fuel pump JAGUAR S TYPE 2005 1.G Technical Guide Update

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2005, Model line: S TYPE, Model: JAGUAR S TYPE 2005 1.GPages: 133, PDF Size: 3.48 MB

Page 43 of 133

JAGUARS-TYPEFuel System

38

Introduction

The fuel tank components, operation and layout

are new to Jaguar and have no commonality with

previous systems. The major features of the fuel

delivery system are the use of a saddle type tank

and a returnless fuel system. The evaporative loss

management system is similar in operation to that

fitted to the XJ and XK Series vehicles and on-

board refuelling vapour recovery (ORVR) is a

standard feature. For NAS markets only, leak test

diagnostics are performed.

Returnless Fuel System

The returnless fuel system delivers the correct

amount of fuel to the engine under all conditions

and at a constant pressure differential with

respect to manifold pressure. This is without the

need for a return line to the tank or a fuel rail

pressure regulator. The use of a return line and

the pressure drop across a regulator contribute to

vapour formation which can affect fuelling

calibration and requires a complex vapour

management system to meet legislative

requirements. Elimination of these components,

D.310.047

together with closed loop control of the variable

speed fuel pump, causes a reduction in the vapour

generated, lower fuel temperatures and better fuel

pressure control. Additional advantages include a

reduced load on the electrical system and

improved fuel economy.

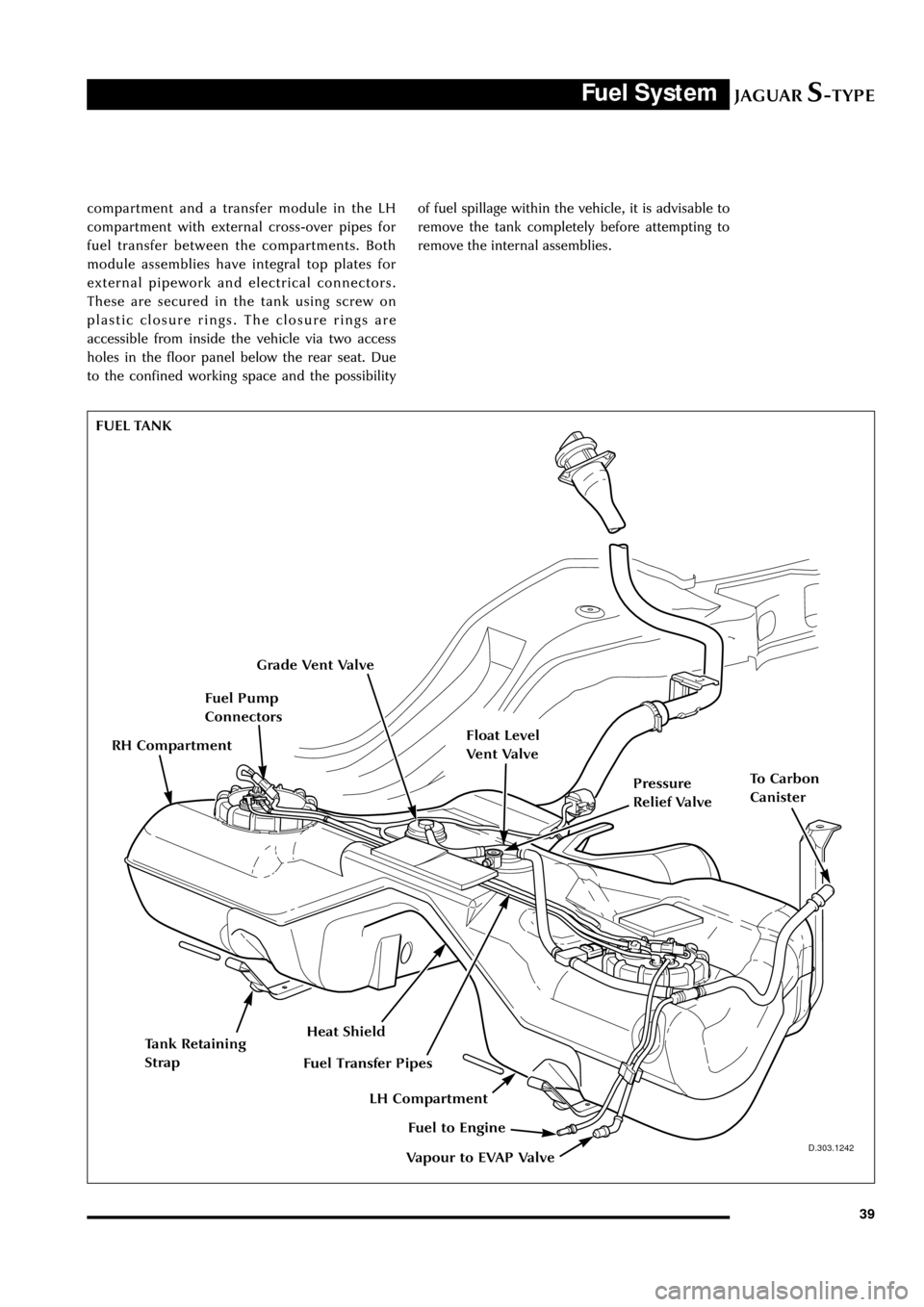

Fuel Tank

The fuel tank is of the ÔsaddleÕ type shape with LH

and RH fuel compartments and is constructed of

high density polyethylene (HDPE), a plastic blow

moulded material. The tank is located below the

rear passenger seat with the drive shaft and

exhaust running through the arch of the tank. The

underside of the tank is protected by a fitted heat

shield and the tank assembly is retained by two

metal straps which are fixed to the underbody at

the front by removeable hinge pins and at the rear

by bolts.

Refuelling is via a separate filler pipe and

connecting hose to a stub pipe on the RH fuel

compartment.

