wheel JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2384 of 2490

Generally, resistance spot welding equipment used in the motor vehicle repair industry does not produce welds of equivalent strength to those achieved during manufactu re. The expression 'single row of resistance spot welds' indicates that the spots

should be spaced on a pitch of 19mm to 25mm, which normally results in mo re spot welds than those produced in the

original factory joint.

Resistance spot welds should be removed using a resistance spot weld cutter. If the new joint is to be MIG plug welded, old

resistance spot welds should be cut from the panel to be reta ined and the resulting holes used for plug welding. Suitable

holes may also be drilled or punched; 8,0 mm dia for sect ions up to 1,6 mm, and 10,0 mm dia for thicker sections.

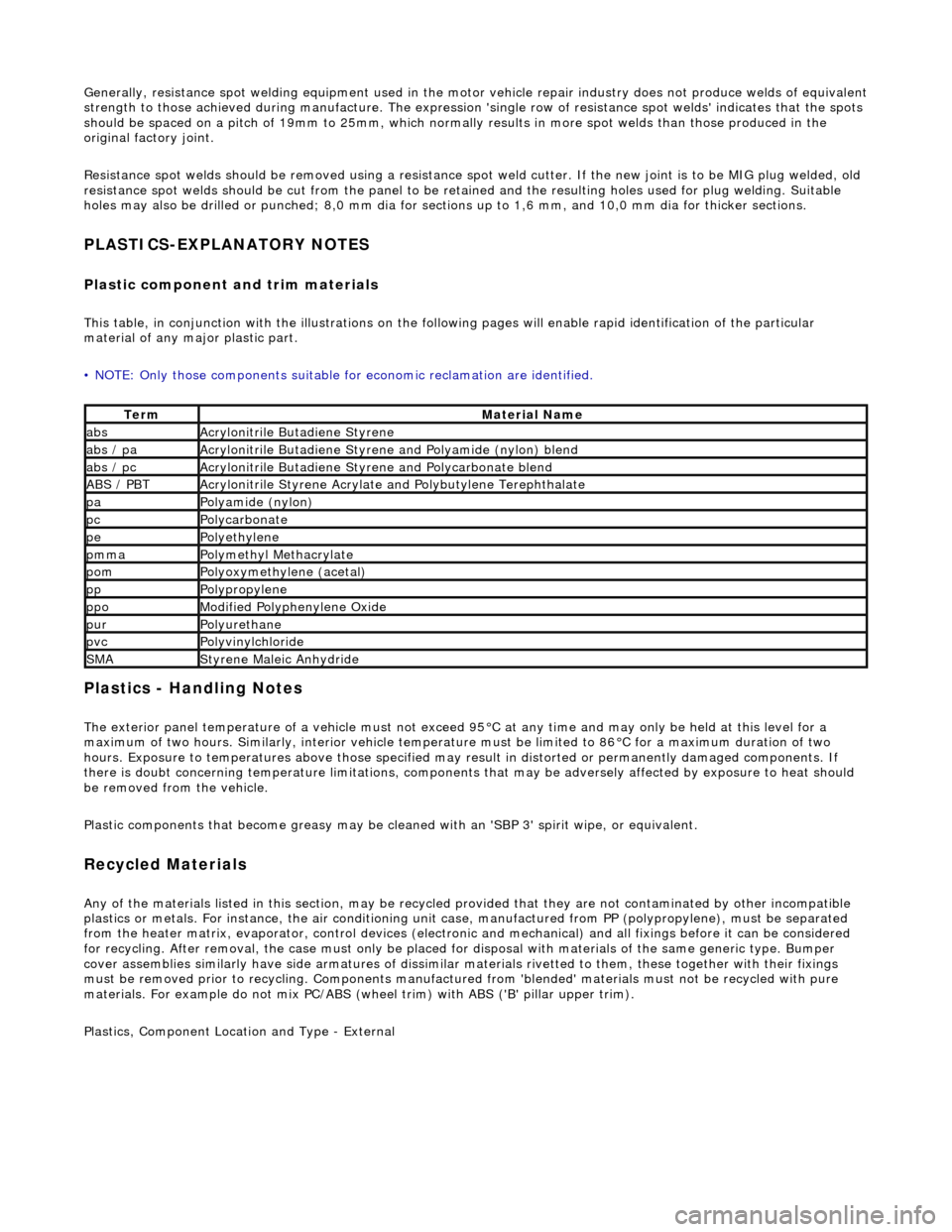

PLASTICS-EXPLANATORY NOTES

Plastic component and trim materials

This table, in conjunction with the illu strations on the following pages will enable rapid identification of the particular

material of any major plastic part.

