handbrake JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 222 of 2490

Remova

l

2

05-2

34 (JD 550-1)

1. CAUTION: Replacement of nuts and bolts: Various

thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt

can be used. See section 100-00 for information.

Release handbrake.

2. Ra

ise the vehicle on a four-post lift.

3. Fully slacken bu

t do not remove parking brake cable adjuster

nut.

4. Relea s

e appropriate side parkin

g brake cable from connecting

clip.

5. With draw parkin

g brake cable th

rough equalizer (LH side cable

only).

6. Lower four-post lift.

7. Raise rear of vehicle to workin g height and support on stands.

Refer to section 100-02.

8. Remove rear wheel. Refer to section 204-04.

Page 226 of 2490

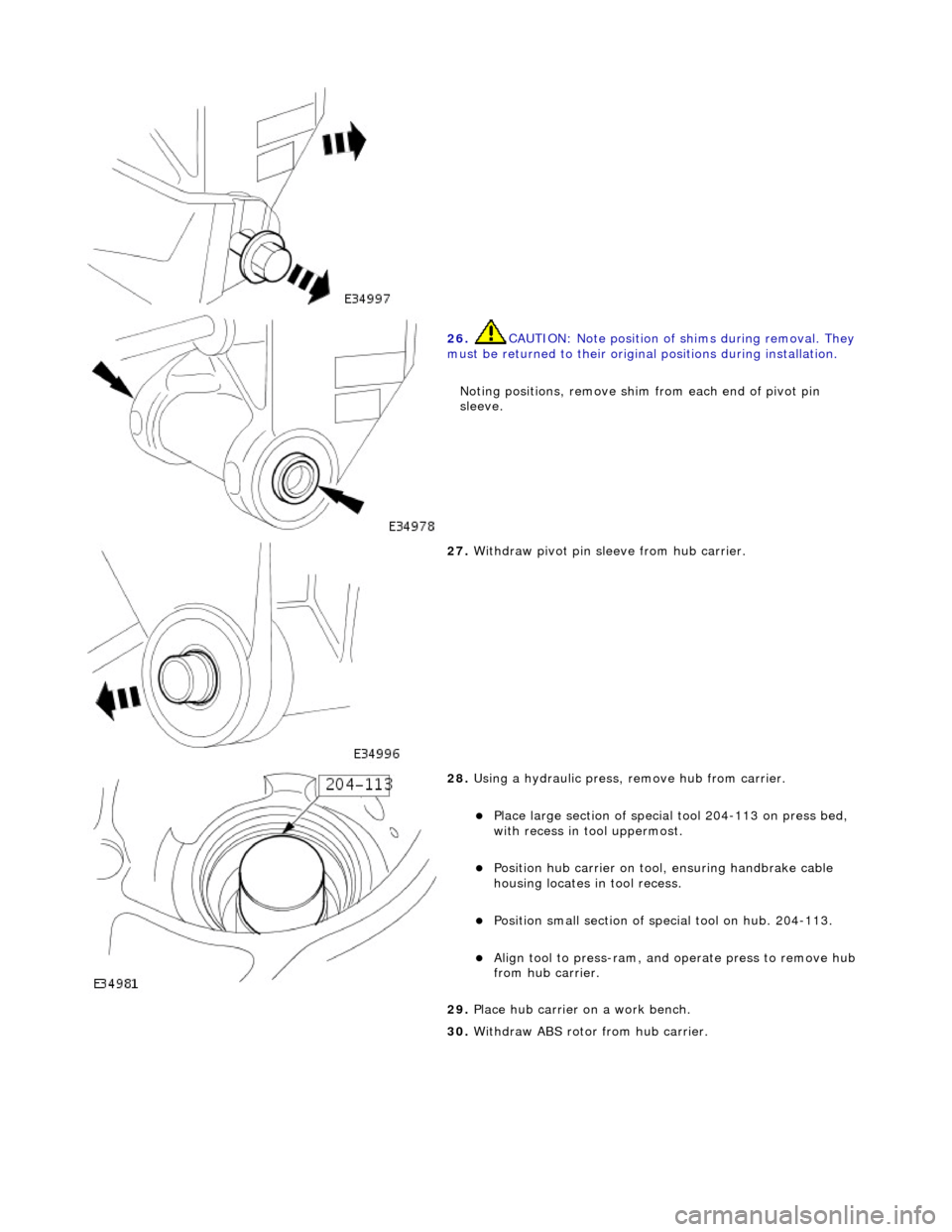

26. CAUTI

ON: Note position of

shims during removal. They

must be returned to their original positions during installation.

