boot JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1199 of 2490

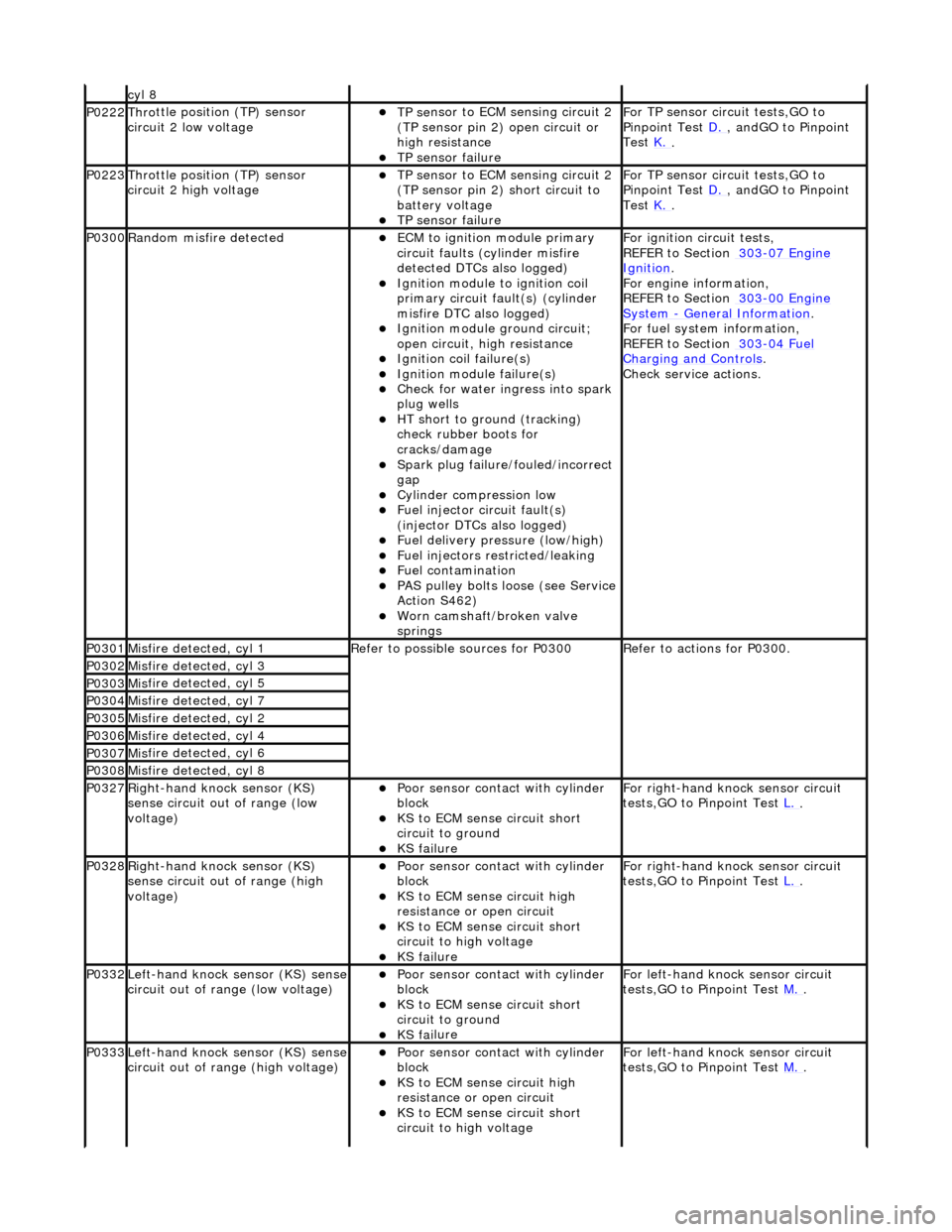

cyl 8

P0222Thro

ttle position (TP) sensor

circuit 2 low voltage

TP se

nsor to ECM sensing circuit 2

(TP sensor pin 2) open circuit or

high resistance

TP sensor

failure

F

or TP sensor circ

uit tests,GO to

Pinpoint Test D.

, andG

O to Pinpoint

Test K.

.

P0223Thro

ttle position (TP) sensor

circuit 2 high voltage

TP se

nsor to ECM sensing circuit 2

(TP sensor pin 2) short circuit to

battery voltage

TP sensor

failure

F

or TP sensor circ

uit tests,GO to

Pinpoint Test D.

, andG

O to Pinpoint

Test K.

.