A fuel pump module is located in the RH

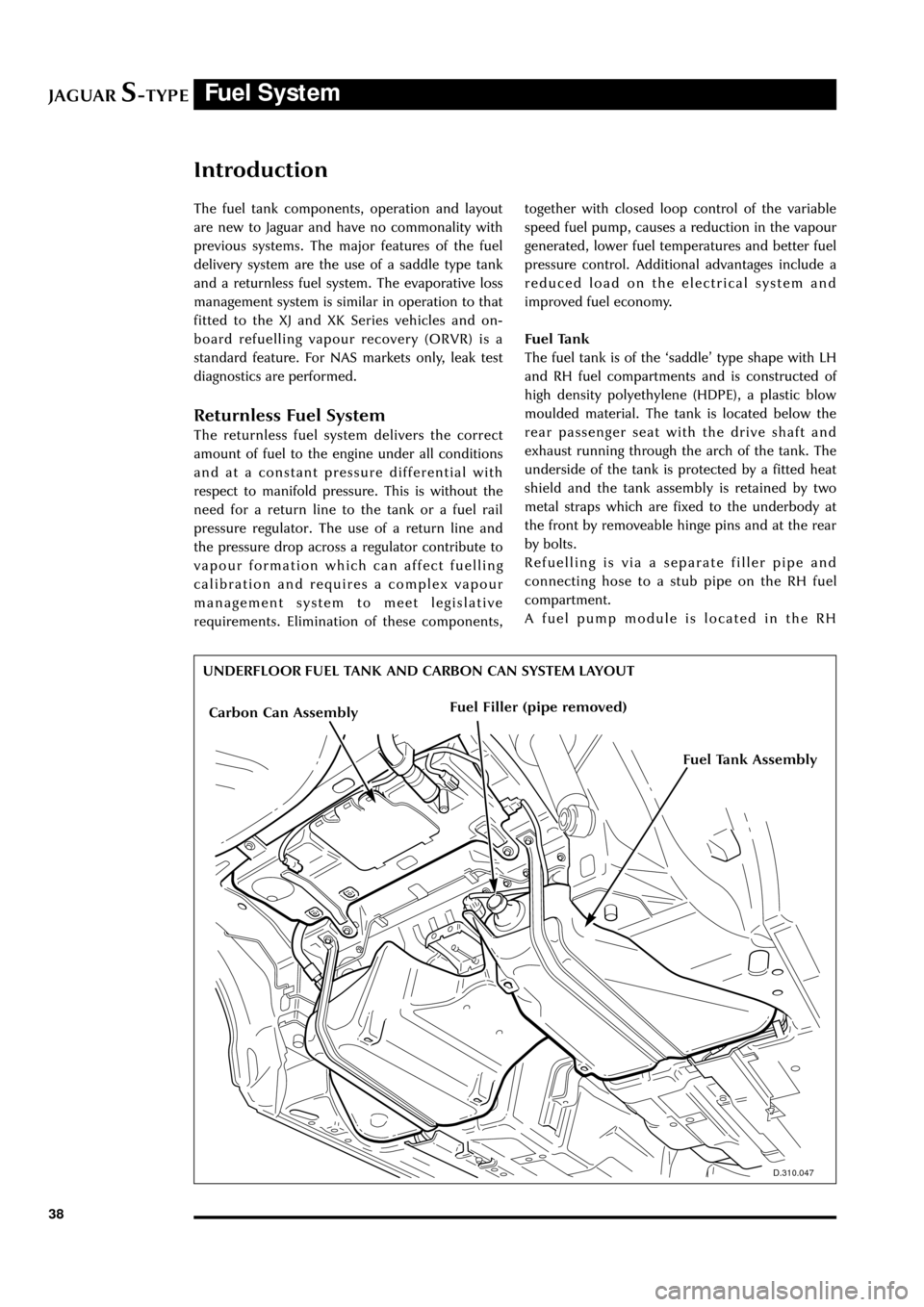

UNDERFLOOR FUEL TANK AND CARBON CAN SYSTEM LAYOUT

Carbon Can AssemblyFuel Filler (pipe removed)

Fuel Tank Assembly

Page 44 of 133

JAGUARS-TYPEFuel System

39

D.303.1242

compartment and a transfer module in the LH

compartment with external cross-over pipes for

fuel transfer between the compartments. Both

module assemblies have integral top plates for

external pipework and electrical connectors.

These are secured in the tank using screw on

plastic closure rings. The closure rings are

accessible from inside the vehicle via two access

holes in the floor panel below the rear seat. Due

to the confined working space and the possibilityof fuel spillage within the vehicle, it is advisable to

remove the tank completely before attempting to

remove the internal assemblies.

