boot JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1022 of 2490

(ECT) se

nsor

Blocked part-load breather

(s

ervice action S474)

Injec

t

or leak

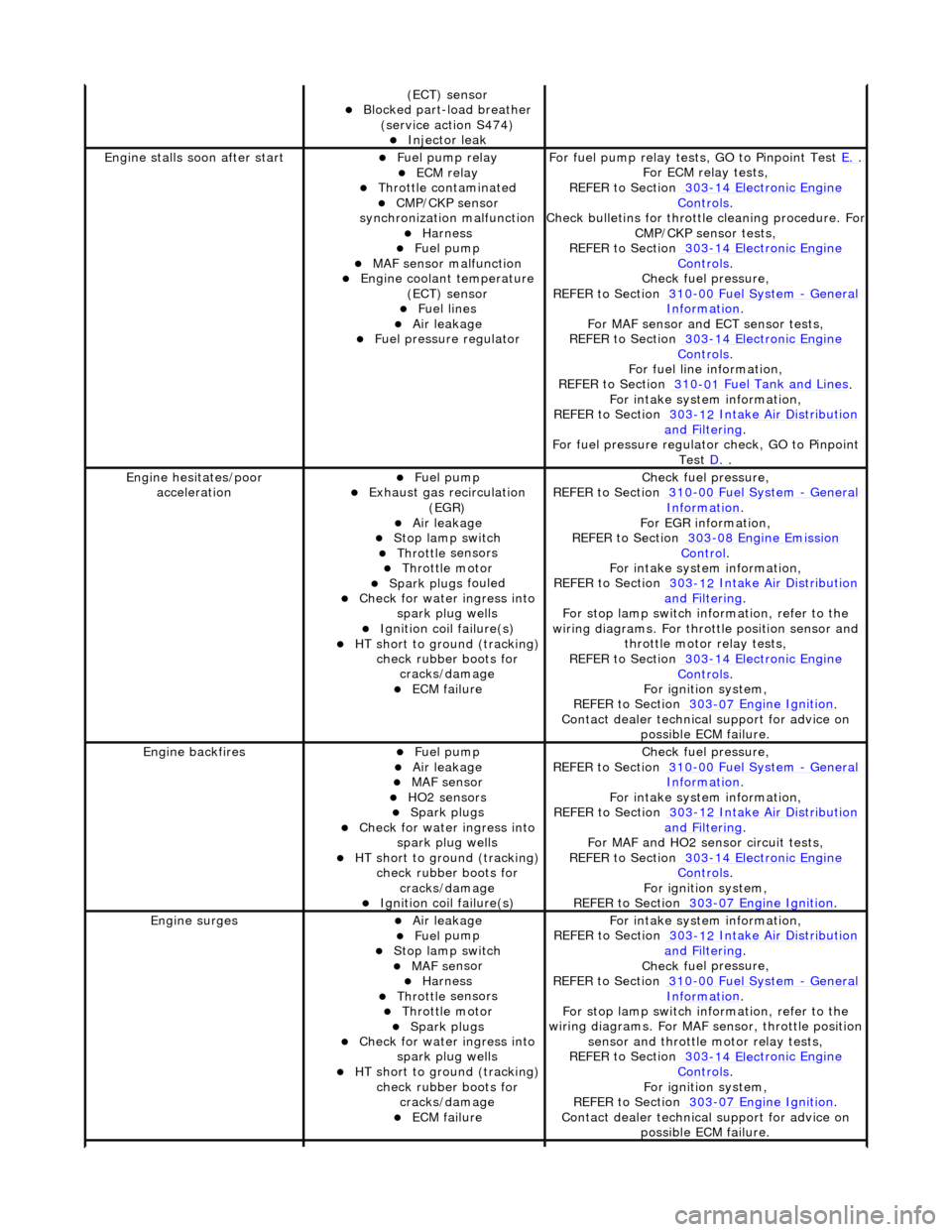

Engine stalls

soon

after start

F

u

el pump relay

ECM relay Thr

o

ttle contaminated

CMP/CKP sen

s

or

synchronization malfunction

Harness Fuel

pump

MAF

s

ensor malfunction

Engine coolan

t

temperature

(ECT) sensor

Fue l

lines

Air leakage Fu

el pressure regulator

F

o

r fuel pump relay tests,

GO to Pinpoint Test E.

.

F or ECM

relay tests,

REFER to Section 303

-14 Elec tronic En

gine

Controls.

Check bull etins for throttl

e cleaning procedure. For

CMP/CKP sensor tests,

REFER to Section 303

-14 Elec tronic En

gine

Controls.

Chec k fu

el pressure,

REFER to Section 310

-00 Fu

el System

- Ge

n

eral

Informati

o

n

.

F or MAF sensor and

ECT sensor tests,

REFER to Section 303

-14 Electronic En

gine

Controls.

For fuel l

ine information,

REFER to Section 310

-01

Fuel Tank and Lines

.

F or i

ntake system information,

REFER to Section 303

-1 2

Intake Air Distribution

and F

ilt

ering

.

F o

r fuel pressure regulato

r check, GO to Pinpoint

Test D.

.

Engine h e

sitates/poor

acceleration

Fue l

pump

Exhaus

t gas

recirculation

(EGR)

Air leakage Stop lamp swi t

ch

Throttl

e

sensors

Throttl

e

motor

Spark plugs

fouled

Check f

o

r water ingress into

spark plug wells

Ignition coil fail

ure(s)

HT sho

rt to ground (tracking)

check rubber

boots for

cracks/damage

ECM failu r

e

Chec

k fu

el pressure,

REFER to Section 310

-00 Fu

el System

- Ge

n

eral

Informati

o

n

.

F o

r EGR information,

REFER to Section 303

-08 En gin

e Emission

Control.

F or i

ntake system information,

REFER to Section 303

-1 2

Intake Air Distribution

and F

ilt

ering

.

F or stop l

amp switch in

formation, refer to the

wiring diagrams. For throttle position sensor and throttle motor relay tests,

REFER to Section 303

-14 Elec tronic En

gine

Controls.

For ign i

tion system,

REFER to Section 303

-07 En

gine Ignition

.

Contact dealer techn i

cal

support for advice on

possible ECM failure.

Engine ba ckfiresFuel

pump

Air leakage MAF s

e

nsor

HO2 sensors Spark plugs

Check fo

r water ingress into

spark plug wells

HT short to ground (tracking) check rubber

boots for

cracks/damage

Ignition coil fail

ure(s)

Chec

k fu

el pressure,

REFER to Section 310

-00 Fu

el System

- Ge

n

eral

Informati

o

n

.

F or i

ntake system information,

REFER to Section 303

-1 2

Intake Air Distribution

and F

ilt

ering

.

For MAF and HO2

sensor circuit tests,

REFER to Section 303

-14 Electronic En

gine

Controls.

For igni

tion system,

REFER to Section 303

-07 En

gine Ignition

.

Engine

s

urges

Air leakage Fue

l

pump

Stop lamp swi

t

ch

MAF s

e

nsor

Harness Throttl

e

sensors

Throttl

e

motor

Spark plugs

Check fo

r water ingress into

spark plug wells

HT sho rt to ground (tracking)

check rubber

boots for

cracks/damage

ECM failu r

e

F

or i

ntake system information,

REFER to Section 303

-1 2

Intake Air Distribution

and F

ilt

ering

.

Chec k fu

el pressure,

REFER to Section 310

-00 Fu

el System

- Gen

e

ral

Informati

o

n

.

F or stop l

amp switch in

formation, refer to the

wiring diagrams. For MAF se nsor, throttle position

sensor and throttle motor relay tests,

REFER to Section 303

-14 Elec tronic En

gine

Controls.

For ign i

tion system,

REFER to Section 303

-07 En

gine Ignition

.

Contact dealer techn i

cal

support for advice on

possible ECM failure.

