supercharger removal JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1009 of 2490

W

ater Pump Pulley Vehicles With: Supercharger

26.50.05

Removal

1. Open the engine compartment and fit paintwork protection sheets.

2. Remove the supercharger drive belt. Refer to Operation <<18.50.08>>.

3

. Slacken the three screws which secure the water pump pulley.

4

.

C

AUTION:

When releasing the belt tension, never apply any torque in a clockwise direction to the pulley

centre bolt (left hand thread) as it could subsequently loosen.

Page 1056 of 2490

Accessory Drive - Accessory Drive Belt

Idler Pulley4.0L SC V8 - AJ26

Re

mo

val and Installation

I

n

stallation

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Remove the supercharger driv e belt, for access. Refer to

operation 18.50.08.

3. Remove the accessory drive belt for access. Refer to Operation

(12.10.40)

4. Re

move the idler pulley.

1. Remove the securing bolt from the idler pulley.

2. Remove the idler pulley.

1. Installation is the reverse of the removal procedure. Tighten

the pulley securing bolt to 53-69 Nm. Ensure that the belt is

correctly and squarely lo cated on each pulley.

2. Refit the supercharger drive belt. Refer to operation 18.50.08.

Page 1058 of 2490

Accessory Drive - Accessory

Drive Belt Tensioner4.0L SC V8 - AJ26

Re

mo

val and Installation

I

n

stallation

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Remove the supercharger driv e belt, for access. Refer to

operation 18.50.08.

3. Remove the accessory drive belt for access. Refer to Operation

(12.10.40)

4. Remove t

he tensioner assembly, which includes the tensioner

pulley..

1. Remove the bolt whic h secures the tensioner

assembly to the engine.

2. Remove the tensioner assembly.

1. Installation is the reverse of the removal procedure. Tighten

the tensioner assembly securing bolt to 38-48 Nm. Ensure that

the belt is correctly and squa rely located on each pulley.