P0300Ran

dom misfire detected

ECM to

ignition module primary

circuit faults (cylinder misfire

detected DTCs also logged)

Igni

tion module to ignition coil

primary circuit fault(s) (cylinder

misfire DTC also logged)

Ignition modu

le ground circuit;

open circuit, hi gh resistance

Ignition coil

failure(s)

Ignition modul

e failure(s)

Check f

or water ingress into spark

plug wells

HT sho

rt to ground (tracking)

check rubber boots for

cracks/damage

Spark plug

failure/fouled/incorrect

gap

Cy

linder compression low

F

uel injector circuit fault(s)

(injector DTCs also logged)

F

uel delivery pressure (low/high)

F

uel injectors restricted/leaking

Fuel contamination

P

AS pulley bolts loose (see Service

Action S462)

W

orn camshaft/broken valve

springs

F

or ignition circuit tests,

REFER to Section 303

-07

Engine

Ignition.

F

or engine information,

REFER to Section 303

-00

Engine

Sy

stem

- General

Information

.

F

or fuel system information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

Check service

actions.

P0301Mis

fire detected, cyl 1

R

efer to possible sources for P0300

R

efer to actions for P0300.

P0302Mis

fire detected, cyl 3

P0303Mis

fire detected, cyl 5

P0304Mis

fire detected, cyl 7

P0305Mis

fire detected, cyl 2

P0306Mis

fire detected, cyl 4

P0307Mis

fire detected, cyl 6

P0308Mis

fire detected, cyl 8

P0327Right

-hand knock sensor (KS)

sense circuit out of range (low

voltage)

Poor sensor cont

act with cylinder

block

KS to

ECM sense circuit short

circuit to ground

KS fai

lure

F

or right-hand knock sensor circuit

tests,GO to Pinpoint Test L.

.

P0328Right

-hand knock sensor (KS)

sense circuit out of range (high

voltage)

Poor sensor cont

act with cylinder

block

KS to EC

M sense circuit high

resistance or open circuit

KS to

ECM sense circuit short

circuit to high voltage

KS fai

lure

F

or right-hand knock sensor circuit

tests,GO to Pinpoint Test L.

.

P0332Left-hand knock sens

or (KS) sense

circuit out of range (low voltage)

Poor sensor cont

act with cylinder

block

KS to

ECM sense circuit short

circuit to ground

KS fai

lure

F

or left-hand knoc

k sensor circuit

tests,GO to Pinpoint Test M.

.

P0333Left-hand knock sens

or (KS) sense

circuit out of range (high voltage)

Poor sensor cont

act with cylinder

block

KS to EC

M sense circuit high

resistance or open circuit

KS to

ECM sense circuit short

circuit to high voltage

F

or left-hand knoc

k sensor circuit

tests,GO to Pinpoint Test M.

.