• NOTE: Only those components suitable for economic reclamation are identified.

Plastics - Handling Notes

The exterior panel temperature of a vehicle must not exceed 95°C at any time and may only be held at this level for a

maximum of two hours. Similarly, interior vehicle temperatur e must be limited to 86°C for a maximum duration of two

hours. Exposure to temperatures above those specified may result in distorted or permanently damaged components. If

there is doubt concerning temperature limitations, components that may be adversel y affected by exposure to heat should

be removed from the vehicle.

Plastic components that become greasy may be clea ned with an 'SBP 3' spirit wipe, or equivalent.

Recycled Materials

Any of the materials listed in this section, may be recycled provided that they ar e not contaminated by other incompatible

plastics or metals. For instan ce, the air conditioning unit case, manufactur ed from PP (polypropylene), must be separated

from the heater matrix, evaporator, contro l devices (electronic and mechanical) and all fixings before it can be considered

for recycling. After removal, the case mu st only be placed for disposal with materials of the same generic type. Bumper

cover assemblies similarly have side arma tures of dissimilar materials rivetted to them, these together with their fixings

must be removed prior to recy cling. Components manufactured from 'blended' materials must not be recycled with pure

materials. For example do not mix PC/ABS (wheel trim) with ABS ('B' pillar upper trim).

Plastics, Component Location and Type - External

TermMaterial Name

absAcrylonitrile Butadiene Styrene

abs / paAcrylonitrile Butadiene Styrene and Polyamide (nylon) blend

abs / pcAcrylonitrile Butadiene Styrene and Polycarbonate blend

ABS / PBTAcrylonitrile Styrene Acrylate and Polybutylene Terephthalate

paPolyamide (nylon)

pcPolycarbonate

pePolyethylene

pmmaPolymethyl Methacrylate

pomPolyoxymethylene (acetal)