FUEL TANK

Grade Vent Valve

Fuel Pump

Connectors

Pressure

Relief Valve

Float Level

Vent Valve

Heat Shield

To Carbon

Canister

Vapour to EVAP Valve

Fuel to Engine

Fuel Transfer Pipes

Tank Retaining

Strap

LH Compartment

RH Compartment

Page 45 of 133

JAGUARS-TYPEFuel System

40

J.310.046

Fuel Filter

Fuel Rail

Fuel Injectors

Fuel Injectors

Fuel Level

Senders

Jet PumpJet PumpFuel Pump

Fuel Reservoir

Parallel Pressure

Relief Valve

Pump and Sender

Electrical Connector

RH Compartment

LH Compartment

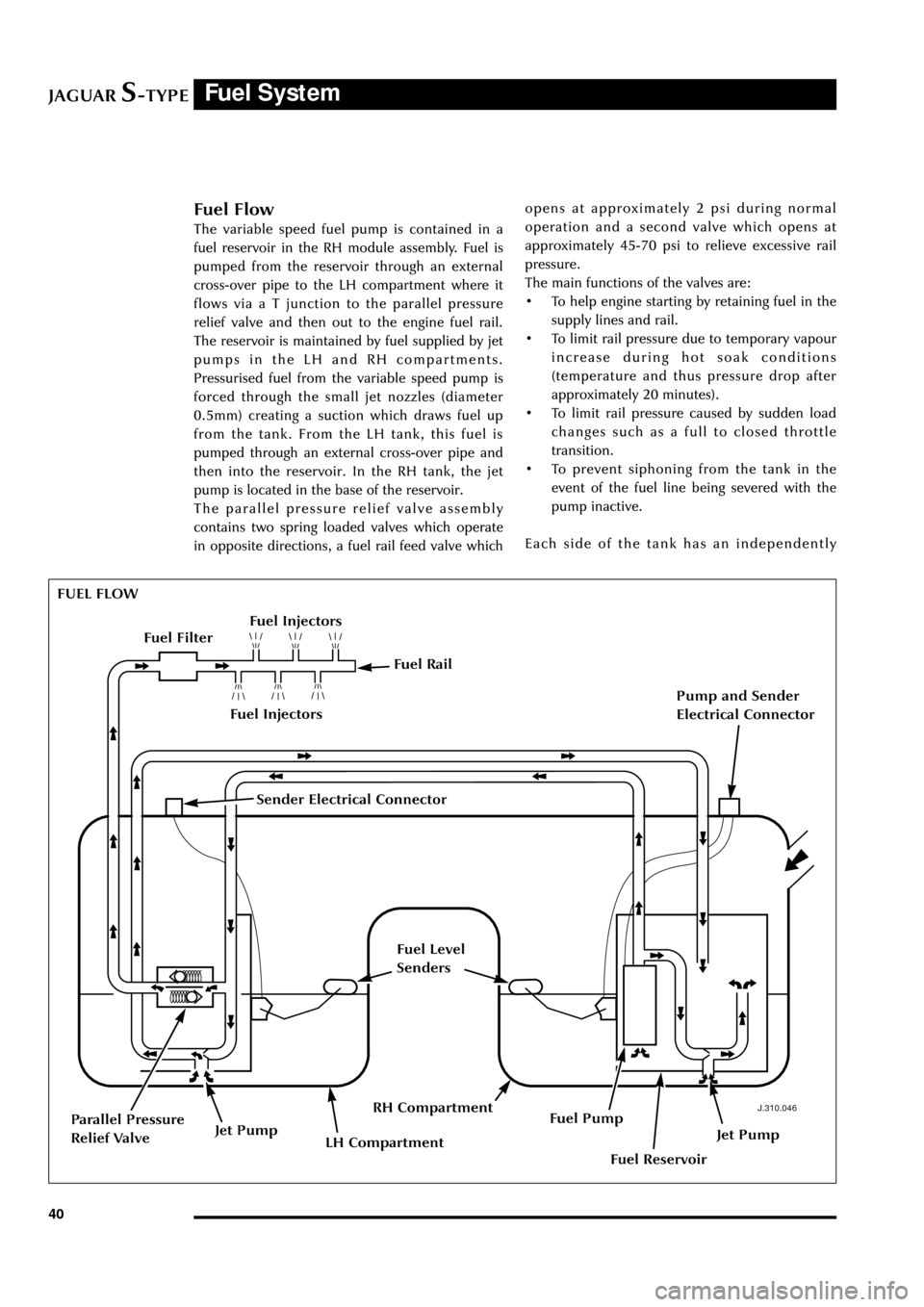

Fuel Flow

The variable speed fuel pump is contained in a

fuel reservoir in the RH module assembly. Fuel is

pumped from the reservoir through an external

cross-over pipe to the LH compartment where it

flows via a T junction to the parallel pressure

relief valve and then out to the engine fuel rail.

The reservoir is maintained by fuel supplied by jet

pumps in the LH and RH compartments.

Pressurised fuel from the variable speed pump is

forced through the small jet nozzles (diameter

0.5mm) creating a suction which draws fuel up

from the tank. From the LH tank, this fuel is

pumped through an external cross-over pipe and

then into the reservoir. In the RH tank, the jet

pump is located in the base of the reservoir.

The parallel pressure relief valve assembly

contains two spring loaded valves which operate

in opposite directions, a fuel rail feed valve whichopens at approximately 2 psi during normal

operation and a second valve which opens at

approximately 45-70 psi to relieve excessive rail

pressure.

The main functions of the valves are:

¥ To help engine starting by retaining fuel in the

supply lines and rail.

¥ To limit rail pressure due to temporary vapour

increase during hot soak conditions

(temperature and thus pressure drop after

approximately 20 minutes).

¥ To limit rail pressure caused by sudden load

changes such as a full to closed throttle

transition.

¥ To prevent siphoning from the tank in the

event of the fuel line being severed with the

pump inactive.

Each side of the tank has an independently

FUEL FLOW

Sender Electrical Connector

Page 46 of 133

JAGUARS-TYPEFuel System

41

JOL.062

INERTIA SWITCH operating fuel level sender assembly mounted on

the respective module assembly.

Control and Operation

The speed of the fuel pump is varied under closed

loop control so as to deliver the required fuel rail

injection pressure in accordance with factors such

as driver demand, manifold pressure and

temperature changes. The control loop sensors,

providing feedback information to the powertrain

control module (PCM), are the engine fuel

temperature (EFT) sensor and the injection

pressure (IP) sensor which are both mounted

directly on the engine fuel rail (see

S-TYPE Powertrain Technical Guide). The IP sensor

also has a vacuum feed from the intake manifold

so as to measure the pressure differential.

The required fuel flow is determined by the PCM

and sent to the rear electronic control module

(RECM) which is the power driver for the fuel

pump. The PCM demand to the RECM is a pulse

width modulated (PWM) signal over a single line

at a frequency of approximately 256 Hz and a

duty cycle of 0-50%. The RECM effecively

amplifies this signal by increasing the frequency

by 64 and doubling the duty cycle, thus providing

the necessary high current drive for the fuel

pump. The fuel pump relay, located in the rear

power distribution box, is energised by the PCM

relay and provides a dedicated fused supply to the

RECM for the pump drive.

When the ignition switch is turned from OFF to

RUN or START, the PCM primes the system by

running the pump for 1 second at full speed. The

pump is switched off 1 second after the engine is

stopped. During hot starts, fuel pressure is

increased to prevent vapour lock.

Fuel pump drive status is monitored by the RECM

and communicated to the PCM via the SCP

network.

Outputs from the fuel senders are connected by

independent wires to the RECM which sends the

data to the instrument pack and the PCM.

