length JAGUAR S TYPE 2005 1.G Technical Guide Update

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2005, Model line: S TYPE, Model: JAGUAR S TYPE 2005 1.GPages: 133, PDF Size: 3.48 MB

Page 19 of 133

JAGUARS-TYPEBody

14

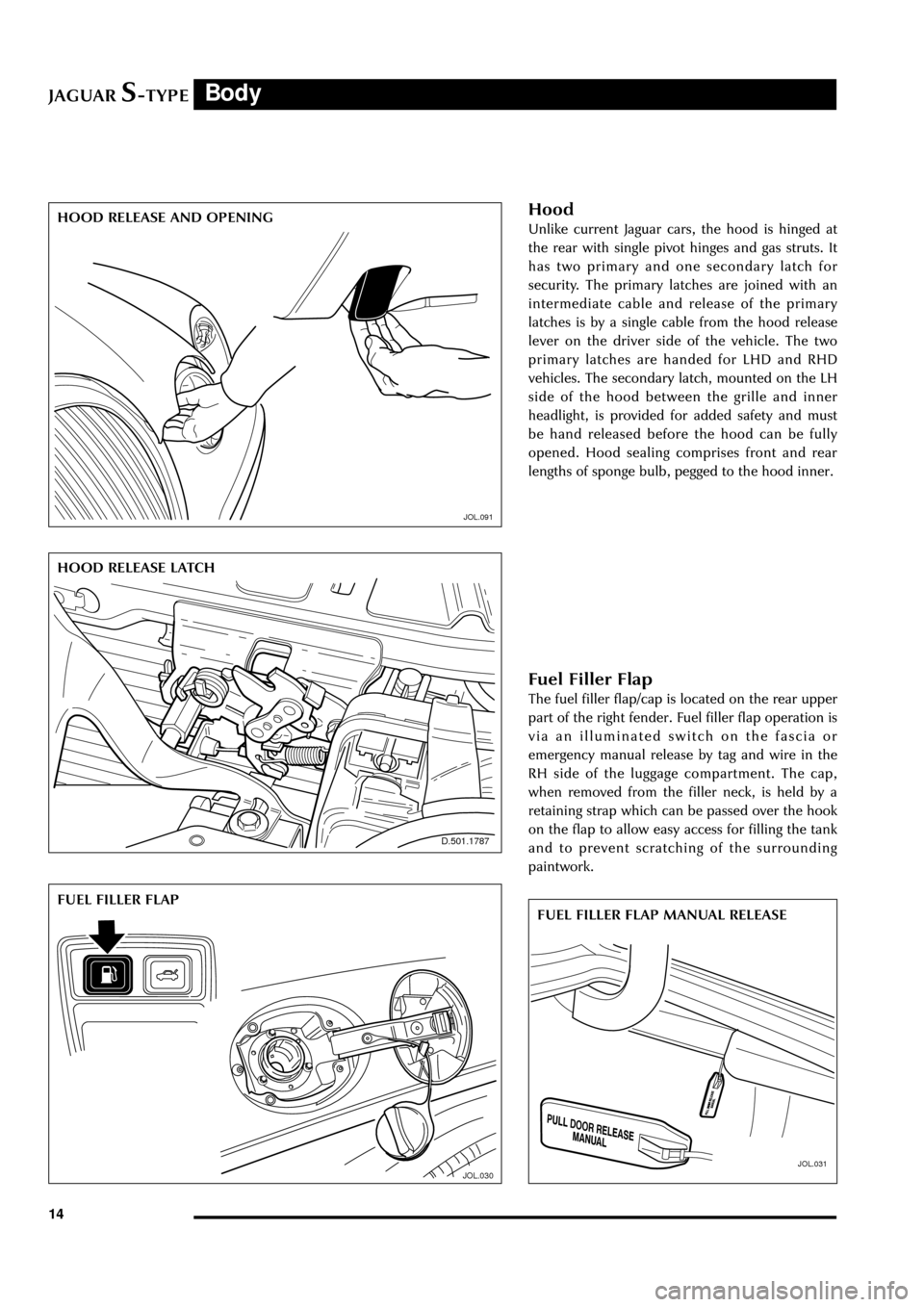

Hood

Unlike current Jaguar cars, the hood is hinged at

the rear with single pivot hinges and gas struts. It

has two primary and one secondary latch for

security. The primary latches are joined with an

intermediate cable and release of the primary

latches is by a single cable from the hood release

lever on the driver side of the vehicle. The two

primary latches are handed for LHD and RHD

vehicles. The secondary latch, mounted on the LH

side of the hood between the grille and inner

headlight, is provided for added safety and must

be hand released before the hood can be fully

opened. Hood sealing comprises front and rear

lengths of sponge bulb, pegged to the hood inner.

JOL.091

HOOD RELEASE AND OPENING

JOL.091

JOL.030

FUEL FILLER FLAP

JOL.031

FUEL FILLER FLAP MANUAL RELEASE

Fuel Filler Flap

The fuel filler flap/cap is located on the rear upper

part of the right fender. Fuel filler flap operation is

via an illuminated switch on the fascia or

emergency manual release by tag and wire in the

RH side of the luggage compartment. The cap,

when removed from the filler neck, is held by a

retaining strap which can be passed over the hook

on the flap to allow easy access for filling the tank

and to prevent scratching of the surrounding

paintwork.

D.501.1787

HOOD RELEASE LATCH

Page 38 of 133

JAGUARS-TYPEOccupant Protection

33

Airbags

Driver Airbag

The driver airbag module is fitted in the centre of

the steering wheel and is of conventional design.

A reduced charge propellant (Ôde-poweredÕ) is

used to minimise impact effects where the driver

is seated close to the wheel.

The module is secured by two side screws on the

left and right underside of the steering wheel.

