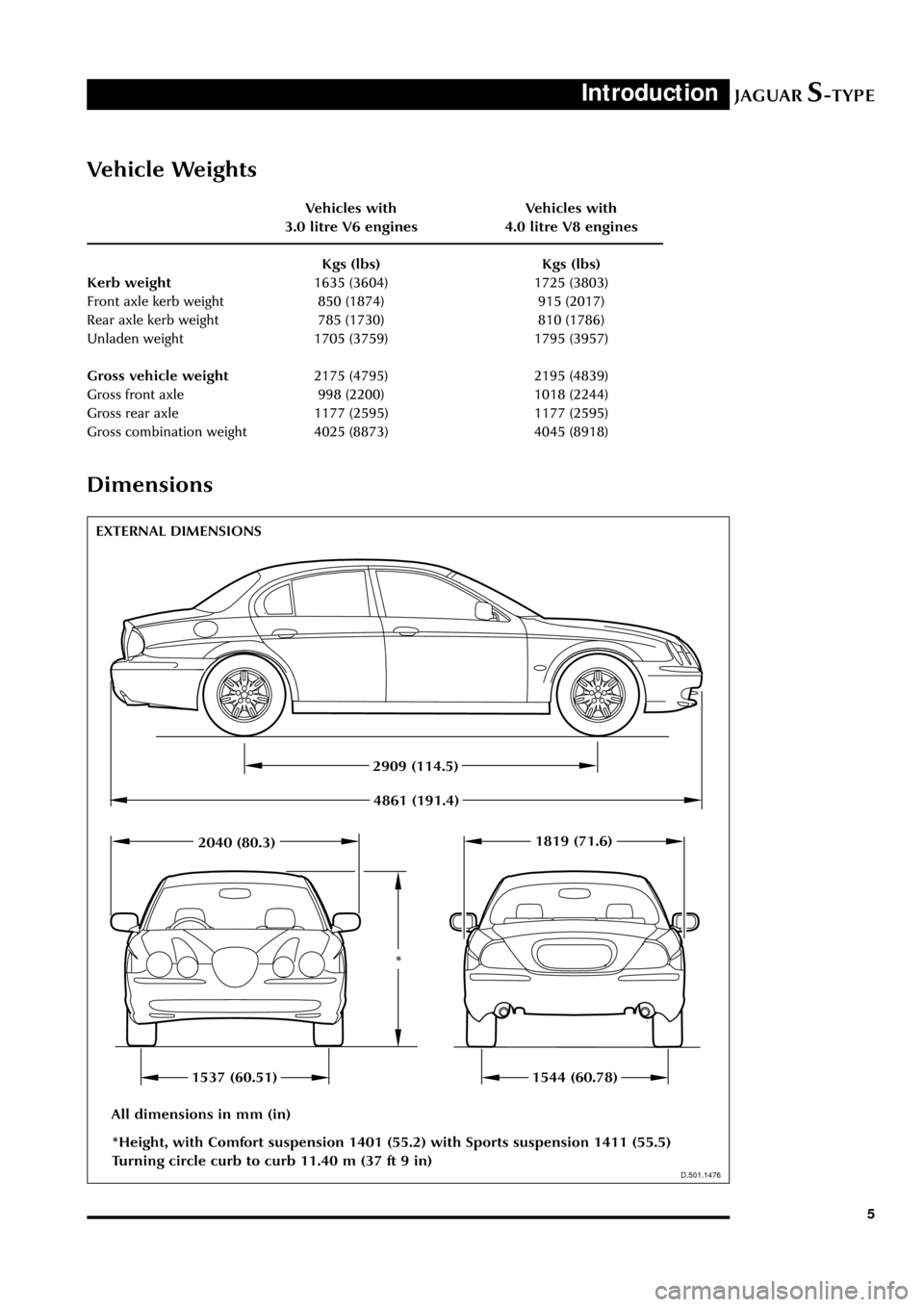

Vehicle Weights

Vehicles with Vehicles with

3.0 litre V6 engines 4.0 litre V8 engines

Kgs (lbs) Kgs (lbs)

Kerb weight1635 (3604) 1725 (3803)

Front axle kerb weight 850 (1874) 915 (2017)

Rear axle kerb weight 785 (1730) 810 (1786)

Unladen weight 1705 (3759) 1795 (3957)

Gross vehicle weight2175 (4795) 2195 (4839)

Gross front axle 998 (2200) 1018 (2244)

Gross rear axle 1177 (2595) 1177 (2595)

Gross combination weight 4025 (8873) 4045 (8918)