Noting positions, remove shim from each end of pivot pin

sleeve.

27 . W

ithdraw pivot pin sleeve from hub carrier.

28 .

Using a h

ydraulic press,

remove hub from carrier.

Plac

e large section of special tool 204-113 on press bed,

with recess in t ool uppermost.

Positi

on hub carrier on tool

, ensuring handbrake cable

housing locates in tool recess.

Posit i

on small section of special tool on hub. 204-113.

Align to

ol to press-r

am, and

operate press to remove hub

from hub carrier.

29. Place hub carrier on a work bench.

30. Withdraw ABS rotor from hub carrier.

Page 234 of 2490

29. Tigh

ten pivot pin nut.

Al

ign mark

er on pivot pin flange with mark made on

wishbone.

Ensuri ng pi

n position is not

disturbed, tighten nut to 88-

118Nm.

30 . Inst

all wheel speed sensor on hub carrier.

Posit

i

on sensor on hub carrier

and install and tighten bolt

to 7-10Nm.

Connect

wheel speed sensor harness to sensor.

31 . Using new ti

e strap, secure wh

eel speed sensor harness to

hub carrier.

32. Install handbrake shoes. Re fer to operation 70.40.05.

33. Install brake disc. Refer to operation 70.10.13.

34. Position special tool 204-195 on hub studs and install

securing nuts.