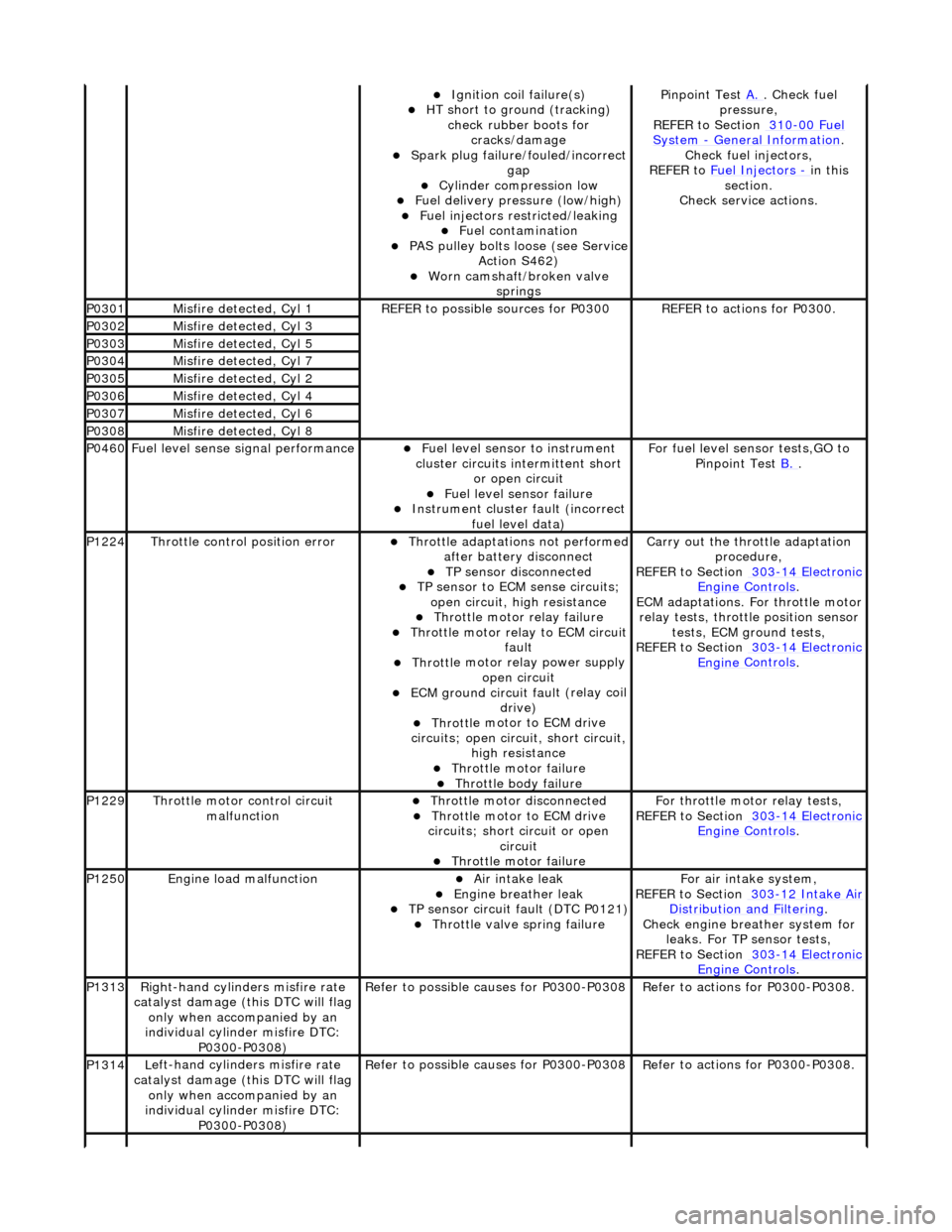

Page 1027 of 2490

Ignition coil

failure(s)

HT sho

rt to ground (tracking)

check rubber boots for cracks/damage

Spark plug

failure/fouled/incorrect

gap

Cy

linder compression low

F

uel delivery pressure (low/high)

F

uel injectors restricted/leaking

Fuel contamination

P

AS pulley bolts loose (see Service

Action S462)

W

orn camshaft/broken valve

springs

P

inpoint Test

A.

.

Check fuel

pressure,

REFER to Section 310

-00

Fuel

Sy

stem

- General

Information

.

Chec

k fuel injectors,

REFER to Fuel Injectors

- in t

his

section.

Check service actions.

P0301Misfire

detected, Cyl 1

R

EFER to possible sources for P0300

R

EFER to actions for P0300.

P0302Misfire

detected, Cyl 3

P0303Misfire

detected, Cyl 5

P0304Misfire

detected, Cyl 7

P0305Misfire

detected, Cyl 2

P0306Misfire

detected, Cyl 4

P0307Misfire

detected, Cyl 6

P0308Misfire

detected, Cyl 8

P0460F

uel level sense signal performance

Fue

l level sensor

to instrument

cluster circuits in termittent short

or open circuit

F

uel level sensor failure

Instrument cluster

faul

t (incorrect

fuel level data)

F

or fuel level sensor tests,GO to

Pinpoint Test B.

.

P1224Throttl

e control position error

Thro

ttle adaptations not performed

after battery disconnect

TP se

nsor disconnected

TP se

nsor to ECM sense circuits;

open circuit, hi gh resistance

Throttl

e motor relay failure

Th

rottle motor relay to ECM circuit

fault

Throttl

e motor relay power supply

open circuit

ECM ground circuit faul

t (relay coil

drive)

Throttl

e motor to ECM drive

circuits; open circuit, short circuit, high resistance

Throttl

e motor failure

Throttl

e body failure

Carry

out the throttle adaptation

procedure,

REFER to Section 303

-14

Electronic

Engine

Controls

.

ECM adaptations. For

throttle motor

relay tests, throttle position sensor tests, ECM ground tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

P1229Throttl

e motor control circuit

malfunction

Throttl

e motor disconnected

Throttl

e motor to ECM drive

circuits; short circuit or open circuit

Throttl

e motor failure

Fo

r throttle moto

r relay tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

P1250Engine

load malfunction

Air

intake leak

Engine

breather leak

TP se

nsor circuit fault (DTC P0121)

Throttl

e valve spring failure

F

or air intake system,

REFER to Section 303

-12

Intake Air

Distribu

tion and Filtering

.

Chec

k engine breather system for

leaks. For TP sensor tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

P1313Right-hand cylinders misfire rate

cat

alyst damage (this DTC will flag

only when accompanied by an

individual cylinder misfire DTC: P0300-P0308)

R

efer to possible causes for P0300-P0308

R

efer to actions for P0300-P0308.

P1314L

eft-hand cylinders misfire rate

catalyst damage (this DTC will flag only when accompanied by an

individual cylinder misfire DTC: P0300-P0308)

R

efer to possible causes for P0300-P0308

R

efer to actions for P0300-P0308.

Page 1070 of 2490

Starting System - Starter Motor

Remo

val and Installation

Remov

a

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Disc

onnect the batt

ery ground cable.

Re

move the battery cover.

3. Place the vehicle on a ramp.

4. Working from below the vehicle, remove the power steering

rack for access. Refer to Operation 57.10.01.

5. Disc

onnect the starter motor main terminal.

1. Reposition the rubber b oot from the main terminal.

2. Remove the nut from the starter motor main terminal.

3. Disconnect the main cable from the terminal.

6. Di

sconnect the starter motor solenoid terminal.

1. Reposition the rubber boot from the terminal.

2. Remove the nut from the solenoid terminal.

3. Disconnect the cable from the terminal.

7. Remove the starter mo tor securing bolts.

1. Remove the upper securing bolt. Preferably, use a short 13 mm spanner or a Snap On Half Moon

spanner CMX1113 to initially loosen the bolt. (Refer

to the next step).