D.501.1476

EXTERNAL DIMENSIONS

2909 (114.5)

*Height, with Comfort suspension 1401 (55.2) with Sports suspension 1411 (55.5)

Turning circle curb to curb 11.40 m (37 ft 9 in)

D.501.1476

Dimensions

4861 (191.4)

1819 (71.6)

1544 (60.78)

2040 (80.3)

1537 (60.51)

*

All dimensions in mm (in)

Page 17 of 133

JAGUARS-TYPEBody

12

Front and Centre Floor Pan

The floor pan is a three-piece construction with

handed dash panels, welded front suspension

housing, an integral centre bearing panel for the

driveshaft and a large under-tunnel heatshield.

Rear Floor Pan

Multi-piece floor pan design, the rear tub is

designed to accept either a full size or space saver

spare wheel and the luggage compartment has

four tie-down luggage loops. Two plastic covers

are located under the rear seat and these give

easy access to the fuel tank mounted components.

A plastic battery tray is located below the luggage

load floor.

Roof

Provision has been made for roof rack fixings and

the roof has reinforcement for vehicles fitted with

a the sliding roof.

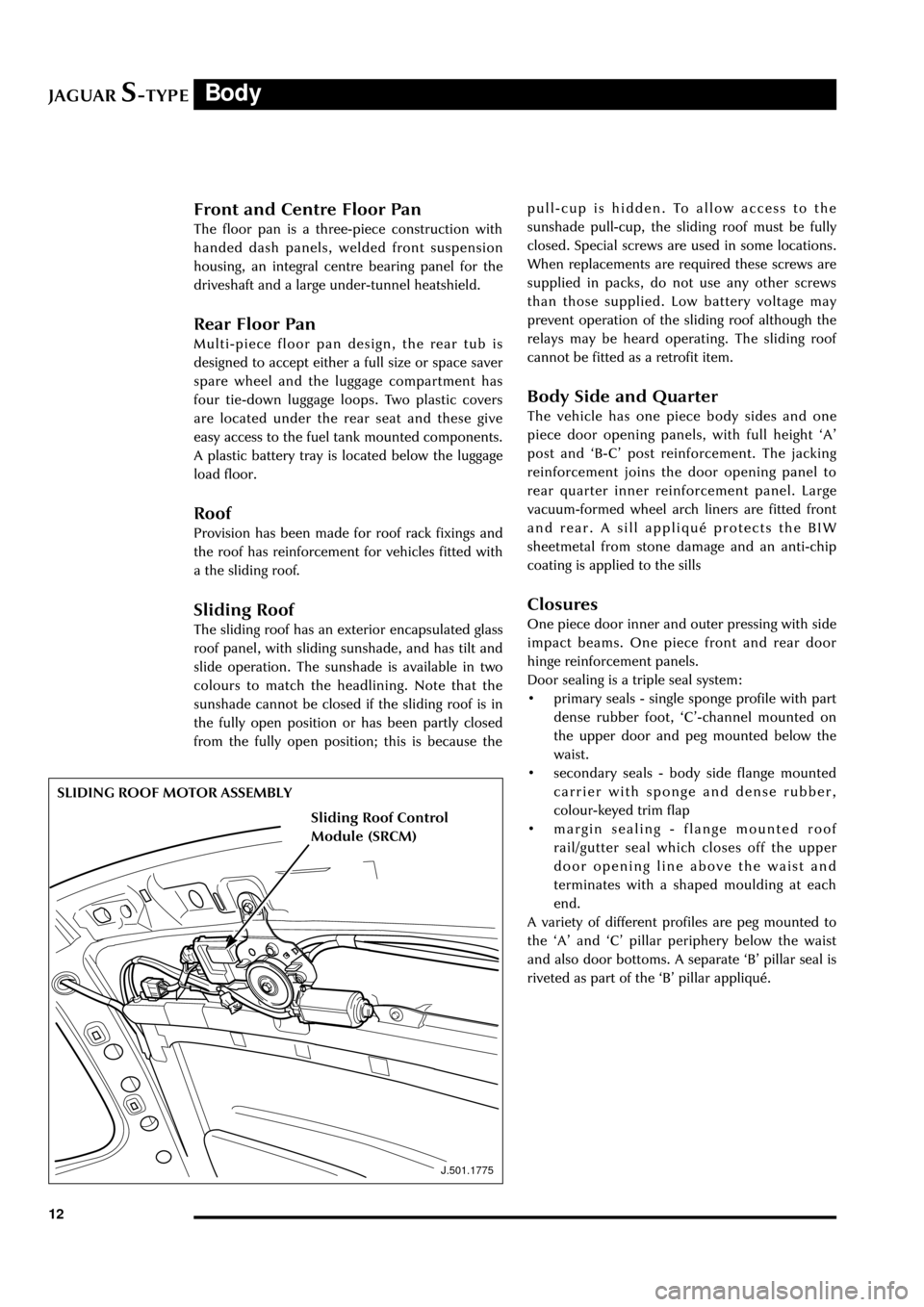

Sliding Roof

The sliding roof has an exterior encapsulated glass

roof panel, with sliding sunshade, and has tilt and

slide operation. The sunshade is available in two

colours to match the headlining. Note that the

sunshade cannot be closed if the sliding roof is in

the fully open position or has been partly closed

from the fully open position; this is because the

J.501.1775

SLIDING ROOF MOTOR ASSEMBLYpull-cup is hidden. To allow access to the

sunshade pull-cup, the sliding roof must be fully

