Electronic engine controls JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1250 of 2490

Electronic

Engine Controls -

Heated Oxygen Sensor (HO2S) RH

Remo

val and Installation

General Equipment

Remov a

l

Installation

Snap -on to

ol S6176

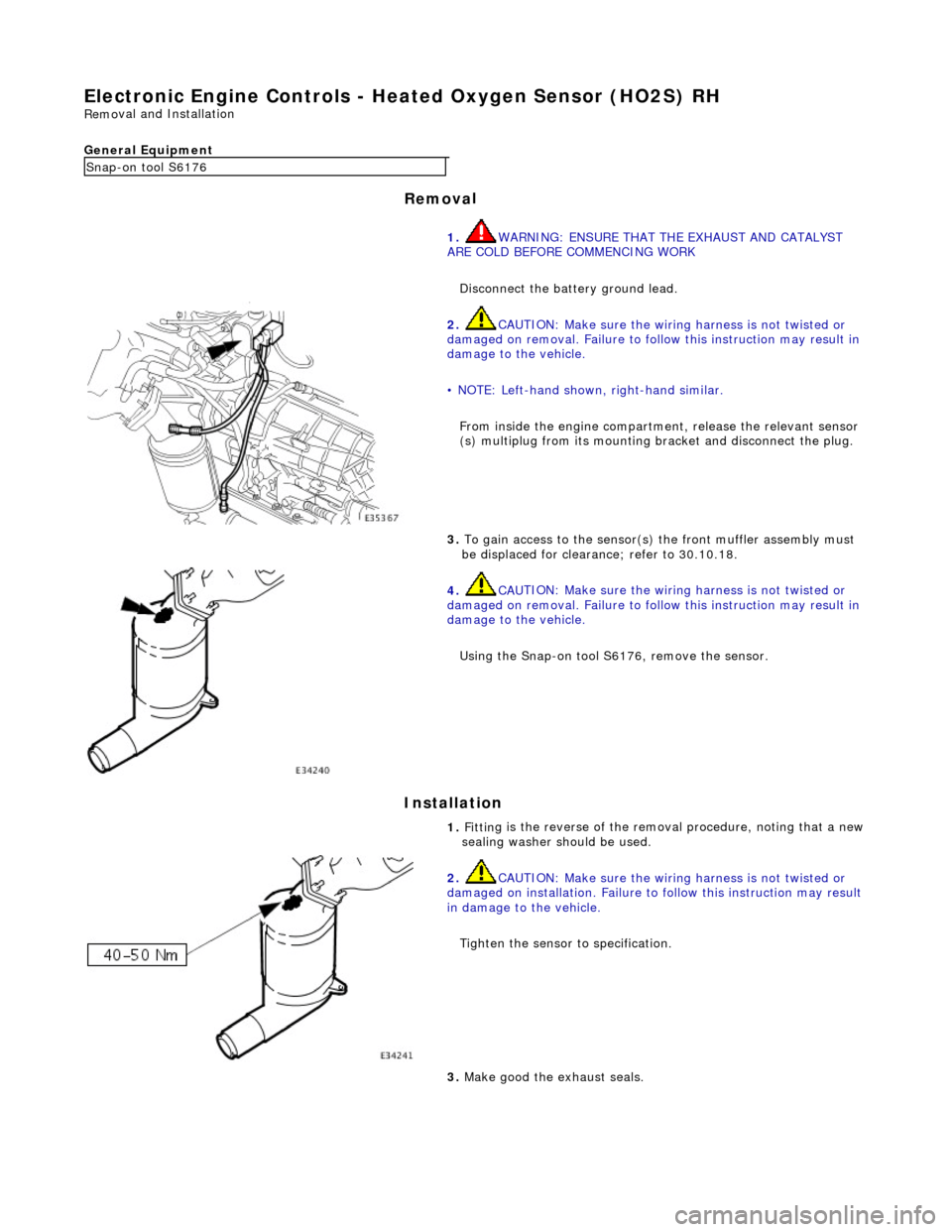

1. WARNING: ENSURE THAT TH E EXHAUST AND CATALYST

ARE COLD BEFORE COMMENCING WORK

Disconnect the battery ground lead.

2. CAU

TION: Make sure the wiring harness is not twisted or

damaged on removal. Failure to follow this instruction may result in

damage to the vehicle.

• NOTE: Left-hand shown, right-hand similar.

From inside the engine compartm ent, release the relevant sensor

(s) multiplug from its mounting bracket and disconnect the plug.

3. To

gain access to the sensor(s)

the front muffler assembly must

be displaced for clearance; refer to 30.10.18.

