speed JAGUAR X308 1998 2.G Owners Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1082 of 2490

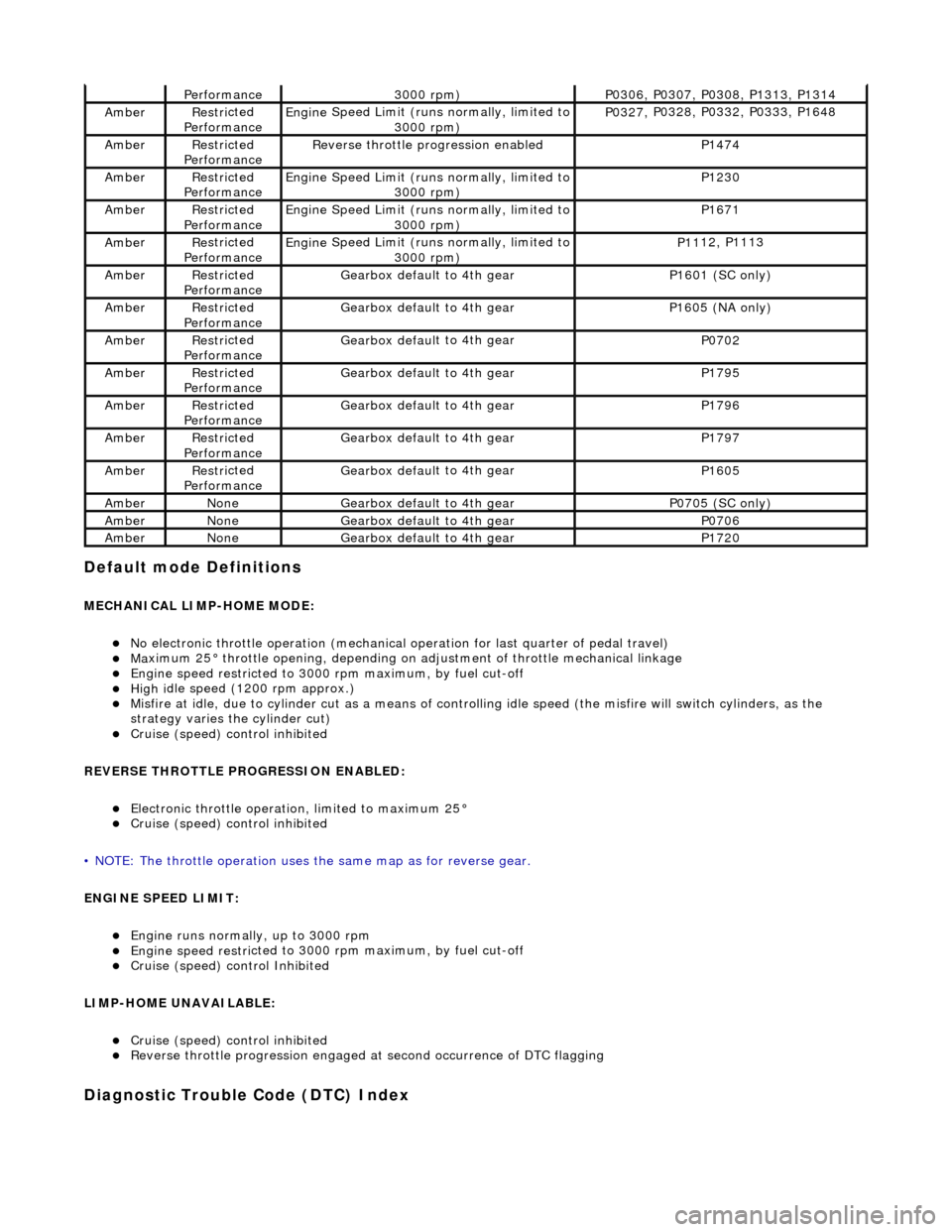

Default mode Definitions

MECHANIC

AL LIMP-HOME MODE:

No elec

tronic throttle operation (mechanical

operation for last quarter of pedal travel)

Ma

ximum 25° throttle opening,

depending on adjustment of th rottle mechanical linkage

Engine speed restri

cted to 3000

rpm maximum, by fuel cut-off

High i

dle speed (1200 rpm approx.)

Misfire

at idle, due

to cylinder cut as a means of control

ling idle speed (the misfire will switch cylinders, as the

strategy varies th e cylinder cut)

Cruise (speed) contr o

l inhibited

REVERSE THROTTLE PROGRESSION ENABLED:

Elec

tronic throttle operation, limited to maximum 25°

Cruise (speed) contr

o

l inhibited

• NOTE: The throttle oper ation uses the same map as for reverse gear.

ENGINE SPEED LIMIT:

Engine runs

normally, up to 3000 rpm.

Engine

speed restri

cted to 3000 rp

m maximum, by fuel cut-off.

Cruise (speed) contr o

l inhibited

LIMP-HOME UNAVAILABLE:

Cruise (speed) contro

l inhibited

Re

verse throttle pr

ogression engaged at second occurrence of DTC flagging

AmberRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P01 16,

P0117, P0118, P0125

Ambe

rRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P01 01,

P0102, P0103, P0104

Ambe

rRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P03 00,

P0301, P0302, P0303, P0304, P0305,

P0306, P0307, P0308, P1313, P1314

Ambe rRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P03 27,

P0328, P0332, P0333, P1648

Ambe

rRestri

cted

Performance

R e

verse throttle pr

ogression enabled

P1474

AmberRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P1230

Ambe rRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P1671

Ambe rRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P11 12,

P1113

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1601 (SC on

ly)

AmberRestri

cted

Performance

Gearbox defau l

t to 4th gear

P16

05 (

NA only)

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P0702

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1795

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1796

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1797

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1605

Ambe

rNoneGearbox defau l

t to 4th gear

P0705 (SC on

ly)

AmberNoneGearbox defau l

t to 4th gear

P0706

Ambe

rNoneGearbox defau l

t to 4th gear

P1720

Page 1110 of 2490

2.2. Cruise

3. 3. Mechanica l

guard

4. 4. Fixed idle

5. 5. Redundancy

6. 6. Full authority

7. 7. Engine shut-down

Normal mode occurs when the EC M uses the mechanical and monitoring arrangem ent of the throttle valve to control throttle

opening. The ECM does not permit driver demand to be exceeded but it can be restricted to allow for such features as

stability / traction control, or engine power limitation.