closed. Special screws are used in some locations.

When replacements are required these screws are

supplied in packs, do not use any other screws

than those supplied. Low battery voltage may

prevent operation of the sliding roof although the

relays may be heard operating. The sliding roof

cannot be fitted as a retrofit item.

Body Side and Quarter

The vehicle has one piece body sides and one

piece door opening panels, with full height ÔAÕ

post and ÔB-CÕ post reinforcement. The jacking

reinforcement joins the door opening panel to

rear quarter inner reinforcement panel. Large

vacuum-formed wheel arch liners are fitted front

and rear. A sill appliquŽ protects the BIW

sheetmetal from stone damage and an anti-chip

coating is applied to the sills

Closures

One piece door inner and outer pressing with side

impact beams. One piece front and rear door

hinge reinforcement panels.

Door sealing is a triple seal system:

¥ primary seals - single sponge profile with part

dense rubber foot, ÔCÕ-channel mounted on

the upper door and peg mounted below the

waist.

¥ secondary seals - body side flange mounted

carrier with sponge and dense rubber,

colour-keyed trim flap

¥ margin sealing - flange mounted roof

rail/gutter seal which closes off the upper

door opening line above the waist and

terminates with a shaped moulding at each

end.

A variety of different profiles are peg mounted to

the ÔAÕ and ÔCÕ pillar periphery below the waist

and also door bottoms. A separate ÔBÕ pillar seal is

riveted as part of the ÔBÕ pillar appliquŽ.

Sliding Roof Control

Module (SRCM)

