Amp JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 639 of 2490

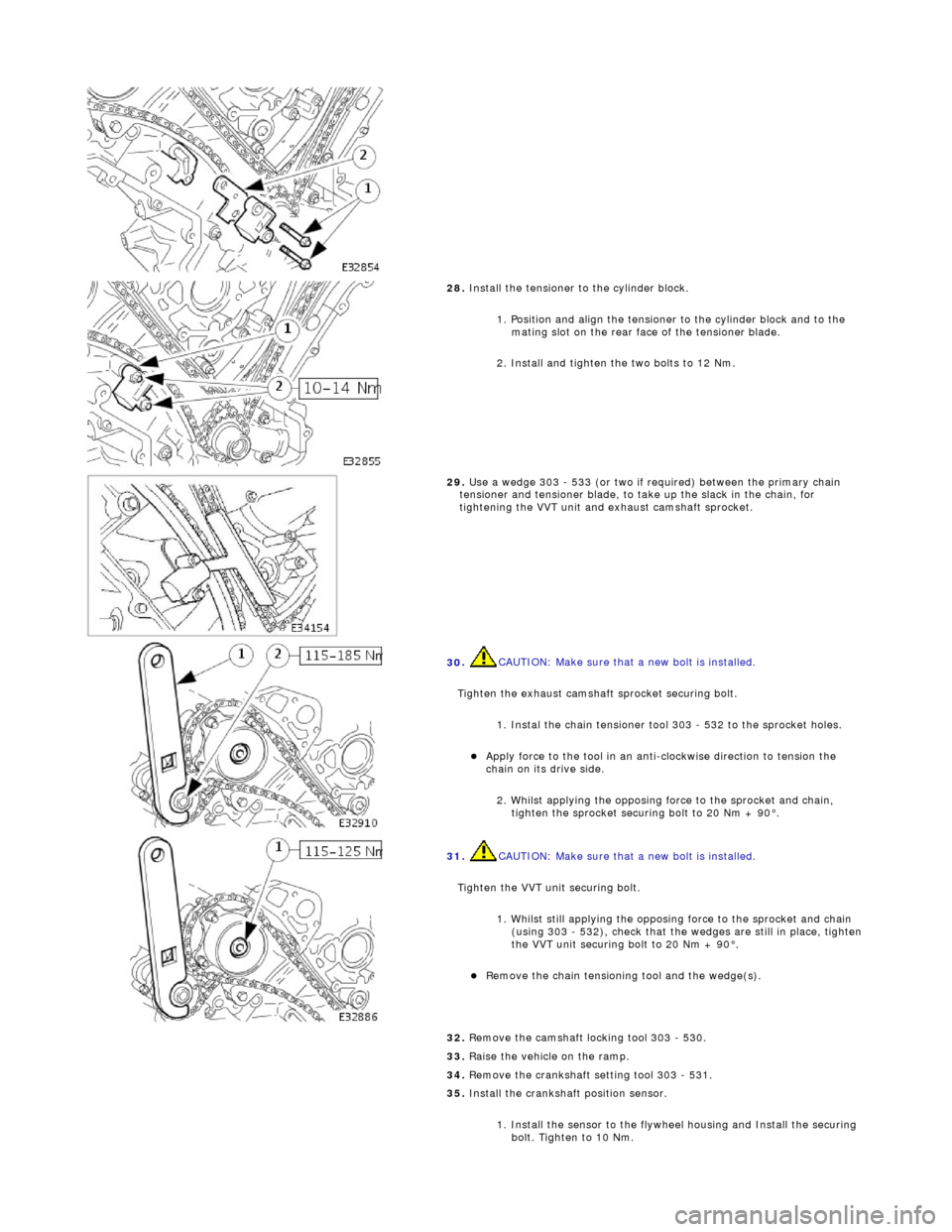

28

.

Install the tensioner to the cylinder block.

1. Position and align the tensioner to the cylinder block and to the mating slot on the rear face of the tensioner blade.

2. Install and tighten the two bolts to 12 Nm.

29

.

Use a wedge 303 - 533 (or two if required) between the primary chain

tensioner and tensioner blade, to ta ke up the slack in the chain, for

tightening the VVT unit and exhaust camshaft sprocket.

30

.

CAUTION: Make sure that a new bolt is installed.

Tighten the exhaust camshaft sprocket securing bolt. 1. Instal the chain tensioner t ool 303 - 532 to the sprocket holes.

Appl

y force to the tool in an anti

-clockwise direction to tension the

chain on its drive side.

2. Whilst applying the opposing force to the sprocket and chain, tighten the sprocket securing bolt to 20 Nm + 90°.

31

.

CAUTION: Make sure that a new bolt is installed.

Tighten the VVT unit securing bolt. 1. Whilst still applying the opposing force to the sprocket and chain (using 303 - 532), check that the wedges are still in place, tighten

the VVT unit securing bolt to 20 Nm + 90°.

R

emove the chain tensioning tool and the wedge(s).

32

.

Remove the camshaft locking tool 303 - 530.