ppPolypropylene

ppoModified Polyphenylene Oxide

purPolyurethane

pvcPolyvinylchloride

SMAStyrene Maleic Anhydride

Page 2386 of 2490

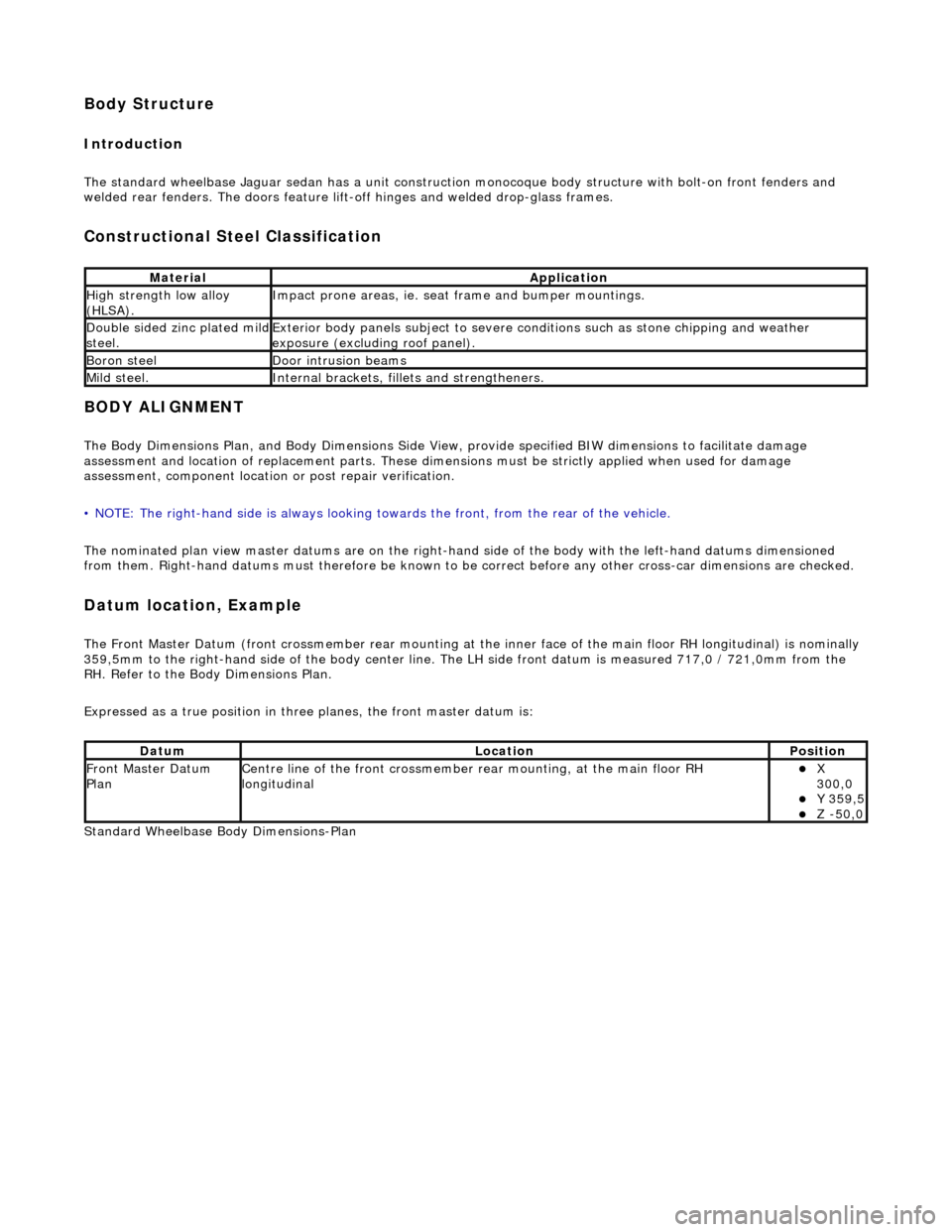

Body Structure

Introduction

The standard wheelbase Jaguar sedan has a unit construction monocoque body structure with bolt-on front fenders and

welded rear fenders. The doors feature lif t-off hinges and welded drop-glass frames.

Constructional Steel Classification

BODY ALIGNMENT

The Body Dimensions Plan, and Body Dimensions Side View, provide specified BIW dimensions to facilitate damage

assessment and location of replacemen t parts. These dimensions must be strictly applied when used for damage

assessment, component location or post repair verification.

• NOTE: The right-hand side is always looking towards the front, from the rear of the vehicle.

The nominated plan view master datums are on the right-hand side of the body with the left-hand datums dimensioned

from them. Right-hand datums must therefore be known to be correct before any other cross-car dimensions are checked.

Datum location, Example

The Front Master Datum (front crossmember rear mounting at the inner face of the main floor RH longitudinal) is nominally

359,5mm to the right-hand side of the body center line. The LH side fron t datum is measured 717,0 / 721,0mm from the

RH. Refer to the Body Dimensions Plan.

Expressed as a true posi tion in three planes, the front master datum is:

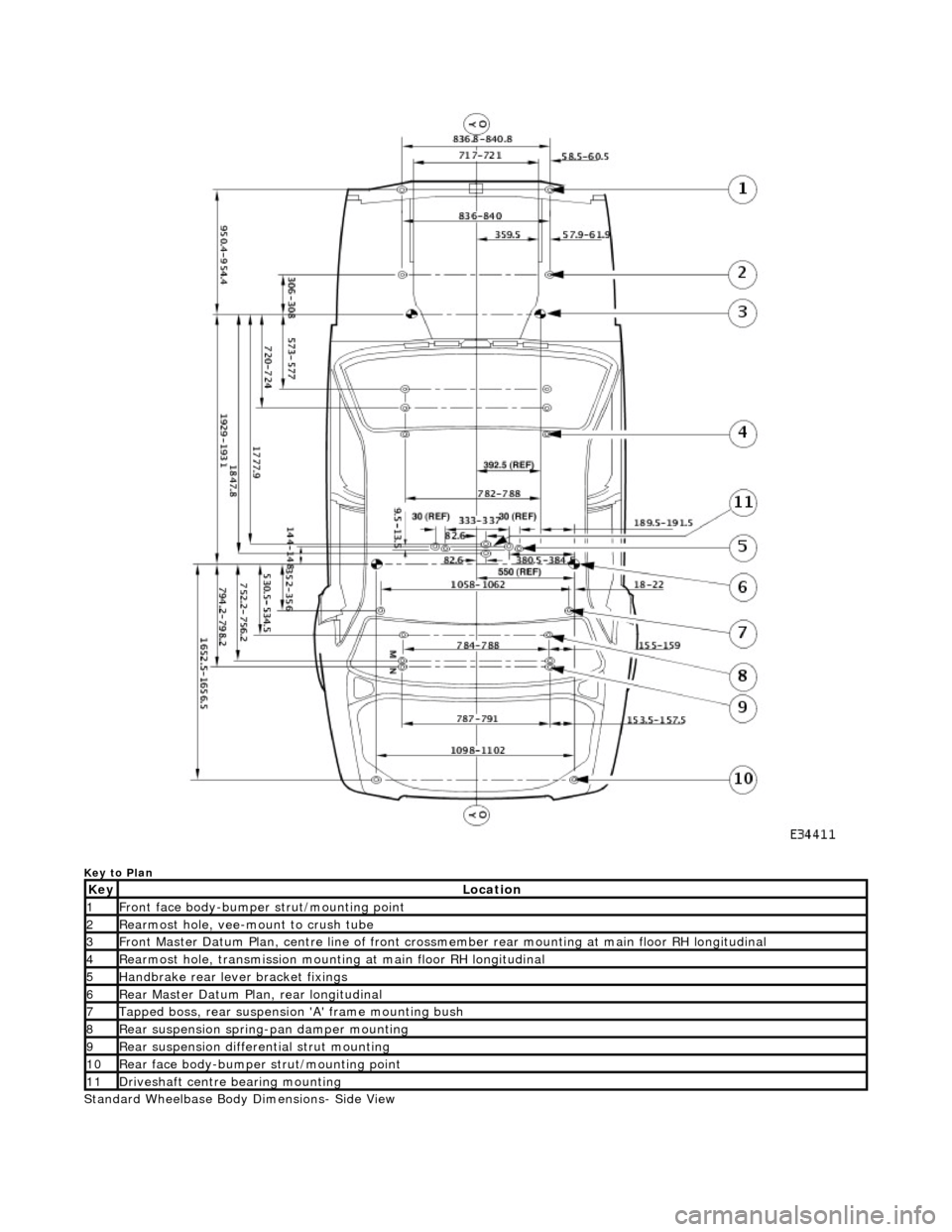

Standard Wheelbase Bo dy Dimensions-Plan

MaterialApplication

High strength low alloy

(HLSA).Impact prone areas, ie. seat frame and bumper mountings.

Double sided zinc plated mild steel.Exterior body panels subject to severe cond itions such as stone chipping and weather

exposure (excluding roof panel).

Boron steelDoor intrusion beams

Mild steel.Internal brackets, fill ets and strengtheners.

DatumLocationPosition

Front Master Datum

PlanCentre line of the front crossmember rear mounting, at the main floor RH

longitudinalX

300,0

Y 359,5 Z -50,0

Page 2387 of 2490

Key to Plan

Standard Wheelbase Body Dimensions- Side View

KeyLocation

1Front face body-bumper strut/mounting point

2Rearmost hole, vee-mount to crush tube

3Front Master Datum Plan, centre li ne of front crossmember rear mount ing at main floor RH longitudinal

