weight JAGUAR S TYPE 2005 1.G Technical Guide Update

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2005, Model line: S TYPE, Model: JAGUAR S TYPE 2005 1.GPages: 133, PDF Size: 3.48 MB

Page 6 of 133

Contents

1

Subject Page

Glossary

Abbreviations 3

Introduction4

Vehicle Weights 5

Dimensions 5

Vehicle Features 6

Body

Body Structure 10

Engine Compartment 15

Trunk 16

Jacking and Towing 18

Glazing 19

Doors and Door Mirrors 21

Windshield Wipers and Washers 23

Exterior and Interior Trim 24

Seats 26

Interior Features 30

Occupant Protection

Seat Belts 32

Airbags 33

SRS Operation 35

Fuel System

Introduction 38

Evaporative Emissions System 42

Exhaust System

Introduction 44

Transmission

Introduction 45

Chassis

Introduction 46

Front Suspension 47

Rear Suspension 49

Wheels and Tyres 52

Driveline 53

Final Drive (differential) 54

Brakes 55

Power Assisted Steering 58

Steering Column 59

Climate Control

System Overview 63

continued:

JAGUARS-TYPE

Page 10 of 133

JAGUARS-TYPEIntroduction

5

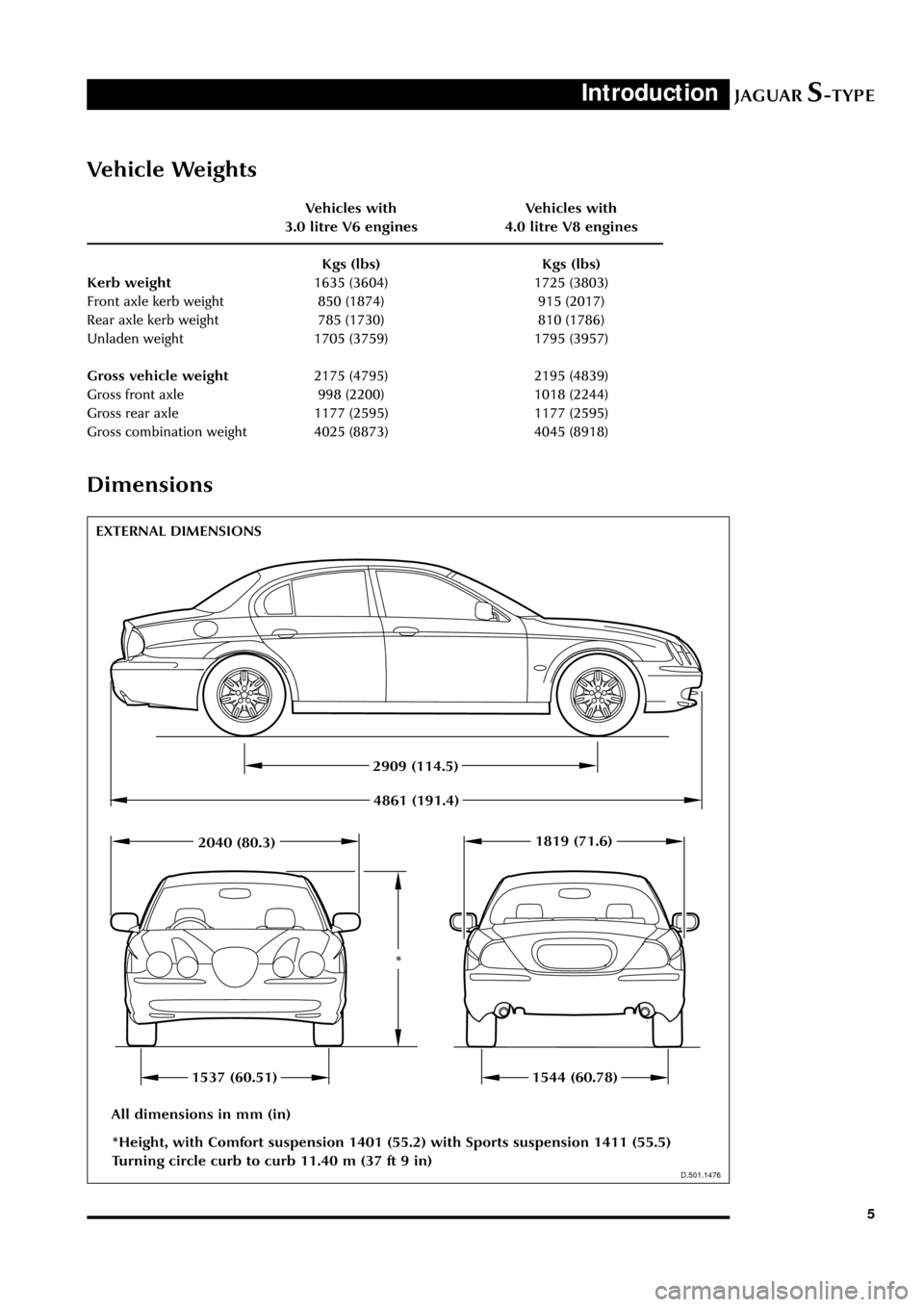

Vehicle Weights

Vehicles with Vehicles with

3.0 litre V6 engines 4.0 litre V8 engines

Kgs (lbs) Kgs (lbs)

Kerb weight1635 (3604) 1725 (3803)

Front axle kerb weight 850 (1874) 915 (2017)

Rear axle kerb weight 785 (1730) 810 (1786)

Unladen weight 1705 (3759) 1795 (3957)

Gross vehicle weight2175 (4795) 2195 (4839)

Gross front axle 998 (2200) 1018 (2244)

Gross rear axle 1177 (2595) 1177 (2595)

Gross combination weight 4025 (8873) 4045 (8918)

D.501.1476

EXTERNAL DIMENSIONS

2909 (114.5)

*Height, with Comfort suspension 1401 (55.2) with Sports suspension 1411 (55.5)

Turning circle curb to curb 11.40 m (37 ft 9 in)

D.501.1476

Dimensions

4861 (191.4)

1819 (71.6)

1544 (60.78)

2040 (80.3)

1537 (60.51)

*

All dimensions in mm (in)