33. Raise the vehicle on the ramp.

34. Remove the crankshaft setting tool 303 - 531.

35. Install the crankshaft position sensor.

1. Install the sensor to the flywheel housing and Install the securing bolt. Tighten to 10 Nm.

Page 640 of 2490

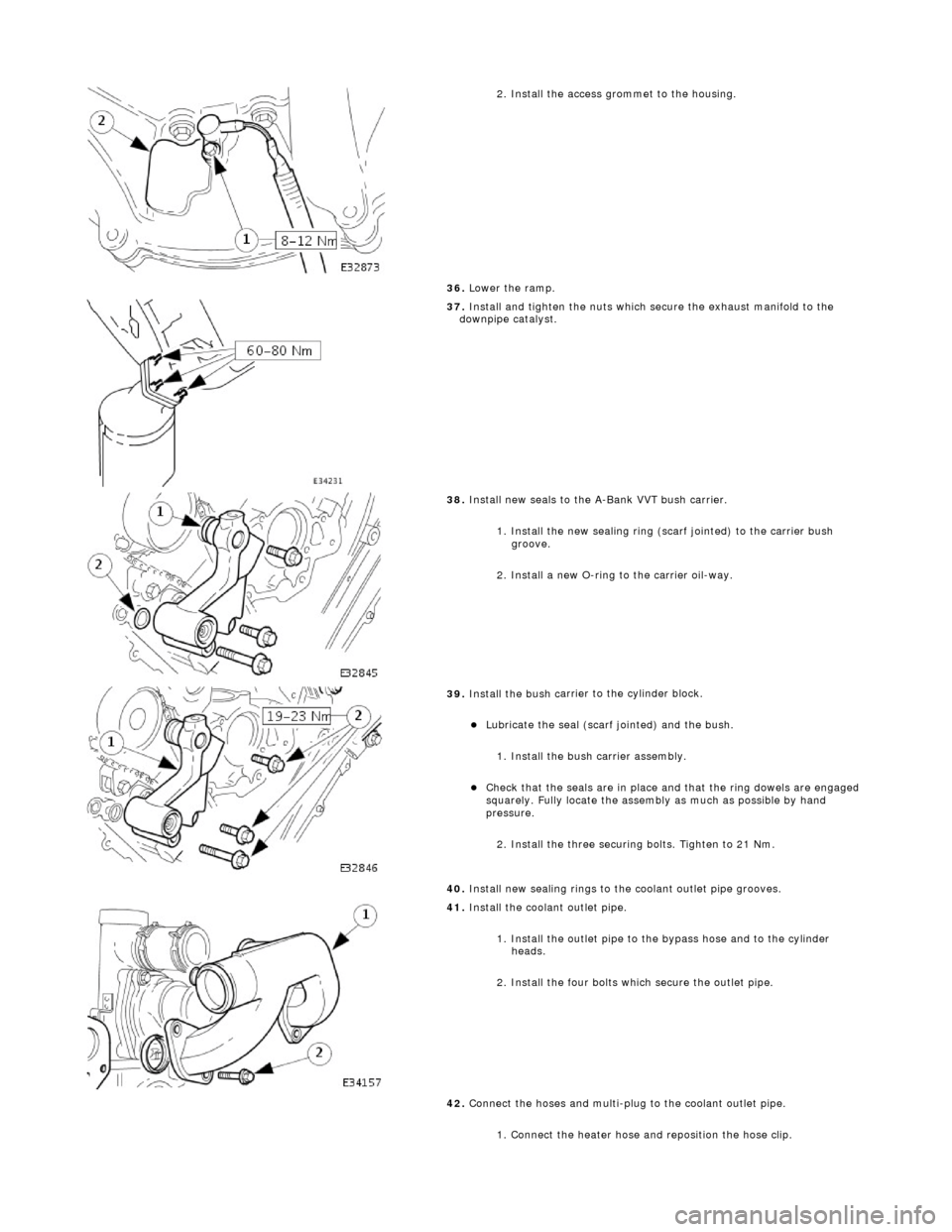

2. In

stall the access grommet to the housing.

36. Lower the ramp.

37. Ins

tall and tighten the nuts which secure the exhaust manifold to the

downpipe catalyst.

38 . In

stall new seals to the A-Bank VVT bush carrier.

1. Install the new sealing ring (scarf jointed) to the carrier bush groove.

2. Install a new O-ring to the carrier oil-way.

39 . Install the bush c

arrier to the cylinder block.

Lu

br

icate the seal (scarf

jointed) and the bush.

1. Install the bush carrier assembly.

Chec k that

the seals are

in place and that the ri ng dowels are engaged

squarely. Fully locate the assembly as much as possible by hand

pressure.

2. Install the three securing bolts. Tighten to 21 Nm.

40. Install new sealing rings to the coolant outlet pipe grooves.

41. Install the coolant

outlet pipe.