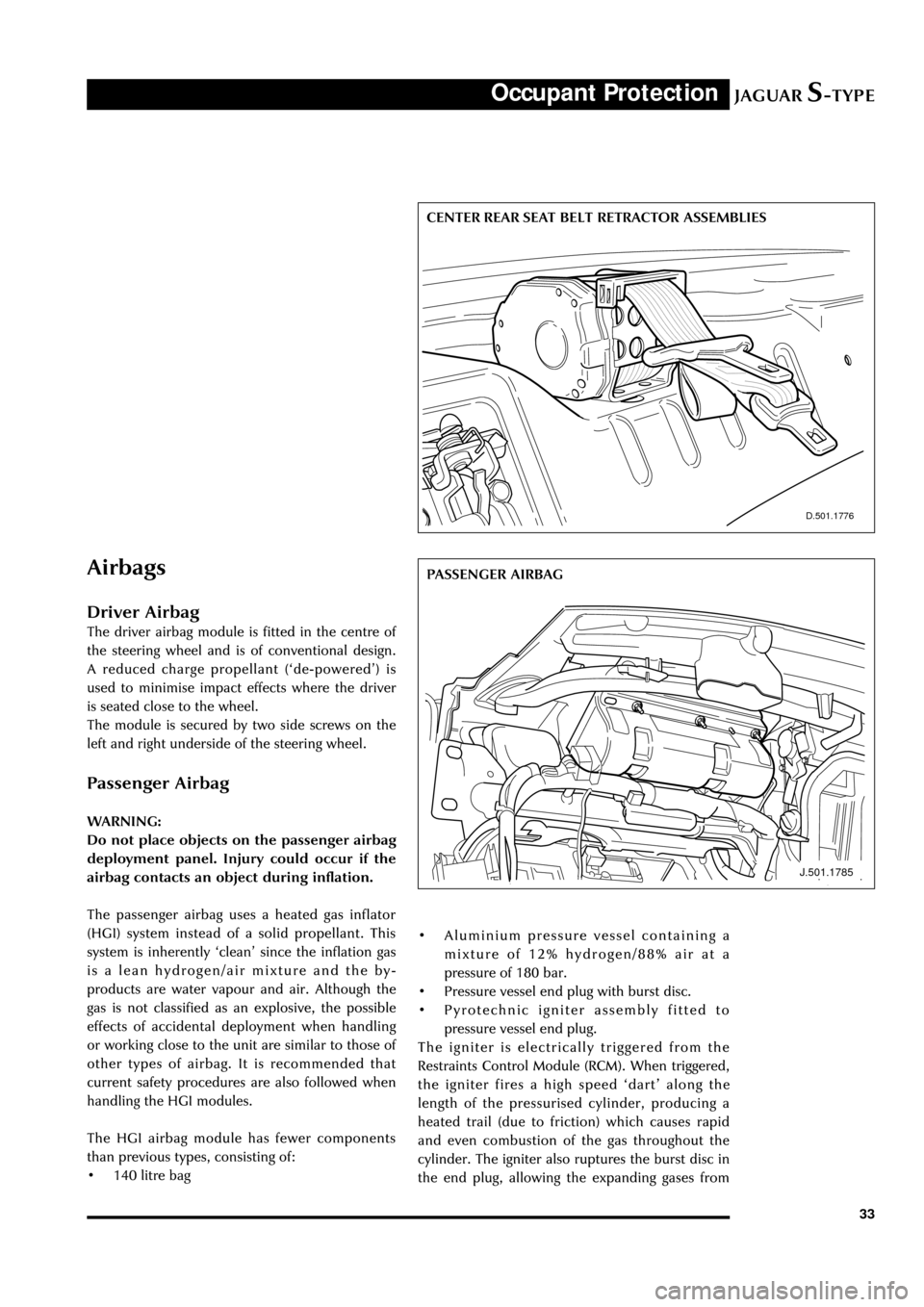

Passenger Airbag

WARNING:

Do not place objects on the passenger airbag

deployment panel. Injury could occur if the

airbag contacts an object during inflation.

The passenger airbag uses a heated gas inflator

(HGI) system instead of a solid propellant. This

system is inherently ÔcleanÕ since the inflation gas

is a lean hydrogen/air mixture and the by-

products are water vapour and air. Although the

gas is not classified as an explosive, the possible

effects of accidental deployment when handling

or working close to the unit are similar to those of

other types of airbag. It is recommended that

current safety procedures are also followed when

handling the HGI modules.

The HGI airbag module has fewer components

than previous types, consisting of:

¥ 140 litre bag

D.501.1776

CENTER REAR SEAT BELT RETRACTOR ASSEMBLIES

J.501.1785

PASSENGER AIRBAG

¥ Aluminium pressure vessel containing a

mixture of 12% hydrogen/88% air at a

pressure of 180 bar.

¥ Pressure vessel end plug with burst disc.

¥ Pyrotechnic igniter assembly fitted to

pressure vessel end plug.

The igniter is electrically triggered from the

Restraints Control Module (RCM). When triggered,

the igniter fires a high speed ÔdartÕ along the

length of the pressurised cylinder, producing a

heated trail (due to friction) which causes rapid

and even combustion of the gas throughout the

cylinder. The igniter also ruptures the burst disc in

the end plug, allowing the expanding gases from

Page 39 of 133

JAGUARS-TYPEOccupant Protection

34

D.501.1474

SIDE AIRBAGS the pressure vessel to inflate the airbag. The

airbag is a top mounted assembly and deploys in

an upwards direction, climbing the windshield

before folding downwards. After deployment, the

bag deflates through two vents.

The airbag deployment door is an integral part of

the top fascia moulding. The airbag module is

bolted to the underside of the fascia via a steel

deployment chute and is also bolted to two

brackets on the tubular cross car beam which

supports the fascia assembly.

Note:The module is not handed. To access the

airbag module, the complete fascia assembly must

be removed.