Page 31 of 133

JAGUARS-TYPEBody

26

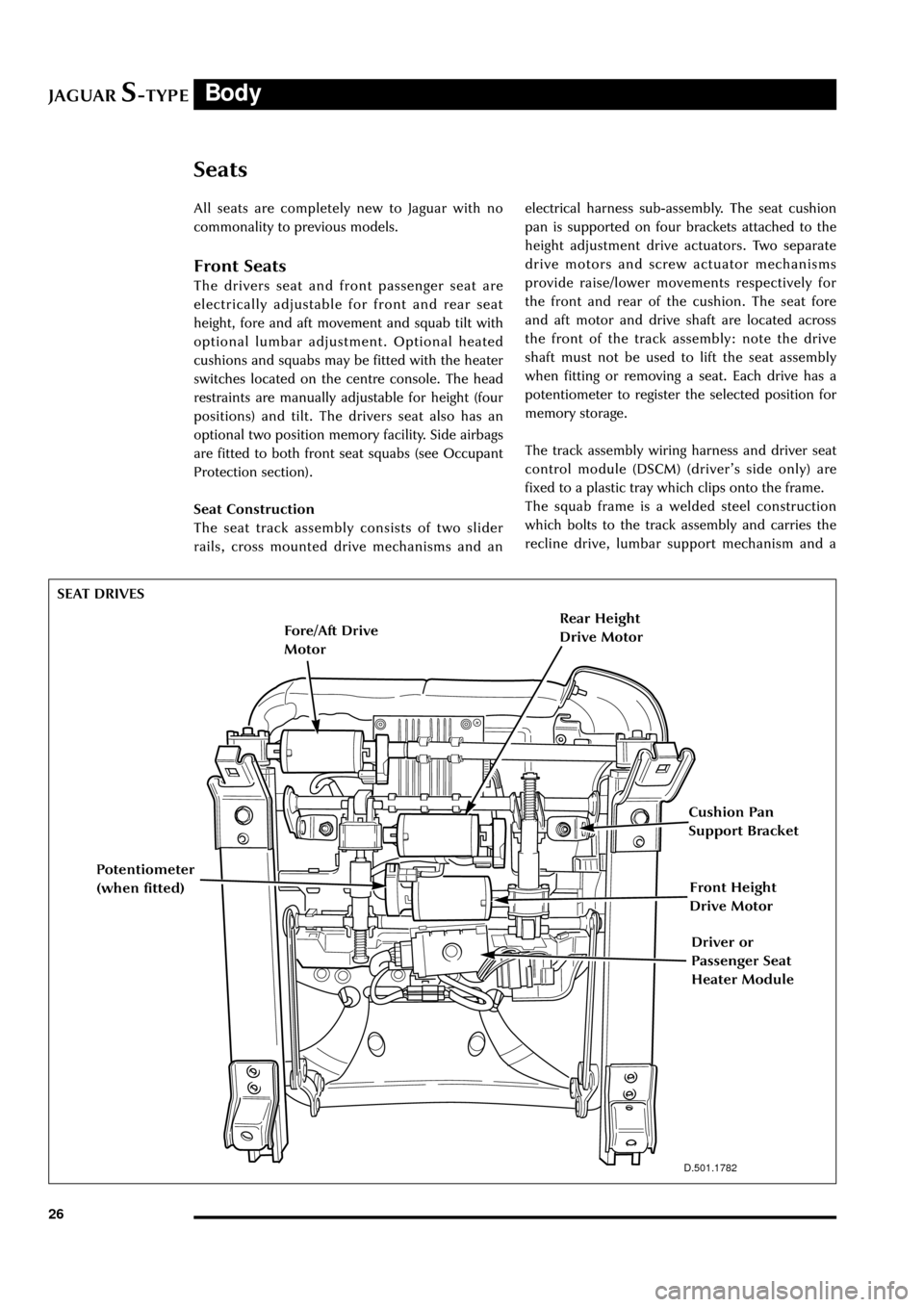

Seats

All seats are completely new to Jaguar with no

commonality to previous models.

Front Seats

The drivers seat and front passenger seat are

electrically adjustable for front and rear seat

height, fore and aft movement and squab tilt with

optional lumbar adjustment. Optional heated

cushions and squabs may be fitted with the heater

switches located on the centre console. The head

restraints are manually adjustable for height (four

positions) and tilt. The drivers seat also has an

optional two position memory facility. Side airbags

are fitted to both front seat squabs (see Occupant

Protection section).

Seat Construction

The seat track assembly consists of two slider

rails, cross mounted drive mechanisms and anelectrical harness sub-assembly. The seat cushion

pan is supported on four brackets attached to the

height adjustment drive actuators. Two separate

drive motors and screw actuator mechanisms

provide raise/lower movements respectively for

the front and rear of the cushion. The seat fore

and aft motor and drive shaft are located across

the front of the track assembly: note the drive

shaft must not be used to lift the seat assembly

when fitting or removing a seat. Each drive has a

potentiometer to register the selected position for

memory storage.

The track assembly wiring harness and driver seat

control module (DSCM) (driverÕs side only) are

fixed to a plastic tray which clips onto the frame.

The squab frame is a welded steel construction

which bolts to the track assembly and carries the

recline drive, lumbar support mechanism and a

D.501.1782

SEAT DRIVES

Fore/Aft Drive

Motor

Cushion Pan

Support Bracket

Driver or

Passenger Seat

Heater Module

Front Height

Drive Motor

Rear Height

Drive Motor

Potentiometer

(when fitted)