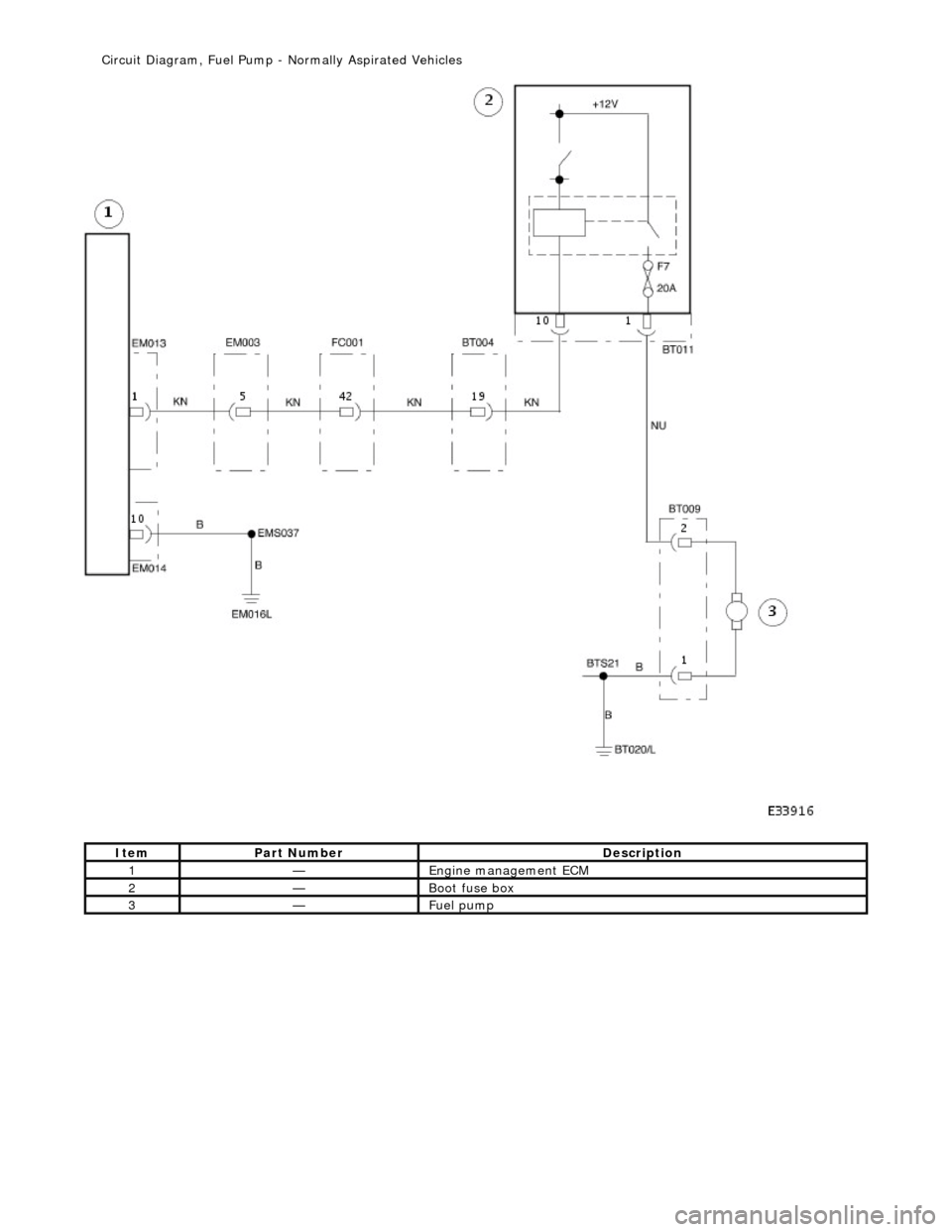

Page 1696 of 2490

Ite

m

Par

t

Number

De

scr

iption

1—Engine

m

anagement ECM

2—Boot fuse box

3—Fue

l

pump

Ci

rcui

t Diagram, Fuel Pump -

Normally Aspirated Vehicles

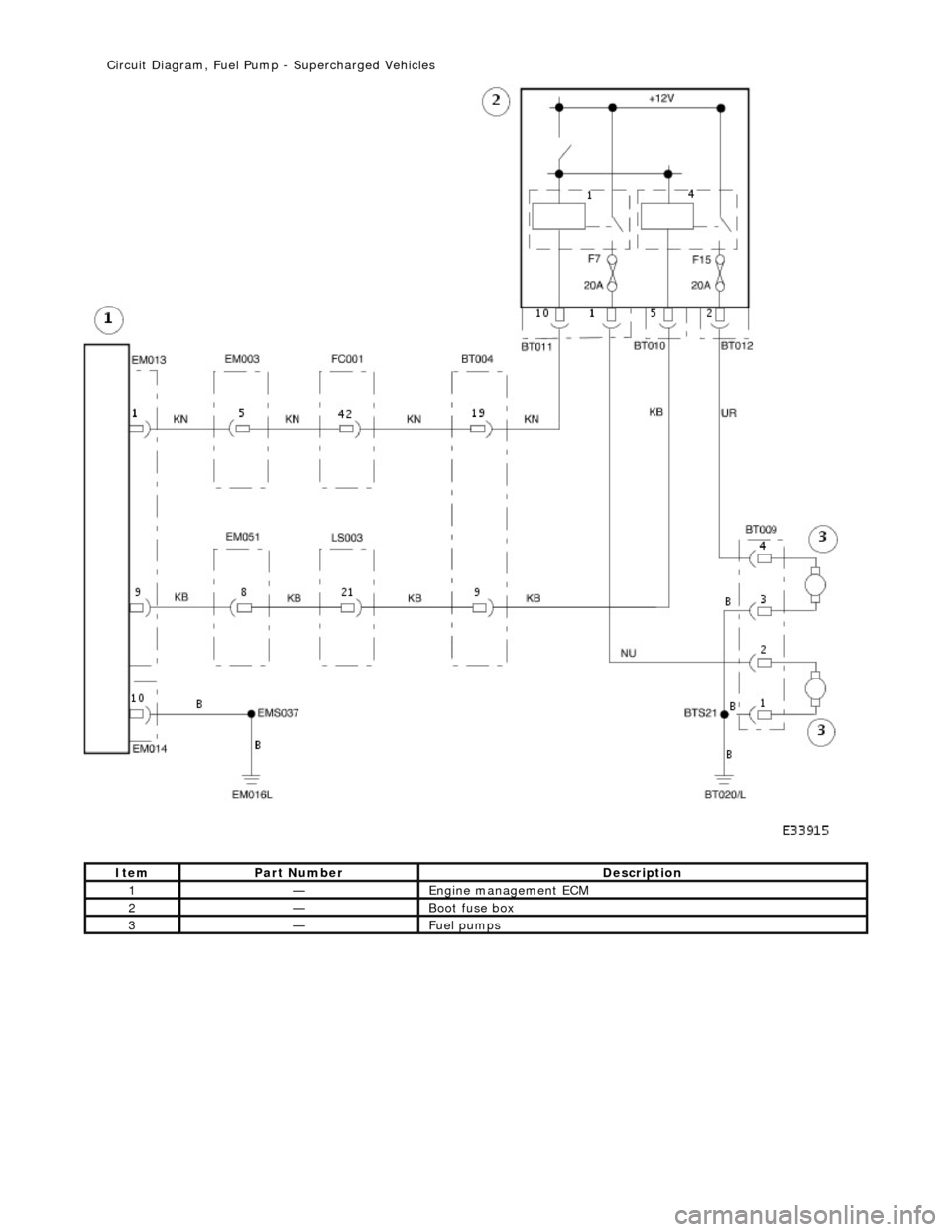

Page 1697 of 2490

It

em

Par

t Number

De

scription

1—Engine

management ECM