Page 15 of 133

JAGUARS-TYPEBody

10

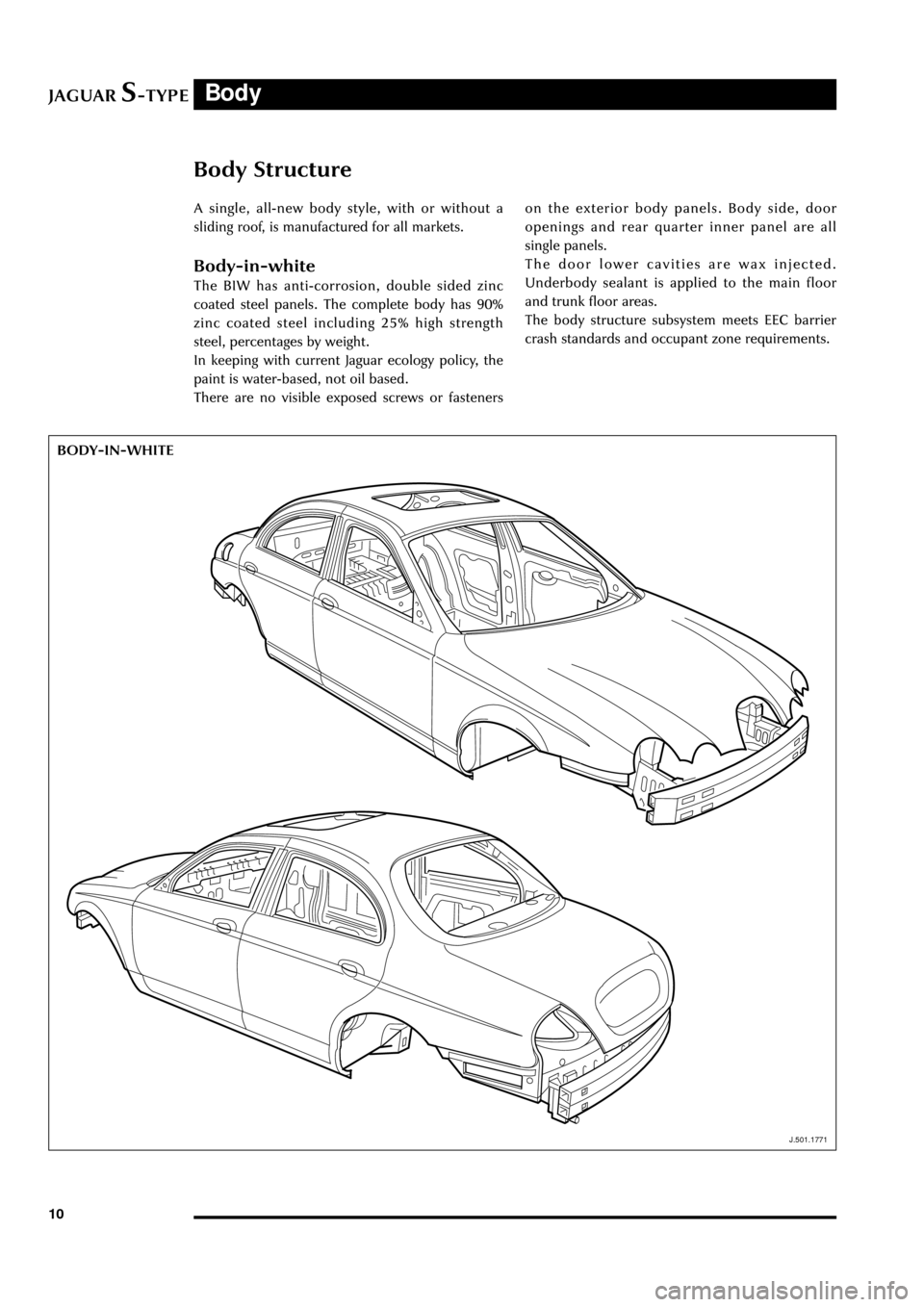

Body Structure

J.501.1771

BODY-IN-WHITE

A single, all-new body style, with or without a

sliding roof, is manufactured for all markets.

Body-in-white

The BIW has anti-corrosion, double sided zinc

coated steel panels. The complete body has 90%

zinc coated steel including 25% high strength

steel, percentages by weight.

In keeping with current Jaguar ecology policy, the

paint is water-based, not oil based.

There are no visible exposed screws or fastenerson the exterior body panels. Body side, door

openings and rear quarter inner panel are all

single panels.

The door lower cavities are wax injected.

Underbody sealant is applied to the main floor

and trunk floor areas.

The body structure subsystem meets EEC barrier

crash standards and occupant zone requirements.