2. Remove the lower securing bolt.

3. Carefully remove the starter motor.

Page 1078 of 2490

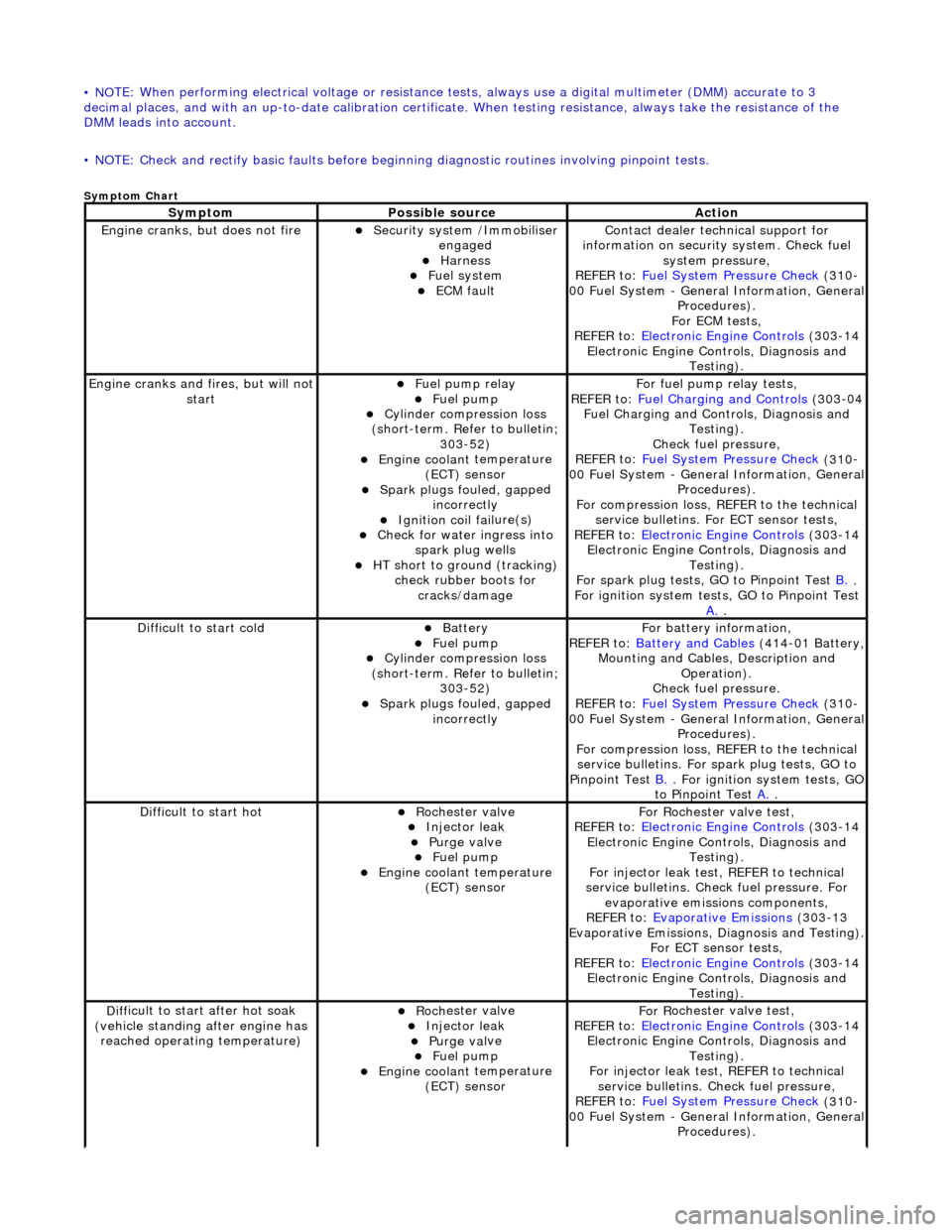

• NO

TE: When performing electrical voltag

e or resistance tests, always use a digital multimeter (DMM) accurate to 3

decimal places, and with an up-t o-date calibration certificate. When testing resistance, always take the resistance of the

DMM leads into account.

• NOTE: Check and rectify basic faults before beginning diagnostic ro utines involving pinpoint tests.

Sym

ptom Chart

Sy

m

ptom

Possib

l

e source

Acti

o

n

Engine

cranks, but does

not fire

Secu

rit

y system /Immobiliser

engaged

Harness Fue l

system

ECM fault

Contact deal er techni

cal support for

information on security system. Check fuel

system pressure,

REFER to: Fuel System Pressure Check

(310

-

00 Fuel System - Genera l Information, General

Procedures).

For ECM tests,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

Engine cranks and

fi

res, but will not

start

Fu

el pump relay

Fuel

pump

Cyl

i

nder compression loss

(short-term. Refer to bulletin; 303-52)

Engine coolan t

temperature

(ECT) sensor

Spark plugs fouled, gapp

ed

incorrectly

Ignition coil fail

ure(s)

Check f

o

r water ingress into

spark plug wells

HT sho rt to ground (tracking)

check rubber

boots for

cracks/damage

Fo

r fuel pump relay tests,

REFER to: Fuel Charging and Controls

(303

-04

Fuel Charging and Controls, Diagnosis and Testing).

Check fuel pressure,

REFER to: Fuel System Pressure Check

(310

-

00 Fuel System - Genera l Information, General

Procedures).

For compression loss, REFER to the technical service bulletins. For ECT sensor tests,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

For spark plug tests, GO to Pinpoint Test B.

.

For ign i

tion system tests, GO to Pinpoint Test

A.

.

Diff

icult to start cold

Batt

ery Fuel

pump

Cyl

i

nder compression loss

(short-term. Refer to bulletin; 303-52)

Spark plugs fouled, gapp

ed

incorrectly

F o

r battery information,

REFER to: Battery and Cables

(414

-01 Battery,

Mounting and Cables, Description and Operation).

Check fuel pressure.

REFER to: Fuel System Pressure Check

(310

-

00 Fuel System - Genera l Information, General

Procedures).

For compression loss, REFER to the technical service bulletins. For spark plug tests, GO to

Pinpoint Test B.

. For ig

nition system tests, GO

to Pinpoint Test A.

.

Diff

icult to start hot

Roc

h

ester valve

Injec

t

or leak

Purge

val

ve

Fue

l

pump

Engine coolan

t

temperature

(ECT) sensor

F or R

ochester

valve test,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

For injector leak test, REFER to technical

service bulletins. Check fuel pressure. For evaporative emissions components,

REFER to: Evaporative Emissions

(303

-13

Evaporative Emissions, Diagnosis and Testing).

For ECT sensor tests,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

D iff

icult to start after hot soak

(vehicle standing after engine has reached operating temperature)

Roc h

ester valve

Injec

t

or leak

Purge

val

ve

Fue

l

pump

Engine coolan

t

temperature

(ECT) sensor

F or R

ochester

valve test,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

For injector leak test, REFER to technical service bulletins. Check fuel pressure,

REFER to: Fuel System Pressure Check

(310

-

00 Fuel System - Genera l Information, General

Procedures).