Page 242 of 2490

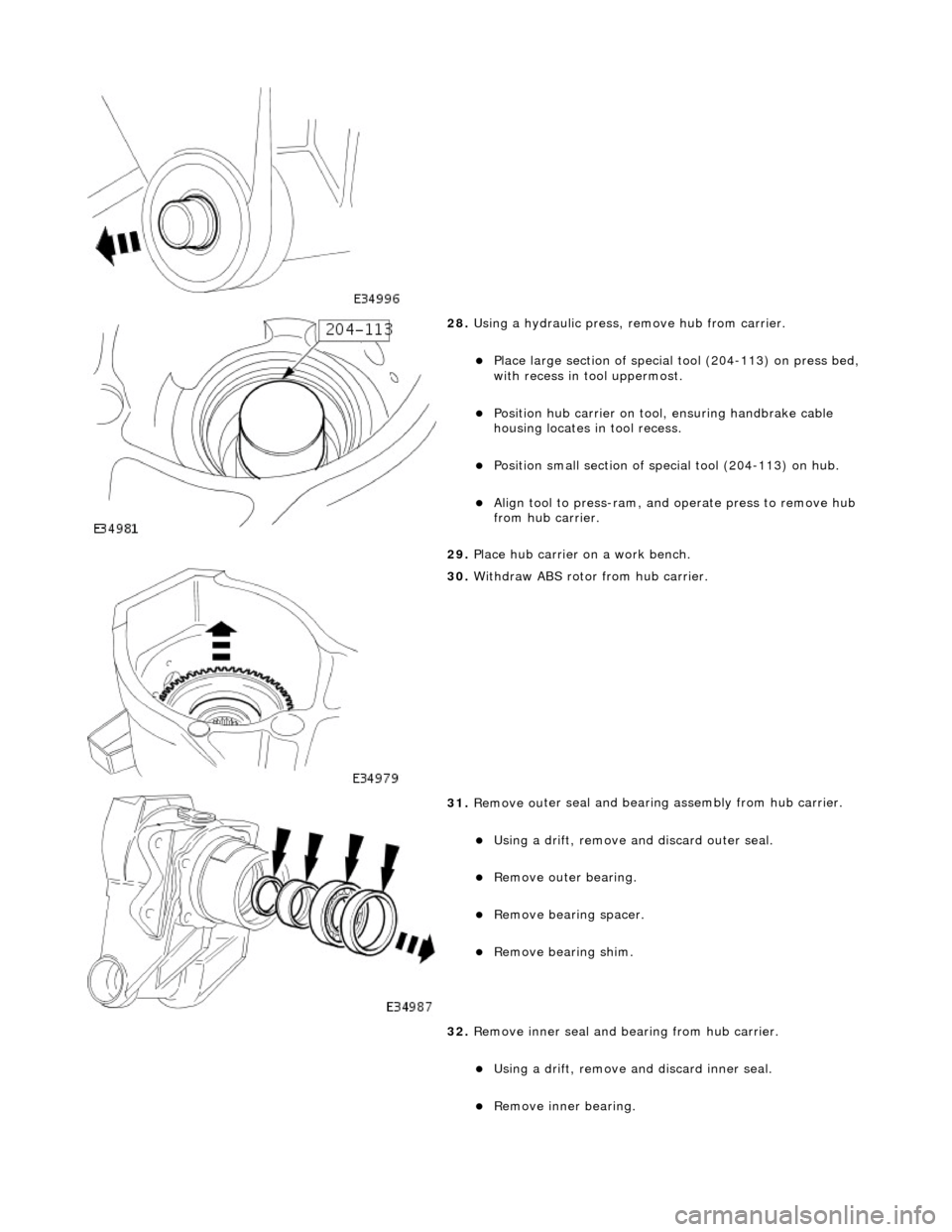

28. Using a h

ydraulic press,

remove hub from carrier.

Pla

ce large section of special tool (204-113) on press bed,

with recess in t ool uppermost.

Positi

on hub carrier on tool

, ensuring handbrake cable

housing locates in tool recess.

P o

sition small section of spec

ial tool (204-113) on hub.

Align tool to press-r

am, and

operate press to remove hub

from hub carrier.

29. Place hub carrier on a work bench.

30 . W

ithdraw ABS rotor from hub carrier.

31 . Remove ou

ter seal and bearin

g assembly from hub carrier.

Using a drift, re

move an

d discard outer seal.

Remove ou ter bearin

g.

Re

mo

ve bearin

g spacer.

Remove bearin g shim.

32

.

Remove inner seal and bearing from hub carrier.

Using a drift, re

move and discard inner seal.

Re

move inner bearing.

Page 246 of 2490

14. Inst

all wheel speed sensor on hub carrier.

Posit

i

on sensor on hub carrier

and install and tighten bolt

to 7-10Nm.

Conne ct

wheel speed sensor harness to sensor.

15 . Using new ti

e strap, secure wh

eel speed sensor harness to

hub carrier.

16. Install handbrake shoes. Re fer to operation 70.40.05.

17. Install brake disc. Refer to operation 70.10.13.

18 . Posit

ion special tool (204-195)

on hub studs and install nuts.

