change time JAGUAR S TYPE 2005 1.G Technical Guide Update

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2005, Model line: S TYPE, Model: JAGUAR S TYPE 2005 1.GPages: 133, PDF Size: 3.48 MB

Page 52 of 133

JAGUARS-TYPEChassis

47

Front Suspension

The independent front wheel suspension is a

double wishbone axle arrangement with

aluminium control arms. The two arms are of

different lengths, which minimises the changes in

track and camber. Inclination of the upper control

arm axis provides anti-dive front suspension

action. There are two front cross members,

known as Number 1 and Number 2.

Number 1, the forward cross member, is a steel

fabrication, non-isolated, which locates the lower

control arm front mounting, the anti-roll bar and

the cooling module.

The rear cross member, Number 2, is an

aluminium casting, non-isolated and it locates the

lower control arm rear mounting, the power

steering rack and the engine hydro-mounts.

WARNING: No attempt must be made to

weld or repair the aluminium cross

member. If it is damaged, a new one must

be installed.

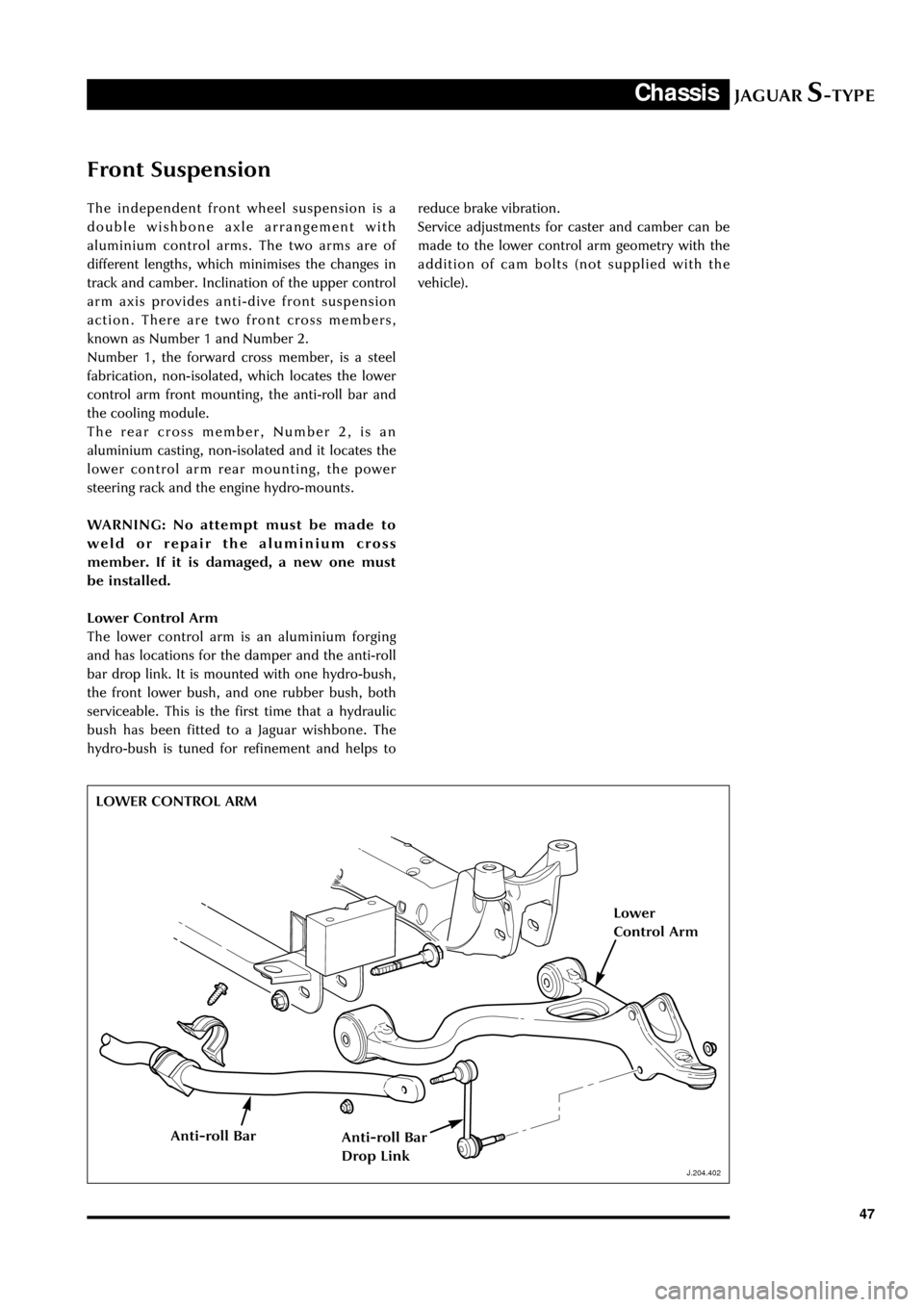

Lower Control Arm

The lower control arm is an aluminium forging

and has locations for the damper and the anti-roll

bar drop link. It is mounted with one hydro-bush,

the front lower bush, and one rubber bush, both

serviceable. This is the first time that a hydraulic

bush has been fitted to a Jaguar wishbone. The

hydro-bush is tuned for refinement and helps to

J.204.402

reduce brake vibration.

Service adjustments for caster and camber can be

made to the lower control arm geometry with the

addition of cam bolts (not supplied with the

vehicle).