Page 1079 of 2490

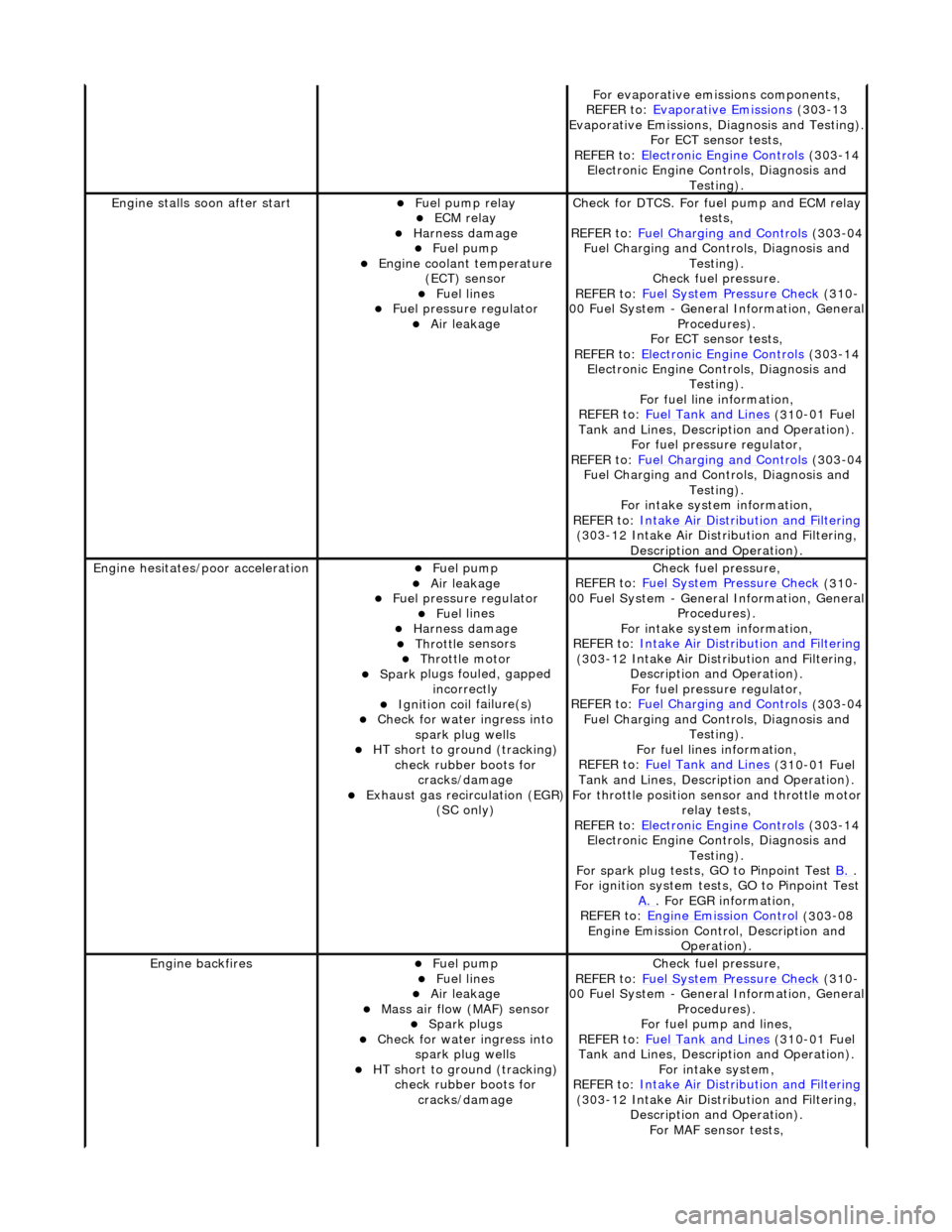

F

or evaporative emissions components,

REFER to: Evaporative Emissions

(30

3-13

Evaporative Emissions, Diagnosis and Testing).

For ECT sensor tests,

REFER to: Electronic Engine Controls

(30

3-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

Engine stalls

soon after start

F

uel pump relay

ECM relay

Harness damage Fue

l pump

Engine coolan

t temperature

(ECT) sensor

Fue

l lines

F

uel pressure regulator

Air leakage

Check f

or DTCS. For fuel pump and ECM relay

tests,

REFER to: Fuel Charging and Controls

(30

3-04

Fuel Charging and Controls, Diagnosis and Testing).

Check fuel pressure.

REFER to: Fuel System Pressure Check

(31

0-

00 Fuel System - Genera l Information, General

Procedures).

For ECT sensor tests,

REFER to: Electronic Engine Controls

(30

3-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

For fuel line information,

REFER to: Fuel Tank and Lines

(31

0-01 Fuel

Tank and Lines, Description and Operation).

For fuel pressure regulator,

REFER to: Fuel Charging and Controls

(30

3-04

Fuel Charging and Controls, Diagnosis and Testing).

For intake system information,

REFER to: Intake Air Distribution and Filtering

(30

3-12 Intake Air Distribution and Filtering,

Description and Operation).

Engine hesi

tates/poor acceleration

Fue

l pump

Air leakage

F

uel pressure regulator

Fue

l lines

Harness damage Throttl

e sensors

Throttl

e motor

Spark

plugs fouled, gapped

incorrectly

Ignition coil

failure(s)

Check f

or water ingress into

spark plug wells

HT sho

rt to ground (tracking)

check rubber boots for cracks/damage

Exhaus

t gas recirculation (EGR)

(SC only)

Chec

k fuel pressure,

REFER to: Fuel System Pressure Check

(31

0-

00 Fuel System - Genera l Information, General

Procedures).

For intake system information,

REFER to: Intake Air Distribution and Filtering

(30

3-12 Intake Air Distribution and Filtering,

Description and Operation). For fuel pressure regulator,

REFER to: Fuel Charging and Controls

(30

3-04

Fuel Charging and Controls, Diagnosis and Testing).

For fuel lines information,

REFER to: Fuel Tank and Lines

(31

0-01 Fuel

Tank and Lines, Description and Operation).

For throttle position se nsor and throttle motor

relay tests,

REFER to: Electronic Engine Controls

(30

3-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

For spark plug tests, GO to Pinpoint Test B.

.

For ign

ition system tests, GO to Pinpoint Test

A.

. F

or EGR information,

REFER to: Engine Emission Control

(30

3-08

Engine Emission Cont rol, Description and

Operation).

Engine ba

ckfires

Fue

l pump

Fue

l lines

Air leakage

Mass ai

r flow (MAF) sensor

Spark plugs

Check f

or water ingress into

spark plug wells

HT sho

rt to ground (tracking)

check rubber boots for cracks/damage

Chec

k fuel pressure,

REFER to: Fuel System Pressure Check

(31

0-

00 Fuel System - Genera l Information, General

Procedures).

For fuel pump and lines,

REFER to: Fuel Tank and Lines

(31

0-01 Fuel

Tank and Lines, Description and Operation).