The ECM determines engine idle speed by controlling the throttle valve motor to vary the blade angle between the non-

adjustable preset limits of the mechanic al guard and the throttle valve motor.

Cruise mode is engaged as a result of the ECM calculating and controlling the required throttle valve opening via the

vacuum system. When the driver releases the throttle pedal, the input shaft disengages from the mechanical guard or the

vacuum actuator pulls the guard away from th e throttle valve. The throttle pedal will feel light should it be pushed again to

accelerate (pressing the pedal further will re-engage the input shaft with the mechanical guard and restore normal feel).

The ECM utilizes sensors to monitor the relative positions of the mechanical guard and throttle valve and adjusts them to

maintain the set cruise speed.

Mechanical guard mode permits full mechanical operation of the throttle if the ECM detects that a problem has been

encountered with the throttle valve position sensor, dc motor, associated harnesses / connecto rs or the ECM.

Fixed idle mode occurs when any two of the three sensors (two input shaft sensors and the mechanical guard sensor) fail.

The ECM will assume values which represent a blade angl e of approximately 2,5° and 1200 rpm (unloaded) maximum

engine speed.

Redundancy mode occurs when any one of the three sensors (two input shaft sensors and the mechanical guard sensor)

fails. The operational pair will be deemed to be safe to co ntinue without intervention, but cruise will be inhibited.

Full authority mode is invoked when a mech anical guard failure occurs which indicates that the guard is stuck fully open.

The red warning lamp will be lit and road speed will be li mited to 120 kph.

Engine shut-down mode will occur followin g multiple failures, such as mechanical guard mode following full authority mode

(or vice versa) or the throttle blade sticks.

Intake Elbow

The intake elbow directs the metered airflow from the electronic throttle to the intake manifold. Stub pipes on both sides of

Page 1149 of 2490

The E

VAP canister purge valve controls th

e flow rate of fuel vapour drawn into the engine during the canister purge

operation. The valve is opened by a vacu um feed from the induction elbow : the vacu um feed is controlled by the integral

valve solenoid and is applied when the so lenoid is energised. The solenoid is pulsed on (energised) and off by a fixed

frequency (100Hz) variable pulse width control signal (pulse width modulation). By varying the pulse on to off time, the

ECM controls the duty cycle of the valve (time that the valve is open to time closed) and thus the vapour flow rate to the

engine.

With no ECM signal applied to the va lve solenoid, the valve remains closed.

Can

ister Purge Operation

The

following pre-conditions are ne

cessary for purging to commence :

aft

er battery disconnection/reconnection, engine

management adaptations must be re-instated.

engine has run for

at least 8 seconds.

engi

ne coolant temperature is not less than 70 °C.

engine

not running in the fuel

cut off condition (eg overrun).

t

he adaptive fuel correction

function has not registered a rich or lean failure

t

he evaporative emission leak test has not failed

no faults have been diagnosted in th

e rel

evant sensor and valve circuits -

Air Flow Meter (AFM), Engine Coolant

Temperature sensor, Evaporativ e Canister Purge valve and Canister Close Valve (CCV).

If these conditions have been satisfied, purging is started. If any failures are registered, purging is inhibited.

The canister(s) is purged during each driv e cycle at various rates in accordance with the prevailing engine conditions. The

engine management software st ores a map of engine speed (RPM) against engine load (grams of air inducted / rev). For

any given engine speed and load, a vapour purge rate is assigned (purge rate increases with engine speed and load).

The preset purge rates are base d on the assumption of a vapour concentratio n of 100%. The actual amount of vapour is

measured by the closed loop fueling system : the input of evaporative fuel into the engine causes the outputs from the

upstream oxygen sensors to change, the am ount of change providing a measure of the vapour concentration. This feedback

causes the original purge rate to be adju sted and also reduces the amount of fuel input via the injectors to maintain the

correct air to fuel ratio.

Engine speed/load mapping and the corresp onding purge rates are different for single canister, running loss and ORVR

evaporative systems.

Page 1179 of 2490

generates a signal when th

e dr

ive plate passes the sensor

sen

ds the ECM signals indicating crankshaft position and engine speed

is e

ssential for calculating spark timing

En

gine Coolant Temperature (ECT) Sensor

sen

ds the ECM a signal indicating the temperature of the engine coolant

is a t

emperature dependent resistor with a negative temperature coefficient (resistance changes inversely with