1. Install the outlet pipe to the bypass hose and to the cylinder heads.

2. Install the four bolts which secure the outlet pipe.

42. Connect the hoses and multi-plug to the coolant outlet pipe.

1. Connect the heater hose and reposition the hose clip.

Page 643 of 2490

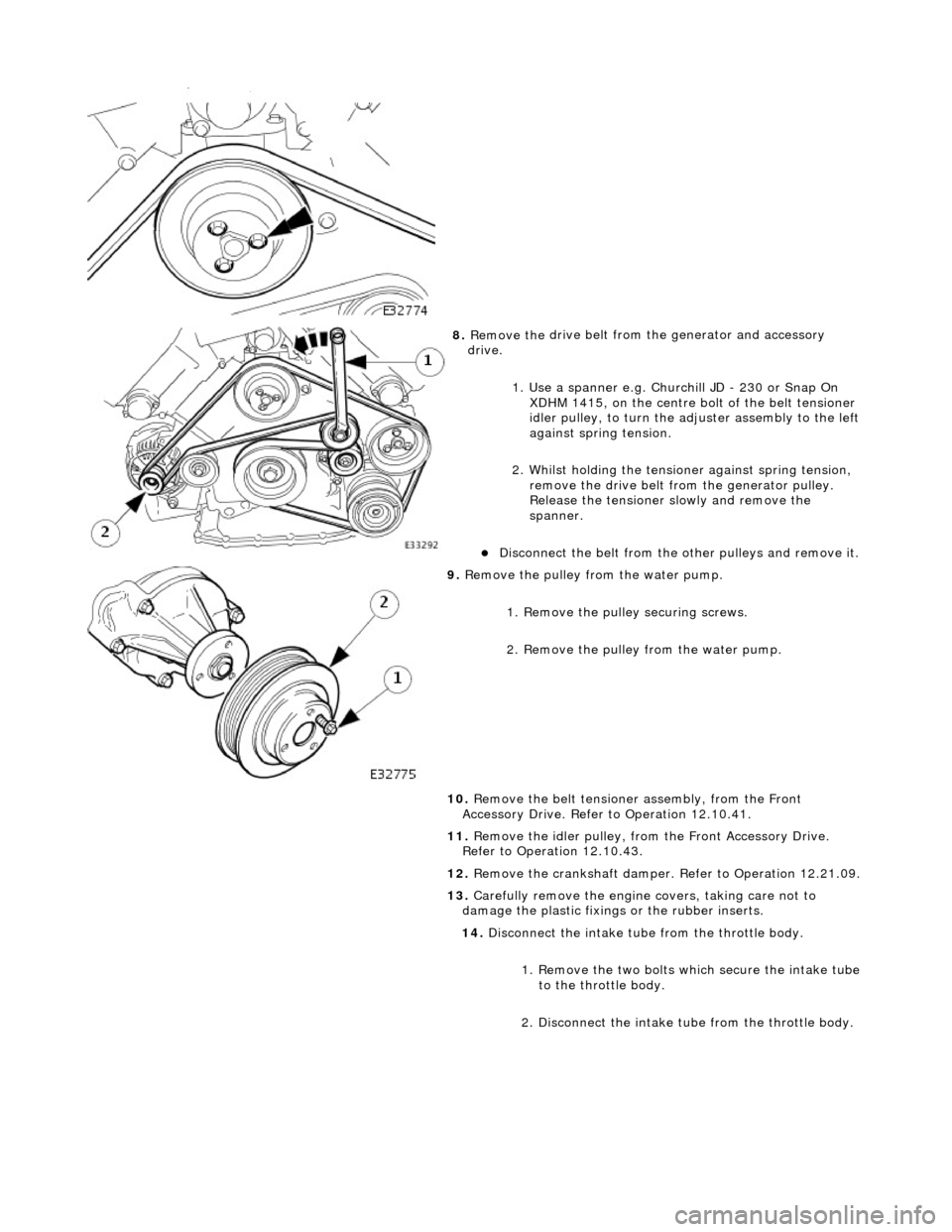

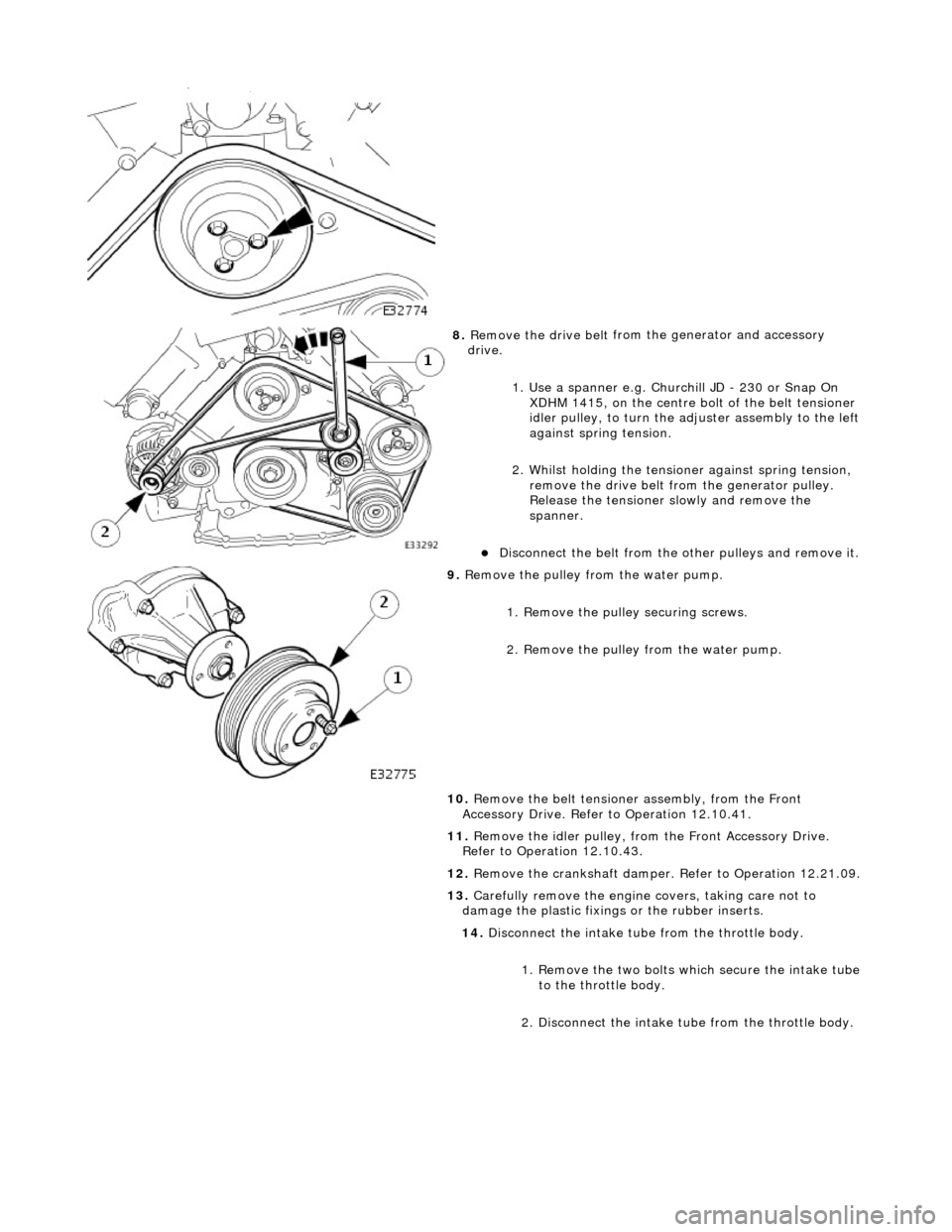

8. Remove the

drive belt from

the generator and accessory

drive.

1. Use a spanner e.g. Churchill JD - 230 or Snap On XDHM 1415, on the centre bo lt of the belt tensioner

idler pulley, to turn the adju ster assembly to the left

against spring tension.

2. Whilst holding the tensioner against spring tension, remove the drive belt from the generator pulley.

Release the tensioner sl owly and remove the

spanner.

D

isconnect the belt from the

other pulleys and remove it.

9. Re

move the pulley from the water pump.

1. Remove the pulley securing screws.

2. Remove the pulley from the water pump.

10. Remove the belt tensione r assembly, from the Front

Accessory Drive. Refer to Operation 12.10.41.

11. Remove the idler pulley, from the Front Accessory Drive.

Refer to Operation 12.10.43.

12. Remove the crankshaft damper. Refer to Operation 12.21.09.

13. Carefully remove the engine covers, taking care not to

damage the plasti c fixings or the rubber inserts.

14. Disconnect the intake tube from the throttle body.

1. Remove the two bolts which secure the intake tube to the throttle body.

2. Disconnect the intake tube from the throttle body.

Page 649 of 2490

15

.

Reconnect the air flow meter multi-plug.

16. Refit the engine covers.

17. Refit the crankshaft damper. Refer to Operation 12.21.09.

18. Refit the idler pulley, to the Front Accessory Drive. Refer to

Operation 12.10.43.

19. Refit the belt tensioner assembly, to the Front Accessory

Drive. Refer to Operation 12.10.41.