2. Refit the supercharger drive belt. Refer to operation 18.50.08.

Page 1059 of 2490

Ac

cessory Drive - Supercharger Belt

Re

moval and Installation

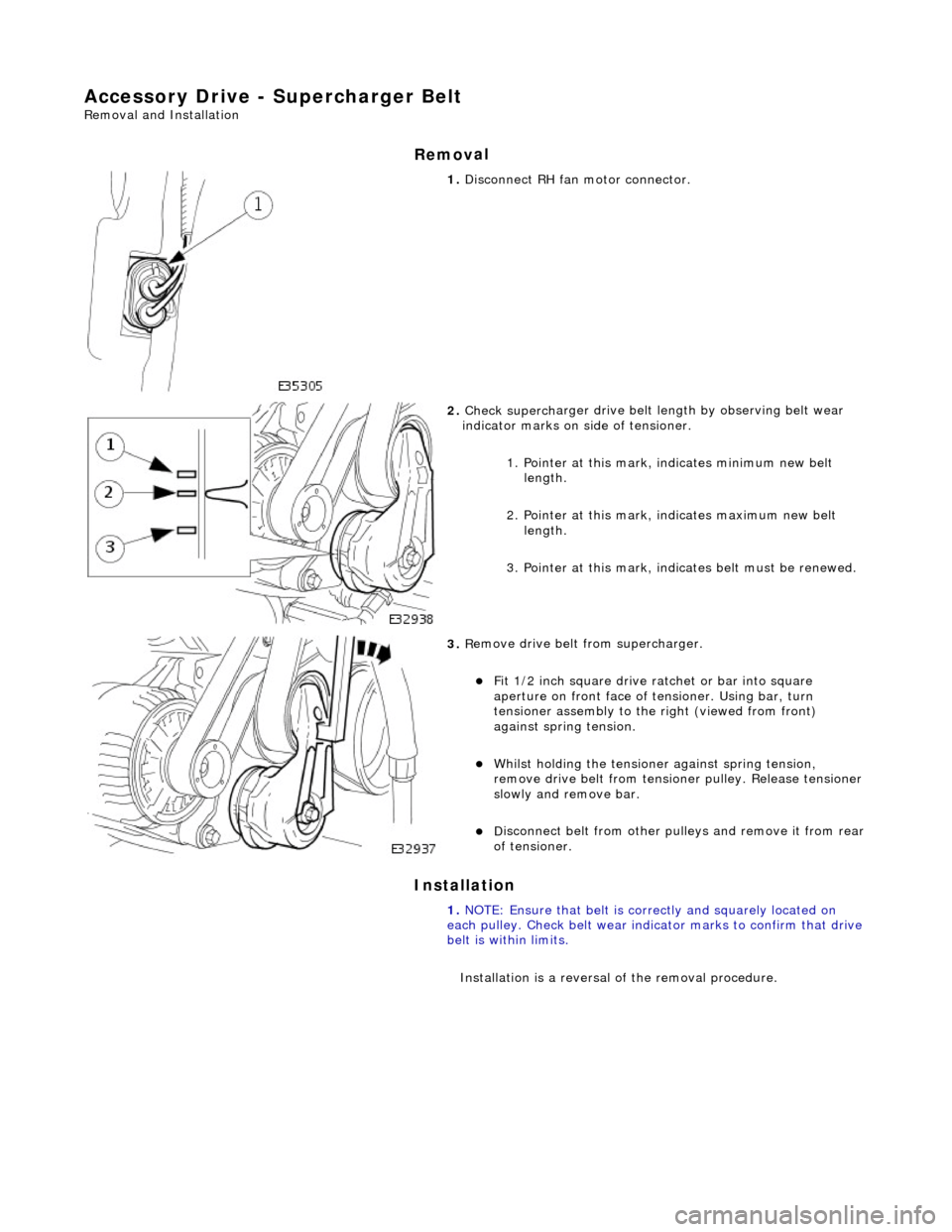

Remov

al

Installation

1.

Di

sconnect RH fa

n motor connector.

2. Check superch

arger dr

ive belt length by observing belt wear

indicator marks on side of tensioner.

1. Pointer at this mark, indicates minimum new belt length.

2. Pointer at this mark, indicates maximum new belt length.

3. Pointer at this mark, indi cates belt must be renewed.

3. R

emove drive belt from supercharger.

F

it 1/2 inch square drive ratchet or bar into square

aperture on front face of tensioner. Using bar, turn

tensioner assembly to the right (viewed from front)

against spring tension.

Wh

ilst holding the tensione

r against spring tension,

remove drive belt fr om tensioner pulley. Release tensioner

slowly and remove bar.

D

isconnect belt from

other pulleys and remove it from rear

of tensioner.

1. NOTE: Ensure that belt is correctly and squarely located on

each pulley. Check belt wear indicator marks to confirm that drive

belt is within limits.

Installation is a reversal of the removal procedure.