LOWER CONTROL ARM

J.204.402

Lower

Control Arm

Anti-roll BarAnti-roll Bar

Drop Link

Page 58 of 133

JAGUARS-TYPEChassis

53

Driveline

Introduction

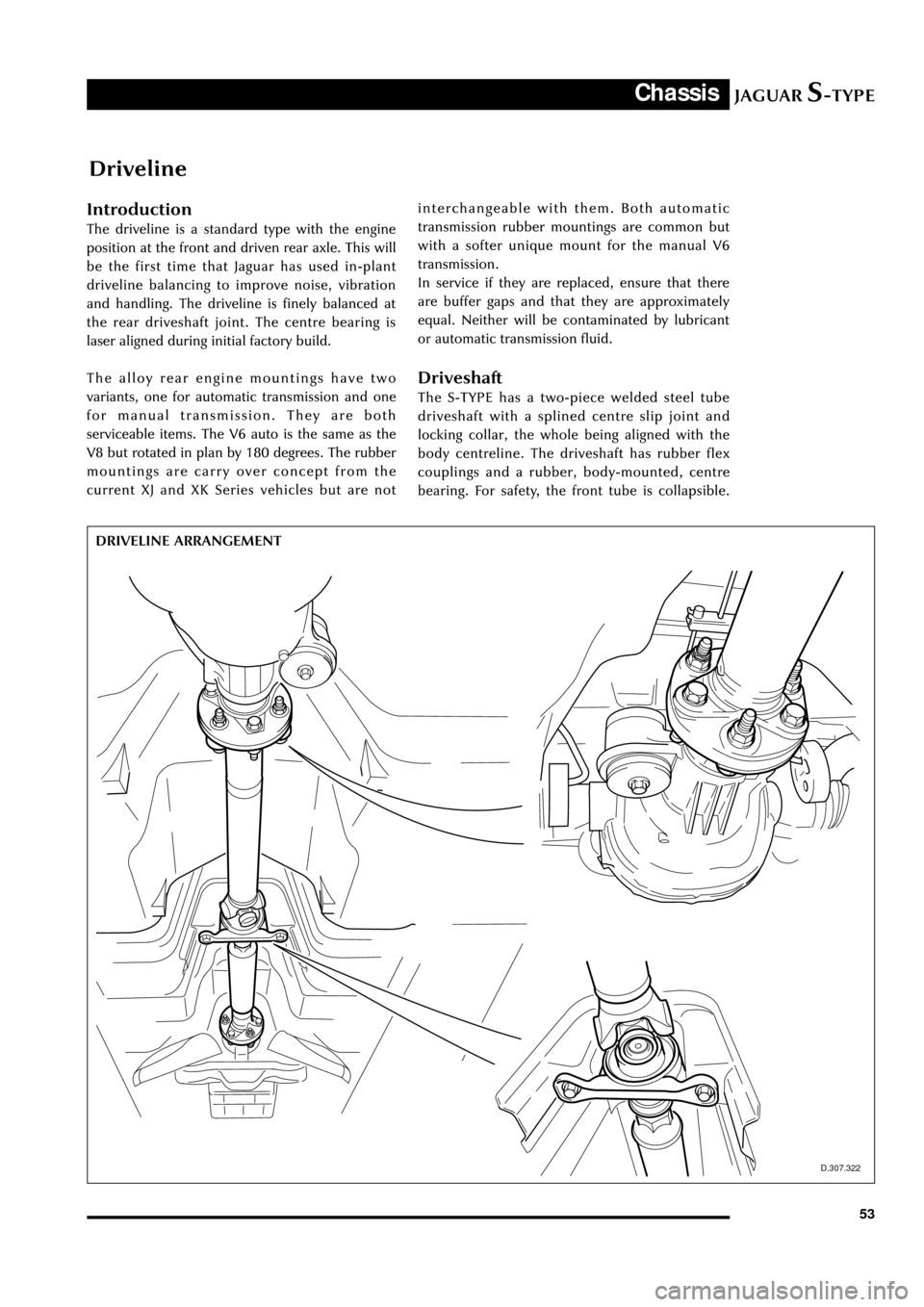

The driveline is a standard type with the engine

position at the front and driven rear axle. This will

be the first time that Jaguar has used in-plant

driveline balancing to improve noise, vibration

and handling. The driveline is finely balanced at

the rear driveshaft joint. The centre bearing is

laser aligned during initial factory build.

The alloy rear engine mountings have two

variants, one for automatic transmission and one

for manual transmission. They are both

serviceable items. The V6 auto is the same as the

V8 but rotated in plan by 180 degrees. The rubber

mountings are carry over concept from the

current XJ and XK Series vehicles but are not

D.307.322

DRIVELINE ARRANGEMENTinterchangeable with them. Both automatic

transmission rubber mountings are common but

with a softer unique mount for the manual V6

transmission.

In service if they are replaced, ensure that there

are buffer gaps and that they are approximately

equal. Neither will be contaminated by lubricant

or automatic transmission fluid.

Driveshaft

The S-TYPE has a two-piece welded steel tube

driveshaft with a splined centre slip joint and

locking collar, the whole being aligned with the

body centreline. The driveshaft has rubber flex

couplings and a rubber, body-mounted, centre

bearing. For safety, the front tube is collapsible.