respect to temperature) and is constantly monitored by the ECM

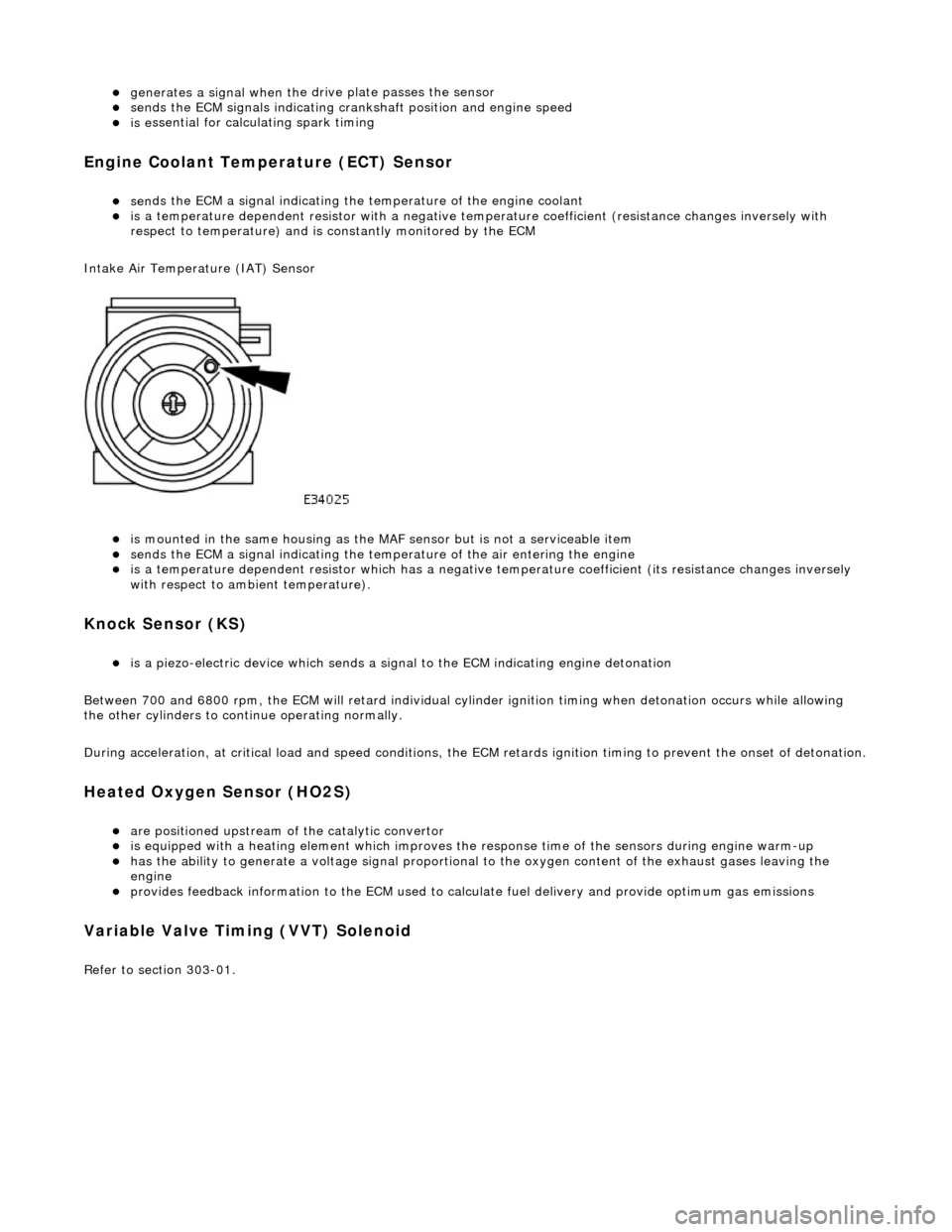

Intake Air Temperature (IAT) Sensor

is m

ounted in the same housing as the MA

F sensor but is not a serviceable item

sen

ds the ECM a signal indicating the temperature of the air entering the engine

is a t

emperature dependent resistor which has a negative

temperature coefficient (its resistance changes inversely

with respect to ambient temperature).

Knock S

ensor (KS)

is a pi

ezo-electric device which sends a signal

to the ECM indicating engine detonation

Between 700 and 6800 rpm, the ECM will retard individual cylinder ignition timing when detonation occurs while allowing

the other cylinders to continue operating normally.

During acceleration, at critical load and speed conditions, the ECM retards ignition timing to prevent the onset of detonation.

H

eated Oxygen Sensor (HO2S)

are

positioned upstream of the catalytic convertor

is equipped with

a heating element wh

ich improves the response time of the sensors during engine warm-up

h

as the ability to generate a voltage signal proportional to the oxygen content of the exhaust gases leaving the

engine

pr

ovides feedback information to the ECM used to calc

ulate fuel delivery and provide optimum gas emissions

Variable V

alve Timing (VVT) Solenoid

R

efer to section 303-01.

