engine JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 910 of 2490

пЃ¬Remove the engine and transmission assembly, upwards

and forwards, from the vehicle.

71. Remove the engine and tran smission assembly from the

vehicle.

пЃ¬Operate the crane controls and the ramp simultaneously

(with assistance) to lower the vehicle to a convenient

working height.

пЃ¬Traverse the crane clear until the assembly can be

lowered.

Page 911 of 2490

Engine - Engine

Installation

Installation

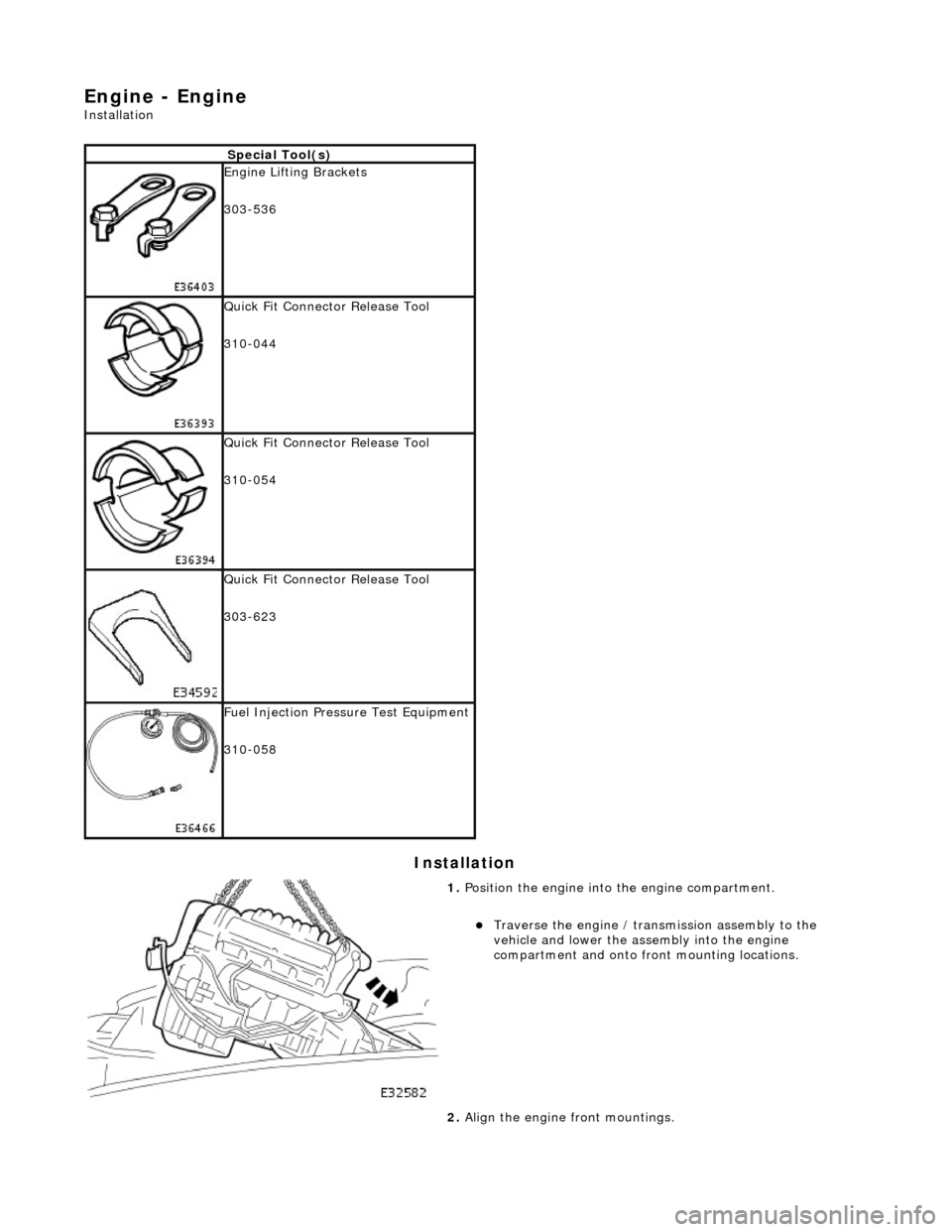

Special Tool(s)

Engine Lifting Brackets

303-536

Quick Fit Connector Release Tool

310-044

Quick Fit Connector Release Tool

310-054

Quick Fit Connector Release Tool

303-623

Fuel Injection Pressure Test Equipment

310-058

1. Position the engine into the engine compartment.

пЃ¬Traverse the engine / transmission assembly to the

vehicle and lower the assembly into the engine

compartment and onto front mounting locations.