J.501.1771

Page 16 of 133

JAGUARS-TYPEBody

11

J.501.1772

AIRBAG

SAJDA1M9XG000484

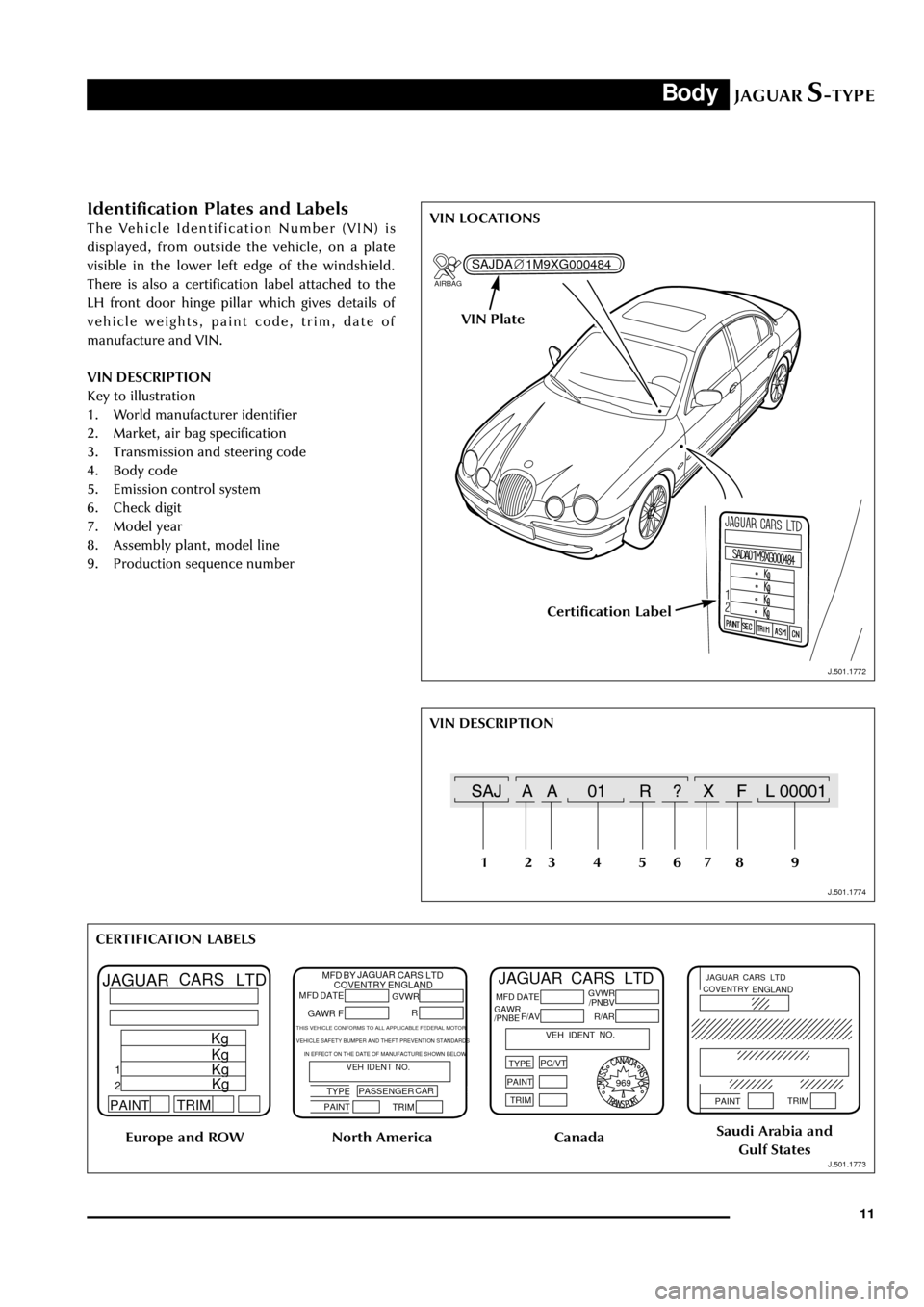

Identification Plates and Labels

The Vehicle Identification Number (VIN) is

displayed, from outside the vehicle, on a plate

visible in the lower left edge of the windshield.

There is also a certification label attached to the

LH front door hinge pillar which gives details of

vehicle weights, paint code, trim, date of

manufacture and VIN.

VIN DESCRIPTION

Key to illustration

1. World manufacturer identifier

2. Market, air bag specification

3. Transmission and steering code

4. Body code

5. Emission control system

6. Check digit

7. Model year

8. Assembly plant, model line

9. Production sequence numberVIN LOCATIONS

J.501.1772

JAGUARCARSLTD

PAINTTRIM

12

Kg

KgKgKg

J.501.1773

JAGUARCARSLTDMFDBY

PASSENGERCAR

MFDDATE

GAWR F

GVWR

R

VEHIDENTNO.

TYPEPAINTTRIM

THIS VEHICLE CONFORMS TO ALL APPLICABLE FEDERAL MOTORVEHICLE SAFETY BUMPER AND THEFT PREVENTION STANDARDSIN EFFECT ON THE DATE OF MANUFACTURE SHOWN BELOW

ENGLANDCOVENTRY

TYPE

JAGUARCARSLTD

MFDDATEGAWR/PNBEF/AV

GVWR/PNBVR/AR

VEHIDENTNO.

PC/VT

PAINT

TRIM

969

TRIMPAINT

JAGUARCARSLTDCOVENTRYENGLAND

J.501.1774

VIN DESCRIPTION

CERTIFICATION LABELS