Page 1191 of 2490

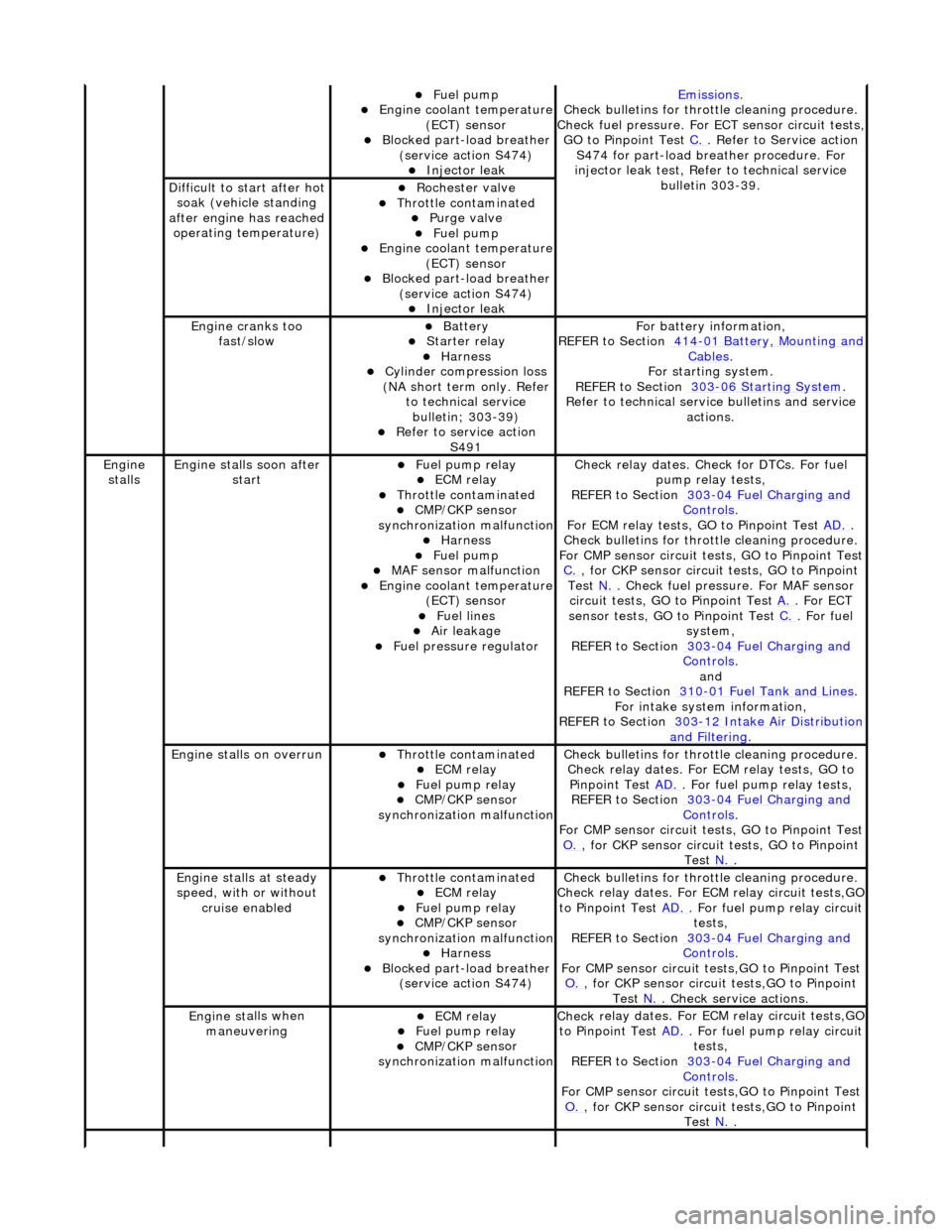

Fue

l pump

Engine coolan

t temperature

(ECT) sensor

Blocked part-load breather (

service action S474)

Injec

tor leak

Emiss

ions

.

Check bull

etins for throttle cleaning procedure.

Check fuel pressure. For ECT sensor circuit tests,

GO to Pinpoint Test C.

. Refer to Servi

ce action

S474 for part-load breather procedure. For

injector leak test, Refer to technical service bulletin 303-39.

D

ifficult to start after hot

soak (vehicle standing

after engine has reached operating temperature)

Roc

hester valve

Thr

ottle contaminated

Purge

valve

Fue

l pump

Engine coolan

t temperature

(ECT) sensor

Blocked part-load breather (

service action S474)

Injec

tor leak

Engine cranks too

fa

st/slow

Batt

ery

Starter relay Harness Cyl

inder compression loss

(NA short term only. Refer to technical service bulletin; 303-39)

R

efer to service action

S491

F

or battery information,

REFER to Section 414

-0

1 Battery, Mounting and

Cables.

F

or starting system.

REFER to Section 303

-06 Sta

rting System

.

R

efer to technical servic

e bulletins and service

actions.

Engine

stalls

Engine st

alls soon after

start

F

uel pump relay

ECM relay Thr

ottle contaminated

CMP/CKP sen

sor

synchronization malfunction

Harness Fue

l pump

MAF

sensor malfunction

Engine coolan

t temperature

(ECT) sensor

Fue

l lines

Air leakage

F

uel pressure regulator

Check r

elay dates. Chec

k for DTCs. For fuel

pump relay tests,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

F

or ECM relay tests, GO to Pinpoint Test

AD.

.

Check bull

etins for throttle cleaning procedure.

For CMP sensor circuit test s, GO to Pinpoint Test

C.

, for

CKP sensor circuit tests, GO to Pinpoint

Test N.

. Check fuel

pressure. For MAF sensor

circuit tests, GO to Pinpoint Test A.

. For EC

T

sensor tests, GO to Pinpoint Test C.

. F

or fuel

system,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

and

REF

ER to Section 310

-0

1 Fuel Tank and Lines

. F

or intake system information,

REFER to Section 303

-1

2 Intake Air Distribution

and F

iltering

.

Engine

stalls on overrun

Thr

ottle contaminated

ECM relay F

uel pump relay

CMP/CKP sen

sor

synchronization malfunction

Check bull

etins for throttle cleaning procedure.

Check relay dates. For ECM relay tests, GO to Pinpoint Test AD.

. F

or fuel pump relay tests,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

F

or CMP sensor circuit test

s, GO to Pinpoint Test

O.

, for

CKP sensor circuit tests, GO to Pinpoint

Test N.

.

E

ngine stalls at steady

speed, with or without cruise enabled

Thr

ottle contaminated

ECM relay F

uel pump relay

CMP/CKP sen

sor

synchronization malfunction

Harness Blocked part-load breather

(

service action S474)

Check bull

etins for throttle cleaning procedure.

Check relay dates. For EC M relay circuit tests,GO

to Pinpoint Test AD.

. F

or fuel pump relay circuit

tests,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

F

or CMP sensor circuit test

s,GO to Pinpoint Test

O.

, for

CKP sensor circuit tests,GO to Pinpoint

Test N.

. Che

ck service actions.

Engine st

alls when

maneuvering

ECM relay F

uel pump relay

CMP/CKP sen

sor

synchronization malfunction

Check r

elay dates. For EC

M relay circuit tests,GO

to Pinpoint Test AD.

. F

or fuel pump relay circuit

tests,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

F

or CMP sensor circuit test

s,GO to Pinpoint Test

O.

, for

CKP sensor circuit tests,GO to Pinpoint

Test N.

.