For intake system,

REFER to: Intake Air Distribution and Filtering

(30

3-12 Intake Air Distribution and Filtering,

Description and Operation). For MAF sensor tests,

Page 1080 of 2490

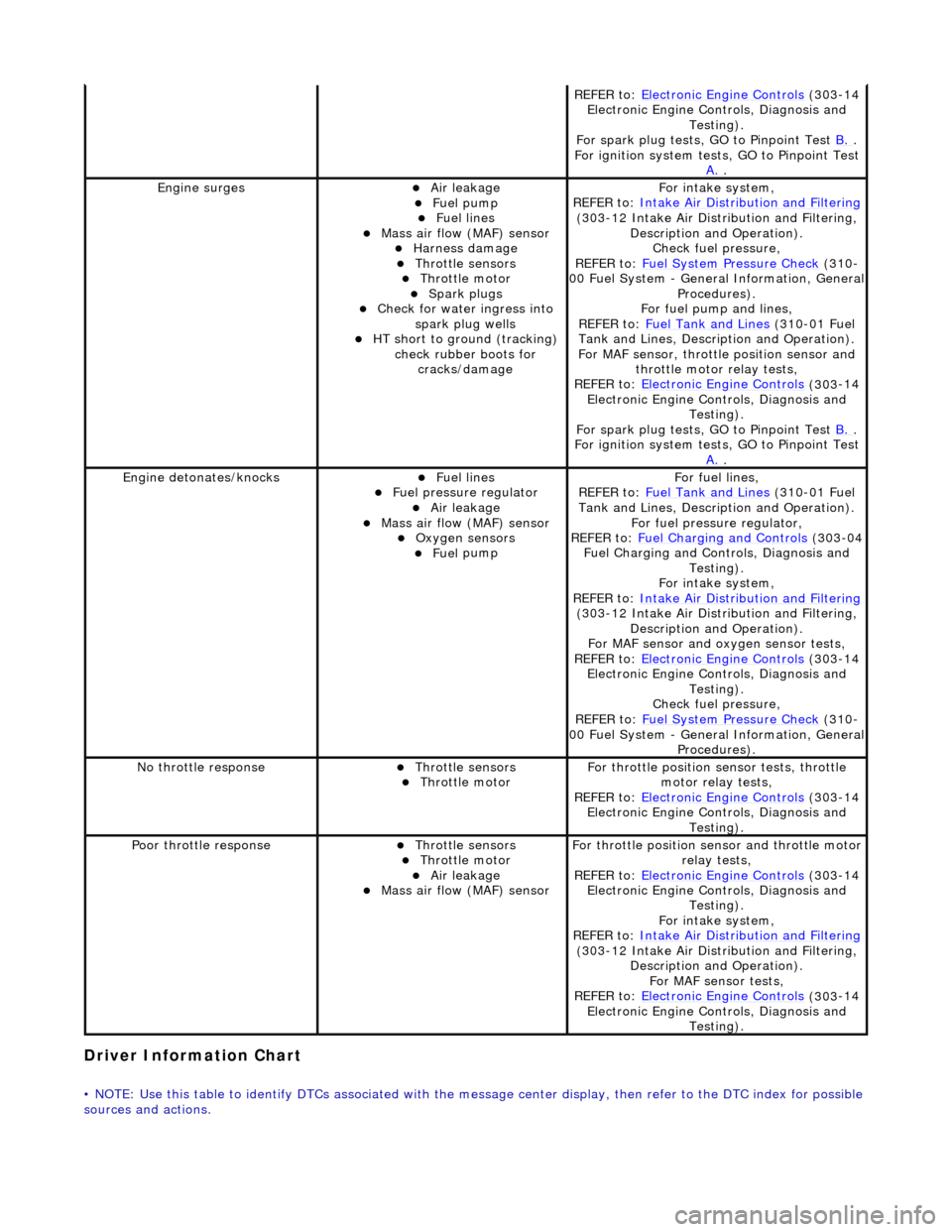

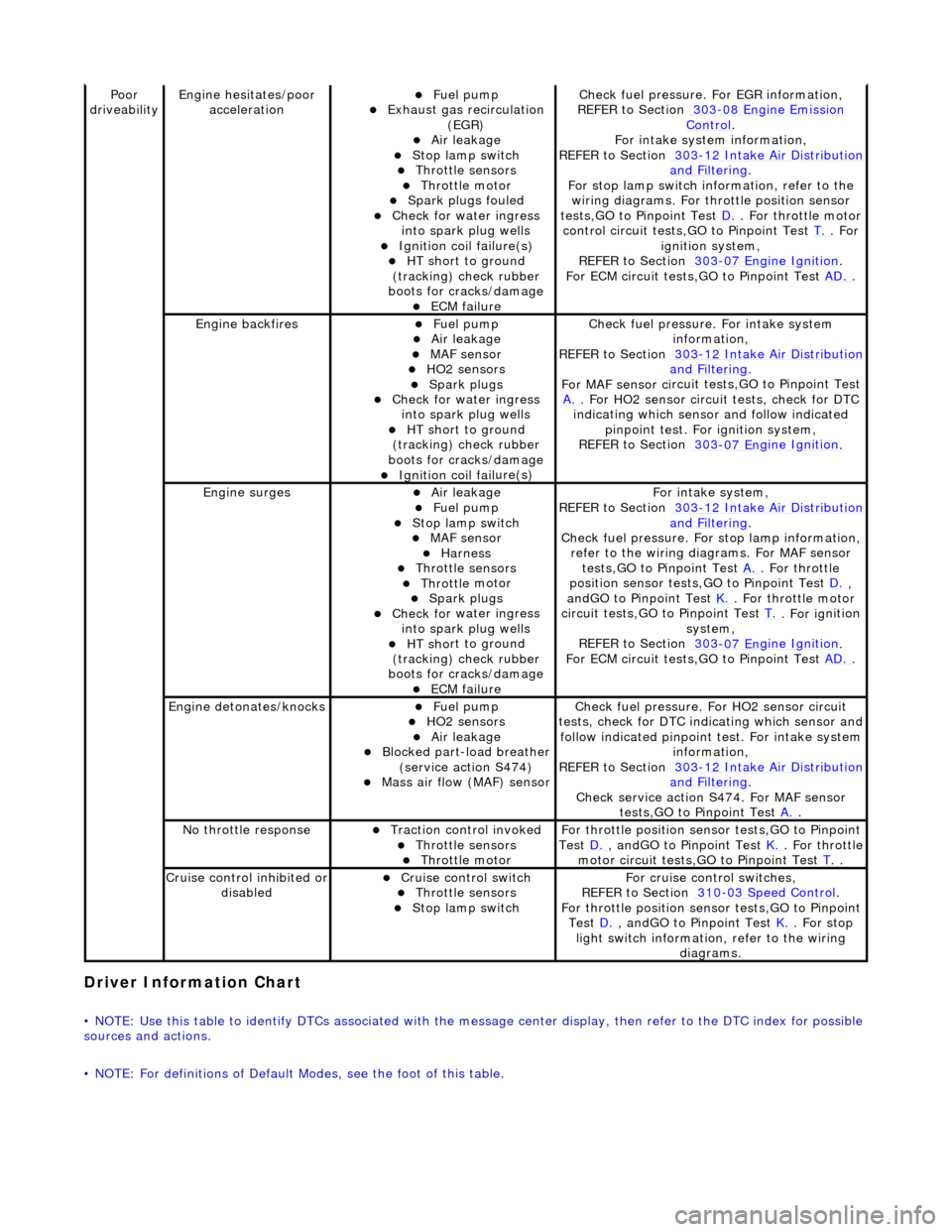

Driver Information

Chart

•

NOTE: Use this table to identify DTCs associated with the me

ssage center display, then refer to the DTC index for possible

sources and actions.

REF E

R to:

Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

For spark plug tests, GO to Pinpoint Test B.

.

For ign i

tion system tests, GO to Pinpoint Test

A.

.

Engine s

urges

Air leakage

Fue

l

pump

Fue

l

lines

Mass ai

r fl

ow (MAF) sensor

Harness damage Throttl

e

sensors

Throttl

e

motor

Spark plugs

Check fo

r water ingress into

spark plug wells

HT short to ground (tracking) check rubber

boots for

cracks/damage

Fo r

intake system,

REFER to: Intake Air Distribution and Filtering

(30 3

-12 Intake Air Distribution and Filtering,

Description and Operation). Check fuel pressure,

REFER to: Fuel System Pressure Check

(310

-

00 Fuel System - Genera l Information, General

Procedures).

For fuel pump and lines,

REFER to: Fuel Tank and Lines

(310

-01 Fuel

Tank and Lines, Description and Operation).

For MAF sensor, throttle position sensor and

throttle motor relay tests,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

For spark plug tests, GO to Pinpoint Test B.

.

For ign i

tion system tests, GO to Pinpoint Test

A.

.

Engine detonates/k

nocks

Fue

l

lines

F

u

el pressure regulator

Air leakage

Mass air fl

ow (MAF) sensor

O

xygen senso

rs

Fue

l

pump

F

o

r fuel lines,

REFER to: Fuel Tank and Lines

(310

-01 Fuel

Tank and Lines, Description and Operation).

For fuel pressure regulator,

REFER to: Fuel Charging and Controls

(303

-04

Fuel Charging and Controls, Diagnosis and Testing).

For intake system,

REFER to: Intake Air Distribution and Filtering

(30 3

-12 Intake Air Distribution and Filtering,

Description and Operation).

For MAF sensor and oxyg en sensor tests,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

Check fuel pressure,

REFER to: Fuel System Pressure Check

(310

-

00 Fuel System - Genera l Information, General

Procedures).