Europe and ROWNorth AmericaCanadaSaudi Arabia and

Gulf States

J.501.1773 J.501.1774

VIN Plate

Certification Label

198765432

Page 59 of 133

JAGUARS-TYPEChassis

54The centre joint is a conventional hookes joint

with staked lugs and the rubber flex couplings

have spigoted sleeves to the transmission and rear

axle final drive unit (three bolt fixings)

All driveshafts are balanced. If undercoating the

vehicle, protect the driveshaft, universal joints

and the axleshafts to prevent overspray of the

undercoating material.

Driveshaft weight is:

¥ V6 auto 12.7 kg

¥ V8 auto 13.4 kg

¥ V6 manual 14.1 kg

Serviceable parts are the centre bearing, flex

coupling, rubber boot, alignment bearing and

fasteners. Lubrication of the driveshaft

components is unnecessary. The universal joint is

equipped with nylon thrust washers, located at

the base of the bearing cup.

Balancing of the driveshaft is achieved using a

PDU with the new vibration analyser. This gives

details of where the shaft is out of balance and by

how much and where to place the balance nuts.

Final Drive (differential)

The final drive, differential, has a steel case and

rear cover, no drain plug and has a sealed for life

lubricant. Differential weight is 27 kilograms and

oil capacity 1.5 litres of synthetic oil (M2C192A).