Page 1060 of 2490

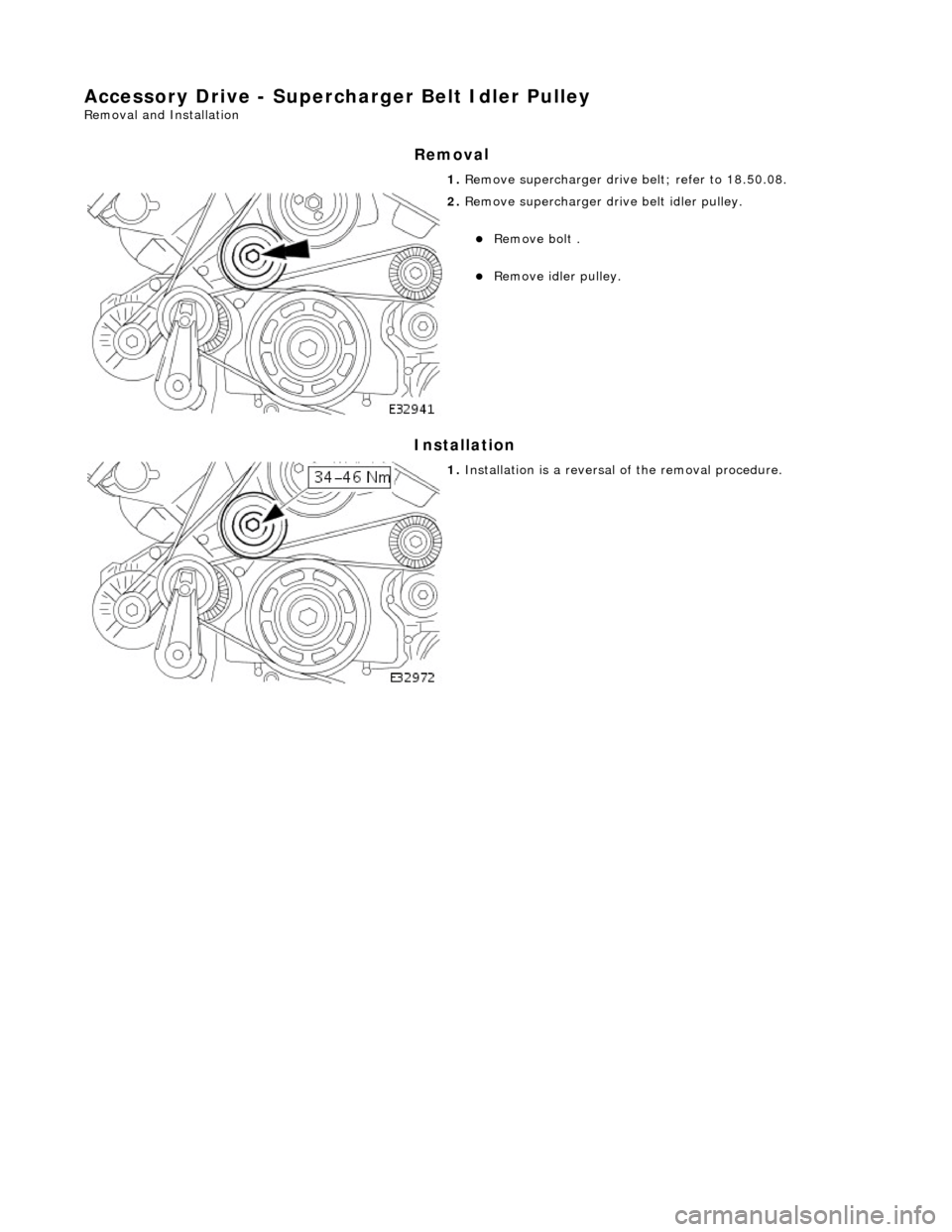

Access

ory Drive - Supercharger Belt Idler Pulley

Re

mo

val and Installation

Remov

a

l

Installation

1.

Re

move supercharger drive belt; refer to 18.50.08.

2. Re

move supercharger drive belt idler pulley.

Re

mo

ve bolt .

R

e

move idler pulley.

1. Installation

is a reversal

of the removal procedure.

Page 1128 of 2490

Intake Air Distribution and Filtering - Supercharger

Remo

val and Installation

Remov

a

l

Installation

1. Disc onne

ct battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Drain radiator coolant; refer to 26.10.01.

3. Remove air cleaner cover / intake assembly; refer to 19.10.30.

4. Remove throttle body; refer to 19.70.04.

5. Remove exhaust gas re-circulation valve (EGR) if installed;

refer to 17.45.01.

6. Remove throttle intake elbo w; refer to (SC) 19.70.28.

7. Remove supercharger outlet duct; refer to 18.50.16.

8. Remove coolant outlet pipe; refe r to operation (SC) 26.31.08.

9. Remove supercharger drive belt; refer to 18.50.08.

10. Disconnect remaining coolant hoses from charge air coolers.

Position pipes to facilitate removal

of supercharger.

Inst

al

l suitable blanking plugs.

11 .

R

emove supercharger from engine.

1. Remove bolt.

2. Remove bolts .

3. Remove supercharger.

1. Inst al

l supercharger.

2. Connect all hoses to charge air coolers.

3. Install supercharger driv e belt; refer to 18.50.08.

4. Install engine coolant outlet pipe; refer to 26.31.08.

5. Install supercharger outlet du ct and new gasket; refer to

18.50.16.

6. Install throttle intake elbow; refer to 19.70.28.

7. Install exhaust gas re-circulation valve (EGR) if applicable;

Page 1133 of 2490

Intake Air Distribution and Filtering - Su

percharger Outl

et Pipe Gasket

Re

moval and Installation

Remov

al

Installation

1.

R

emove supercharger outlet

duct; refer to 18.50.16.

1. Installation is a reversal of the removal procedure.

Page 1253 of 2490

E

lectronic Engine Controls - Knock

Sensor (KS) LH4.0L SC V8 - AJ26

Re

moval and Installation

Remov

al

Installation

1.

R

emove supercharger; refer to 18.50.15.

2. Remove knock sensor from engine.

De

tach connector and disconnect.

R

emove knock sensor.

1. Installation is a reversal of the removal procedure.

2. Tighten sensor to 31 - 41 Nm.

Page 1255 of 2490

E

lectronic Engine Controls - Knock

Sensor (KS) RH4.0L SC V8 - AJ26

Re

moval and Installation

Remov

al

Installation

1.

R

emove supercharger; refer to 18.50.15.

2. Remove knock sensor from engine.

De

tach connector and disconnect.

R

emove knock sensor.