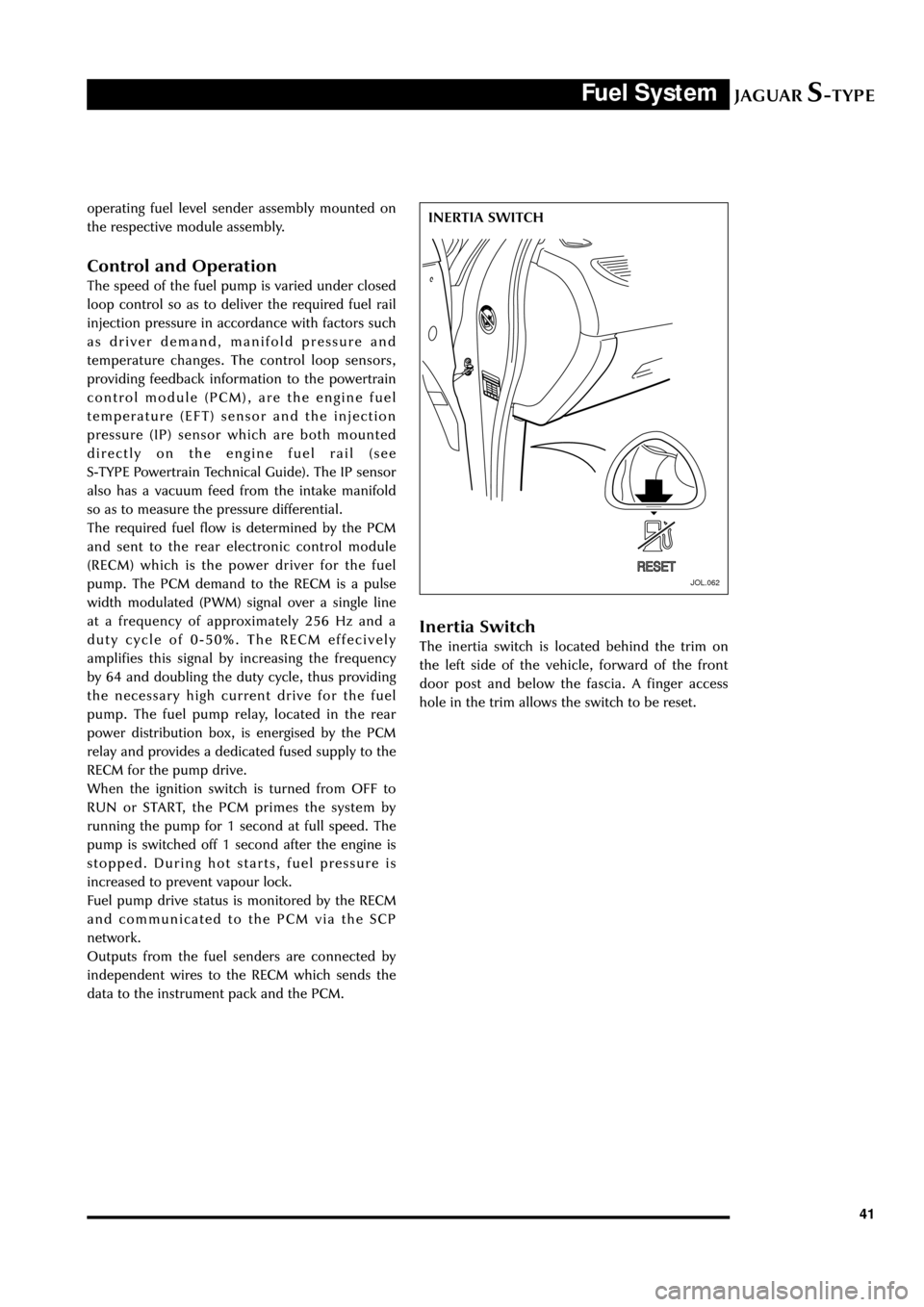

Inertia Switch

The inertia switch is located behind the trim on

the left side of the vehicle, forward of the front

door post and below the fascia. A finger access

hole in the trim allows the switch to be reset.

Page 47 of 133

JAGUARS-TYPEFuel System

42

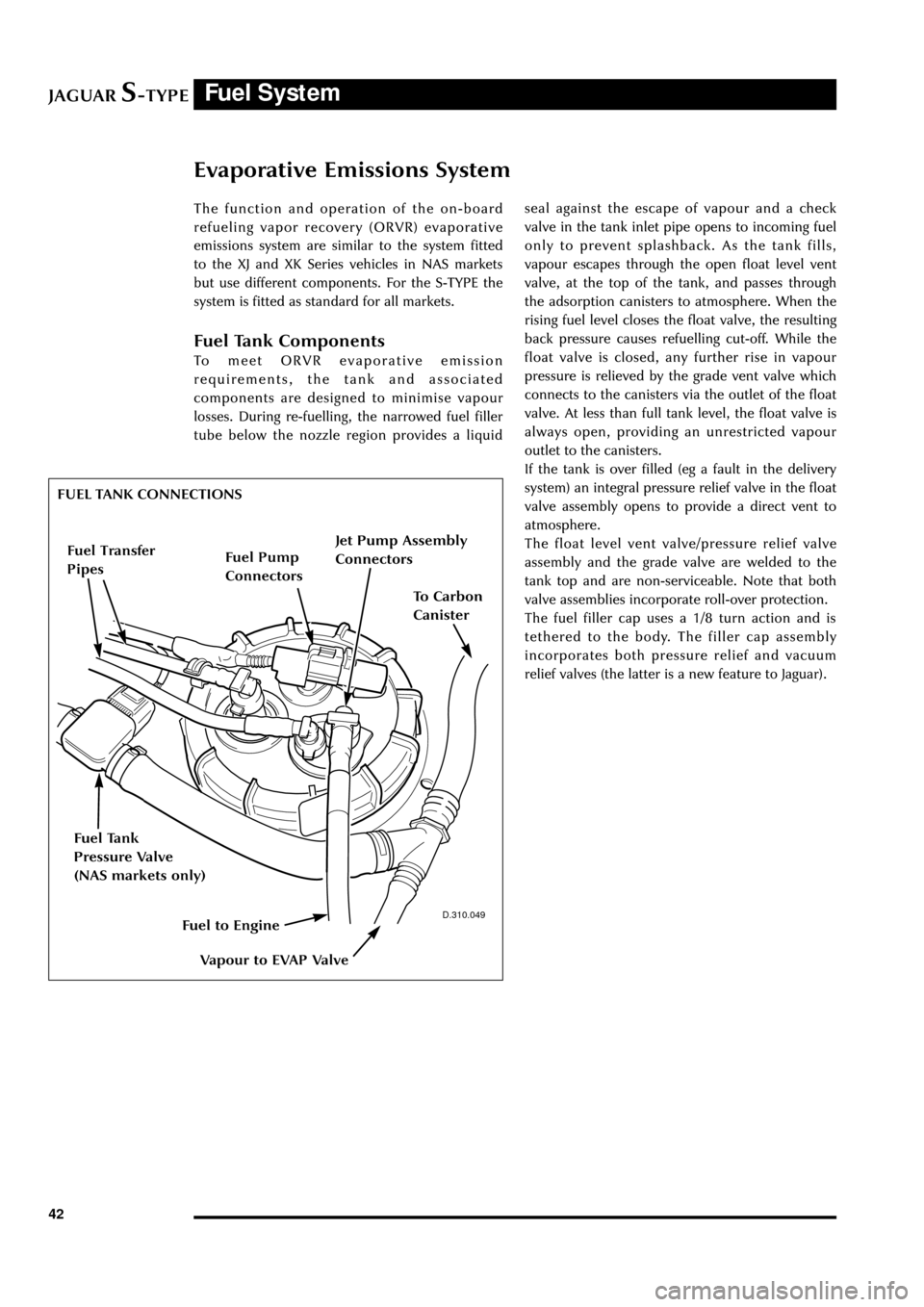

Evaporative Emissions System

The function and operation of the on-board

refueling vapor recovery (ORVR) evaporative

emissions system are similar to the system fitted

to the XJ and XK Series vehicles in NAS markets

but use different components. For the S-TYPE the

system is fitted as standard for all markets.