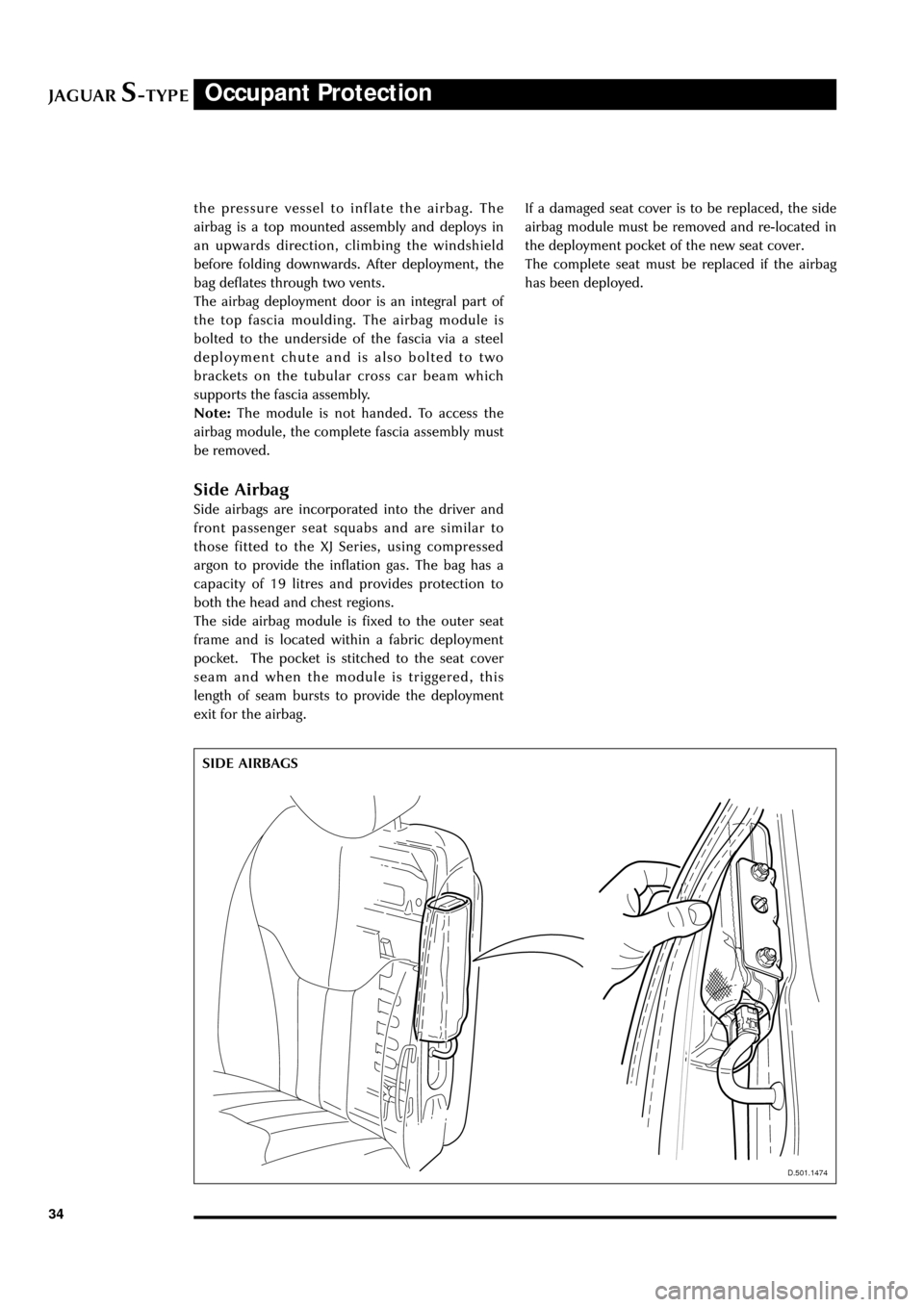

Side Airbag

Side airbags are incorporated into the driver and

front passenger seat squabs and are similar to

those fitted to the XJ Series, using compressed

argon to provide the inflation gas. The bag has a

capacity of 19 litres and provides protection to

both the head and chest regions.

The side airbag module is fixed to the outer seat

frame and is located within a fabric deployment

pocket. The pocket is stitched to the seat cover

seam and when the module is triggered, this

length of seam bursts to provide the deployment

exit for the airbag.