No t

hrottle response

Throttl

e

sensors

Throttl

e

motor

Fo

r th

rottle position sensor tests, throttle

motor relay tests,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

Poor throttle responseThrottl e

sensors

Throttl

e

motor

Air leakage Mass air fl

ow (MAF) sensor

F

or throttl

e position se

nsor and throttle motor

relay tests,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

For intake system,

REFER to: Intake Air Distribution and Filtering

(30 3

-12 Intake Air Distribution and Filtering,

Description and Operation). For MAF sensor tests,

REFER to: Electronic Engine Controls

(303

-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

Page 1083 of 2490

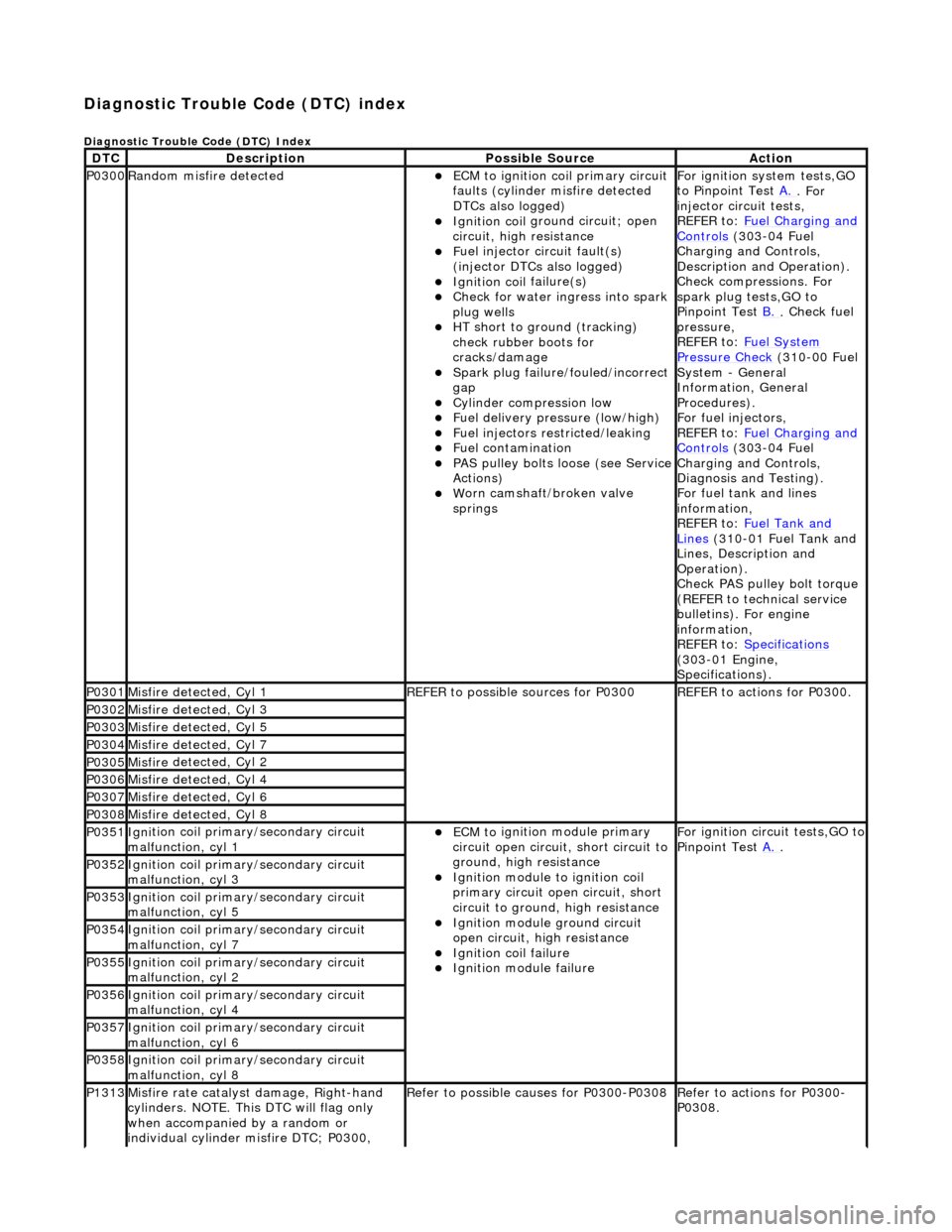

Diagnostic Trouble Code (D

TC) index

D

iagnostic Trouble Code (DTC) Index

DT

C

De

scription

Possib

le Source

Acti

on

P0300Ran

dom misfire detected

ECM t

o ignition coil primary circuit

faults (cylinder misfire detected

DTCs also logged)

Ignition coil

ground circuit; open

circuit, high resistance

F

uel injector circuit fault(s)

(injector DTCs also logged)

Ignition coil

failure(s)

Check f

or water ingress into spark

plug wells

HT sho

rt to ground (tracking)

check rubber boots for

cracks/damage

Spark plug

failure/fouled/incorrect

gap

Cy

linder compression low

F

uel delivery pressure (low/high)

F

uel injectors restricted/leaking

Fuel contamination

P

AS pulley bolts loose (see Service

Actions)

W

orn camshaft/broken valve

springs

For ign

ition system tests,GO

to Pinpoint Test A.

. For

inje

ctor circuit tests,

REFER to: Fuel Charging and

Controls (30

3-04 Fuel

Charging and Controls,

Description and Operation).

Check compressions. For

spark plug tests,GO to

Pinpoint Test B.

.

Check fuel

pressure,

REFER to: Fuel System

Pressure Check (31

0-00 Fuel

System - General

Information, General

Procedures).

For fuel injectors,

REFER to: Fuel Charging and

Controls (30

3-04 Fuel

Charging and Controls,

Diagnosis and Testing).

For fuel tank and lines

information,

REFER to: Fuel Tank and

Lin

es

(310-01 Fuel Tank and

Lines, Description and

Operation).

Check PAS pulley bolt torque

(REFER to technical service

bulletins). For engine

information,

REFER to: Specifications

(3

03-01 Engine,

Specifications).

P0301Misfire

detected, Cyl 1

R

EFER to possible sources for P0300

R

EFER to actions for P0300.

P0302Misfire

detected, Cyl 3

P0303Misfire

detected, Cyl 5

P0304Misfire

detected, Cyl 7

P0305Misfire

detected, Cyl 2

P0306Misfire

detected, Cyl 4

P0307Misfire

detected, Cyl 6

P0308Misfire

detected, Cyl 8

P0351Igni

tion coil primary/secondary circuit

malfunction, cyl 1

ECM to

ignition module primary

circuit open circuit, short circuit to

ground, high resistance

Igni

tion module to ignition coil

primary circuit open circuit, short

circuit to ground, high resistance

Ignition modu

le ground circuit

open circuit, hi gh resistance

Ignition coil

failure

Ignition modul

e failure

F

or ignition circuit tests,GO to

Pinpoint Test A.

.

P0352Igni

tion coil primary/secondary circuit

malfunction, cyl 3

P0353Igni

tion coil primary/secondary circuit

malfunction, cyl 5

P0354Igni

tion coil primary/secondary circuit

malfunction, cyl 7

P0355Igni

tion coil primary/secondary circuit

malfunction, cyl 2

P0356Igni

tion coil primary/secondary circuit

malfunction, cyl 4

P0357Igni

tion coil primary/secondary circuit

malfunction, cyl 6

P0358Igni

tion coil primary/secondary circuit

malfunction, cyl 8

P1313Misfire rate

catalyst damage, Right-hand

cylinders. NOTE. This DTC will flag only

when accompanied by a random or

individual cylinder misfire DTC; P0300,

R

efer to possible causes for P0300-P0308

R

efer to actions for P0300-

P0308.