2—Boot fuse box

3—Fue

l pumps

Ci

rcuit Diagram, Fuel Pump

- Supercharged Vehicles

Page 1890 of 2490

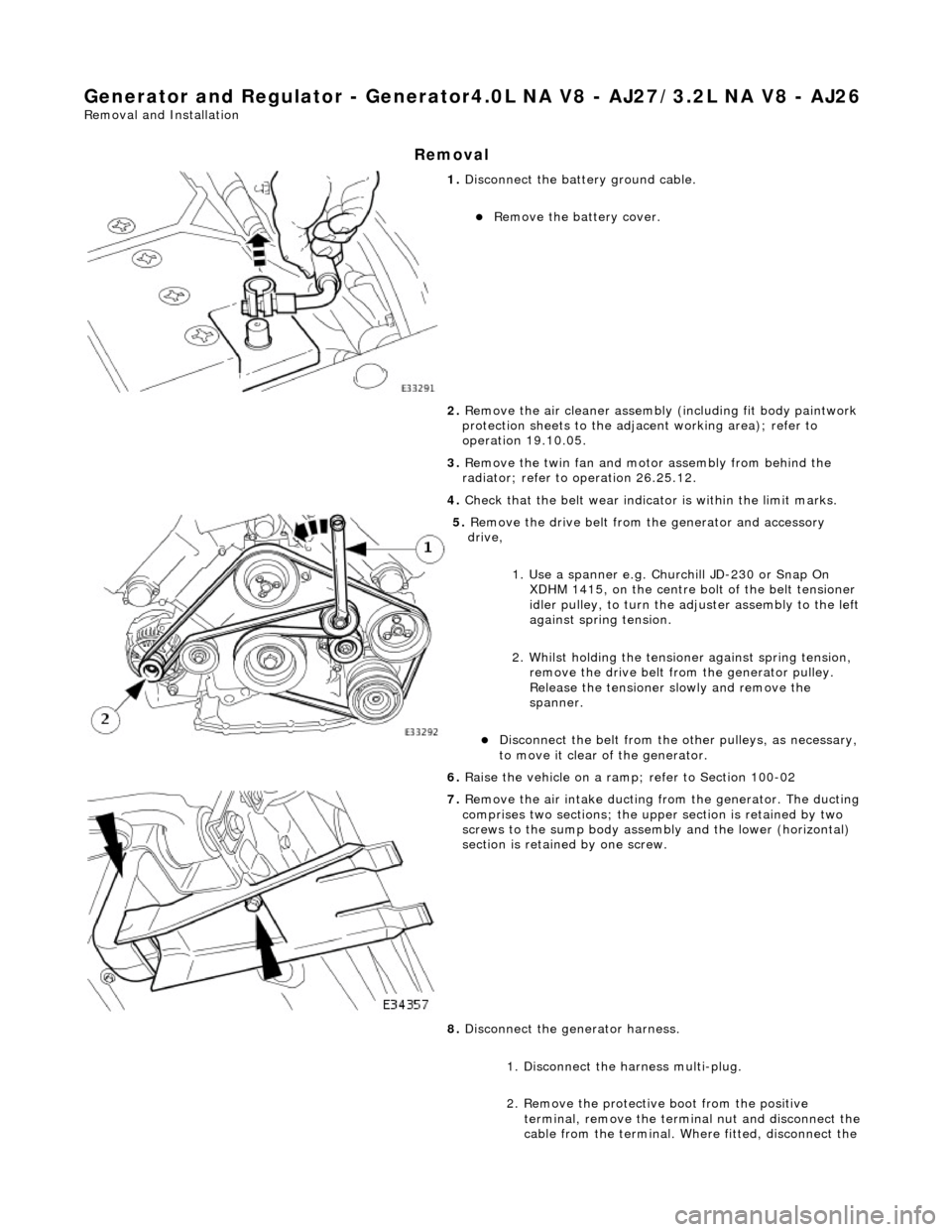

Generator and Regulator - Generator4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

Removal and Installation

Removal

1. Disconnect the batt ery ground cable.

Remove the battery cover.