Page 1192 of 2490

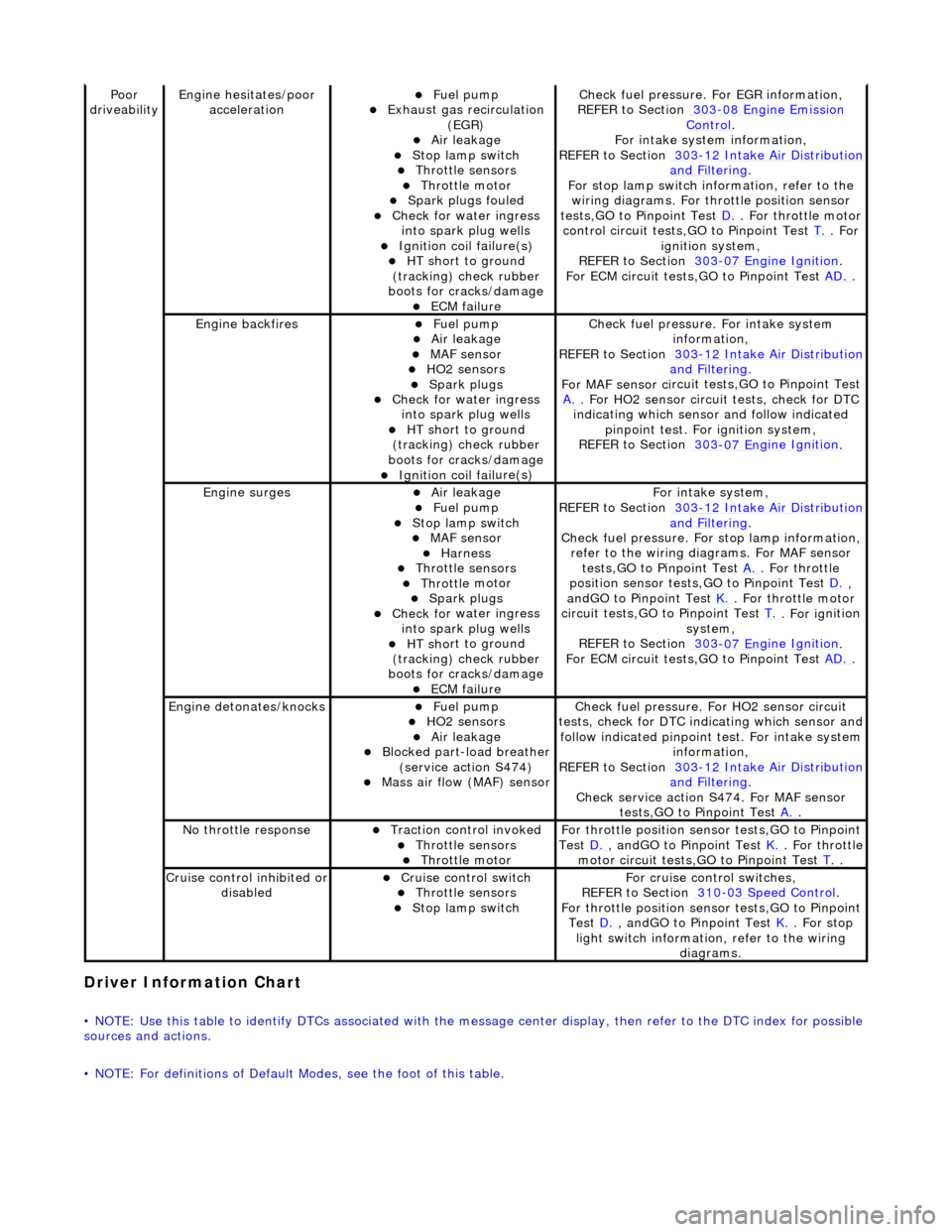

Driver Information

Chart

•

NOTE: Use this table to identify DTCs associated with the me

ssage center display, then refer to the DTC index for possible

sources and actions.

• NOTE: For definitions of Default Modes, see the foot of this table.

Poor

dr iveabilityEngine h e

sitates/poor

acceleration

Fue l

pump

Exhaus

t gas

recirculation

(EGR)

Air leakage Stop lamp swi t

ch

Throttl

e

sensors

Throttl

e

motor

Spark

plugs

fouled

Check f

o

r water ingress

into spark plug wells

Ignition coil fail

ure(s)

HT sh

o

rt to ground

(tracking) check rubber

boots for cracks/damage

ECM failu r

e

Check f

u

el pressure. For EGR information,

REFER to Section 303

-08 En gin

e Emission

Control.

F or i

ntake system information,

REFER to Section 303

-1 2

Intake Air Distribution

and F

ilt

ering

.

F or stop l

amp switch in

formation, refer to the

wiring diagrams. For throttle position sensor

tests,GO to Pinpoint Test D.

. Fo

r throttle motor

control circuit tests,GO to Pinpoint Test T.

. For

igni t

ion system,

REFER to Section 303

-07 En

gine Ignition

.

F or ECM

circuit tests,GO to Pinpoint Test

AD.

.

Engine backfiresFuel

pump

Air leakage MAF se

nsor

HO2 sensors

Spark plugs Check fo

r water ingress

into spark plug wells

HT sh o

rt to ground

(tracking) check rubber

boots for cracks/damage

Ignition coil fail

ure(s)

Chec

k fu

el pressure. For intake system

information,

REFER to Section 303

-12

Intake Air Distribution

and Filt

ering

.

F or MAF sensor ci

rcuit test

s,GO to Pinpoint Test

A.

. F or HO2 sensor

circui

t tests, check for DTC

indicating which sensor and follow indicated pinpoint test. For ignition system,

REFER to Section 303

-07 En

gine Ignition

.

Engine

s

urges

Air leakage

Fuel

pump

Stop lamp swit

ch

MAF s

e

nsor

Harness Throttl

e

sensors

Throttl

e

motor

Spark plugs

Check fo

r water ingress

into spark plug wells

HT sh o

rt to ground

(tracking) check rubber

boots for cracks/damage

ECM failu r

e

Fo

r

intake system,

REFER to Section 303

-1 2

Intake Air Distribution

and Filt

ering

.