19. Tighten hub nut to 304-336Nm.

Page 251 of 2490

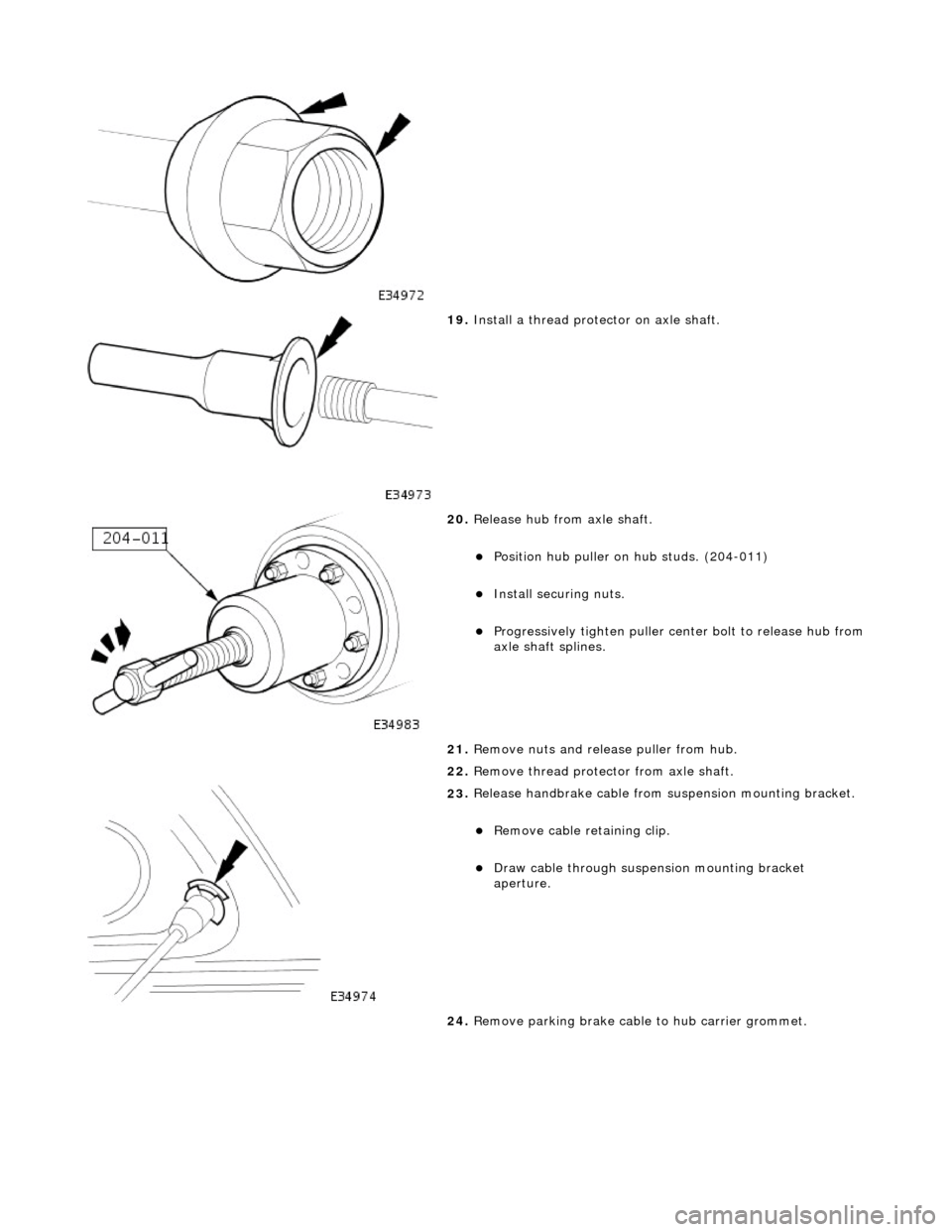

19

.

Install a thread protector on axle shaft.

20

.

Release hub from axle shaft.

Position hu

b puller on hub studs. (204-011)

Inst

all securing nuts.

Progres

sively tighten

puller center bolt to release hub from

axle shaft splines.

21. Remove nuts and release puller from hub.

22. Remove thread protec tor from axle shaft.

23

.

Release handbrake cable from suspension mounting bracket.

Remove cable reta

ining clip.

Draw c

able through suspension mounting bracket

aperture.

24. Remove parking brake cable to hub carrier grommet.

Page 397 of 2490

I

nstallation

Re

move bolts.

R

emove lever.

10

.

Remove gasket.

11

.

Remove warning-light switch from lever.

R

emove screws.

Re

move switch.

1. Inst

all warning-light switch to hand lever.

Install and tigh

ten

screws to 3 Nm.

2. Install gasket to handbrake lever.

Page 399 of 2490

Parking Brake and Act

uation - Parking Brake Control Shroud

Re

moval and Installation

Remov

al

Installation

1.

Position ha

ndbrake lever fully up.

2. Remove trim from handbrake lever.

1. Release press stud at to p of handbrake lever trim.

2. Ease lower moulding away from boss at base of lever and slide trim upwards.

1. Slide trim over handbrake lever and position lower moulding

over boss.