2. Align the engine front mountings.

Page 912 of 2490

пЃ¬Align th

e engine front mountings and fit the securing nuts.

пЃ¬Tighte

n to the stated torque value.

3. Operate the crane controls and the ramp simultaneously (with

assistance) to raise the vehicle to a convenient working height.

4. Po

sition the transmission jack and raise it to take the weight of

the transmission. Fit and adjust the chains to secure the

transmission to the jack.

5. Fit th

e engine rear mounting bracket.

пЃ¬Fi

t the four bolts which secu

re the crossmember to the

body.

пЃ¬Fi t t

he bolt which secures the

engine rear mounting rubber

to the transmission.

6. Tigh ten th

e rear mounting bolts

to the stated torque figure.

7. Release and remove the transmission jack.

8. Operate the crane controls and the ramp simultaneously (with

assistance) to lower the vehicle to a convenient working height.

9. Lower th e cran

e and remove th

e chain assembly and lifting

eyes.

Page 913 of 2490

пЃ¬R

emove the engine re

ar lifting eyes.

10. Move the crane away from the vehicle.

11. Raise the vehicle on the ramp.

12

.

Connect the transmission selector cable.

1. Fit the selector lever to the cross shaft.

2. Fit the nut which secures the selector lever to the transmission cross shaft.

3. Reposition the selector cable abutment bracket to the transmission and fit the securing bolts.

13

.

Connect the transmission harness connector.

1. Connect the transmission harness connector.

2. Secure the leve r lock mechanism.

14

.

Reposition the ground lead to the transmission casing and fit

the securing bolt.

15. Fit the brackets which suppo rt the downpipe catalytic

converters to the bell housing.

пЃ¬Po

sition the mounting bracket and fit the two bolts which

secure it to the bell housing.

Page 915 of 2490

пЃ¬Connect

the front muffler to

the intermediate muffler,

noting the alignment of the indicator rings.

пЃ¬W

ith the front muffler positioned correctly, tighten the

clamps (left-hand and right-hand sides) to the catalytic

converter.

21

.

Tighten the clamps (left-hand and right-hand sides),

intermediate mufflers to front muffler.

22

.

Tighten the downpipe bracket se curing bolts to the correct

torque

23

.

Connect the oil cooler pipes (w here fitted) to the engine.

1. Remove the blanking plugs from the pipes and from the mating unions on the engine.

2. Fit new O-ring seals to the pipes and lubricate with new engine oil.

3. Connect the pipes to the engine and fit the clamping

plate and bolt.

24. Lower the vehicle on the ramp.

25. Connect the heater and brake servo hoses.

1. Connect the heat er return hose.

2. Connect the heater feed hose and secure the locking

lever.

Page 916 of 2490

3. Conne

ct the brake servo hose.

26. Conne

ct the P.I. harness to the engine management

harness.

1. Reposition the engi ne management harness

connector to the bracket.

2. Fit the nut which secures the engine management harness connector to the mounting bracket.

3. Connect the connectors.

4. Fit the bolt which secures the P.I. harness connector to the engine management harness.

27 . Conne

ct the transmission rotary

switch harness connector.

пЃ¬Re

position and connect the harness.

28 . Con

nect the throttle cable.

1. Fit the bolts which secure the abutment bracket to the throttle body. Tighten to 4-6 Nm.

2. Rotate the butterfly actuator cam and connect the cable. Reposition the cable into the cam.

пЃ¬Re

move any tape or plastic

strap which was fitted when

disconnecting the cable abutment.