Fuel Tank Components

To meet ORVR evaporative emission

requirements, the tank and associated

components are designed to minimise vapour

losses. During re-fuelling, the narrowed fuel filler

tube below the nozzle region provides a liquidseal against the escape of vapour and a check

valve in the tank inlet pipe opens to incoming fuel

only to prevent splashback. As the tank fills,

vapour escapes through the open float level vent

valve, at the top of the tank, and passes through

the adsorption canisters to atmosphere. When the

rising fuel level closes the float valve, the resulting

back pressure causes refuelling cut-off. While the

float valve is closed, any further rise in vapour

pressure is relieved by the grade vent valve which

connects to the canisters via the outlet of the float

valve. At less than full tank level, the float valve is

always open, providing an unrestricted vapour

outlet to the canisters.

If the tank is over filled (eg a fault in the delivery

system) an integral pressure relief valve in the float

valve assembly opens to provide a direct vent to

atmosphere.

The float level vent valve/pressure relief valve

assembly and the grade valve are welded to the

tank top and are non-serviceable. Note that both

valve assemblies incorporate roll-over protection.

The fuel filler cap uses a 1/8 turn action and is

tethered to the body. The filler cap assembly

incorporates both pressure relief and vacuum

relief valves (the latter is a new feature to Jaguar).

D.310.049

FUEL TANK CONNECTIONS

Fuel Tank

Pressure Valve

(NAS markets only)

Jet Pump Assembly

Connectors

Fuel Pump

Connectors

To Carbon

Canister

Vapour to EVAP Valve

Fuel to Engine

Fuel Transfer

Pipes

Page 81 of 133

JAGUARS-TYPEElectrical/Electronic

76Air Conditioning Control Module (A/CCM)

The A/CCM is connected to the SCP

communication network. The A/CCM controls

automatic climate functions that maintain the

vehicle at a constant temperature setting.

Instrument Pack

The instrument pack is connected to the SCP

communication network. The instrument pack

displays information received on the SCP

including speedometer, odometer, fuel, and

message center warnings. The instrument pack

also controls the passive anti-theft system (PATS).

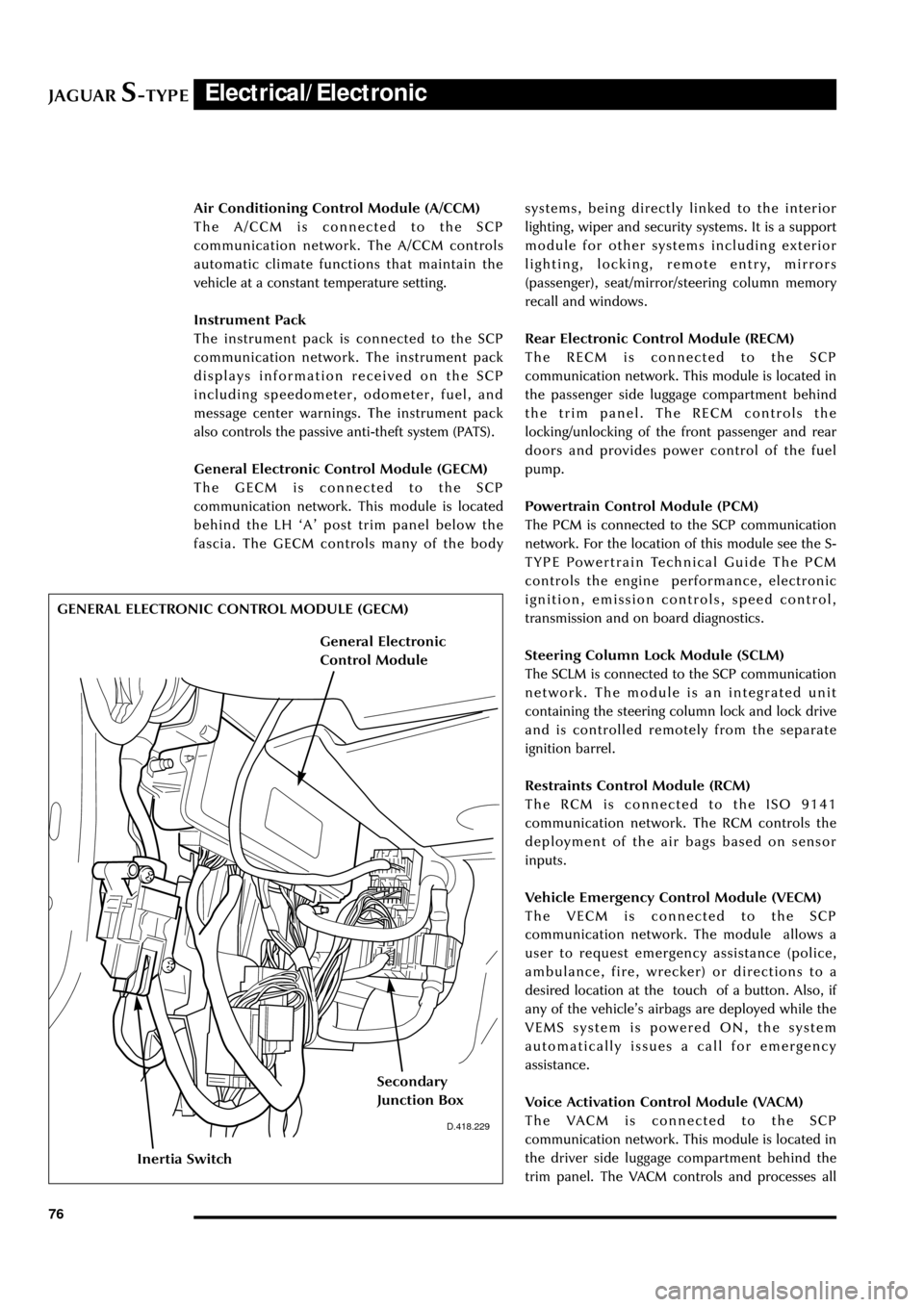

General Electronic Control Module (GECM)

The GECM is connected to the SCP

communication network. This module is located

behind the LH ÔAÕ post trim panel below the

fascia. The GECM controls many of the bodysystems, being directly linked to the interior

lighting, wiper and security systems. It is a support

module for other systems including exterior

lighting, locking, remote entry, mirrors

(passenger), seat/mirror/steering column memory

recall and windows.