4. CAU

TION: Make sure the wiring harness is not twisted or

damaged on removal. Failure to follow this instruction may result in

damage to the vehicle.

Using the Snap-on tool S6176, remove the sensor.

1. Fittin

g is the reverse of the remo

val procedure, noting that a new

sealing washer should be used.

2. CAU

TION: Make sure the wiring harness is not twisted or

damaged on installation. Failure to follow this instruction may result

in damage to the vehicle.

Tighten the sensor to specification.

3. M

ake good the exhaust seals.

Page 1268 of 2490

Input speed is monitored by the TCM with a rationality check being made against output speed. A fault will be flagged if the

indicated input speed exceeds 7400 rpm. Additionally, a failure judgement will be made if the indicated input speed is <160

rpm with engine speed >608 rpm and output speed >224 rpm

The procedure is similar for the output sp eed diagnostic. A fault (non OBDII) will be flagged if the indicated input speed

exceeds 6712 rpm. Additionally a failure judgement will be ma de if the indicated output speed is <160 rpm and the average

road wheel speed exceeds 100 rpm.

Under normal circumstance s after the output speed diagnost ic fault code has been set, the TCM uses rear wheel speed

information to compute its calculations, this has no effect on transmission operation. However, should a second fault occur,

in the ABS system, thus making rear wheel speed information unavailable, an additional fault code will be logged.

Control Systems

Introduction

Gear selection is achieved by controlling the flow of transmission fluid to internal multi-disc clutches.

The three solenoid valves direct the transmission fluid flow to the selected clutches and the pressure regulators control the

fluid pressure to each component. One pr essure regulator serves as a master pressure control for the entire system and a

second is used exclusively for torque converter clutch lock-up operation.

The TCM controls the internal components thus determining gear selection and shift pattern.

In the event of an electronic system fault the basic function s Park, Reverse Neutral and Drive Fourth are retained by the

hydraulic system.