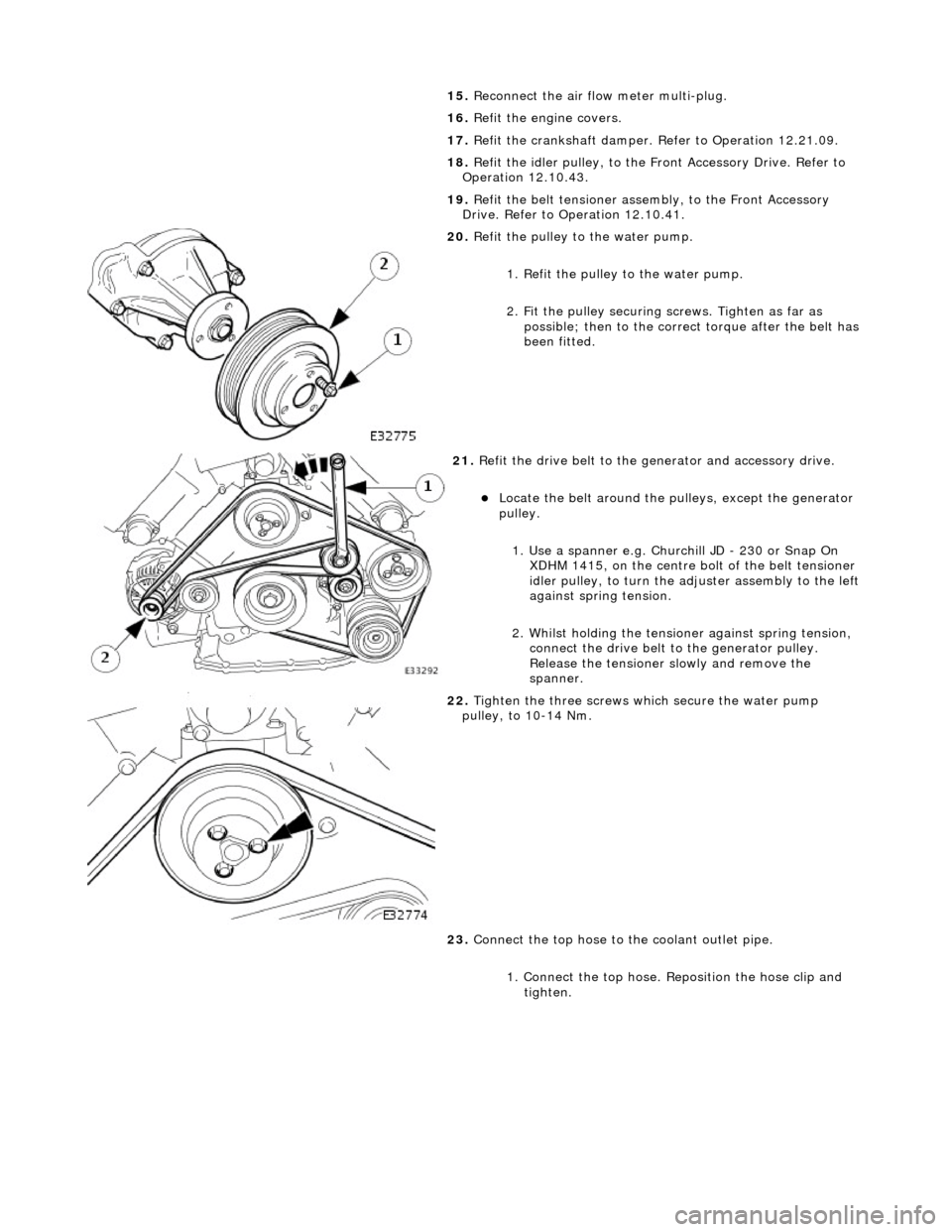

20

.

Refit the pulley to the water pump.

1. Refit the pulley to the water pump.

2. Fit the pulley securing screws. Tighten as far as

possible; then to the correct torque after the belt has

been fitted.

21

.

Refit the drive belt to the generator and accessory drive.

Locat

e the belt around the pulleys, except the generator

pulley.

1. Use a spanner e.g. Churchill JD - 230 or Snap On XDHM 1415, on the centre bo lt of the belt tensioner

idler pulley, to turn the adju ster assembly to the left

against spring tension.

2. Whilst holding the tensioner against spring tension, connect the drive belt to the generator pulley.

Release the tensioner sl owly and remove the

spanner.

22

.

Tighten the three screws wh ich secure the water pump

pulley, to 10-14 Nm.

23. Connect the top hose to the coolant outlet pipe.

1. Connect the top hose. Reposition the hose clip and tighten.

Page 652 of 2490

8. Remove the drive belt

from

the generator and accessory

drive.

1. Use a spanner e.g. Churchill JD - 230 or Snap On XDHM 1415, on the centre bo lt of the belt tensioner

idler pulley, to turn the adju ster assembly to the left

against spring tension.

2. Whilst holding the tensioner against spring tension, remove the drive belt from the generator pulley.

Release the tensioner sl owly and remove the

spanner.

D i

sconnect the belt from the

other pulleys and remove it.

9. Remove t

he pulley from the water pump.

1. Remove the pulley securing screws.

2. Remove the pulley from the water pump.

10. Remove the belt tensione r assembly, from the Front

Accessory Drive. Refer to Operation 12.10.41.

11. Remove the idler pulley, from the Front Accessory Drive.

Refer to Operation 12.10.43.

12. Remove the crankshaft damper. Refer to Operation 12.21.09.

13. Carefully remove the engine covers, taking care not to

damage the plasti c fixings or the rubber inserts.