The hypoid gearset is mounted in taper roller

bearings. It has a two point differential assembly

retained by bearing straps. The central pinion is

on the body centreline. Pinion and output oil

seals, the companion flange and nut and the

needle roller output bearing are the only

serviceable items.

Final drive ratios are:

3.31:1 (V6 and V8 auto)

2.87:1 (V6 manual)

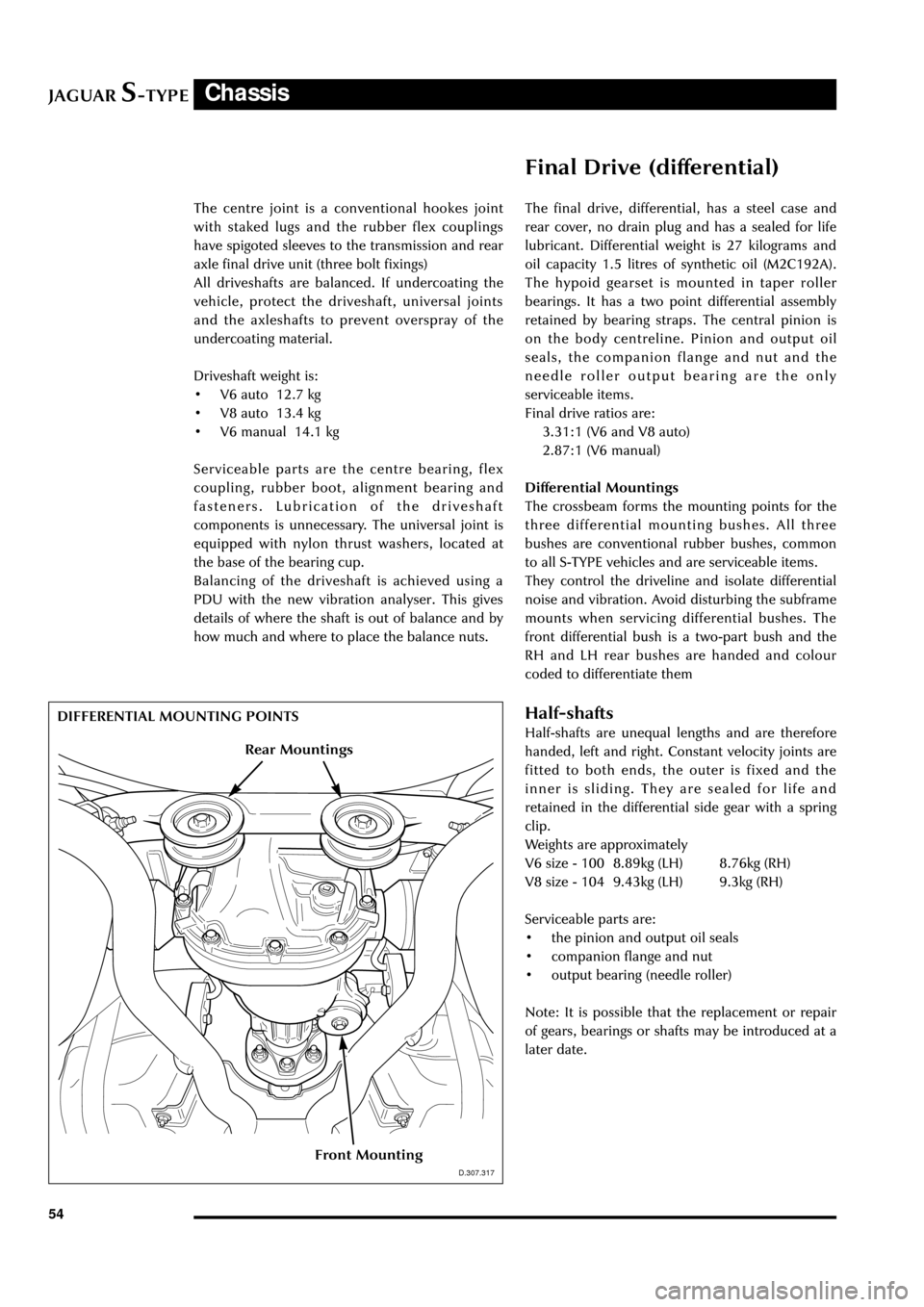

Differential Mountings

The crossbeam forms the mounting points for the

three differential mounting bushes. All three

bushes are conventional rubber bushes, common

to all S-TYPE vehicles and are serviceable items.