1. Installation is a reversal of the removal procedure.

2. Tighten sensor to 31 - 41 Nm.

Page 1804 of 2490

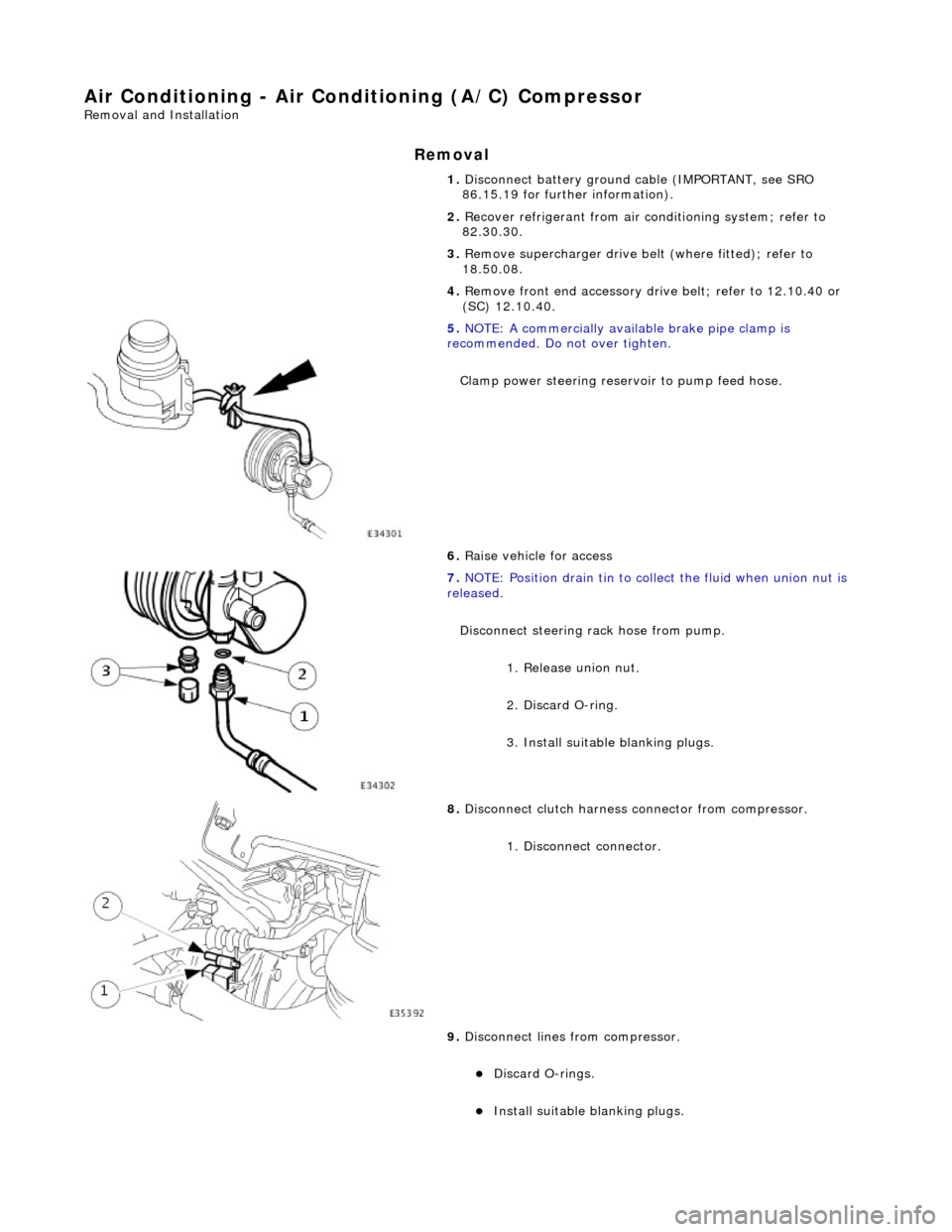

Air Conditioning - Air Conditioning (A/C) Compressor

Removal and Installation

Removal

1. Disconnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Recover refrigerant from air co nditioning system; refer to

82.30.30.

3. Remove supercharger drive belt (where fitted); refer to

18.50.08.

4. Remove front end accessory dr ive belt; refer to 12.10.40 or

(SC) 12.10.40.

5. NOTE: A commercially availa ble brake pipe clamp is

recommended. Do not over tighten.

Clamp power steering reservoir to pump feed hose.

6. Raise vehicle for access

7. NOTE: Position drain tin to collect the fluid when union nut is

released.

Disconnect steering rack hose from pump. 1. Release union nut.

2. Discard O-ring.

3. Install suitable blanking plugs.

8. Disconnect clutch harness connector from compressor.

1. Disconnect connector.

9. Disconnect lines from compressor.

Discard O-rings.

Install suitable blanking plugs.