2. Remove the air cleaner assembly (including fit body paintwork

protection sheets to the adja cent working area); refer to

operation 19.10.05.

3. Remove the twin fan and moto r assembly from behind the

radiator; refer to operation 26.25.12.

4. Check that the belt wear indicator is within the limit marks.

5. Remove the drive belt from the generator and accessory

drive,

1. Use a spanner e.g. Churchill JD-230 or Snap On XDHM 1415, on the centre bo lt of the belt tensioner

idler pulley, to turn the adju ster assembly to the left

against spring tension.

2. Whilst holding the tensioner against spring tension, remove the drive belt from the generator pulley.

Release the tensioner sl owly and remove the

spanner.

Disconnect the belt from the ot her pulleys, as necessary,

to move it clear of the generator.

6. Raise the vehicle on a ramp; refer to Section 100-02

7. Remove the air intake ducting fr om the generator. The ducting

comprises two sections; the upper section is retained by two

screws to the sump body assembly and the lower (horizontal)

section is retained by one screw.

8. Disconnect the generator harness.

1. Disconnect the harness multi-plug.

2. Remove the protective boot from the positive

terminal, remove the termin al nut and disconnect the

cable from the terminal. Where fitted, disconnect the

Page 1893 of 2490

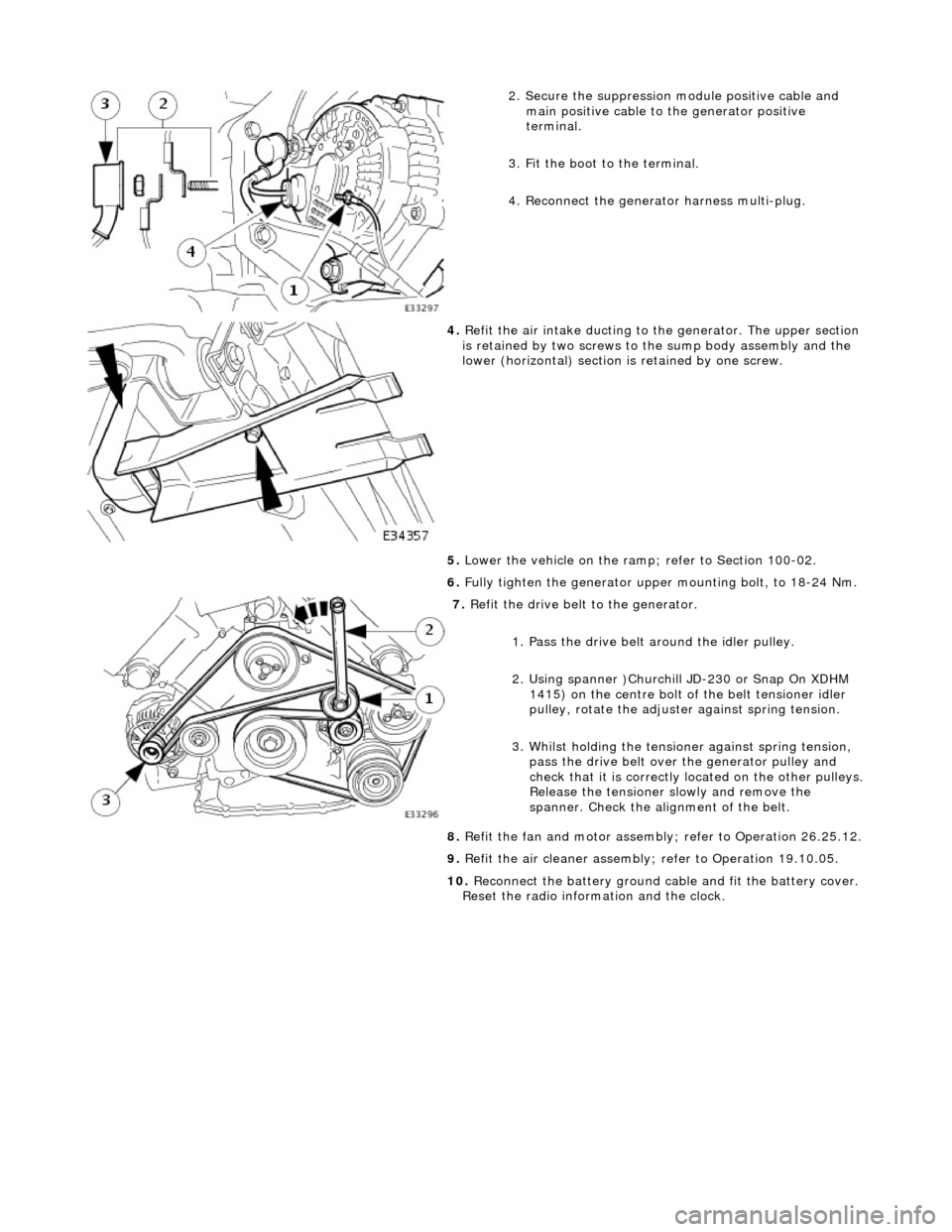

2. Secure the suppression module positive cable and

main positive cable to the generator positive

terminal.