Rear Electronic Control Module (RECM)

The RECM is connected to the SCP

communication network. This module is located in

the passenger side luggage compartment behind

the trim panel. The RECM controls the

locking/unlocking of the front passenger and rear

doors and provides power control of the fuel

pump.

Powertrain Control Module (PCM)

The PCM is connected to the SCP communication

network. For the location of this module see the S-

TYPE Powertrain Technical Guide The PCM

controls the engine performance, electronic

ignition, emission controls, speed control,

transmission and on board diagnostics.

Steering Column Lock Module (SCLM)

The SCLM is connected to the SCP communication

network. The module is an integrated unit

containing the steering column lock and lock drive

and is controlled remotely from the separate

ignition barrel.

Restraints Control Module (RCM)

The RCM is connected to the ISO 9141

communication network. The RCM controls the

deployment of the air bags based on sensor

inputs.

Vehicle Emergency Control Module (VECM)

The VECM is connected to the SCP

communication network. The module allows a

user to request emergency assistance (police,

ambulance, fire, wrecker) or directions to a

desired location at the touch of a button. Also, if

any of the vehicleÕs airbags are deployed while the

VEMS system is powered ON, the system

automatically issues a call for emergency

assistance.

Voice Activation Control Module (VACM)

The VACM is connected to the SCP

communication network. This module is located in

the driver side luggage compartment behind the

trim panel. The VACM controls and processes all

D.418.229

GENERAL ELECTRONIC CONTROL MODULE (GECM)