D.501.1474

If a damaged seat cover is to be replaced, the side

airbag module must be removed and re-located in

the deployment pocket of the new seat cover.

The complete seat must be replaced if the airbag

has been deployed.

Page 52 of 133

JAGUARS-TYPEChassis

47

Front Suspension

The independent front wheel suspension is a

double wishbone axle arrangement with

aluminium control arms. The two arms are of

different lengths, which minimises the changes in

track and camber. Inclination of the upper control

arm axis provides anti-dive front suspension

action. There are two front cross members,

known as Number 1 and Number 2.

Number 1, the forward cross member, is a steel

fabrication, non-isolated, which locates the lower

control arm front mounting, the anti-roll bar and

the cooling module.

The rear cross member, Number 2, is an

aluminium casting, non-isolated and it locates the

lower control arm rear mounting, the power

steering rack and the engine hydro-mounts.

WARNING: No attempt must be made to

weld or repair the aluminium cross

member. If it is damaged, a new one must

be installed.

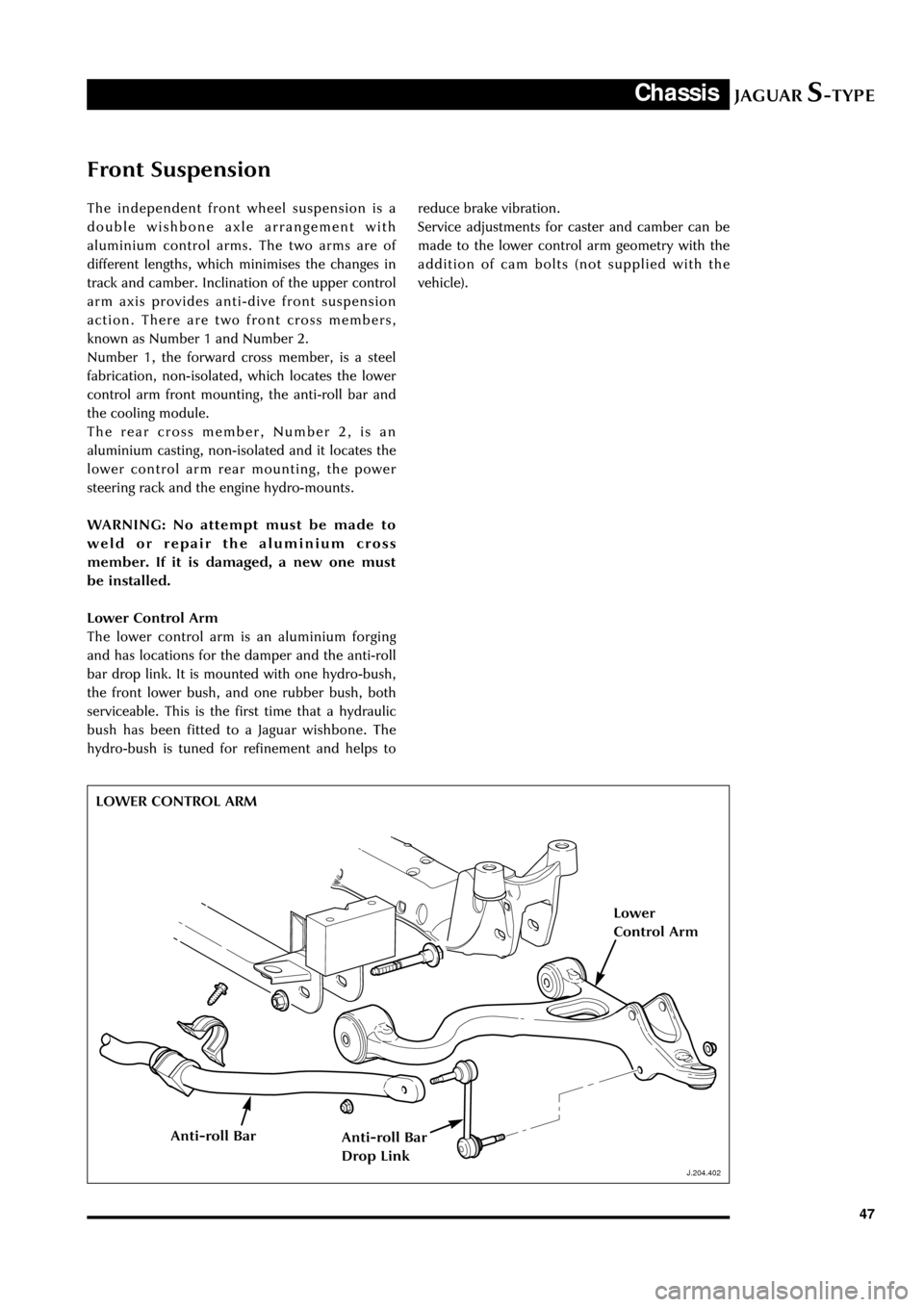

Lower Control Arm

The lower control arm is an aluminium forging

and has locations for the damper and the anti-roll

bar drop link. It is mounted with one hydro-bush,

the front lower bush, and one rubber bush, both

serviceable. This is the first time that a hydraulic

bush has been fitted to a Jaguar wishbone. The

hydro-bush is tuned for refinement and helps to

J.204.402

reduce brake vibration.

Service adjustments for caster and camber can be

made to the lower control arm geometry with the