Check fu

el pressure. For

stop lamp information,

refer to the wiring diagrams. For MAF sensor tests,GO to Pinpoint Test A.

. Fo

r throttle

position sensor tests,GO to Pinpoint Test D.

,

a n

dGO to Pinpoint Test

K.

. Fo

r throttle motor

circuit tests,GO to Pinpoint Test T.

. For ig

nition

system,

REFER to Section 303

-07 En

gine Ignition

.

F or ECM

circuit tests,GO to Pinpoint Test

AD.

.

Engine detonates/k

nocks

Fue

l

pump

HO2 sensors

Air leakage Blocked part-load breather

(s

ervice action S474)

Mass ai

r fl

ow (MAF) sensor

Chec

k fu

el pressure. Fo

r HO2 sensor circuit

tests, check for DTC indicating which sensor and

follow indicated pinpoint test. For intake system

information,

REFER to Section 303

-1 2

Intake Air Distribution

and Filt

ering

.

Check service action S474

. For MAF sensor

tests,GO to Pinpoint Test A.

.

No t

hrottle response

Traction contr

o

l invoked

Throttl

e

sensors

Throttl

e

motor

Fo

r th

rottle position sensor tests,GO to Pinpoint

Test D.

, andG O to Pinpoint

Test

K.

. Fo

r throttle

motor circuit tests,GO to Pinpoint Test T.

.

Cru i

se control inhibited or

disabled

Cru i

se control switch

Throttle

sensors

Stop lamp swit

ch

For cru

i

se control switches,

REFER to Section 310

-03

Speed Control

.

For th

rottle position sensor tests,GO to Pinpoint

Test D.

, andG O to Pinpoint

Test

K.

. For s t

op

light switch information, refer to the wiring diagrams.