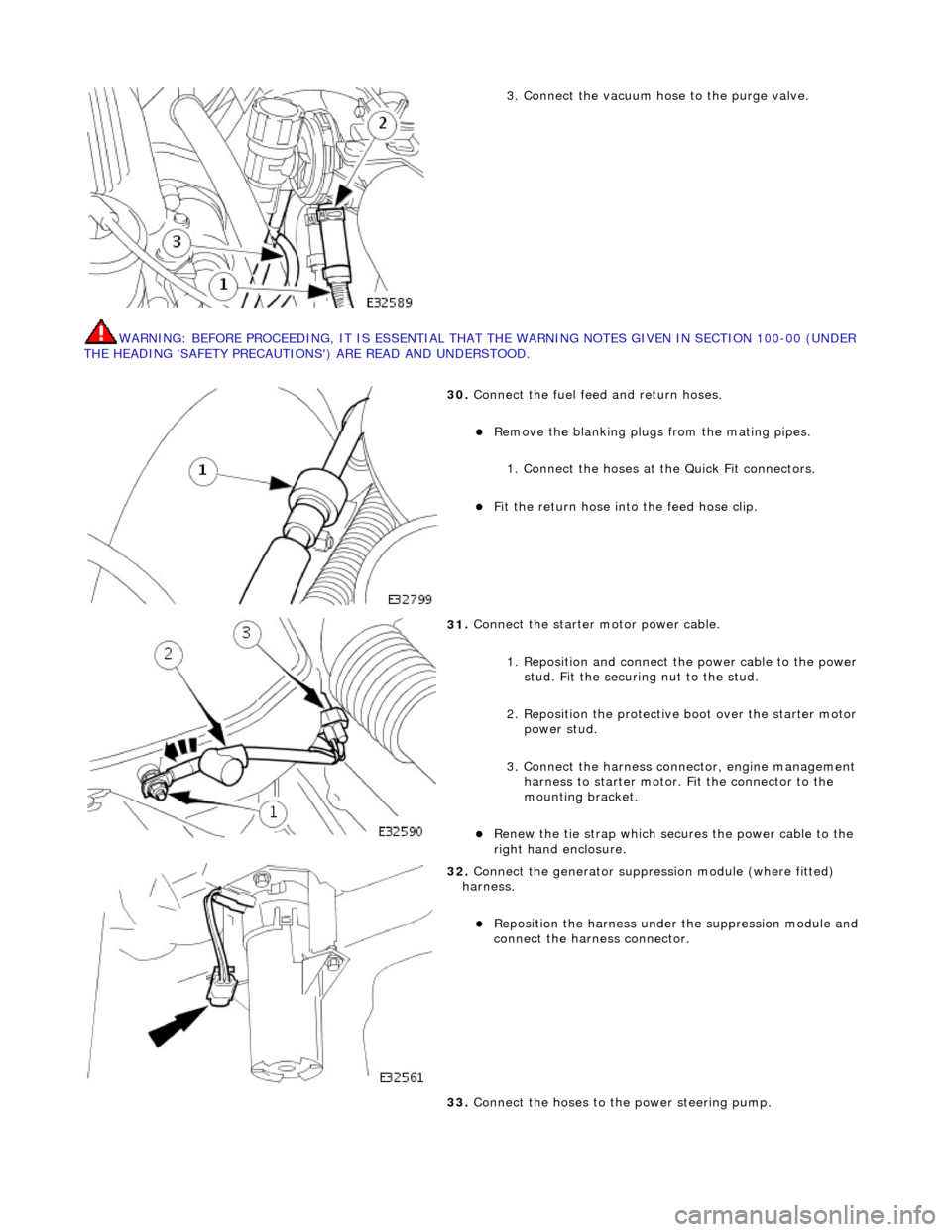

29. Connect the pipes to the purge valve.

1. Connect the part load breather hose.

2. Fit the clip which secures the part load breather hose

to the purge valve.

Page 917 of 2490

WARNING: B

EFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER

THE HEADING 'SAFETY PRECAUTION S') ARE READ AND UNDERSTOOD.

3.

Connect the vacuum hose to the purge valve.

30

.

Connect the fuel feed and return hoses.

пЃ¬R

emove the blanking plugs

from the mating pipes.

1. Connect the hoses at the Quick Fit connectors.

пЃ¬F

it the return hose into the feed hose clip.

31

.

Connect the starter motor power cable.

1. Reposition and connect the power cable to the power stud. Fit the securing nut to the stud.

2. Reposition the protective boot over the starter motor power stud.

3. Connect the harness connector, engine management harness to starter motor. Fit the connector to the

mounting bracket.

пЃ¬R

enew the tie strap which secures the power cable to the

right hand enclosure.

32

.

Connect the generator suppressi on module (where fitted)

harness.

пЃ¬Re

position the harn

ess under the suppression module and

connect the harness connector.