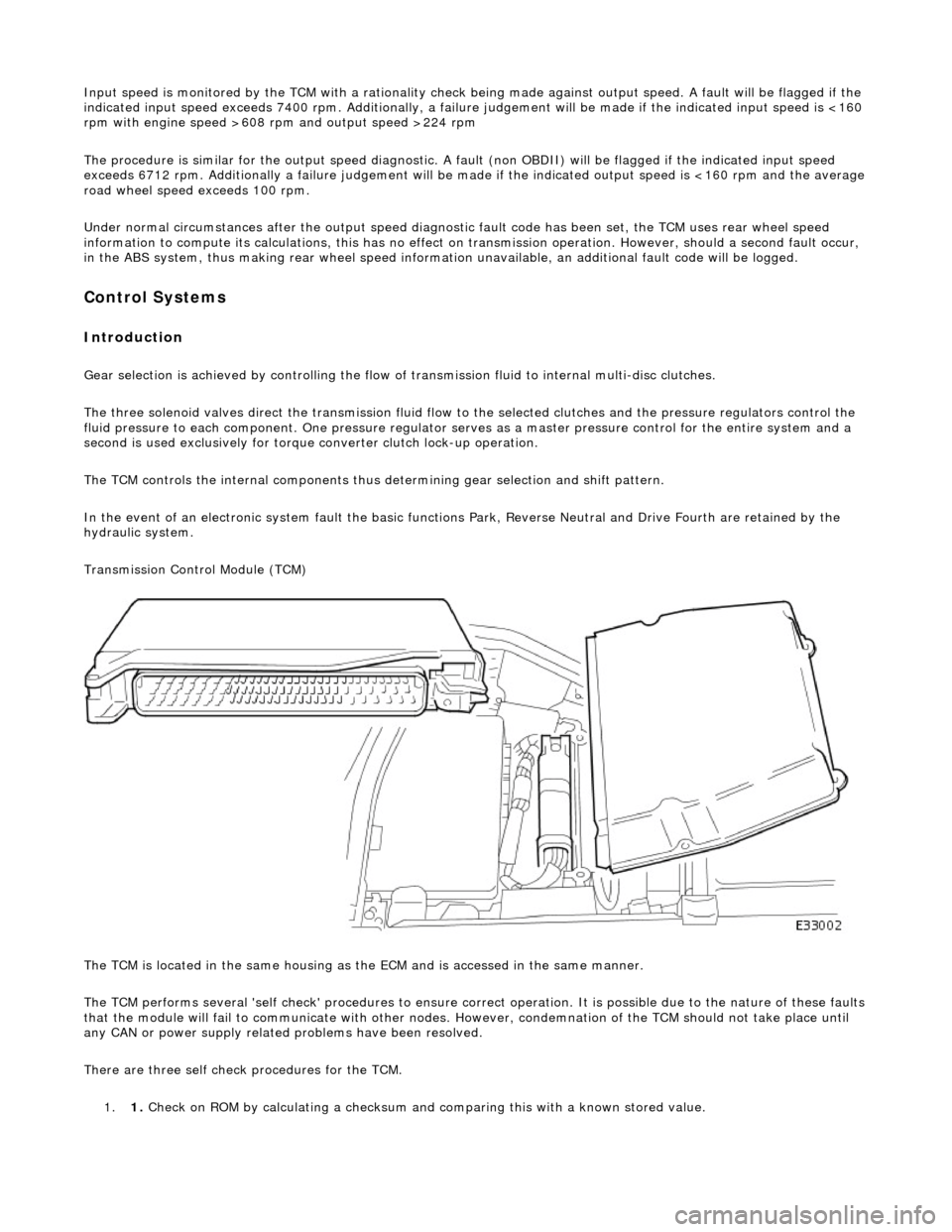

Transmission Control Module (TCM)

The TCM is located in the same housing as th e ECM and is accessed in the same manner.

The TCM performs several 'self check' procedur es to ensure correct operation. It is possible due to the nature of these faults

that the module will fail to communicate with other nodes. However, condemnation of the TCM should not take place until

any CAN or power supply related problems have been resolved.

There are three self check procedures for the TCM. 1. 1. Check on ROM by calculatin

g a checksum and comparing this with a known stored value.

Page 1390 of 2490

Stator, intermediate and output shafts. Three epicyclic geartrains. Six multi-disc clutch/brake packs. Two freewheels (One-way clutches). Hydraulic pump. Parking lock assembly. Electro-hydraulic control unit. Internal harness and 13 pin connector with bayonet lock.

Hydraulic pump

This engine driven pump is located at the front of the transmission casing and provides pressure for the hydraulic

functions.

Supplies fluid under pressure to the torq ue converter, geartrain, electro-hydraulic control unit and the lubrication

circuit.

Draws fluid from the fluid pa n below the transmission casing, through a filter.

Parking lock

This component prevents movement of th e vehicle by engaging a fixed pawl with the parking lock gear located on the

output shaft. The pawl is engaged by movi ng the gear selector lever to the park (P) position.

Electro-hydraulic control unit

This unit, mounted in the transmission lower case, converts signals, mechanical from the J-gate and electrical from the

TCM, into hydraulic functions.

The following components ar e assembled to the unit:

Selector valve. Shift plate. Control valve - modulating pressure. Control valve - shift pressure. Solenoid valve 1 <-> 2 and 4 <-> 5 shift. Solenoid valve 3 <-> 4 shift. Solenoid valve 2 <-> 3 shift. Solenoid valve - converter lock-up. Speed sensors (2). Temperature sensor.

Speed sensors

There are two speed sensors within the transmission assembly which provide input to the TCM. These inputs, when used in

conjunction with CAN data relative to engine speed (from ECM) and road speed (from ABS), are used to electronically

control the transmission.

Temperature sensor

The output from this sensor allows the TCM to compensate for the affect of fluid temperature on shift time and quality

Control Systems

Hydraulic Control

The selector valve is operated directly by the J-gate and directs fluid flow for P R N D.

Of the four solenoid valves, 3 control shifts and 1 controls converter lock-up. One control valve controls modulating pressure

and the other shift pressure.

Regulating valves are used to maintain/control pressure for lu brication, normal operating functions, and the supply to the

control valves and shift valves.