3. Fit the boot to the terminal.

4. Reconnect the generator harness multi-plug.

4. Refit the air intake ducting to the generator. The upper section

is retained by two screws to the sump body assembly and the

lower (horizontal) section is retained by one screw.

5. Lower the vehicle on the ramp ; refer to Section 100-02.

6. Fully tighten the generator upper mounting bolt, to 18-24 Nm.

7. Refit the drive belt to the generator.

1. Pass the drive belt around the idler pulley.

2. Using spanner )Churchill JD-230 or Snap On XDHM 1415) on the centre bolt of the belt tensioner idler

pulley, rotate the adjuster against spring tension.

3. Whilst holding the tensioner against spring tension, pass the drive belt over the generator pulley and

check that it is correctly located on the other pulleys.

Release the tensioner slowly and remove the

spanner. Check the alignment of the belt.

8. Refit the fan and motor assembly ; refer to Operation 26.25.12.

9. Refit the air cleaner assembly; refer to Operation 19.10.05.

10. Reconnect the battery ground cable and fit the battery cover.

Reset the radio inform ation and the clock.

Page 1895 of 2490

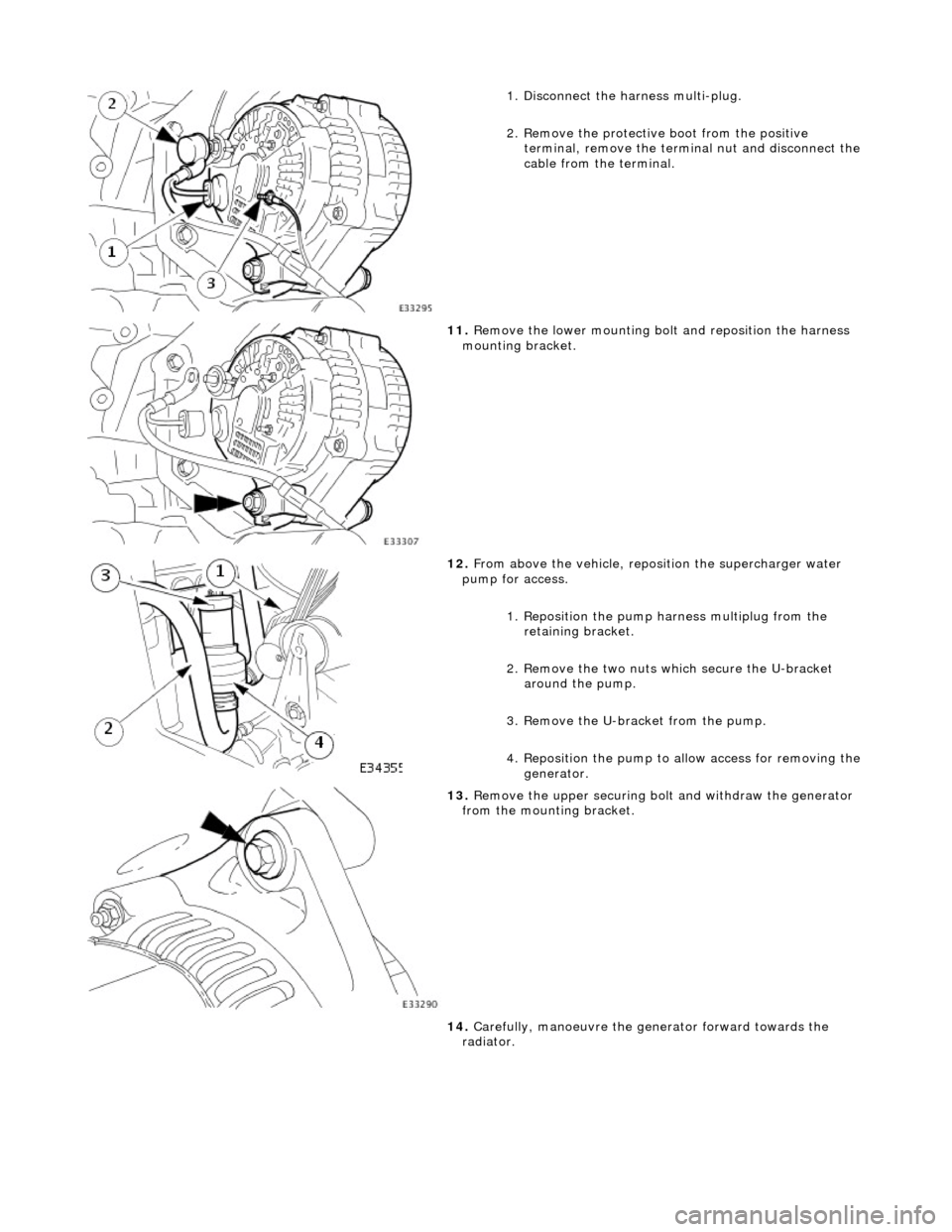

1. Disconnect the harness multi-plug.

2. Remove the protective boot from the positive

terminal, remove the termin al nut and disconnect the

cable from the terminal.

11. Remove the lower mounting bolt and reposition the harness

mounting bracket.

12. From above the vehicle, reposi tion the supercharger water

pump for access.

1. Reposition the pump harness multiplug from the

retaining bracket.

2. Remove the two nuts which secure the U-bracket around the pump.

3. Remove the U-bracket from the pump.

4. Reposition the pump to al low access for removing the

generator.

13. Remove the upper securing bolt and withdraw the generator

from the mounting bracket.

14. Carefully, manoeuvre the ge nerator forward towards the

radiator.

Page 1897 of 2490

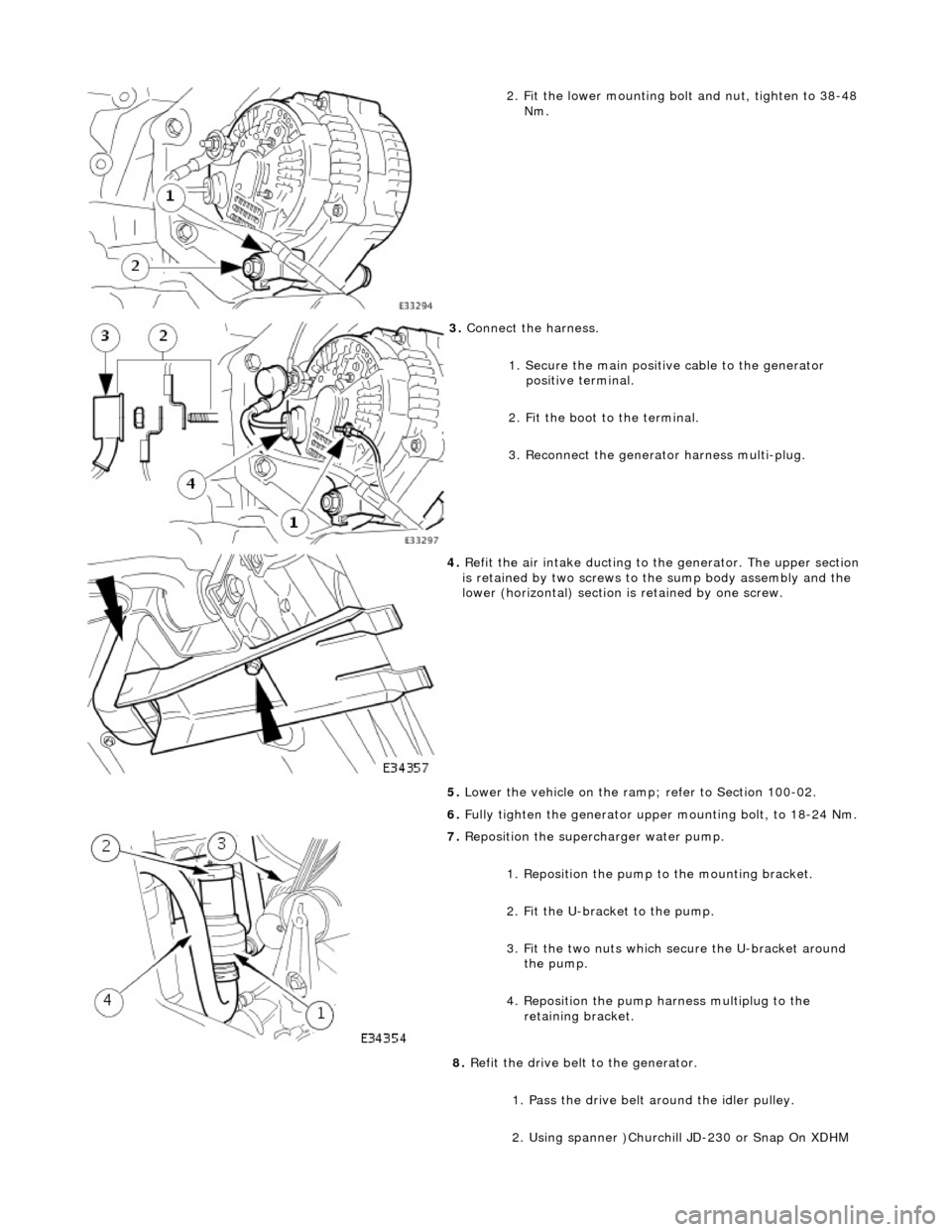

2. Fit the lower mounting bolt and nut, tighten to 38-48

Nm.