33. Connect the hoses to the power steering pump.

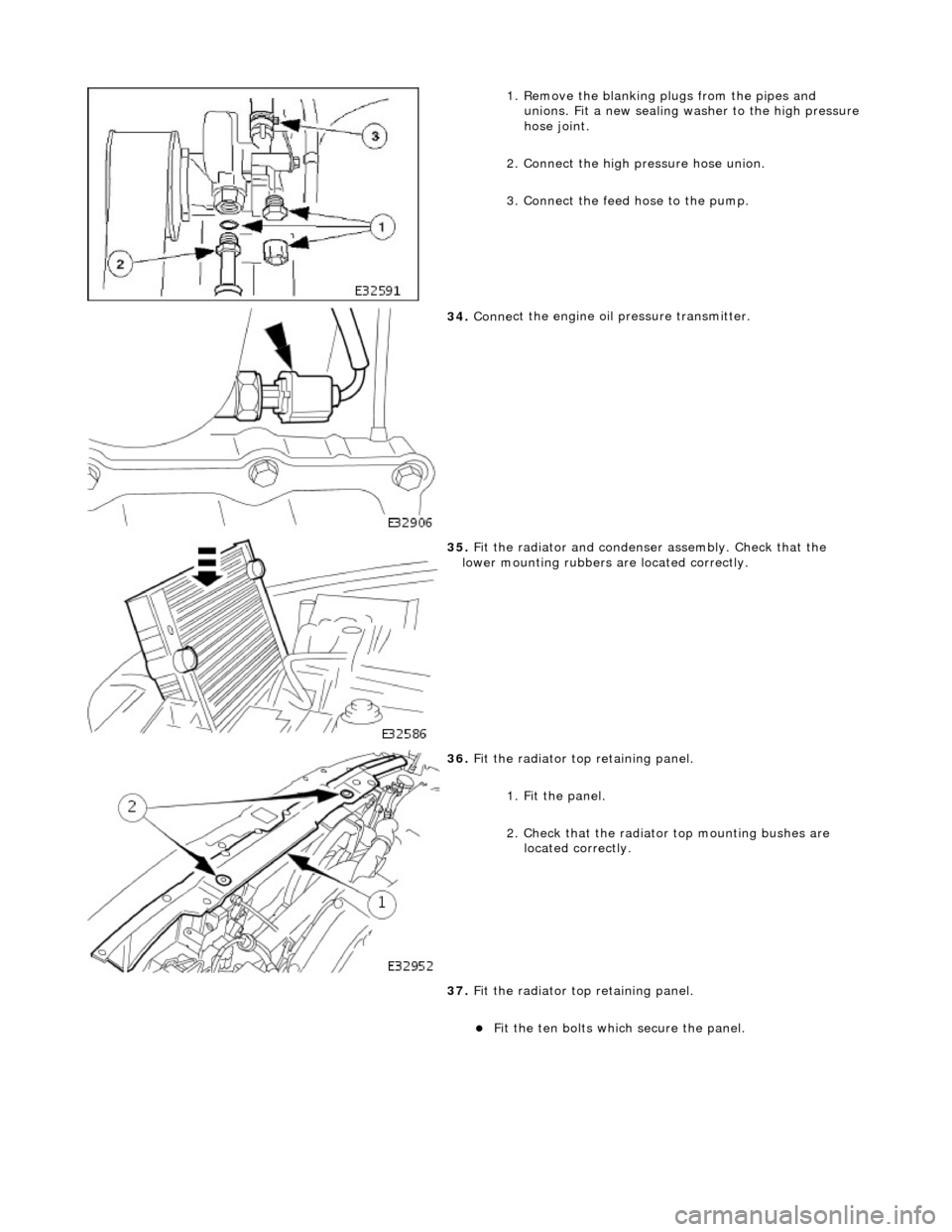

Page 918 of 2490

1.

Remove the blanking plugs from the pipes and

unions. Fit a new sealing washer to the high pressure

hose joint.

2. Connect the high pressure hose union.

3. Connect the feed hose to the pump.

34 . Conne

ct the engine oil

pressure transmitter.

35 .

Fit the radiator and

condense

r assembly. Check that the

lower mounting rubbers are located correctly.

36 . Fit the radiator top

retaining panel.

1. Fit the panel.

2. Check that the radiator top mounting bushes are

located correctly.

37. Fit the radiator top retaining panel.

пЃ¬Fit

the ten bolts which secure the panel.