addition of cam bolts (not supplied with the

vehicle).

LOWER CONTROL ARM

J.204.402

Lower

Control Arm

Anti-roll BarAnti-roll Bar

Drop Link

Page 59 of 133

JAGUARS-TYPEChassis

54The centre joint is a conventional hookes joint

with staked lugs and the rubber flex couplings

have spigoted sleeves to the transmission and rear

axle final drive unit (three bolt fixings)

All driveshafts are balanced. If undercoating the

vehicle, protect the driveshaft, universal joints

and the axleshafts to prevent overspray of the

undercoating material.

Driveshaft weight is:

¥ V6 auto 12.7 kg

¥ V8 auto 13.4 kg

¥ V6 manual 14.1 kg

Serviceable parts are the centre bearing, flex

coupling, rubber boot, alignment bearing and

fasteners. Lubrication of the driveshaft

components is unnecessary. The universal joint is

equipped with nylon thrust washers, located at

the base of the bearing cup.

Balancing of the driveshaft is achieved using a

PDU with the new vibration analyser. This gives

details of where the shaft is out of balance and by

how much and where to place the balance nuts.

Final Drive (differential)

The final drive, differential, has a steel case and

rear cover, no drain plug and has a sealed for life

lubricant. Differential weight is 27 kilograms and

oil capacity 1.5 litres of synthetic oil (M2C192A).

The hypoid gearset is mounted in taper roller

bearings. It has a two point differential assembly

retained by bearing straps. The central pinion is

on the body centreline. Pinion and output oil

seals, the companion flange and nut and the

needle roller output bearing are the only

serviceable items.

Final drive ratios are:

3.31:1 (V6 and V8 auto)

2.87:1 (V6 manual)

