fuel injector connector JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1040 of 2490

Fuel Char

ging and Controls - Fu

el Injectors4.0L SC V8 - AJ26

Remo

val and Installation

Remov

a

l

Installation

1. Disc onne

ct battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. WARNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

Depressurize fuel syst em; refer to 19.50.02.

3. Drain radiator coolant; refer to 2

6.10.01.

4. Remove air cleaner cover / inta ke assembly; refer 19.10.30.

5. Remove throttle body; refer to 19.70.04.

6. Remove throttle induction elbo w; refer to (SC) 19.70.28.

7. Remove exhaust gas re-circulation valve (EGR) if fitted; refer

to 17.45.01.

8. Remove supercharger outlet duct and gasket; refer to

18.50.16.

9. Remove coolant outlet pipe; refer to (SC) 26.31.08 .

10. Remove supercharger drive belt; refer to 18.50.08.

11. Remove supercharger assembly; refer to 18.50.15.

12. Remove bank 1 or 2 charge air cooler as required; refer to

18.50.18 and / or 18.50.19.

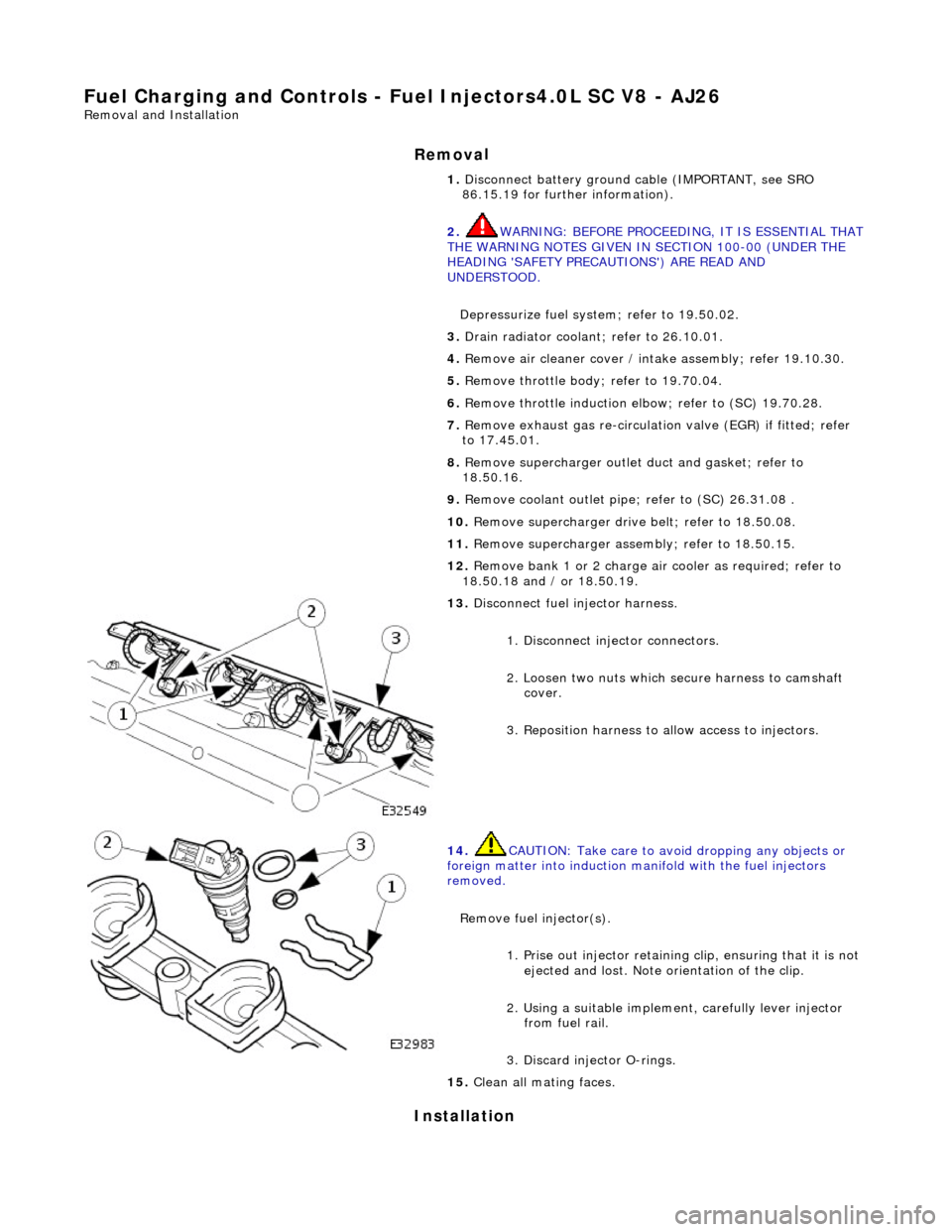

13 . Di

sconnect fuel injector harness.

1. Disconnect injector connectors.

2. Loosen two nuts which se cure harness to camshaft

cover.

3. Reposition harness to al low access to injectors.

14. CAUTI

ON: Take care to avoi

d dropping any objects or

foreign matter into induction ma nifold with the fuel injectors

removed.

Remove fuel injector(s). 1. Prise out injector retaining clip, ensuring that it is not

ejected and lost. Note orientation of the clip.

2. Using a suitable implemen t, carefully lever injector

from fuel rail.

3. Discard injector O-rings.

15 . Cle

an all mating faces.