Inertia Switch

Secondary

Junction Box

General Electronic

Control Module

Page 85 of 133

JAGUARS-TYPEElectrical/Electronic

80

J.418.430

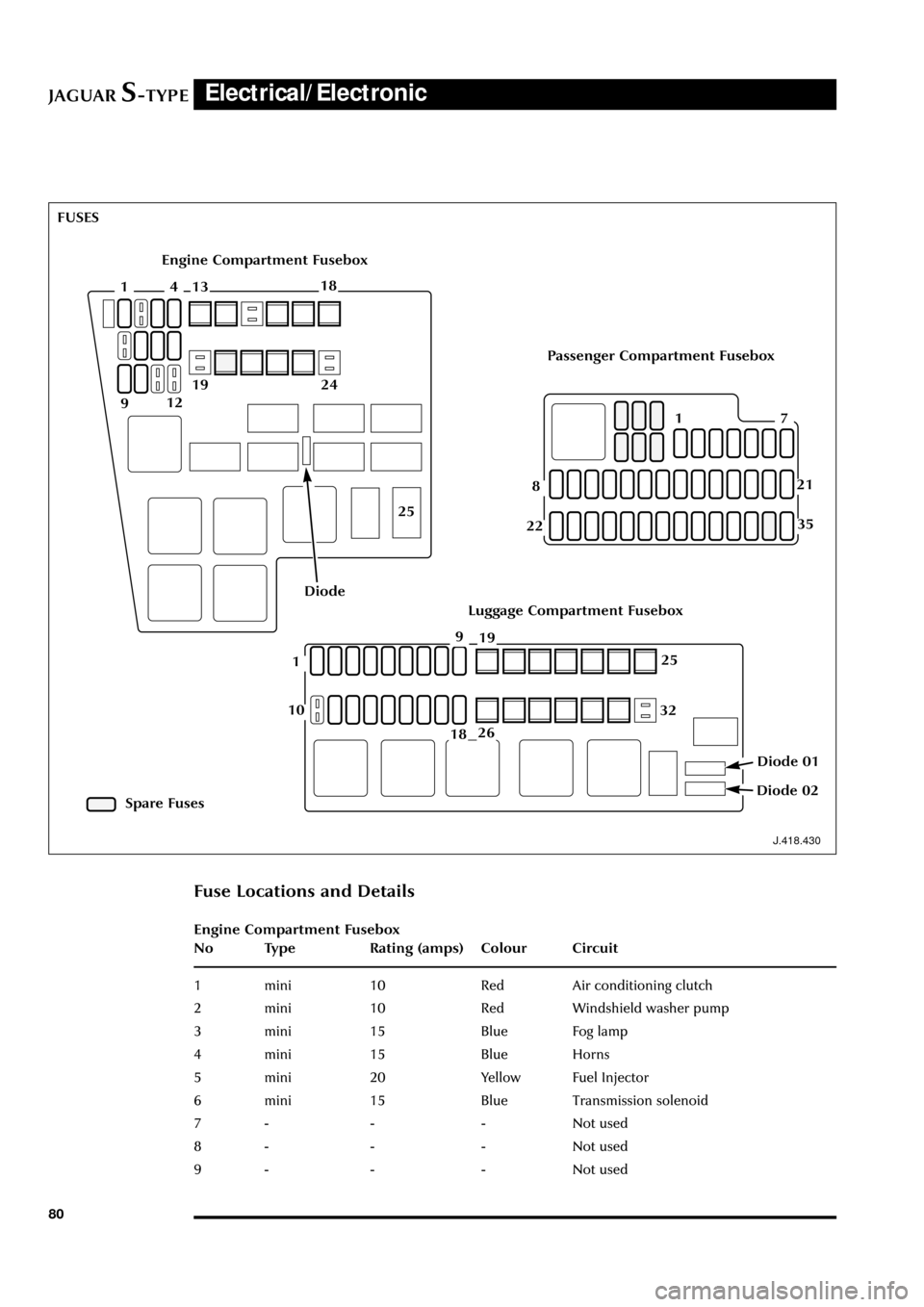

Fuse Locations and Details

Engine Compartment Fusebox

No Type Rating (amps) Colour Circuit

1 mini 10 Red Air conditioning clutch

2 mini 10 Red Windshield washer pump

3 mini 15 Blue Fog lamp

4 mini 15 Blue Horns

5 mini 20 Yellow Fuel Injector

6 mini 15 Blue Transmission solenoid

7 - - - Not used

8 - - - Not used

9 - - - Not used

Engine Compartment Fusebox

Luggage Compartment Fusebox

Passenger Compartment Fusebox

Spare Fuses FUSES

411318

912

2419

25

Diode

71

8

22

21

251

18

10

9

32

26

19

Diode 02

Diode 01

35

Page 86 of 133

JAGUARS-TYPEElectrical/Electronic

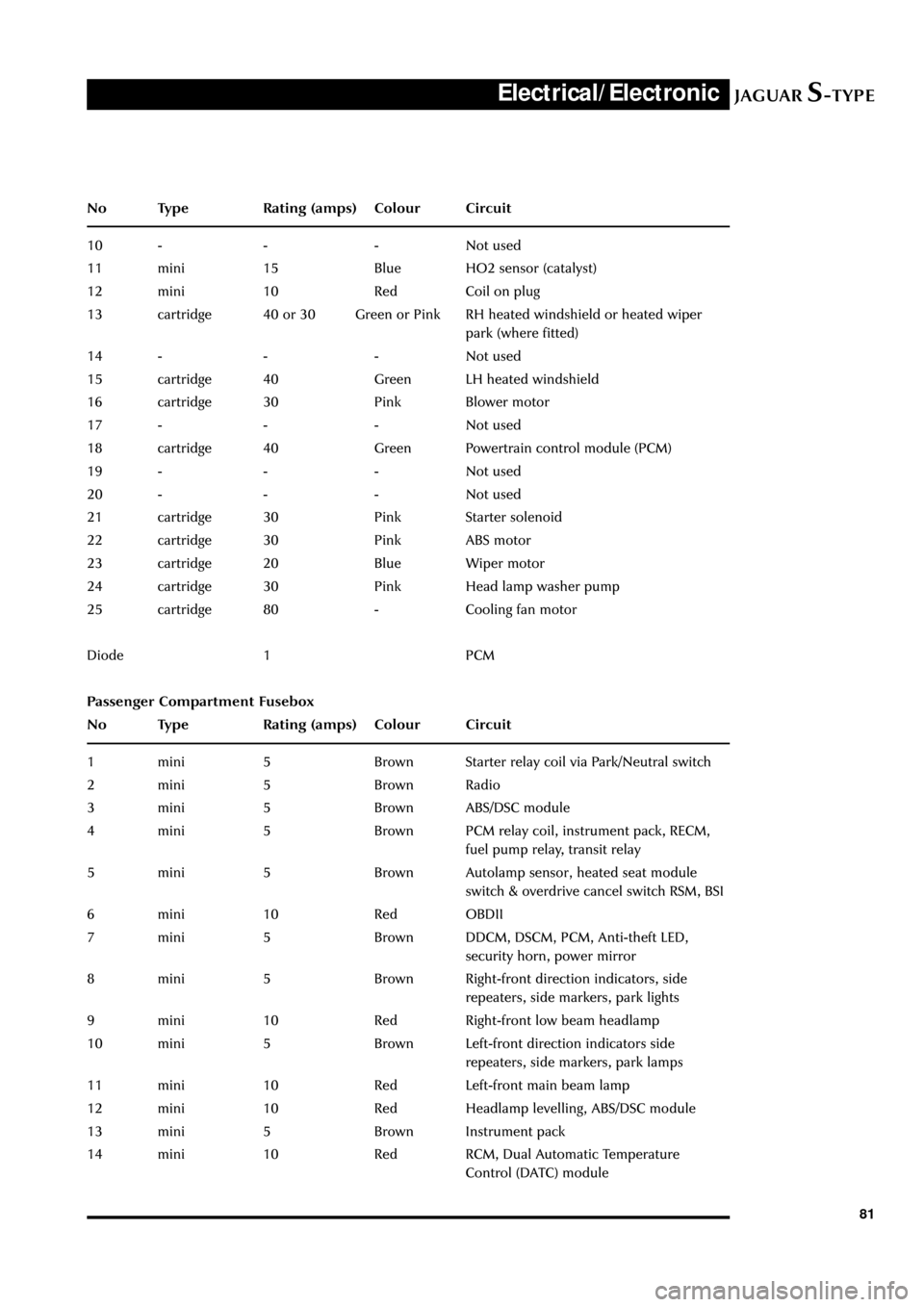

81 No Type Rating (amps) Colour Circuit

10 - - - Not used

11 mini 15 Blue HO2 sensor (catalyst)

12 mini 10 Red Coil on plug

13 cartridge 40 or 30 Green or Pink RH heated windshield or heated wiper

park (where fitted)

14 - - - Not used

15 cartridge 40 Green LH heated windshield

16 cartridge 30 Pink Blower motor

17 - - - Not used

18 cartridge 40 Green Powertrain control module (PCM)

19 - - - Not used

20 - - - Not used

21 cartridge 30 Pink Starter solenoid

22 cartridge 30 Pink ABS motor

23 cartridge 20 Blue Wiper motor

24 cartridge 30 Pink Head lamp washer pump

25 cartridge 80 - Cooling fan motor

Diode 1 PCM

Passenger Compartment Fusebox

No Type Rating (amps) Colour Circuit

1 mini 5 Brown Starter relay coil via Park/Neutral switch

2 mini 5 Brown Radio

3 mini 5 Brown ABS/DSC module

4 mini 5 Brown PCM relay coil, instrument pack, RECM,

fuel pump relay, transit relay

5 mini 5 Brown Autolamp sensor, heated seat module

switch & overdrive cancel switch RSM, BSI

6 mini 10 Red OBDII

7 mini 5 Brown DDCM, DSCM, PCM, Anti-theft LED,

security horn, power mirror

8 mini 5 Brown Right-front direction indicators, side

repeaters, side markers, park lights

9 mini 10 Red Right-front low beam headlamp

10 mini 5 Brown Left-front direction indicators side

repeaters, side markers, park lamps

11 mini 10 Red Left-front main beam lamp

12 mini 10 Red Headlamp levelling, ABS/DSC module

13 mini 5 Brown Instrument pack

14 mini 10 Red RCM, Dual Automatic Temperature

Control (DATC) module

Page 88 of 133

JAGUARS-TYPEElectrical/Electronic

83 No Type Rating (amps) Colour Circuit

12 mini 5 Brown RECM - logic, Transit relay

13 mini 15 Blue Adaptive damper ride control (ADRC)