Page 1095 of 2490

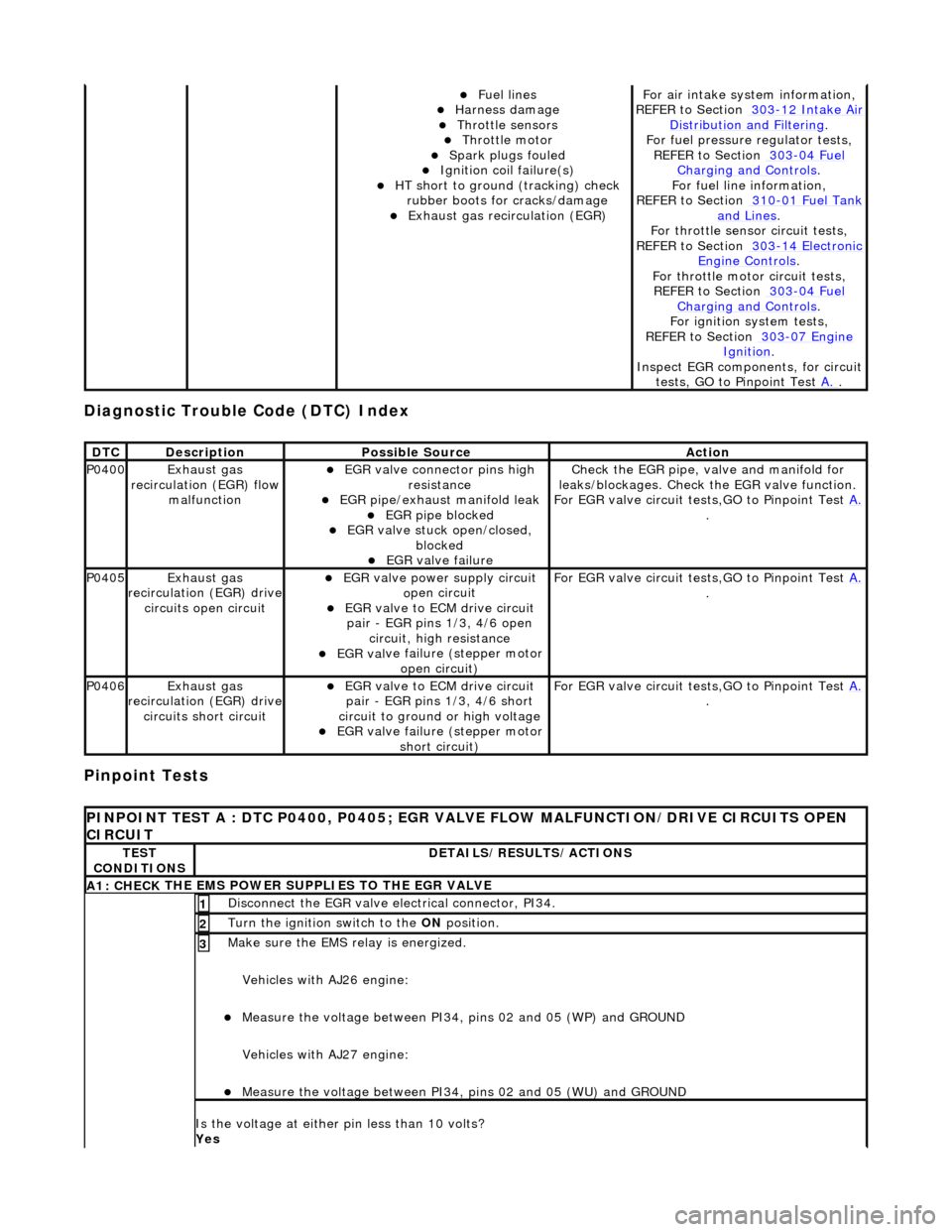

Diagnostic Trouble Code (D

TC) Index

Pinpoint Tests

Fue

l lines

Harness damage

Throttl

e sensors

Throttl

e motor

Spark plugs

fouled

Ignition coil

failure(s)

HT sho

rt to ground (tracking) check

rubber boots for cracks/damage

Exhaus

t gas recirculation (EGR)

F

or air intake syst

em information,

REFER to Section 303

-12

Intake Air

Distribu

tion and Filtering

.

F

or fuel pressure

regulator tests,

REF

ER to Section 303

-04

Fuel

Charging and Con

trols

.

F

or fuel line information,

REFER to Section 310

-01

Fuel Tank

and Lines.

F

or throttle sensor

circuit tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

Fo

r throttle motor

circuit tests,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

For ign

ition system tests,

REFER to Section 303

-07

Engine

Ignition.

Inspe

ct EGR components, for circuit

tests, GO to Pinpoint Test A.

.

DT

C

De

scription

Possib

le Source

Acti

on

P0400Exhaus

t gas

recirculation (EGR) flow malfunction

EGR

valve connector pins high

resistance

EGR pipe/exhaust manifold leak EGR pipe block

ed

EGR val

ve stuck open/closed,

blocked

EGR

valve failure

Check the EGR pi

pe, valve and manifold for

leaks/blockages. Check the EGR valve function.

For EGR valve circuit tests,GO to Pinpoint Test A.

.

P0405Exhaus

t gas

recirculation (EGR) drive

circuits open circuit

EGR valve power supply circuit o

pen circuit

EGR valve t

o ECM drive circuit

pair - EGR pins 1/3, 4/6 open circuit, high resistance

EGR val

ve failure (stepper motor

open circuit)

F

or EGR valve circuit tests,GO to Pinpoint Test

A.

.

P0406Exhaus

t gas

recirculation (EGR) drive

circuits short circuit

EGR valve t

o ECM drive circuit

pair - EGR pins 1/3, 4/6 short

circuit to ground or high voltage

EGR val

ve failure (stepper motor

short circuit)

F

or EGR valve circuit tests,GO to Pinpoint Test

A.

.

P

INPOINT TEST A : DTC P0400, P0405; EGR VALV

E FLOW MALFUNCTION/DRIVE CIRCUITS OPEN

CIRCUIT

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A1: CHECK

THE EMS POWER SU

PPLIES TO THE EGR VALVE

D

isconnect the EGR valve electrical connector, PI34.

1

Turn the ignition swi

tch to the ON

position.

2

Make sure the EMS re lay i

s energized.

Vehicles with AJ26 engine:

Me

asure the voltage between PI34, pins 02 and 05 (WP) and GROUND

Vehicles with AJ27 engine:

Me

asure the voltage between PI34, pins 02 and 05 (WU) and GROUND

3

Is th

e voltage at either pin less than 10 volts?

Yes

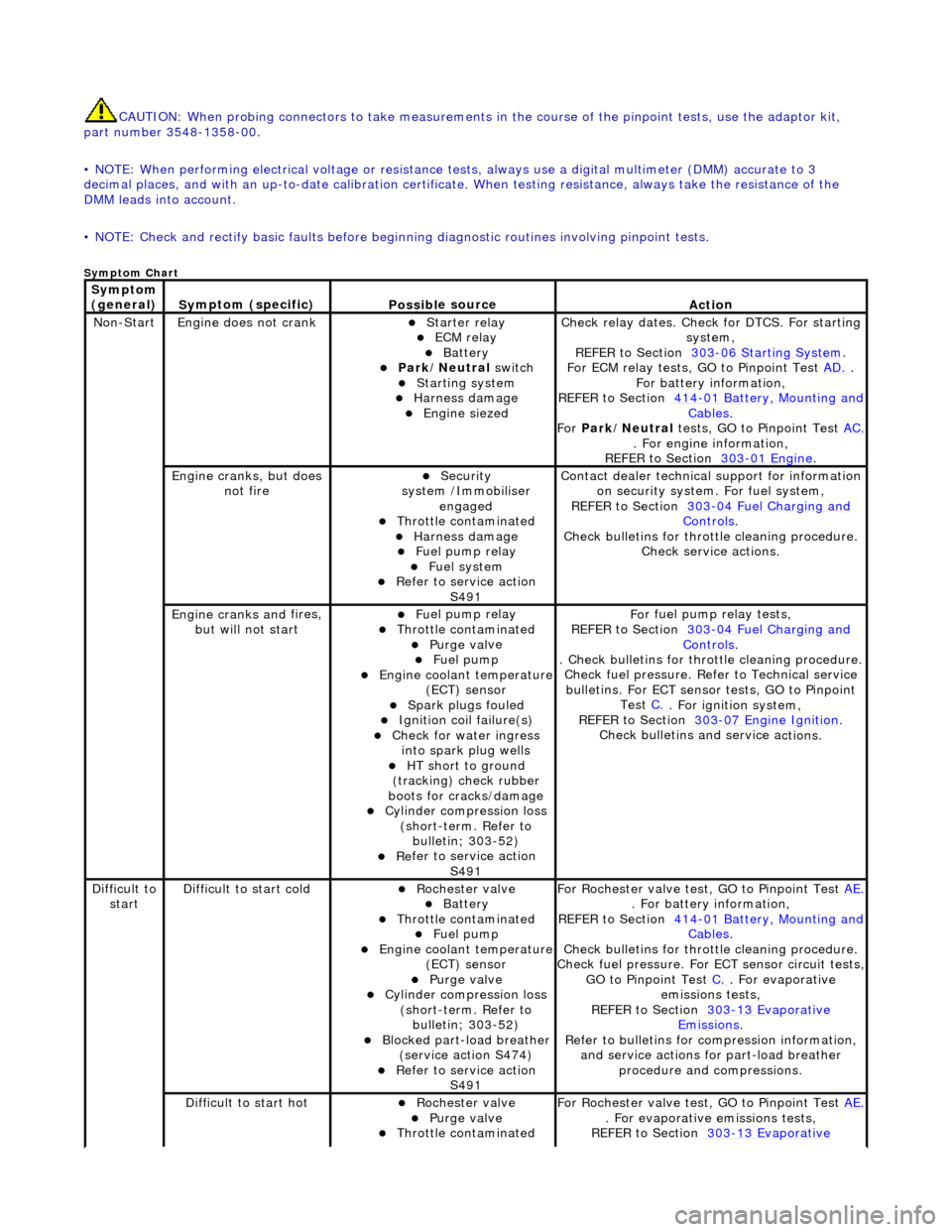

Page 1190 of 2490

CAUTIO

N: When probing connectors to take

measurements in the course of the pinpoint tests, use the adaptor kit,

part number 3548-1358-00.