Page 1138 of 2490

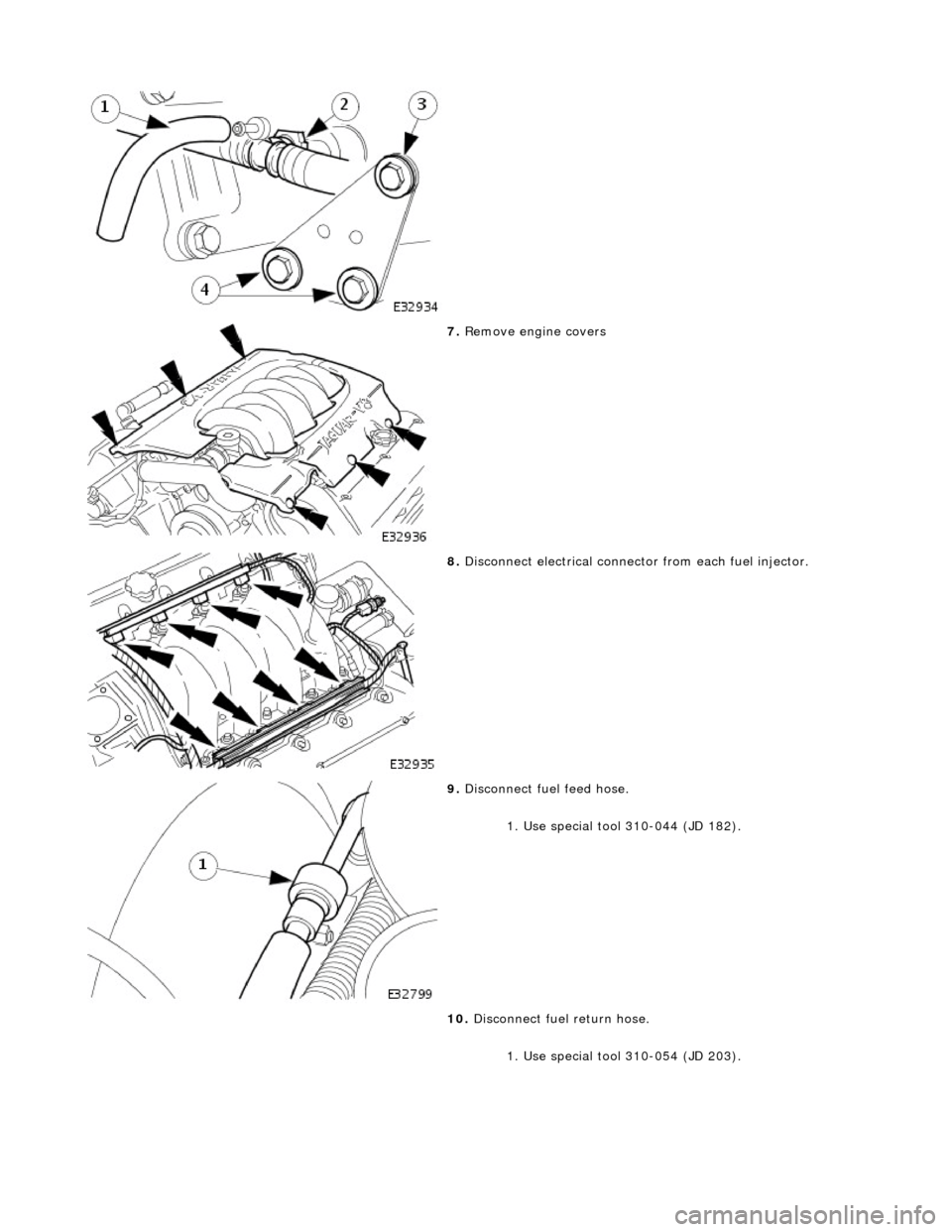

7. Re

move engine covers

8. Disc onne

ct electrical connector from each fuel injector.

9. Disc

onnect fuel feed hose.