2. Fasten press stud at top of trim.

3. Check that 'J' gate selector is in position P.

4. Lower handbrake lever, checki ng for freedom of movement.

5. Pull handbrake lever fully up.

Page 896 of 2490

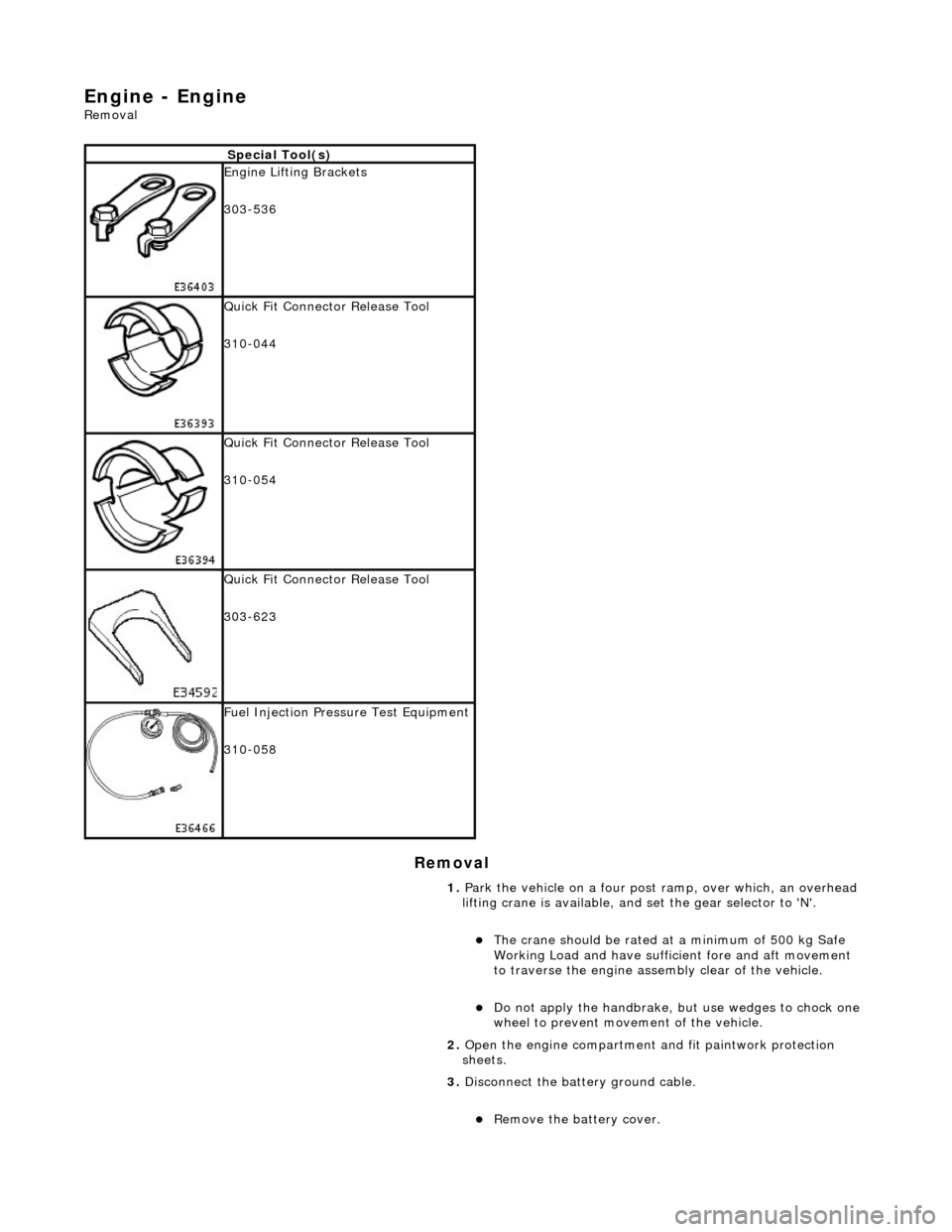

Engine - Engine

Removal

Removal

Special Tool(s)

Engine Lifting Brackets

303-536

Quick Fit Connector Release Tool

310-044

Quick Fit Connector Release Tool

310-054

Quick Fit Connector Release Tool

303-623

Fuel Injection Pressure Test Equipment

310-058

1. Park the vehicle on a four post ramp, over which, an overhead

lifting crane is available, and set the gear selector to 'N'.

The crane should be rated at a minimum of 500 kg Safe

Working Load and have suffici ent fore and aft movement

to traverse the engine assemb ly clear of the vehicle.

Do not apply the handbrake, but use wedges to chock one

wheel to prevent movement of the vehicle.

2. Open the engine compartment and fit paintwork protection

sheets.

3. Disconnect the batt ery ground cable.

Remove the battery cover.

Page 1855 of 2490

The In

strument Cluster is the primary electronic control module for the speedomete

r, tachometer, coolant temperature, fuel

level, driver information (Message Centre) and warning lamps.

The Instrument Cluster also:

- provides input / output informatio n signals for use by other modules.

- acts as a protocol converter (software language translator - the languages used on each network are very similar, but

neither can be directly interp reted by the opposite system) for communication between all modules on both the CAN and

SCP multiplexed networks. The Instrument Cluster is the only module on the vehicle which communicates between the two

networks.