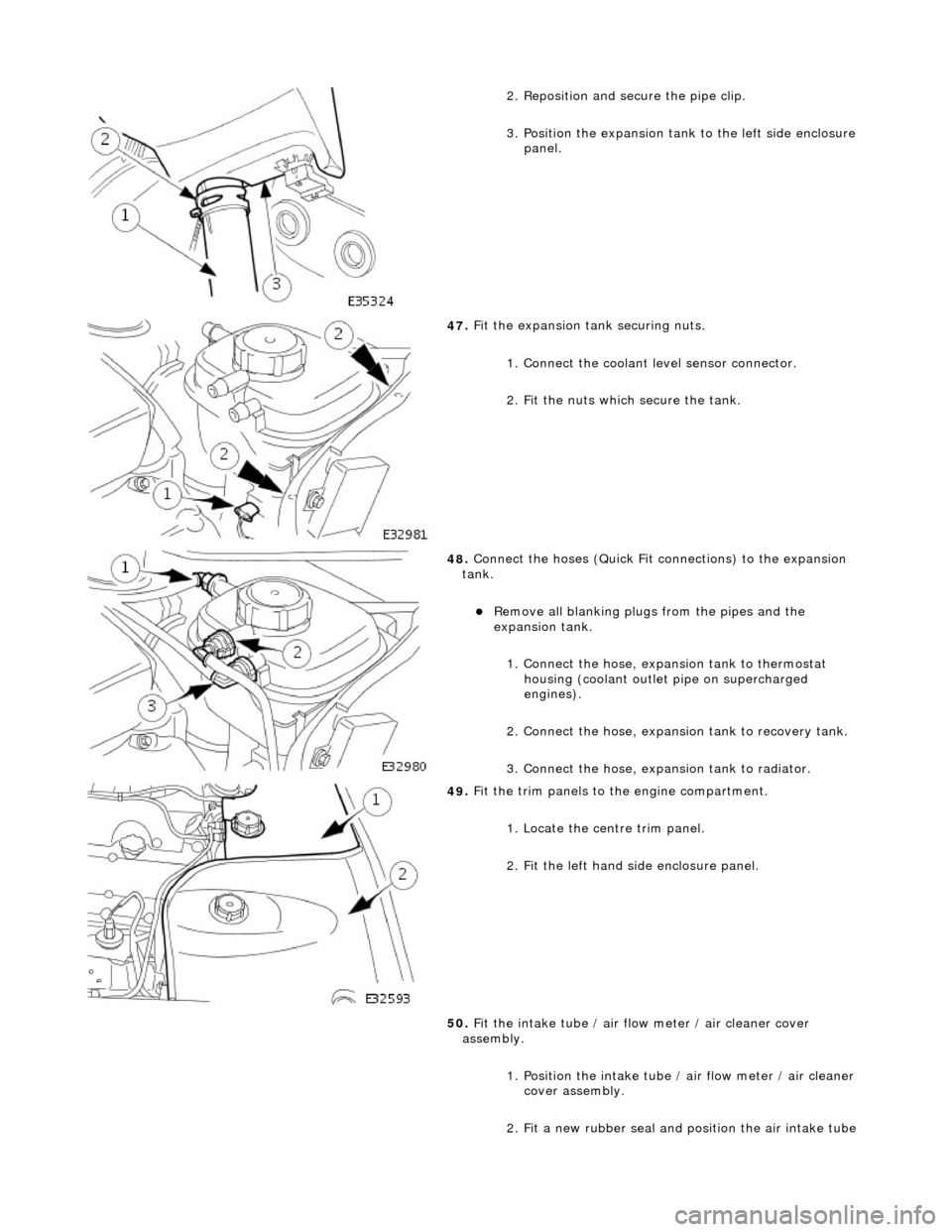

Page 921 of 2490

2

. Reposition and secure the pipe clip.

3. Position the expansion tank to the left side enclosure

panel.

47

.

Fit the expansion tank securing nuts.

1. Connect the coolant level sensor connector.

2. Fit the nuts which secure the tank.

48

.

Connect the hoses (Quick Fit connections) to the expansion

tank.

пЃ¬Remove all blanking plug s

from the pipes and the

expansion tank.

1. Connect the hose, expansion tank to thermostat housing (coolant outlet pipe on supercharged

engines).

2. Connect the hose, expansion tank to recovery tank.

3. Connect the hose, expansion tank to radiator.

49

.

Fit the trim panels to the engine compartment.