Page 77 of 133

JAGUARS-TYPEElectrical/Electronic

72

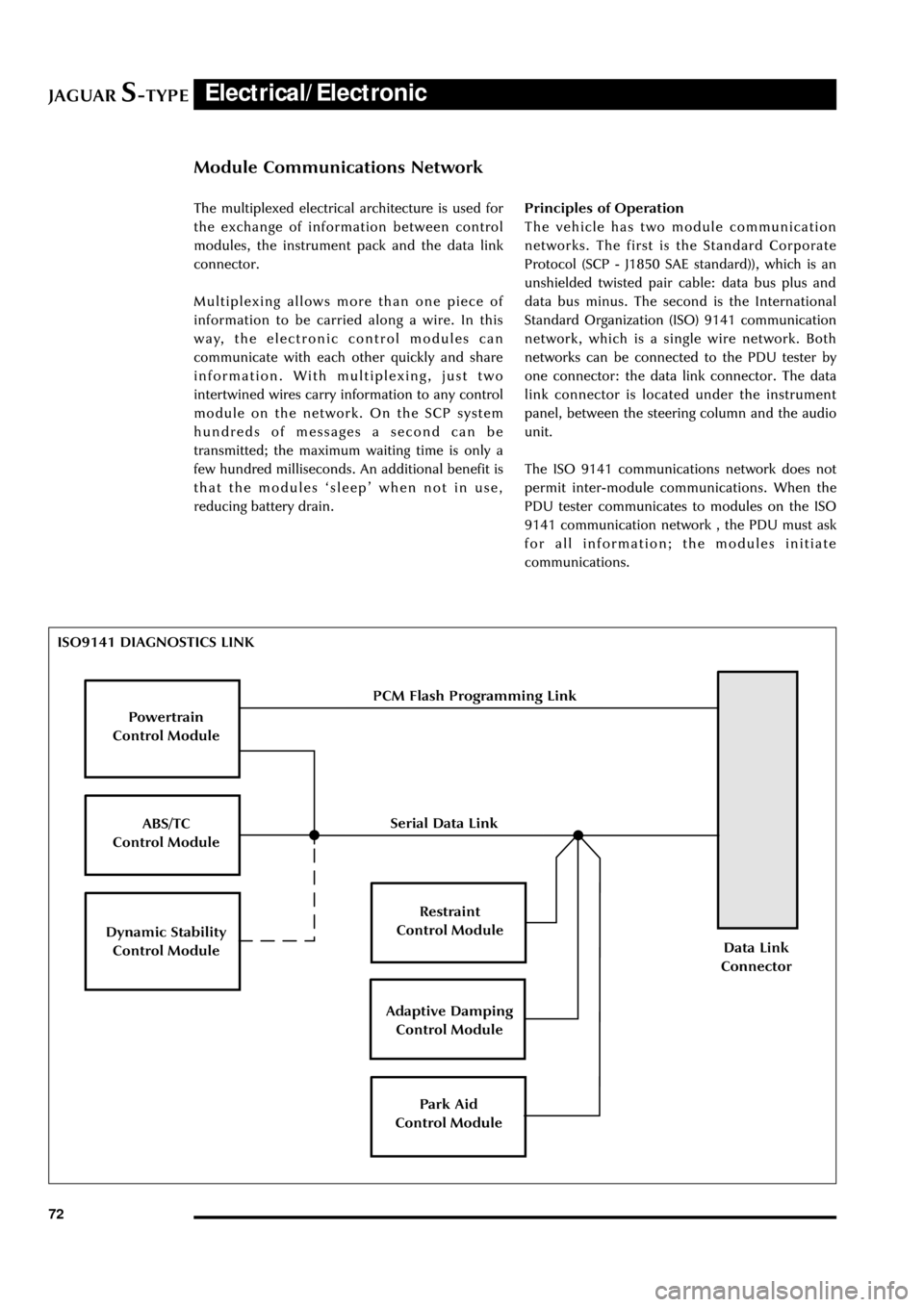

Module Communications Network

ISO9141 DIAGNOSTICS LINK

Powertrain

Control Module

ABS/TC

Control Module

Dynamic Stability

Control Module

Restraint

Control Module

Adaptive Damping

Control Module

Park Aid

Control Module

Data Link

Connector

PCM Flash Programming Link

Serial Data Link The multiplexed electrical architecture is used for

the exchange of information between control

modules, the instrument pack and the data link

connector.

Multiplexing allows more than one piece of

information to be carried along a wire. In this

way, the electronic control modules can

communicate with each other quickly and share

information. With multiplexing, just two

intertwined wires carry information to any control

module on the network. On the SCP system

hundreds of messages a second can be

transmitted; the maximum waiting time is only a

few hundred milliseconds. An additional benefit is

that the modules ÔsleepÕ when not in use,

reducing battery drain.Principles of Operation

The vehicle has two module communication

networks. The first is the Standard Corporate

Protocol (SCP - J1850 SAE standard)), which is an

unshielded twisted pair cable: data bus plus and

data bus minus. The second is the International

Standard Organization (ISO) 9141 communication

network, which is a single wire network. Both

networks can be connected to the PDU tester by

one connector: the data link connector. The data

link connector is located under the instrument

panel, between the steering column and the audio

unit.

The ISO 9141 communications network does not

permit inter-module communications. When the

PDU tester communicates to modules on the ISO

9141 communication network , the PDU must ask

for all information; the modules initiate

communications.