3. Connect the harness.

1. Secure the main positive cable to the generator positive terminal.

2. Fit the boot to the terminal.

3. Reconnect the generator harness multi-plug.

4. Refit the air intake ducting to the generator. The upper section

is retained by two screws to the sump body assembly and the

lower (horizontal) section is retained by one screw.

5. Lower the vehicle on the ramp ; refer to Section 100-02.

6. Fully tighten the generator upper mounting bolt, to 18-24 Nm.

7. Reposition the superc harger water pump.

1. Reposition the pump to the mounting bracket.

2. Fit the U-bracket to the pump.

3. Fit the two nuts which secure the U-bracket around the pump.

4. Reposition the pump harness multiplug to the retaining bracket.

8. Refit the drive belt to the generator.

1. Pass the drive belt around the idler pulley.

2. Using spanner )Churchill JD-230 or Snap On XDHM

Page 2383 of 2490

Paint

The inhalation of sprays, fumes, or dust during paint application or sanding processes should always be avoided. Ensure

that there is efficient ventilation / extrac tion at all times. Paint spraying should be confined as far as possible to spray

booths. Personnel with a history of asth ma should not be employed in any process involving the use of isocyanates.

Operators working in a spray booth where isocyanate material is present must use air-fed breathing equipment with air

supplied to the visor at the re commended pressure and filtered to remove oil, water, and fumes. Operators involved in

handling mixing or spraying should wear protective clothing including gloves and goggles, to avoid skin and eye contact.

Particle masks or canister type respir atosr should be worn when sanding.

Applied Heat

When welding, flame cutting, brazing etc, the operator shou ld use as appropriate, goggles, mask / fume extractor and

flameproof protective clothing. It is especially important when working with polyurethane compounds to use air-fed

breathing equipment. Appropriat e fire fighting equipment and personnel trai ned in its use must always be available.

Metal Repair

Appropriate eye and hand protection should be worn when sanding, drilling, cutting, chiselling, flatting or welding. Face

masks or air-fed visors should also be wo rn when sanding or flatting either body solder or fillers. On completion of a

soldering operation, swarf must be re moved from the work area and the operat or must wash his hands thoroughly.

GENERAL REPAIR NOTES

The following advice should be noted before any repair work is carried out.

Disconnect the vehicle battery gr ound lead (disconnect the alternator where electric welding is used) and take note of the

reconnection procedures as detailed in 86.15.15.

Where structural parts are straightened or renewed, a body alignment / straightening jig must be used. The application of

heat, especially excessive heat, reduces the strength of steels, where appropriate therefore, structural sections should be

straightened by cold processes.

Repairs may only be carried out successful ly, and any warranties protected, if genuine Jaguar replacement parts and Jaguar

approved materials are used.

The correct tools, procedures and facilities must always be us ed. The quality of the work must not be compromised by using

inappropriate methods or equipment.

All trim and electrical components in the locality of the repair must be removed or disconnected prior to panel removal /

replacement; this is especially important where hollow sectio ns may contain harnesses, tubes or foam, see section A4.3.5.

WARNING: DO NOT WORK IN THE VICINITY OF A LIVE AIR BAG, REMOVE IT COMPLETELY. READ WORKING

PRACTICES AIR BAG, SECTION 20. ANY SEAT BELT WHICH HAS BEEN WORN IN AN ACCIDENT MUST BE RENEWED.

CAUTION: Electric arc welding should not be used on Jaguar vehicles. The high voltages produced by this process will

cause irreparable damage to the electric al control and microprocessor systems.

The following welding and gas processes are the only ones recommended by Jaguar Cars Ltd.

Welding and Gas Processes

Resistance spot welding, MIG welding and all gas processes may only be carried out on bare, unpainted or unplated metal.

The flanges of panels to be welded toge ther, must be clean, corrosion free and tr eated as appropriate, with either weld-

through primer or inter-weld sealer. Only materials and processes specified in the 'Body Sealing and Preservation Manual'

should be used in the relevant application areas detailed in this section. Refer to 'Zinc Coated Panels' Section