Page 37 of 133

JAGUARS-TYPEOccupant Protection

32

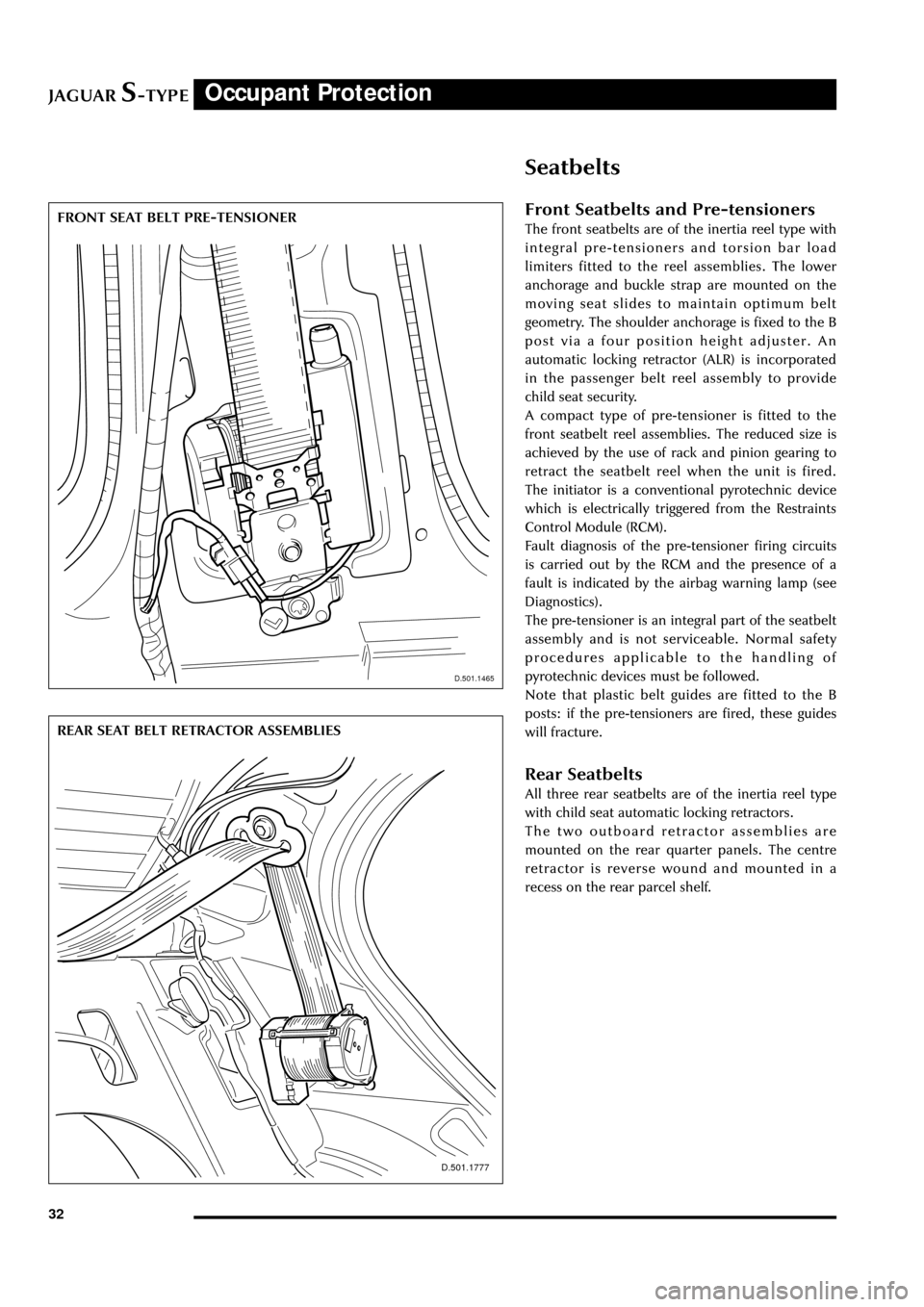

Seatbelts

D.501.1777

REAR SEAT BELT RETRACTOR ASSEMBLIES

D.501.1465

FRONT SEAT BELT PRE-TENSIONERFront Seatbelts and Pre-tensioners

The front seatbelts are of the inertia reel type with

integral pre-tensioners and torsion bar load

limiters fitted to the reel assemblies. The lower

anchorage and buckle strap are mounted on the

moving seat slides to maintain optimum belt

geometry. The shoulder anchorage is fixed to the B

post via a four position height adjuster. An

automatic locking retractor (ALR) is incorporated

in the passenger belt reel assembly to provide

child seat security.

A compact type of pre-tensioner is fitted to the

front seatbelt reel assemblies. The reduced size is

achieved by the use of rack and pinion gearing to

retract the seatbelt reel when the unit is fired.

The initiator is a conventional pyrotechnic device

which is electrically triggered from the Restraints

Control Module (RCM).

Fault diagnosis of the pre-tensioner firing circuits

is carried out by the RCM and the presence of a

fault is indicated by the airbag warning lamp (see

Diagnostics).

The pre-tensioner is an integral part of the seatbelt

assembly and is not serviceable. Normal safety

procedures applicable to the handling of

pyrotechnic devices must be followed.

Note that plastic belt guides are fitted to the B

posts: if the pre-tensioners are fired, these guides

will fracture.

Rear Seatbelts

All three rear seatbelts are of the inertia reel type

with child seat automatic locking retractors.

The two outboard retractor assemblies are

mounted on the rear quarter panels. The centre

retractor is reverse wound and mounted in a

recess on the rear parcel shelf.

D.501.1465