1. Locate the centre trim panel.

2. Fit the left hand side enclosure panel.

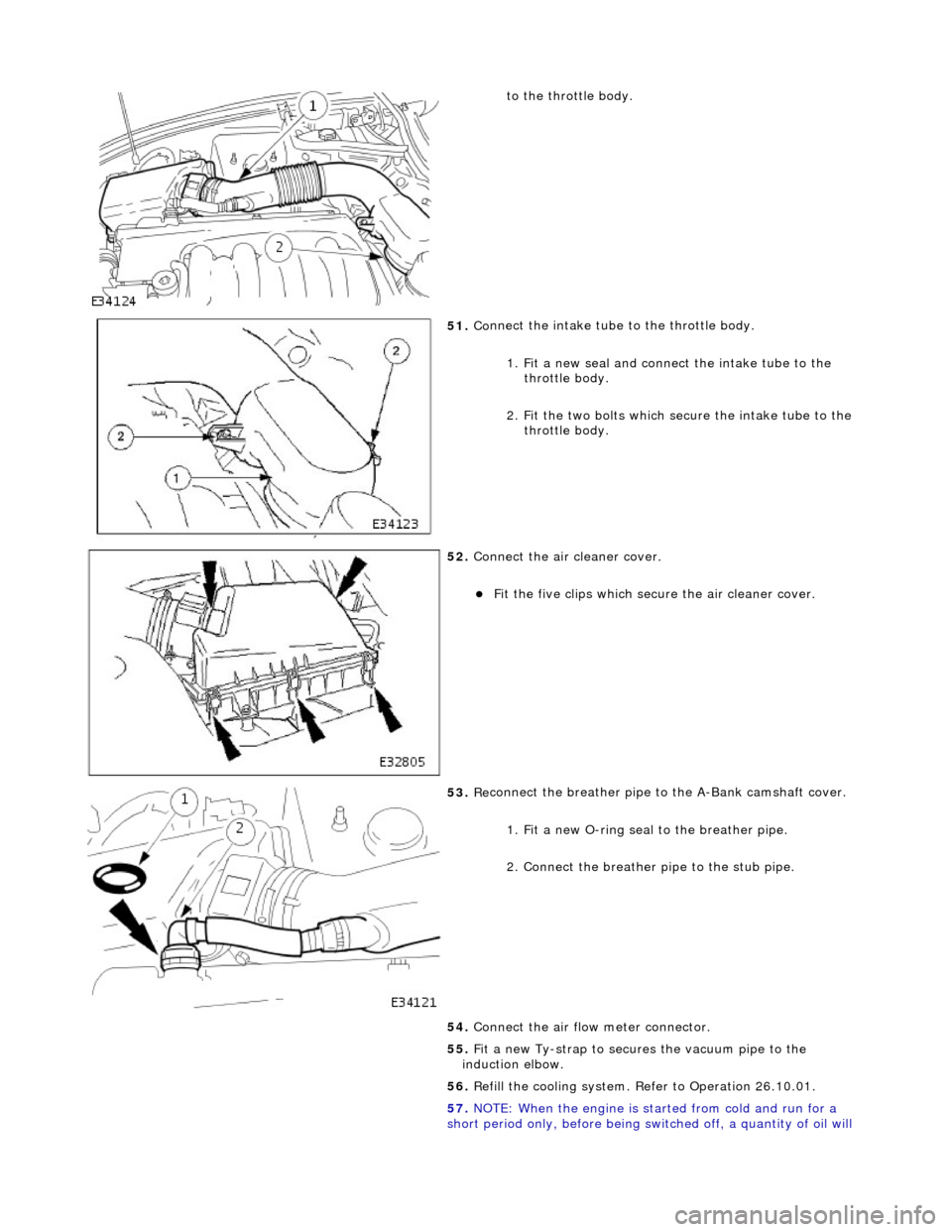

50. Fit the intake tube / air flow meter / air cleaner cover

assembly.

1. Position the intake tube / air flow meter / air cleaner

cover assembly.

2. Fit a new rubber seal and po sition the air intake tube

Page 922 of 2490

to th

e throttle body.

51 . Co

nnect the intake tube to the throttle body.

1. Fit a new seal and connect the intake tube to the throttle body.

2. Fit the two bolts which secure the intake tube to the throttle body.

52 . Conne

ct the air cleaner cover.

пЃ¬F

it

the five clips which secu

re the air cleaner cover.

53 . Re

connect the breather pipe to the A-Bank camshaft cover.

1. Fit a new O-ring seal to the breather pipe.

2. Connect the breather pipe to the stub pipe.

54. Connect the air flow meter connector.

55. Fit a new Ty-strap to secures the vacuum pipe to the

induction elbow.

56. Refill the cooling system. Refer to Operation 26.10.01.

57. NOTE: When the engine is star ted from cold and run for a

short period only, before being swit ched off, a quantity of oil will