They control the driveline and isolate differential

noise and vibration. Avoid disturbing the subframe

mounts when servicing differential bushes. The

front differential bush is a two-part bush and the

RH and LH rear bushes are handed and colour

coded to differentiate them

Half-shafts

Half-shafts are unequal lengths and are therefore

handed, left and right. Constant velocity joints are

fitted to both ends, the outer is fixed and the

inner is sliding. They are sealed for life and

retained in the differential side gear with a spring

clip.

Weights are approximately

V6 size - 100 8.89kg (LH) 8.76kg (RH)

V8 size - 104 9.43kg (LH) 9.3kg (RH)

Serviceable parts are:

¥ the pinion and output oil seals

¥ companion flange and nut

¥ output bearing (needle roller)

Note: It is possible that the replacement or repair

of gears, bearings or shafts may be introduced at a

later date.

D.307.317

DIFFERENTIAL MOUNTING POINTS

D.307.317

Front Mounting

Rear Mountings

Page 72 of 133

JAGUARS-TYPEClimate Control

67 Pipework

The suction hose and liquid line are a one-piece

assembly. A single screw connects them to the air

conditioning unit manifold at the bulkhead. A

further screw fixing and push-in clip secures them

at the side of the engine bay. The liquid line fixed

to the cooling module then joins with a block

fitting and the suction hose connects with a quick

connect fitting and routes across the underneath

of the cooling module to the compressor. The

compressor suction and discharge hoses are also a

one piece assembly.

A pressure transducer is fitted to the discharge

hose as it connects to the rear of the condenser.

The high side charge port is situated on the

manifold connecting to the receiver drier whilst

the low side is adjacent to the compressor behind

the LH front wheel.

The compressor is a 9Occ scroll, which is variable

from 100% to 30%. Compressor is standard

specification to all vehicles although package

makes them unique to V6 and V8.

Air Distribution

Air distribution is as follows:

¥ Defrost duct integral with the fascia.

¥ Face vents, plenum, manifold, centre face

duct, side face duct, side window demist duct

are all sub-assembled into the fascia.

¥ Driver and front seat passenger foot ducts are

installed in the fascia after it has been fitted

to the vehicle.

¥ Rear foot ducts are fitted to the underframe.

¥ Rear face duct fitted to transmission tunnel.

¥ Rear face vent fitted to console.

¥ Extractor boxes fitted in rear quarter panels.

All flaps are electric servo controlled and

comprise:

¥ Fresh/recirculation - heater/evaporator unit.

¥ Cold air bypass - heater/evaporator unit.

¥ Foot flap - mounted on plenum.

¥ Defrost flap - mounted on plenum.

¥ Face flap - mounted on plenum.

Sensors, for operation of the system, are:

¥ Ambient temperature sensor - located behind

the lower front grille.

¥ Solar sensor - fitted to the top centre of the

fascia at the defrost grille

¥ In-car sensor - aspirated from the plenum

venturi sensor mounted inboard of the

steering column.¥ Two heater air outlet sensors

¥ One evaporator air outlet sensor

Servicing

Routine servicing consists of particle filter

replacement.

Replaceable items on the climate control system

are:

¥ Servo complete with linkages

¥ Sensors

¥ Evaporator and seals

¥ Heater core and seals

¥ Blower motor

¥ Impeller/blower motor wheel

¥ Hoses

¥ Registers/vents

¥ Ducts, except the defrost

¥ Defrost and side window demist grilles

¥ Control unit

¥ Compressor

¥ Water pump

¥ Water valve

¥ Receiver/drier

¥ Condenser

There are no panel diagnostics but PDU facility is

available with extensive capability, similar to

current XJ and XK Series.

System refrigerant is R134a. Vehicle charge weight

is 800 gms and charging is through the high side

charge port only.

Oil type is WSH-MIC231-B and refill quantity is

180 cc -220 cc.

Special tools are hose clamp pliers and air-

conditioning hoses spring lock de-coupler.

General information

Ensure that the grille at the base of the windshield

is kept clear of leaves, snow or other obstructions.

A solar sensor is mounted on top of the fascia, in

the centre of the defrost grille, and this should not

be covered.

The air conditioning system should be run briefly

at least once each week with a cold setting to

prevent the seals from drying out with subsequent

refrigerant leaks.

When the engine and vehicle interior are cold the

fan speed may be low until the engine has warmed

up, this avoids excessively cold air being blown

into the cabin.