1. Use special tool 310-044 (JD 182).

10. Disconnect fuel return hose.

1. Use special tool 310-054 (JD 203).

Page 1140 of 2490

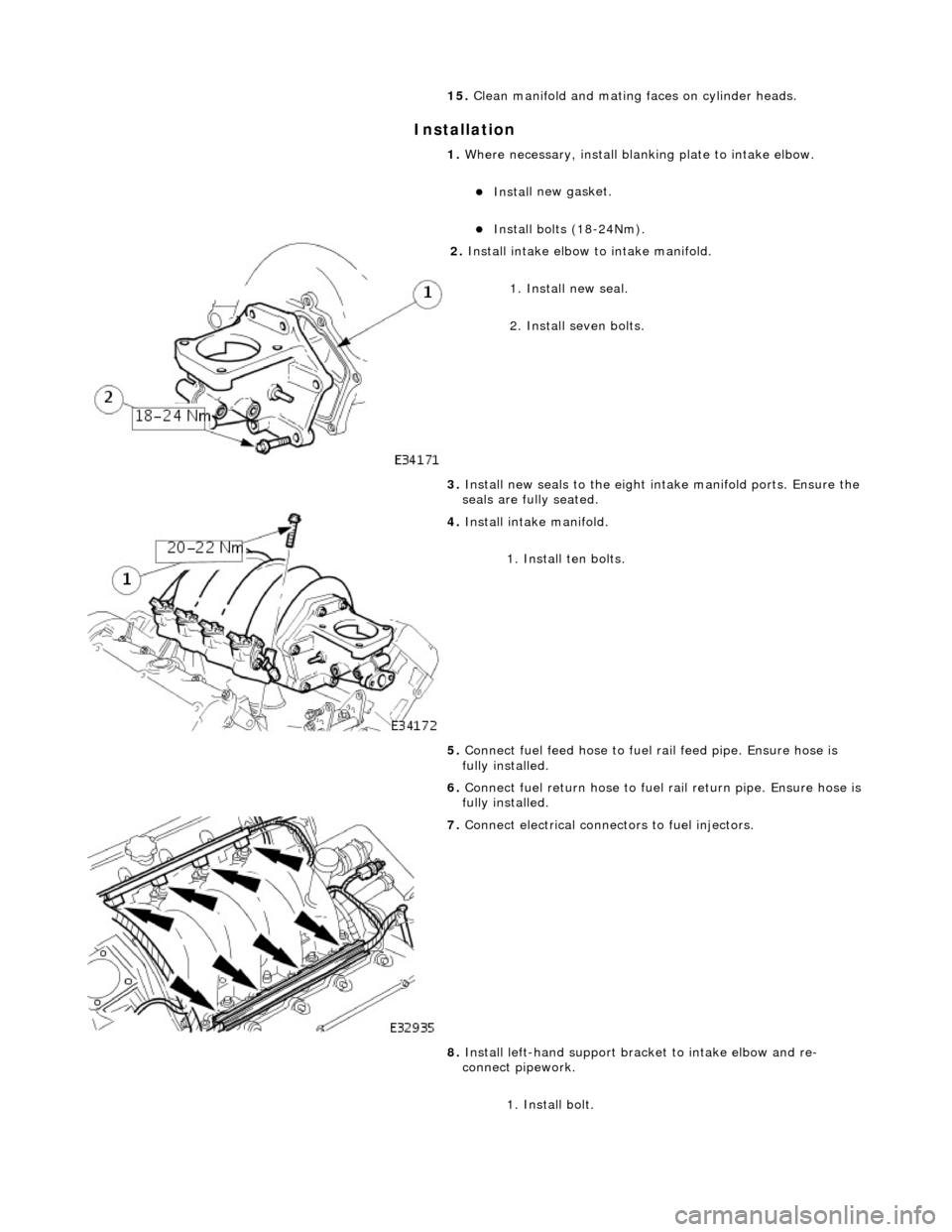

In

stallation

15.

Cle

an manifold and mating faces on cylinder heads.

1. Where necessary, install blanking plate to intake elbow.

Inst al

l new gasket.

Inst

al

l bolts (18-24Nm).

2. Inst al

l intake elbow to intake manifold.

1. Install new seal.

2. Install seven bolts.

3. Install new seals to the eight intake manifold ports. Ensure the

seals are fully seated.

4. Inst al

l intake manifold.

1. Install ten bolts.

5. Connect fuel feed hose to fuel rail feed pipe. Ensure hose is

fully installed.

6. Connect fuel return hose to fuel rail return pipe. Ensure hose is

fully installed.

7. Con n

ect electrical connectors to fuel injectors.

8. Install left-hand support brac ket to intake elbow and re-

connect pipework.

1. Install bolt.

Page 1693 of 2490

Filler Cap and P

ipe

The fuel

filler cap with bayonet-type fixi

ng is located beneath a remote-release sp ring-latched lid on the rear saddle panel

on the left-hand-side of the vehicle.

Fuel Pum

p

The fu

el pump(s) is energized by an ECM co

ntrolled relay. Fuel is drawn by this pu mp and supplied to the fuel injectors via

the fuel line, filter and fuel rails.

Servicing of the fuel pump re quires fuel tank removal.

Ev

aporative Loss Flange Assembly

The evaporative-loss flan

ge asse

mbly is mounted centrally on top of the tank. The flange assembly consists of a removeable