14. Disconnect the intake tube from the throttle body.

1. Remove the two bolts which secure the intake tube to the throttle body.

2. Disconnect the intake tube from the throttle body.

Page 658 of 2490

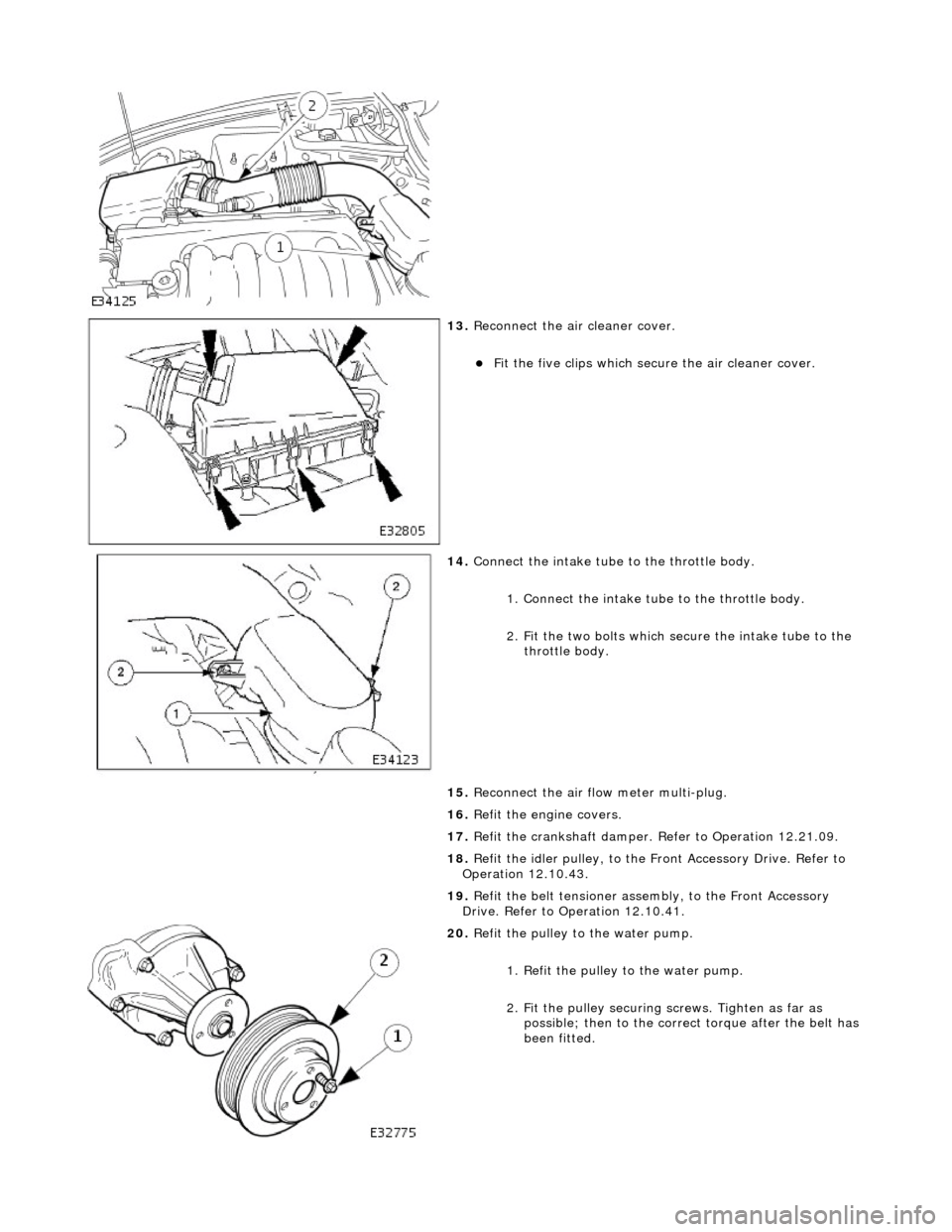

13. Reconnect the air cleaner cover.

Fit the five clips which secu re the air cleaner cover.

14. Connect the intake tube to the throttle body.

1. Connect the intake tube to the throttle body.

2. Fit the two bolts which secure the intake tube to the throttle body.

15. Reconnect the air flow meter multi-plug.

16. Refit the engine covers.

17. Refit the crankshaft damper. Refer to Operation 12.21.09.

18. Refit the idler pulley, to the Front Accessory Drive. Refer to

Operation 12.10.43.

19. Refit the belt tensioner assembly, to the Front Accessory

Drive. Refer to Operation 12.10.41.

20. Refit the pulley to the water pump.

1. Refit the pulley to the water pump.

2. Fit the pulley securing screws. Tighten as far as

possible; then to the correct torque after the belt has

been fitted.