Page 1394 of 2490

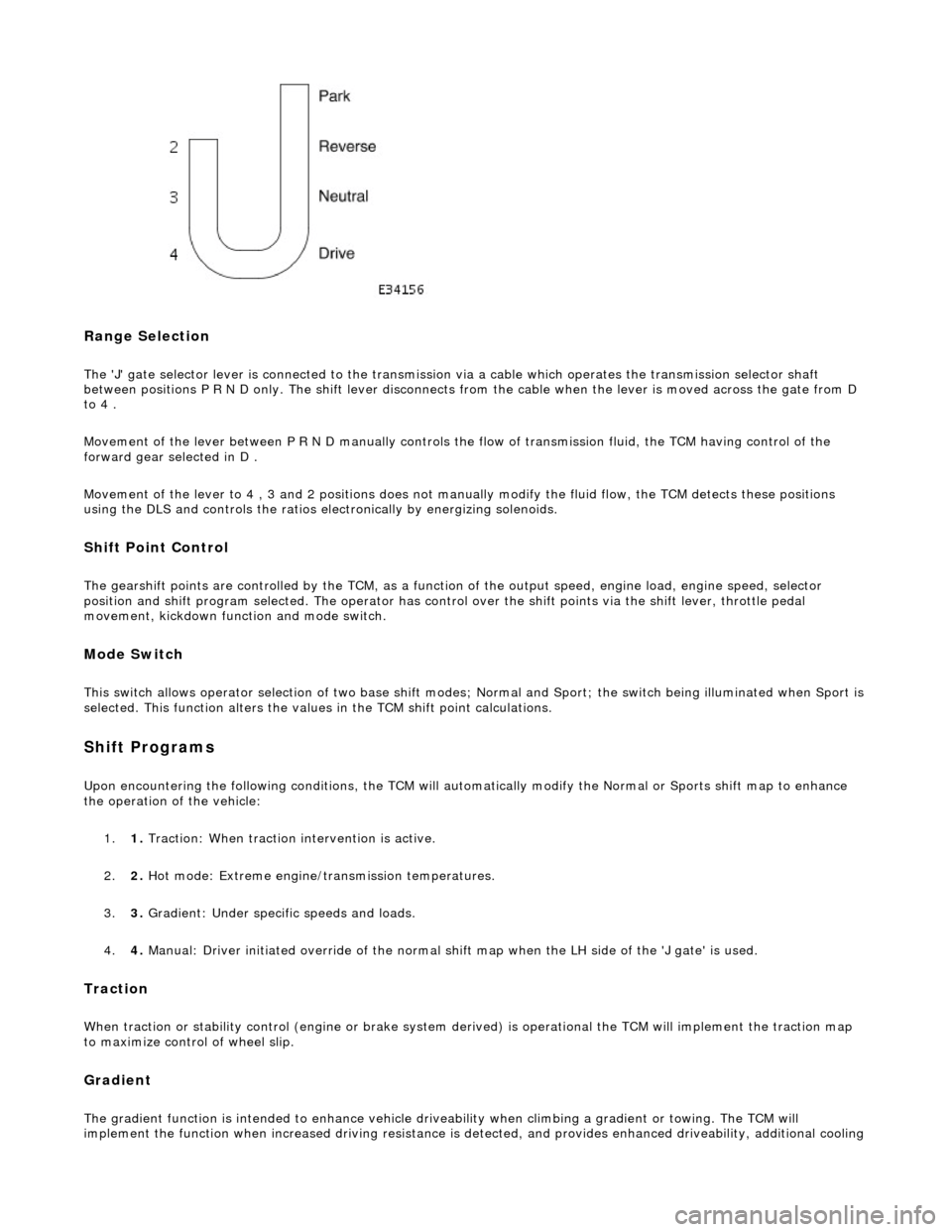

Range Selection

The 'J' gate selector lever is connected to the transmission via a cable which operates the transmission selector shaft

between positions P R N D only. The shift lever disconnects from the cable when the lever is moved across the gate from D

to 4 .

Movement of the lever between P R N D manu ally controls the flow of transmission fluid, the TCM having control of the

forward gear selected in D .

Movement of the lever to 4 , 3 and 2 positions does not manu ally modify the fluid flow, the TCM detects these positions

using the DLS and controls the ratios electronically by energizing solenoids.

Shift Point Control

The gearshift points are controlled by the TCM, as a function of the output speed, engine load, engine speed, selector

position and shift program selected. The operator has control over the shift points via the shift lever, throttle pedal

movement, kickdown function and mode switch.

Mode Switch

This switch allows operator selection of two base shift modes; Normal and Sport; th e switch being illuminated when Sport is

selected. This function alters the values in the TCM shift point calculations.

Shift Programs

Upon encountering the following conditions, the TCM will auto matically modify the Normal or Sports shift map to enhance

the operation of the vehicle:

1. 1. Traction: When traction intervention is active.

2. 2. Hot mode: Extreme engine/transmission temperatures.

3. 3. Gradient: Under specific speeds and loads.

4. 4. Manual: Driver initiated override of the normal shif t map when the LH side of the 'J gate' is used.

Traction

When traction or stability control (engine or brake system de rived) is operational the TCM will implement the traction map

to maximize control of wheel slip.

Gradient

The gradient function is intended to enhance vehicle drivea bility when climbing a gradient or towing. The TCM will

implement the function when increased driving resistance is de tected, and provides enhanced driveability, additional cooling