4Rearmost hole, transmission mounting at main floor RH longitudinal

5Handbrake rear lever bracket fixings

6Rear Master Datum Plan, rear longitudinal

7Tapped boss, rear suspension 'A' frame mounting bush

8Rear suspension spring-pan damper mounting

9Rear suspension differential strut mounting

10Rear face body-bumper strut/mounting point

11Driveshaft centre bearing mounting

Page 2388 of 2490

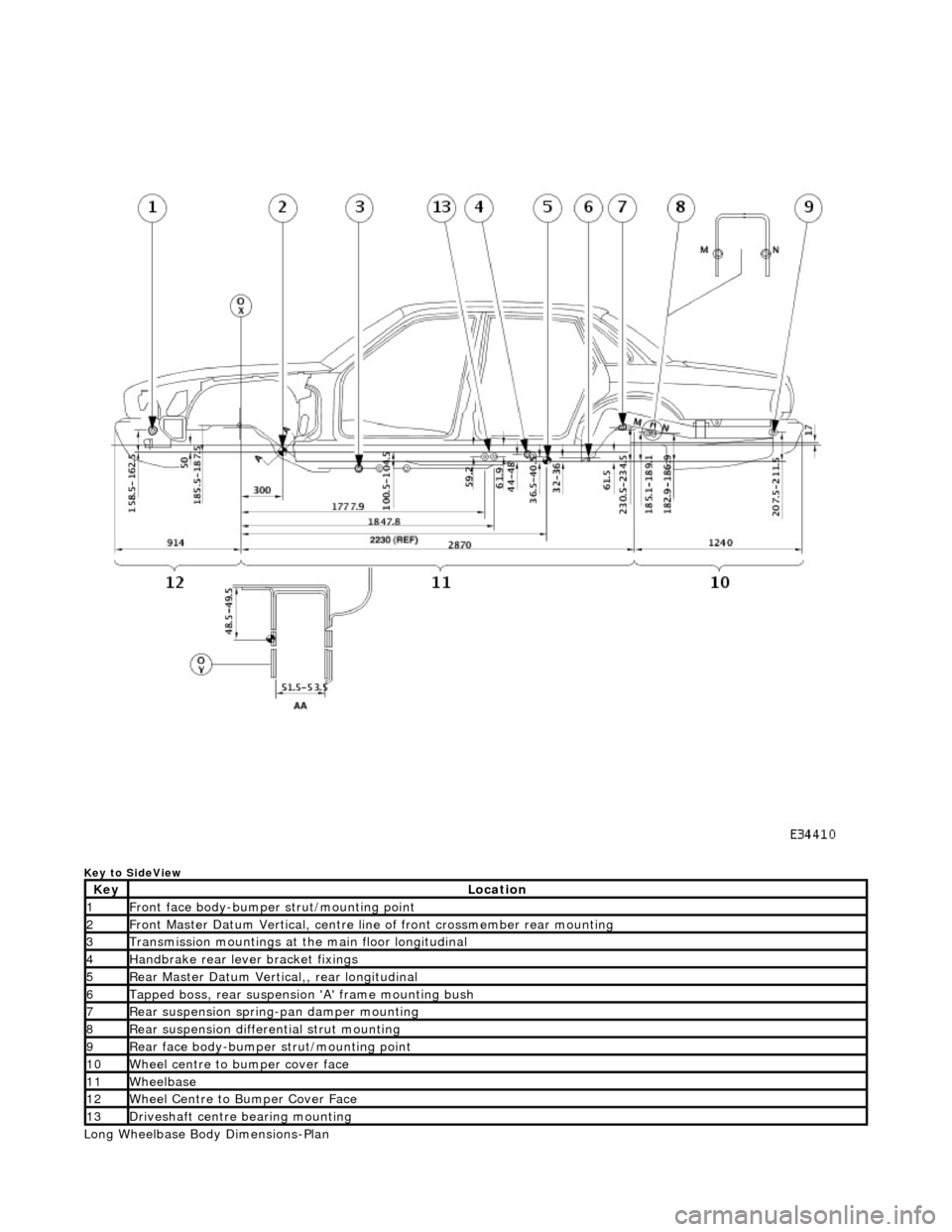

Key to SideView

Long Wheelbase Body Dimensions-Plan

KeyLocation

1Front face body-bumper strut/mounting point

2Front Master Datum Vertical, centre line of front crossmember rear mounting

3Transmission mountings at the main floor longitudinal

4Handbrake rear lever bracket fixings