• NOTE: When performing electrical voltag e or resistance tests, always use a digital multimeter (DMM) accurate to 3

decimal places, and with an up-t o-date calibration certificate. When testing resistance, always take the resistance of the

DMM leads into account.

• NOTE: Check and rectify basic faults before beginning diagnostic ro utines involving pinpoint tests.

Sym

ptom Chart

Sym

ptom

(general)

S y

mptom (specific)

Possib

l

e source

Acti

o

n

No

n

-Start

Engine

does not cran

k

Starter relay ECM relay Batt

ery Park

/Neutral

switch

Starting system

Harness damage

Engine s

iezed

Check r

e

lay dates. Check

for DTCS. For starting

system,

REFER to Section 303

-06 Sta r

ting System

.

F or ECM

relay tests, GO to Pinpoint Test

AD.

.

F o

r battery information,

REFER to Section 414

-0 1

Battery, Mounting and

Cables.

Fo r

Park/Neutral tests, GO to Pinpoint Test AC.

. Fo

r engine information,

REFER to Section 303

-01 En

gine

.

Engine cranks, but does

not fireSecurity

syst

em /Immobiliser

engaged

Thr o

ttle contaminated

Harness damage

Fu

el pump relay

Fue

l

system

R

e

fer to service action

S491

Contact dealer techni

cal

support for information

on security system. For fuel system,

REFER to Section 303

-0 4

Fuel Charging and

Controls.

Check bull etins for throttl

e cleaning procedure.

Check service actions.

Engine cranks an d

fires,

but will not start

F u

el pump relay

Thr

o

ttle contaminated

Purge

val

ve

Fue

l

pump

Engine coolan

t

temperature

(ECT) sensor

Spark plugs

fouled

Ignition coil

fail

ure(s)

Check f

o

r water ingress

into spark plug wells

HT sh o

rt to ground

(tracking) check rubber

boots for cracks/damage

Cyli

nder compression loss

(short-term. Refer to bulletin; 303-52)

Re

fer to service action

S491

Fo

r fuel pump relay tests,

REFER to Section 303

-0 4

Fuel Charging and

Controls.

. Check bulletins for throttl

e cleaning procedure.

Check fuel pressure. Refe r to Technical service

bulletins. For ECT sensor tests, GO to Pinpoint Test C.

. Fo

r ignition system,

REFER to Section 303

-07 En

gine Ignition

.

Check bulletins an d service a

ctions.

Di

f

ficult to

start

D iff

icult to start cold

Roc

h

ester valve

Batt

ery Thro

ttle contaminated

Fue

l

pump

Engine coolan

t

temperature

(ECT) sensor

Purge val

ve

Cyl

i

nder compression loss

(short-term. Refer to bulletin; 303-52)

Blocked part-load breather (s

ervice action S474)

R

e

fer to service action

S491

For R

ochester valv

e test, GO to Pinpoint Test AE.

. Fo

r battery information,

REFER to Section 414

-0 1

Battery, Mounting and

Cables.

Check bull etins for throttl

e cleaning procedure.

Check fuel pressure. For ECT sensor circuit tests,

GO to Pinpoint Test C.

. F

or evaporative

emissions tests,

REFER to Section 303

-1 3

Evaporative

Emiss

i

ons

.

R e

fer to bulletins for co

mpression information,

and service actions for part-load breather procedure and compressions.

Diff

icult to start hot

Roc

h

ester valve

Purge

val

ve

Thr

o

ttle contaminated

F

or R

ochester valv

e test, GO to Pinpoint Test AE.

. F

or evaporative emissions tests,

REFER to Section 303

-1 3

Evaporative

Page 1192 of 2490

Driver Information

Chart

•

NOTE: Use this table to identify DTCs associated with the me

ssage center display, then refer to the DTC index for possible

sources and actions.

• NOTE: For definitions of Default Modes, see the foot of this table.

Poor

dr iveabilityEngine h e

sitates/poor

acceleration

Fue l

pump

Exhaus

t gas

recirculation

(EGR)

Air leakage Stop lamp swi t

ch

Throttl

e

sensors

Throttl

e

motor

Spark

plugs

fouled

Check f

o

r water ingress

into spark plug wells

Ignition coil fail

ure(s)

HT sh

o

rt to ground

(tracking) check rubber

boots for cracks/damage

ECM failu r

e

Check f

u

el pressure. For EGR information,

REFER to Section 303

-08 En gin

e Emission

Control.

F or i

ntake system information,

REFER to Section 303

-1 2

Intake Air Distribution

and F

ilt

ering

.

F or stop l

amp switch in

formation, refer to the

wiring diagrams. For throttle position sensor

tests,GO to Pinpoint Test D.

. Fo

r throttle motor

control circuit tests,GO to Pinpoint Test T.

. For

igni t

ion system,

REFER to Section 303

-07 En

gine Ignition

.

F or ECM

circuit tests,GO to Pinpoint Test

AD.

.

Engine backfiresFuel

pump

Air leakage MAF se

nsor

HO2 sensors

Spark plugs Check fo

r water ingress

into spark plug wells

HT sh o

rt to ground

(tracking) check rubber

boots for cracks/damage

Ignition coil fail

ure(s)

Chec

k fu

el pressure. For intake system

information,

REFER to Section 303

-12

Intake Air Distribution

and Filt

ering

.

F or MAF sensor ci

rcuit test

s,GO to Pinpoint Test

A.

. F or HO2 sensor

circui

t tests, check for DTC

indicating which sensor and follow indicated pinpoint test. For ignition system,

REFER to Section 303

-07 En

gine Ignition

.

Engine

s

urges

Air leakage

Fuel

pump

Stop lamp swit

ch

MAF s

e

nsor

Harness Throttl

e

sensors

Throttl

e

motor

Spark plugs

Check fo

r water ingress

into spark plug wells

HT sh o

rt to ground

(tracking) check rubber

boots for cracks/damage

ECM failu r

e

Fo

r

intake system,

REFER to Section 303

-1 2

Intake Air Distribution

and Filt

ering

.

Check fu

el pressure. For

stop lamp information,

refer to the wiring diagrams. For MAF sensor tests,GO to Pinpoint Test A.

. Fo

r throttle

position sensor tests,GO to Pinpoint Test D.

,

a n

dGO to Pinpoint Test

K.

. Fo

r throttle motor

circuit tests,GO to Pinpoint Test T.

. For ig

nition

system,

REFER to Section 303

-07 En

gine Ignition

.

F or ECM

circuit tests,GO to Pinpoint Test

AD.

.

Engine detonates/k

nocks

Fue

l

pump

HO2 sensors

Air leakage Blocked part-load breather

(s

ervice action S474)

Mass ai

r fl

ow (MAF) sensor

Chec

k fu

el pressure. Fo

r HO2 sensor circuit

tests, check for DTC indicating which sensor and

follow indicated pinpoint test. For intake system

information,

REFER to Section 303

-1 2

Intake Air Distribution

and Filt

ering

.

Check service action S474

. For MAF sensor

tests,GO to Pinpoint Test A.

.

No t

hrottle response

Traction contr

o

l invoked

Throttl

e

sensors

Throttl

e

motor

Fo

r th

rottle position sensor tests,GO to Pinpoint

Test D.

, andG O to Pinpoint

Test

K.

. Fo

r throttle

motor circuit tests,GO to Pinpoint Test T.

.

Cru i

se control inhibited or

disabled

Cru i

se control switch

Throttle

sensors

Stop lamp swit

ch

For cru

i

se control switches,

REFER to Section 310

-03

Speed Control

.

For th

rottle position sensor tests,GO to Pinpoint

Test D.

, andG O to Pinpoint

Test

K.

. For s t

op

light switch information, refer to the wiring diagrams.