14 mini 5 Brown Phone, CD, Vehicle emergency message

system (VEMS)

15 mini 5 Brown Alternator sense

16 mini 20 Yellow Sliding roof

17 mini 15 Blue Fuel pump

18 mini 20 Yellow Subwoofer amplifier

19 cartridge 20 Blue RECM, left rear window

20 cartridge 30 Pink Driver door module - Driver window

21 cartridge 30 Pink Driver lumbar

22 cartridge 20 Blue Ignition

23 cartridge 30 Pink Switched system power 4

24 cartridge 30 Pink Switched system power 3

25 cartridge 40 Green Primary junction box

26 cartridge 30 Pink GECM Passenger window

(30amp early cars)

27 cartridge 30 Pink RECM, right rear window

28 cartridge 30 Pink Passenger lumbar

29 cartridge 30 Pink Rear defroster

30 cartridge 20 Blue Switched system power 1

31 cartridge 30 Pink Switched system power 2

32 - - - Unused

Diode 01 Unused

Diode 02 1 Fuel pump motor

Page 90 of 133

JAGUARS-TYPEElectrical/Electronic

85 5. Switched system power 4 relay

6. Fuel pump relay

7. Brake shift interlock relay

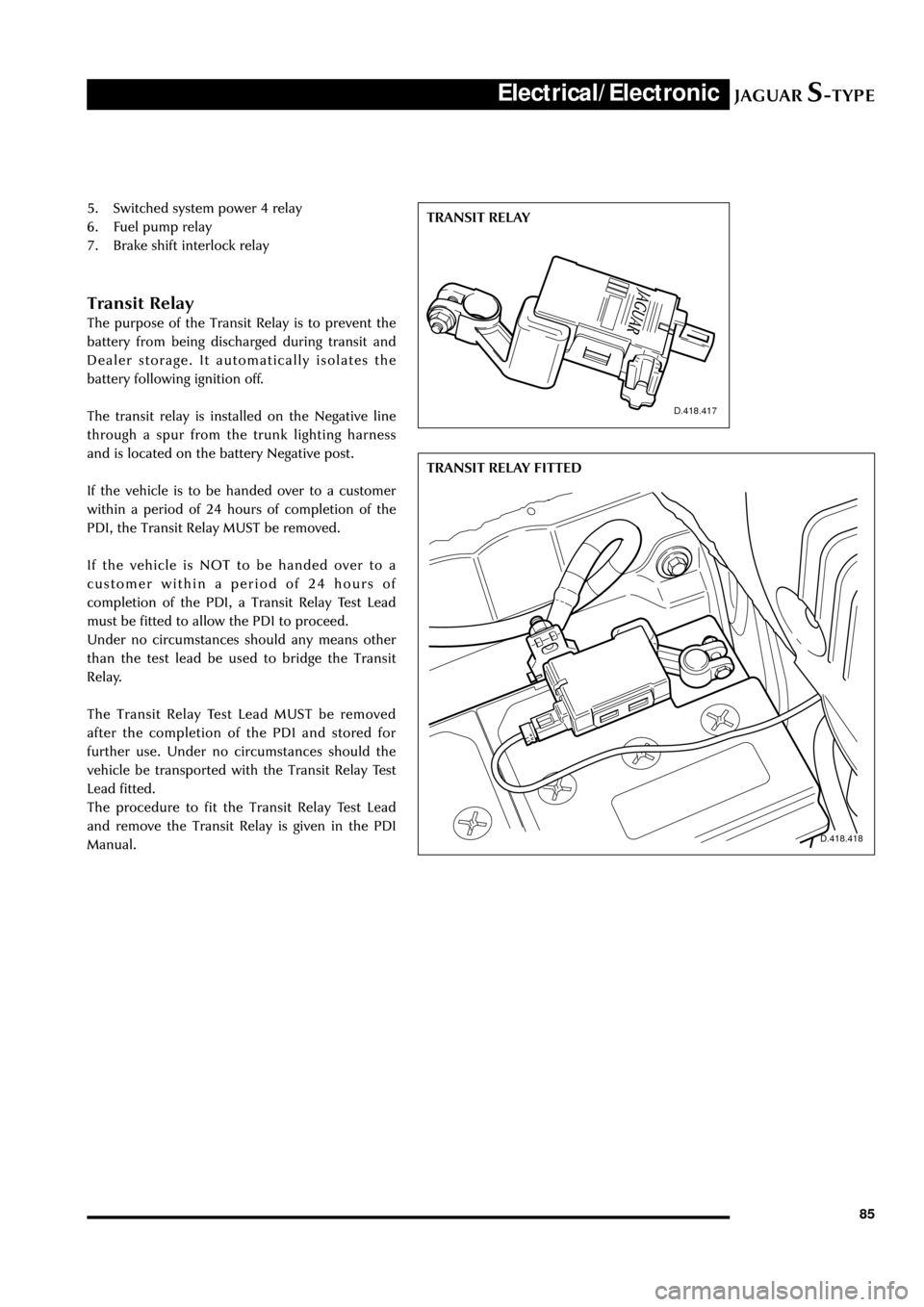

Transit Relay

The purpose of the Transit Relay is to prevent the

battery from being discharged during transit and

Dealer storage. It automatically isolates the

battery following ignition off.

The transit relay is installed on the Negative line

through a spur from the trunk lighting harness

and is located on the battery Negative post.

If the vehicle is to be handed over to a customer

within a period of 24 hours of completion of the

PDI, the Transit Relay MUST be removed.

If the vehicle is NOT to be handed over to a

customer within a period of 24 hours of

completion of the PDI, a Transit Relay Test Lead

must be fitted to allow the PDI to proceed.

Under no circumstances should any means other

than the test lead be used to bridge the Transit

Relay.

The Transit Relay Test Lead MUST be removed

after the completion of the PDI and stored for

further use. Under no circumstances should the

vehicle be transported with the Transit Relay Test

Lead fitted.

The procedure to fit the Transit Relay Test Lead

and remove the Transit Relay is given in the PDI

Manual.

D.418.417

D.418.418

TRANSIT RELAY

TRANSIT RELAY FITTED