Page 664 of 2490

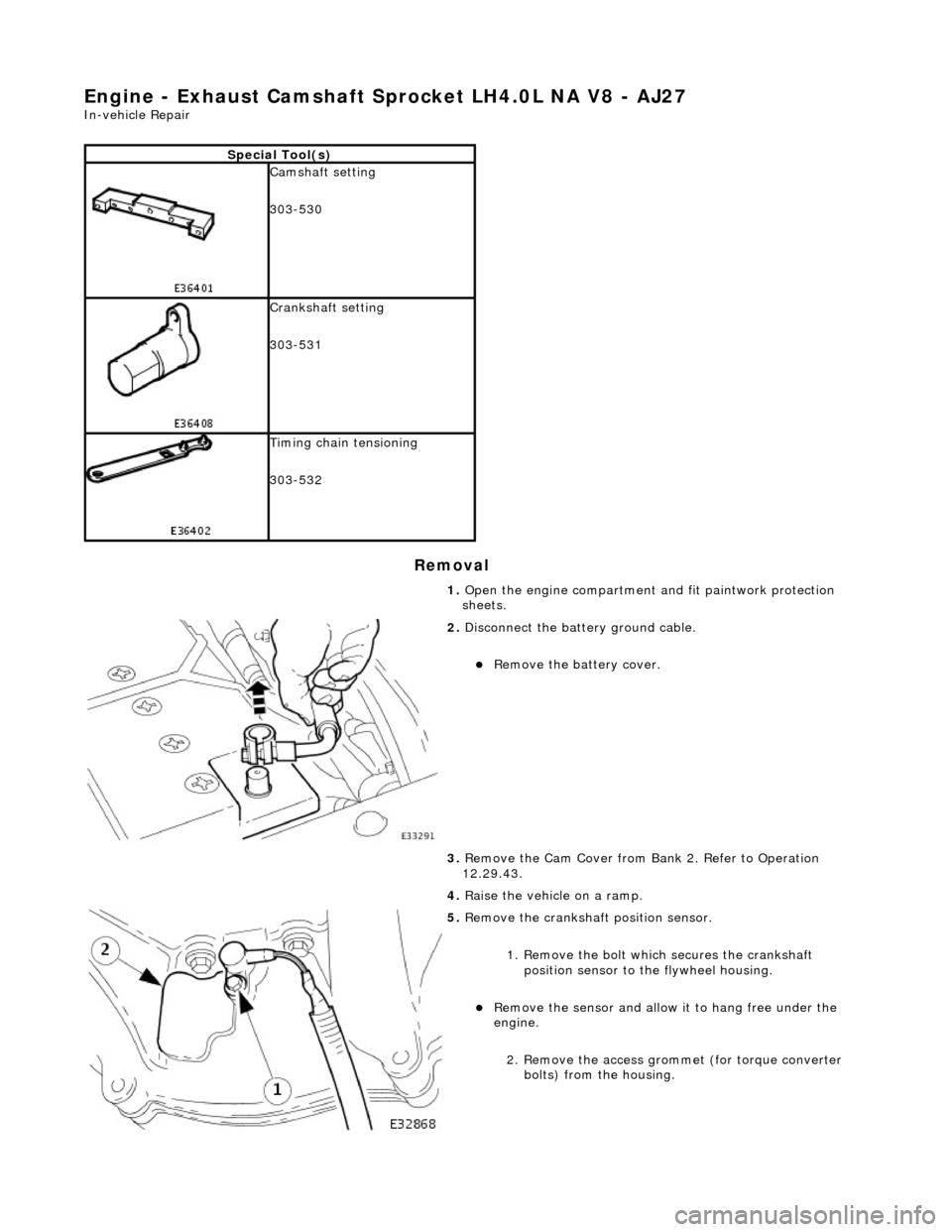

Engine - Exhaust Camshaft Sprocket LH4.0L NA V8 - AJ27

In-vehicle Repair

Removal

Special Tool(s)

Camshaft setting

303-530

Crankshaft setting

303-531

Timing chain tensioning

303-532

1. Open the engine compartment and fit paintwork protection

sheets.

2. Disconnect the batt ery ground cable.

Remove the battery cover.

3. Remove the Cam Cover from Ba nk 2. Refer to Operation

12.29.43.

4. Raise the vehicle on a ramp.

5. Remove the crankshaft position sensor.

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

Remove the sensor and allow it to hang free under the

engine.

2. Remove the access grommet (for torque converter bolts) from the housing.

Page 665 of 2490

6. Rotate the crankshaft until the triangular arrow indent on

the drive plate is visible thro ugh the access hole; confirm

that the timing flat on ea ch camshaft is uppermost.

7. Install the crankshaft setting peg 303-531 to the crankshaft

position sensor location.

1. Install the crankshaft setting peg 303-531.

Position the crankshaft so that the setting peg engages

fully into the timing slot.

2. Install and tighten the bolt to secure the setting peg.

8. Lower the vehicle on the ramp.

9. Install the camshaft locking tool 303-530 to Bank 2 camshafts,

aligning the shafts sl ightly as necessary.

10. CAUTION: Use a length of steel strip that will not fall

into the timing cover.

Protect the upper face of the ti ming cover from scratches, when

removing the bolt which secures the sprocket.

1. Place a flat piece of stee l strip along the timing cover

horizontal jointing face, adjacent to the exhaust

camshaft sprocket.

2. Secure the steel strip in place with adhesive tape.

11. A ball-ended hexagon drive bit is required to remove the

sprocket securing bolt. A suitable tool is available from Snap On as (FABLM10E) Long Series 10mm AF.

Page 667 of 2490

4. Remove the tape and steel stri p from the timing cover upper

face. Wipe any residue of tape from the joint face.