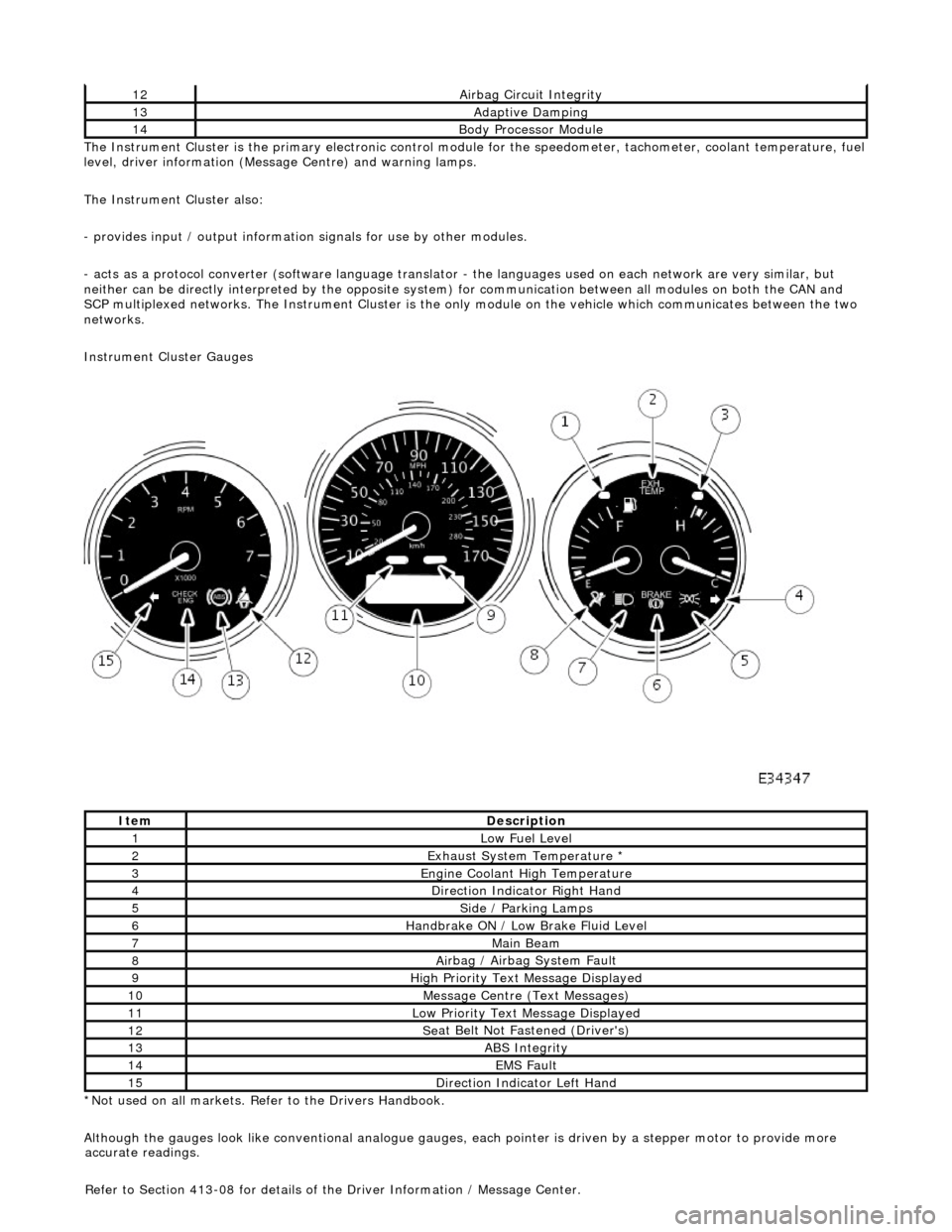

Instrument Cluster Gauges

*Not used on all markets. Refer to the Drivers Handbook.

Although the gauges look like conventional analogue gauges, each pointer is driven by a stepper motor to provide more

12Ai

rbag Circuit Integrity

13Adaptive Damping

14Body Processor

Module

It

em

De

scription

1Low Fu

el Level

2Exhaus

t System Temperature *

3E

ngine Coolant High Temperature

4Di

rection Indicator Right Hand

5Side

/ Parking Lamps

6Handbrake ON / Low

Bra

ke Fluid Level

7Main

Beam

8Ai

rbag / Airbag System Fault

9Hi

gh Priority Text

Message Displayed

10M

essage Centre (Text Messages)

11Low Pri

ority Text Message Displayed

12Se

at Belt Not Fa

stened (Driver's)

13ABS Integrity

14EMS Fault

15D

irection Indicator Left Hand

accu

rate readings.

Refer to Section 413-08 for details of the Driver Information / Message Center.