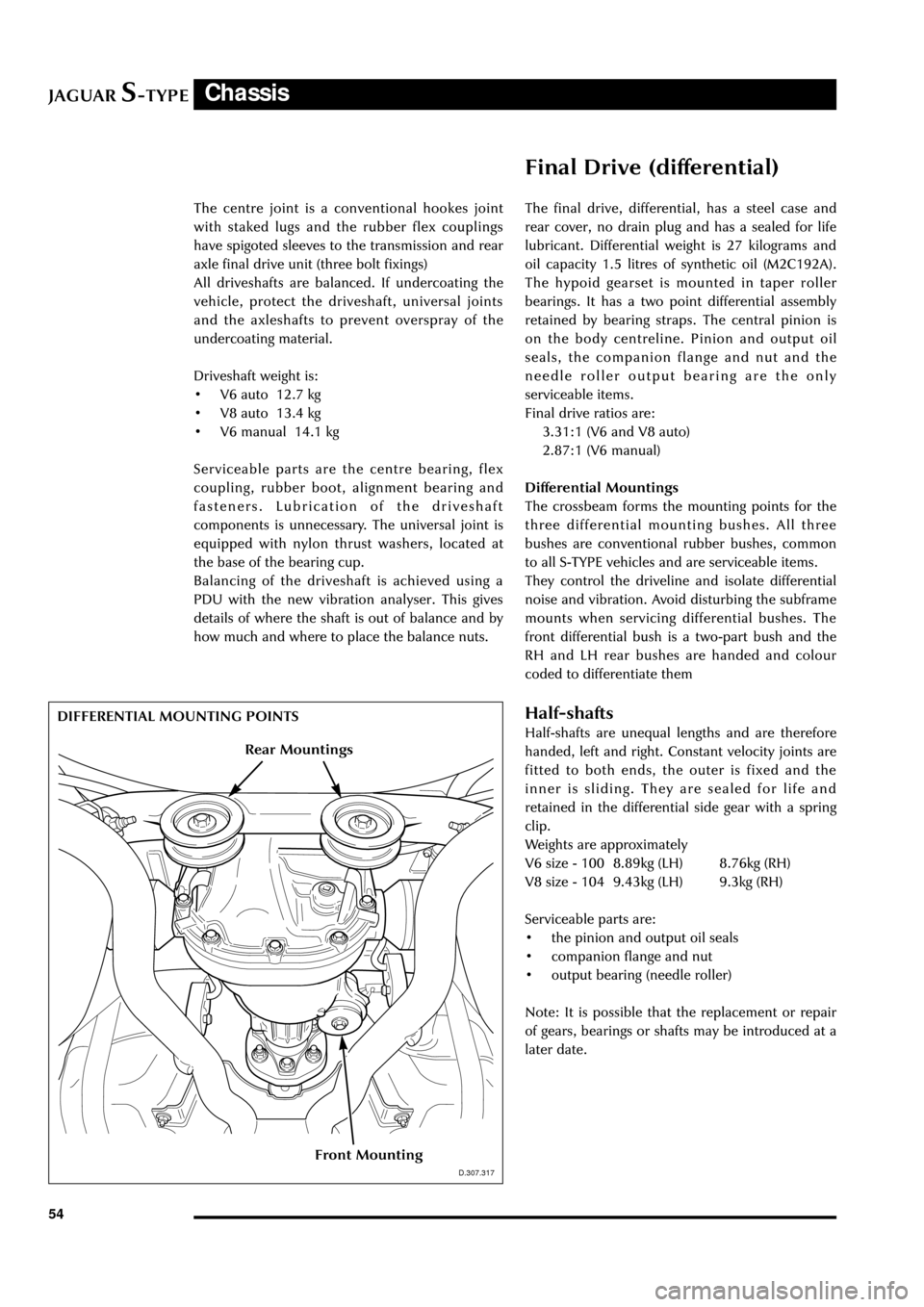

Differential Mountings

The crossbeam forms the mounting points for the

three differential mounting bushes. All three

bushes are conventional rubber bushes, common

to all S-TYPE vehicles and are serviceable items.

They control the driveline and isolate differential

noise and vibration. Avoid disturbing the subframe

mounts when servicing differential bushes. The

front differential bush is a two-part bush and the

RH and LH rear bushes are handed and colour

coded to differentiate them

Half-shafts

Half-shafts are unequal lengths and are therefore

handed, left and right. Constant velocity joints are

fitted to both ends, the outer is fixed and the

inner is sliding. They are sealed for life and

retained in the differential side gear with a spring

clip.

Weights are approximately

V6 size - 100 8.89kg (LH) 8.76kg (RH)

V8 size - 104 9.43kg (LH) 9.3kg (RH)

Serviceable parts are:

¥ the pinion and output oil seals

¥ companion flange and nut

¥ output bearing (needle roller)

Note: It is possible that the replacement or repair

of gears, bearings or shafts may be introduced at a

later date.

D.307.317

DIFFERENTIAL MOUNTING POINTS

D.307.317

Front Mounting

Rear Mountings