Page 1193 of 2490

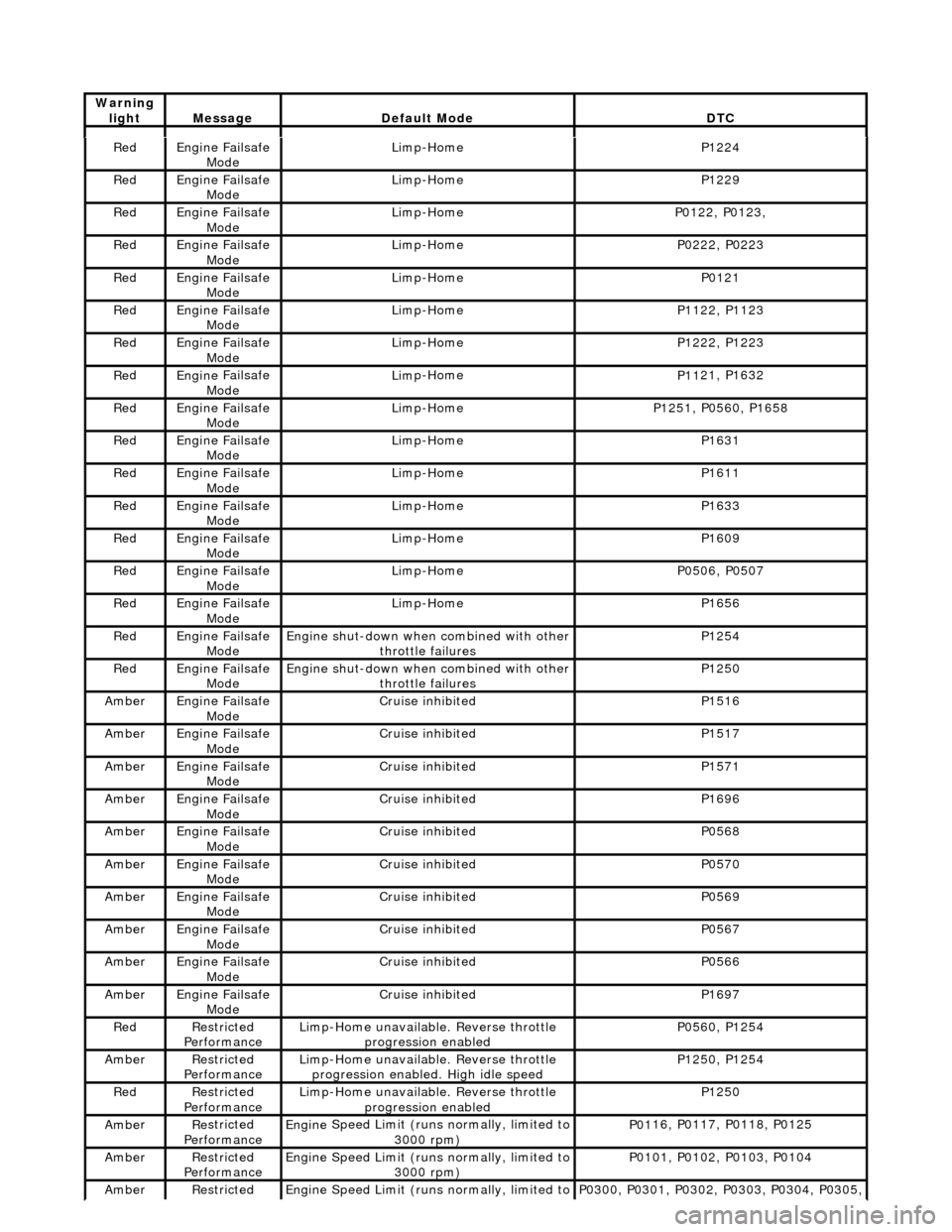

Re

d

Engine

Failsafe

Mode

Lim

p-Home

P1224

Re

d

Engine

Failsafe

Mode

Lim

p-Home

P1229

Re

d

Engine

Failsafe

Mode

Lim

p-Home

P01

22, P0123,

Re

d

Engine

Failsafe

Mode

Lim

p-Home

P02

22, P0223

Re

d

Engine

Failsafe

Mode

Lim

p-Home

P0121

Re

d

Engine

Failsafe

Mode

Lim

p-Home

P11

22, P1123

Re

d

Engine

Failsafe

Mode

Lim

p-Home

P12

22, P1223

Re

d

Engine

Failsafe

Mode

Lim

p-Home

P11

21, P1632

Re

d

Engine

Failsafe

Mode

Lim

p-Home

P12

51, P0560, P1658

Re

d

Engine

Failsafe

Mode

Lim

p-Home

P1631

Re

d

Engine

Failsafe

Mode

Lim

p-Home

P1611

Re

d

Engine

Failsafe

Mode

Lim

p-Home

P1633

Re

d

Engine

Failsafe

Mode

Lim

p-Home

P1609

Re

d

Engine

Failsafe

Mode

Lim

p-Home

P05

06, P0507

Re

d

Engine

Failsafe

Mode

Lim

p-Home

P1656

Re

d

Engine

Failsafe

Mode

Engine

shut-down when combined with other

throttle failures

P1254

Re

d

Engine

Failsafe

Mode

Engine

shut-down when combined with other

throttle failures

P1250

Ambe

r

Engine

Failsafe

Mode

Cruis

e inhibited

P1516

Ambe

r

Engine

Failsafe

Mode

Cruis

e inhibited

P1517

Ambe

r

Engine

Failsafe

Mode

Cruis

e inhibited

P1571

Ambe

r

Engine

Failsafe

Mode

Cruis

e inhibited

P1696

Ambe

r

Engine

Failsafe

Mode

Cruis

e inhibited

P0568

Ambe

r

Engine

Failsafe

Mode

Cruis

e inhibited

P0570

Ambe

r

Engine

Failsafe

Mode

Cruis

e inhibited

P0569

Ambe

r

Engine

Failsafe

Mode

Cruis

e inhibited

P0567

Ambe

r

Engine

Failsafe

Mode

Cruis

e inhibited

P0566

Ambe

r

Engine

Failsafe

Mode

Cruis

e inhibited

P1697

Re

d

Re

stricted

Performance

Li

mp-Home unavailable. Reverse throttle

progression enabled

P05

60, P1254

Ambe

r

Re

stricted

Performance

Li

mp-Home unavailable. Reverse throttle

progression enabled. High idle speed

P12

50, P1254

Re

d

Re

stricted

Performance

Li

mp-Home unavailable. Reverse throttle

progression enabled

P1250

Ambe

r

Re

stricted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P01

16, P0117, P0118, P0125

Ambe

r

Re

stricted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P01

01, P0102, P0103, P0104

Ambe

r

Re

stricted

Engine

Speed Limit (runs normally, limited to

P03

00, P0301, P0302, P0303, P0304, P0305,

Warning

lightMess

age

De

fault Mode

DT

C

Page 1194 of 2490

Default mode Definitions

MECHANIC

AL LIMP-HOME MODE:

No elec

tronic throttle operation (mechanical

operation for last quarter of pedal travel)

Ma

ximum 25° throttle opening,

depending on adjustment of th rottle mechanical linkage

Engine speed restri

cted to 3000

rpm maximum, by fuel cut-off

High i

dle speed (1200 rpm approx.)

Misfire

at idle, due

to cylinder cut as a means of control

ling idle speed (the misfire will switch cylinders, as the

strategy varies th e cylinder cut)

Cruise (speed) contr

o

l inhibited

REVERSE THROTTLE PROGRESSION ENABLED:

Elec

tronic throttle operation, limited to maximum 25°

Cruise (speed) contr

o

l inhibited

• NOTE: The throttle oper ation uses the same map as for reverse gear.

ENGINE SPEED LIMIT:

Engine runs

normally, up to 3000 rpm

Engine

speed restri

cted to 3000

rpm maximum, by fuel cut-off

Cruise (speed) contr o

l Inhibited

LIMP-HOME UNAVAILABLE:

Cruise (speed) contro

l inhibited

R

e

verse throttle pr

ogression engaged at second occurrence of DTC flagging

Diagnostic Trouble Code (D TC) Index

Performance3000

rpm)

P03

06,

P0307, P0308, P1313, P1314

Ambe

rRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P03 27,

P0328, P0332, P0333, P1648

Ambe

rRestri

cted

Performance

R e

verse throttle pr

ogression enabled

P1474

AmberRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P1230

Ambe rRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P1671

Ambe rRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P11 12,

P1113

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1601 (SC on

ly)

AmberRestri

cted

Performance

Gearbox defau l

t to 4th gear

P16

05 (

NA only)

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P0702

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1795

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1796

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1797

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1605

Ambe

rNoneGearbox defau l

t to 4th gear

P0705 (SC on

ly)

Ambe

rNoneGearbox defau l

t to 4th gear

P0706

Ambe

rNoneGearbox defau l

t to 4th gear

P1720

Page 1201 of 2490

leak

/blockage

EVAP valve failure

P0444Evaporati

ve emissions system

(EVAP) valve circuit open circuit

EVAP t

o ECM drive circuit open

circuit or high resistance

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0445Evaporati

ve emissions system

(EVAP) valve circuit short circuit

E

VAP to ECM drive circuit short

circuit to ground

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0447Cani

ster close valve (CCV) circuit

open circuit

CCV to ECM

drive circuit open

circuit, high resi stance or short

circuit to ground

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0448Cani

ster close valve (CCV) circuit

short circuit

CCV to

ECM drive circuit short

circuit to high voltage

CCV failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0452F

uel tank pressure (FTP) sensor

circuit low voltage

FTP

sensor disconnected

FTP

sensor to ECM sense circuit

open circuit or short circuit to

ground

FTP sen

sor to ECM power supply

circuit open circuit or short circuit

to ground

F

TP sensor failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0453F

uel tank pressure (FTP) sensor

circuit high voltage

FTP

sensor to ECM signal ground

circuit open circuit

F

TP sensor to ECM wiring (supply,

sense, signal, ground) short circuit

to each other

FTP

sensor to ECM sense circuit

short circuit to high voltage

F

TP sensor failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0460Fue

l level sense signal

performance

Fue

l level sensor

to instrument

cluster circuits in termittent short or

open circuit

F

uel level sensor failure

Instrument cluster

faul

t (incorrect

fuel level data)

F

or fuel level sensor

circuit tests,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0506Idl

e rpm lower than expected

Ai

r intake blockage

Acce

ssory drive overload

(defective/siezed component)

Thr

ottle valve stuck closed

Throttl

e assembly failure

Chec

k the air intake system.