steel cap which mounts the evaporative emissions system vapor outlet valves and, if applicable, a pressure sensor. The

external electrical supply to th e fuel pump(s) is also made via a connector on the flange.

The flange assembly is fixed to the tank by a locking ring which is turned usin g special tool JD-174. A seal is fitted between

the flange assembly and the tank. Three di fferent flange assemblies are applicable according to the evaporative emission

system fitted to the vehicle. The fl ange size and fixing are identical fo r the three systems, as described.

Removal of the evaporative flange assembly is necessary to gain access to th e fuel pump(s) and other internal components.

To remove the evaporative fl ange assembly the fuel tank must first be removed.

The evaporative flange variant assemblies are described, together with service information, in Section 303-13.

Fuel R

eturn

Excess fuel

is directed back to

the fuel tank via a return line.

Fuel Pum

p Relay

The

fuel pump relay,

under control of the ECM, switches power to the fuel pump motor.

I

nertia Fuel Shutoff (IFS) Switch

The IF

S switch is located in the right-hand

side footwell behind the footboard carpet . When activated the switch isolates the

ignition system and fuel pump, releases any locked doors and disables unnecessary electrical systems. The system can be

reset by pressing down the flexible cover on the top of the switch.

• NOTE: The doors will not unlock if the IFS switch is tripped when the ignition switch is in position '0'.