5. Remove the camshaft locking tool.

6. Install the Cam Cover to Bank 2. Refer to Operation 12.29.43.

7. Raise the vehicle on the ramp.

8. Remove the crankshaft setting tool 303-531.

9. Install the crankshaft position sensor.

1. Install the sensor to the flywheel housing and fit the

securing bolt. Tighten to 8-12 Nm.

2. Install the access grommet to the housing.

10. Lower the ramp.

11. Remove the paint protection sheets and close the engine

compartment cover.

12. Connect the battery and in stall the battery cover.

Refer to the Battery Reconnection Procedure 86.15.15.

Page 668 of 2490

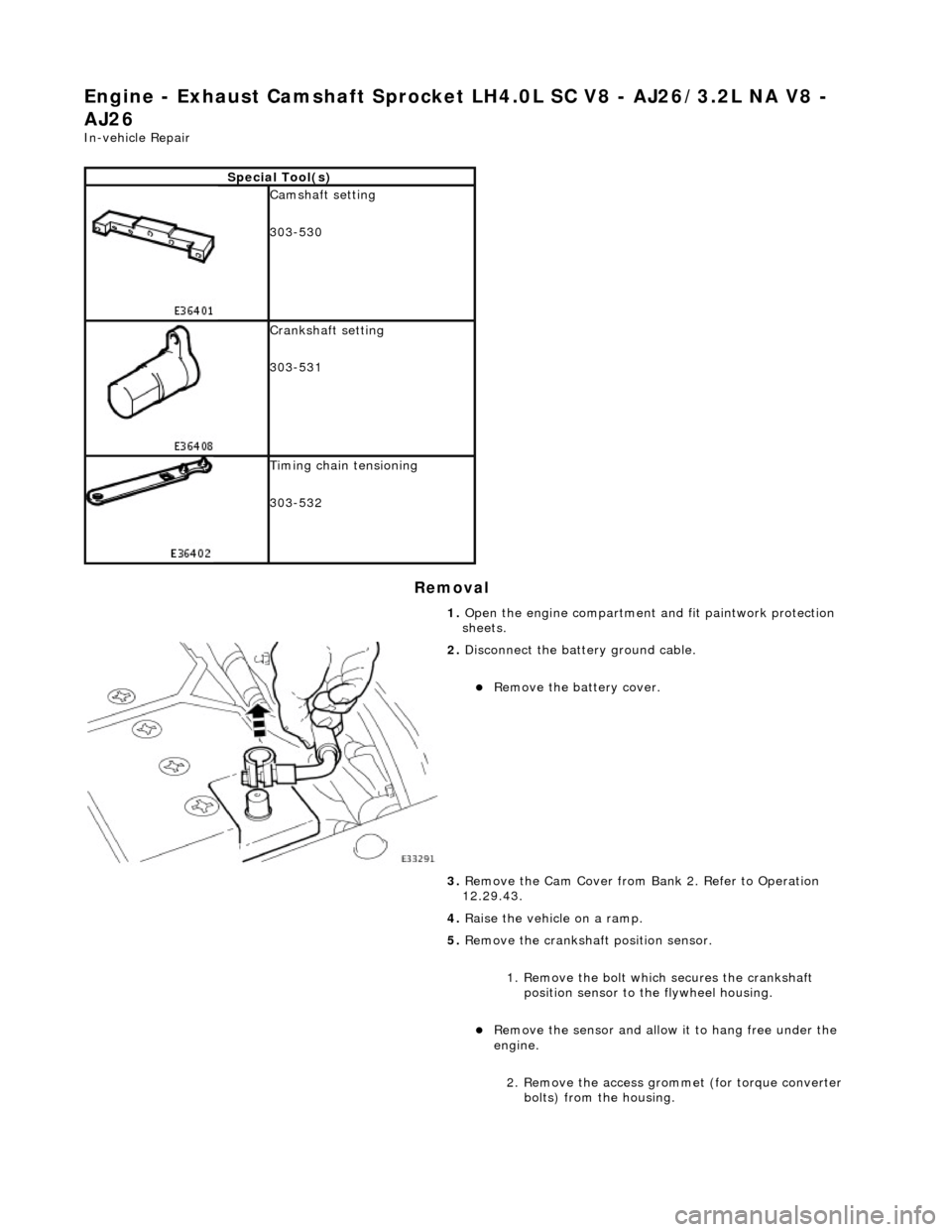

Engine - Exhaust Camshaft Sprocket LH4.0L SC V8 - AJ26/3.2L NA V8 -

AJ26

In-vehicle Repair

Removal

Special Tool(s)

Camshaft setting

303-530

Crankshaft setting

303-531

Timing chain tensioning

303-532

1. Open the engine compartment and fit paintwork protection

sheets.

2. Disconnect the batt ery ground cable.

Remove the battery cover.

3. Remove the Cam Cover from Ba nk 2. Refer to Operation

12.29.43.

4. Raise the vehicle on a ramp.

5. Remove the crankshaft position sensor.

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

Remove the sensor and allow it to hang free under the

engine.

2. Remove the access grommet (for torque converter bolts) from the housing.