REFER to Section 303

-1

2 Intake Air

Distribu

tion and Filtering

.

Check t

he accessory drive

components,

REFER to Section 303

-0

5 Accessory

Dr

ive

.

F

or throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0507Idle rpm

higher than expected

Inta

ke air leak between MAF

sensor and throttle

Inta

ke air leak between throttle

and engine

Engine

breather leak

Cruis

e (speed) control vacuum

failure

Thr

ottle valve stuck open

Throttl

e assembly failure

Chec

k the air intake system.

REFER to Section 303

-1

2 Intake Air

Distribu

tion and Filtering

.

Chec

k the engine breather system,

REFER to Section 303

-08

Engine

Emissi

on Control

.

F

or cruise (speed) control information,

REFER to Section 310

-03

Speed

Control.

F

or throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0560Vehicle voltage

malfunction

ECM battery

power supply open

circuit, high resistance

F

or ECM power supply circuit tests,

GO to Pinpoint Test AD.

.

P0566Cruise (speed) contr

ol

CANCEL

switch ON fault

Cru

ise (speed) control switches

internal steering wheel short circuit

to ground

For cru

ise (speed) control circuit tests,

REFER to Section 310

-03

Speed

Page 1202 of 2490

St

eering wheel cassette reel short

circuit to ground

Cassette reel to ECM c

ircuit short

circuit to ground

CANC EL

switch failure (stuck ON)

Control.

P0567Cruise (speed) contr

o

l

RESUME

switch ON fault

Cru i

se (speed) control switches

internal steering wheel short circuit

to ground

S t

eering wheel cassette reel short

circuit to ground

Cassette reel to ECM c

ircuit short

circuit to ground

RESUME s

witch failure (stuck ON)

For cru

i

se (speed) control circuit tests,

REFER to Section 310

-03 Sp

eed

Control.

P0568Cru

i

se (speed) control switch

ground malfunction

Cru i

se (speed) control switches

internal steering wheel open circuit

St

eering wheel cassette reel open

circuit or high resistance

Cassette reel to ECM ci

rcuit

ACCEL/DECEL open circuit or high

resistance

ACC E

L/DECEL

switch failure

For crui

se (speed) control circuit tests,

REFER to Section 310

-03 Sp

eed

Control.

P0569Cruise (speed) contr

o

l

DECEL/SET (SET-) switch ON

fault

Cru i

se (speed) control switches

internal steering wheel short circuit

to ground

S t

eering wheel cassette reel short

circuit to ground

Cassette reel to ECM c

ircuit short

circuit to ground

DECE

L/SET

switch failure (stuck

ON)

For cru i

se (speed) control circuit tests,

REFER to Section 310

-03 Sp

eed

Control.

P0570Cruise (speed) contro

l

ACCEL/SET (SET+) switch ON

fault

Crui

se (speed) control switches

internal steering wheel short circuit

to ground

S t

eering wheel cassette reel short

circuit to ground

Cassette reel to ECM c

ircuit short

circuit to ground

ACC E

L/SET

switch failure (stuck

ON)

For crui

se (speed) control circuit tests,

REFER to Section 310

-03 Sp

eed

Control.

P0603ECM dat

a

corrupted

ECM failu

r

e

Contact deal

er techni

cal support for

advice on possible ECM failure.

P1000 Sy

stem checks not complete since

last memory clear

O B

D diagnostic monitors have not

completed

Carr y out comprehensi

ve component

monitor drive cycle. Refer to the DTC

section of JTIS.

P1104Mass ai r fl

ow (MAF) sensor ground

malfunction

MAF sensor to EC

M reference

ground circuit open circuit, short

circuit to high voltage, high

resistance

MAF s

ensor to ECM sensing circuit

open circuit

MAF sensor fai

lure

For MAF

se

nsor circuit tests,GO to

Pinpoint Test A.

.

P1111Syst

em checks complete since last

memory clear

O B

D diagnostic monitors have completed

N

o

action necessary.

P1112In

t

ake air temperature (IAT)

sensor 2 sense circuit high voltage

(low charge air temperature)

IAT sensor 2 di sconnect

ed

IAT sensor 2

to ECM sensing circuit

high resistance, open circuit or

short circuit to high voltage

IAT se nsor 2 failure

F

or IAT sensor

2 circuit tests,GO to

Pinpoint Test Q.

.

P1113Int

ake air temperature (IAT)

sensor 2 sense circuit low voltage

(high charge air temperature)

Supercharger interco

oler failure

IAT se

nsor 2

to ECM sensing circuit

short circuit to ground

IAT se nsor 2 failure

F

or IAT sensor

2 circuit tests,GO to

Pinpoint Test Q.

.

P1121Accele

rator pedal position (APP)

sensor circuit 'A'

range/performance

A P

P sensor to ECM sense circuit

'A' (sensor pin 5) open circuit,

short circuit or high resistance

Sensor power su pply fault

Sensor r

e

ference ground fault

APP s

e

nsor failure

For APP

sen

sor circuit tests,GO to

Pinpoint Test R.

, andGO to Pinpoint

Test S.

.