parking sensors JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1390 of 2490

Stator, intermediate and output shafts. Three epicyclic geartrains. Six multi-disc clutch/brake packs. Two freewheels (One-way clutches). Hydraulic pump. Parking lock assembly. Electro-hydraulic control unit. Internal harness and 13 pin connector with bayonet lock.

Hydraulic pump

This engine driven pump is located at the front of the transmission casing and provides pressure for the hydraulic

functions.

Supplies fluid under pressure to the torq ue converter, geartrain, electro-hydraulic control unit and the lubrication

circuit.

Draws fluid from the fluid pa n below the transmission casing, through a filter.

Parking lock

This component prevents movement of th e vehicle by engaging a fixed pawl with the parking lock gear located on the

output shaft. The pawl is engaged by movi ng the gear selector lever to the park (P) position.

Electro-hydraulic control unit

This unit, mounted in the transmission lower case, converts signals, mechanical from the J-gate and electrical from the

TCM, into hydraulic functions.

The following components ar e assembled to the unit:

Selector valve. Shift plate. Control valve - modulating pressure. Control valve - shift pressure. Solenoid valve 1 <-> 2 and 4 <-> 5 shift. Solenoid valve 3 <-> 4 shift. Solenoid valve 2 <-> 3 shift. Solenoid valve - converter lock-up. Speed sensors (2). Temperature sensor.

Speed sensors

There are two speed sensors within the transmission assembly which provide input to the TCM. These inputs, when used in

conjunction with CAN data relative to engine speed (from ECM) and road speed (from ABS), are used to electronically

control the transmission.

Temperature sensor

The output from this sensor allows the TCM to compensate for the affect of fluid temperature on shift time and quality

Control Systems

Hydraulic Control

The selector valve is operated directly by the J-gate and directs fluid flow for P R N D.

Of the four solenoid valves, 3 control shifts and 1 controls converter lock-up. One control valve controls modulating pressure

and the other shift pressure.

Regulating valves are used to maintain/control pressure for lu brication, normal operating functions, and the supply to the

control valves and shift valves.

Page 1869 of 2490

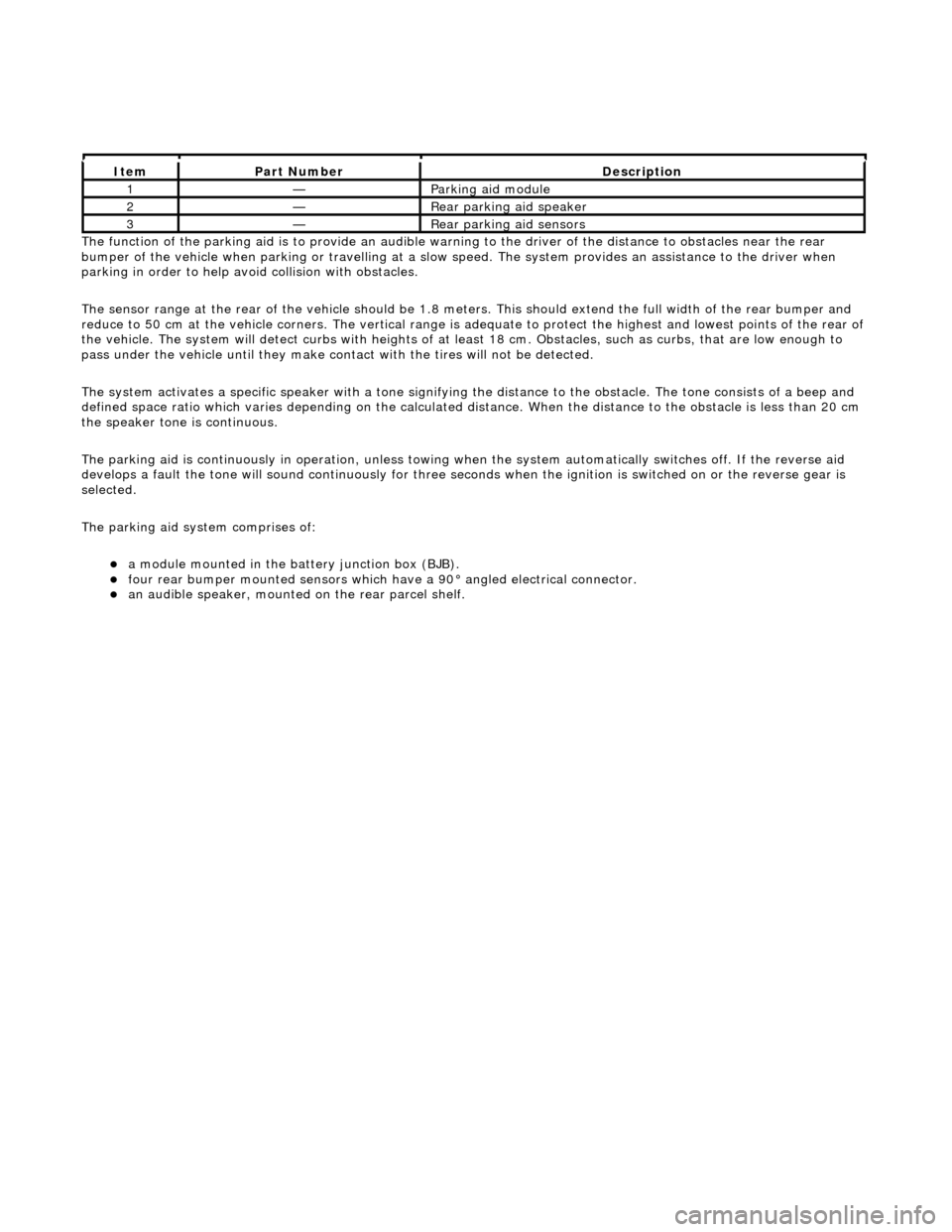

The functi

on of the parking aid is to prov

ide an audible warning to the driver of the distance to obstacles near the rear

bumper of the vehicle when parking or travelling at a slow sp eed. The system provides an assistance to the driver when

parking in order to help avoid collision with obstacles.

The sensor range at the rear of the vehicl e should be 1.8 meters. This should extend the full width of the rear bumper and

reduce to 50 cm at the vehicle co rners. The vertical range is adequate to protec t the highest and lowest points of the rear of

the vehicle. The system will detect curbs with heights of at least 18 cm. Obstacles, such as curbs, that are low enough to

pass under the vehicle until they make contact with the tires will not be detected.

The system activates a specific speaker with a tone signifying the distance to the obstacle. The tone consists of a beep and

defined space ratio which varies depending on the calculated distance. When the distance to the obstacle is less than 20 cm

the speaker tone is continuous.

The parking aid is continuously in operation, unless towing wh en the system automatically switches off. If the reverse aid

develops a fault the tone will sound continuously for three seconds when the igni tion is switched on or the reverse gear is

selected.

The parking aid system comprises of:

a

module mounted in the batte

ry junction box (BJB).

fou

r rear bumper mounted sensors which have a 90° angled electrical connector.

an audible speaker, moun

ted on

the rear parcel shelf.

It

em

Par

t Number

De

scription

1—Parkin

g aid module

2—Rear

parking aid speaker

3—Rear

parking aid sensors