5Rear Master Datum Vertical,, rear longitudinal

6Tapped boss, rear suspensi on 'A' frame mounting bush

7Rear suspension spring-pan damper mounting

8Rear suspension differential strut mounting

9Rear face body-bumper strut/mounting point

10Wheel centre to bumper cover face

11Wheelbase

12Wheel Centre to Bumper Cover Face

13Driveshaft centre bearing mounting

Page 2389 of 2490

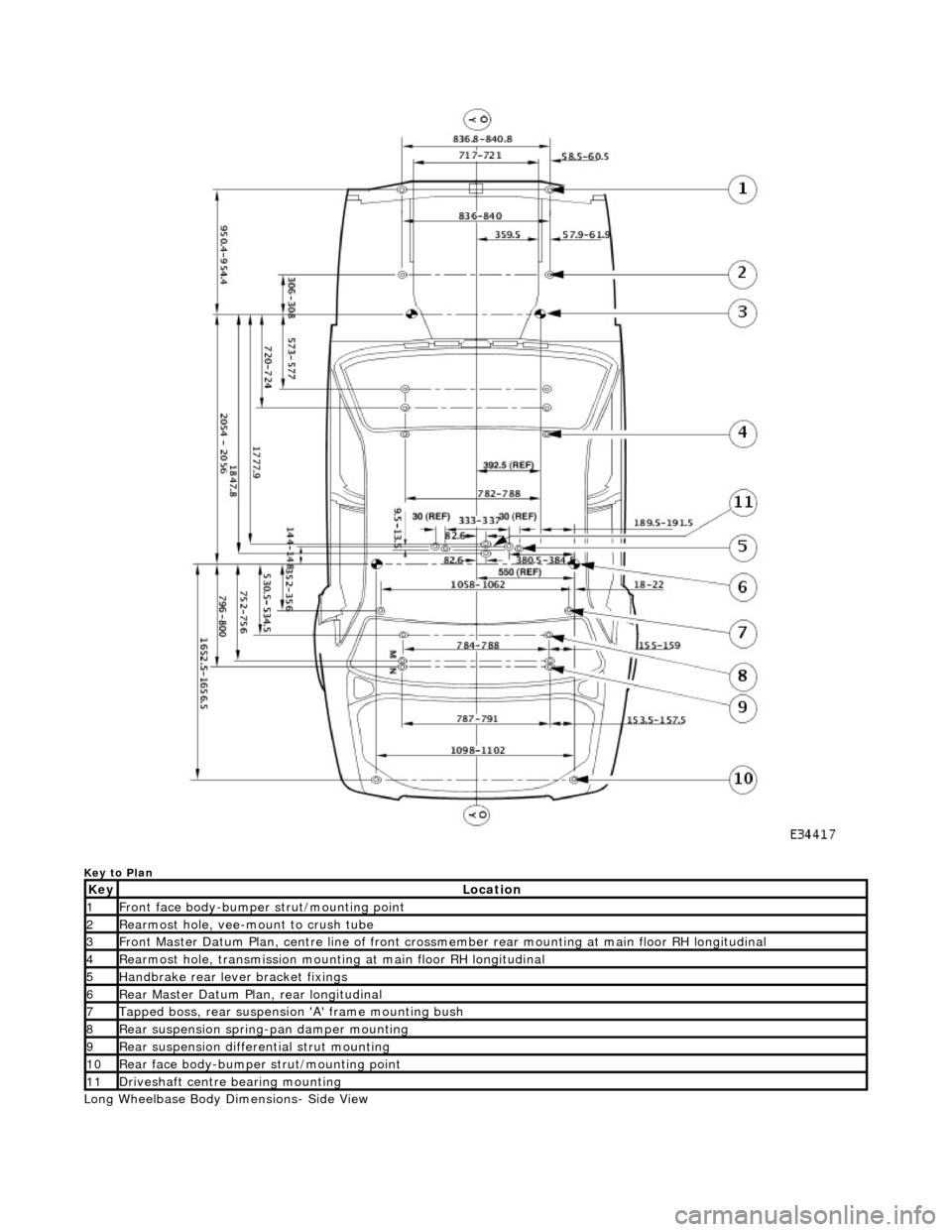

Key to Plan

Long Wheelbase Body Dimensions- Side View

KeyLocation

1Front face body-bumper strut/mounting point

2Rearmost hole, vee-mount to crush tube

3Front Master Datum Plan, centre line of front crossmember rear mount ing at main floor RH longitudinal

4Rearmost hole, transmission mounting at main floor RH longitudinal

5Handbrake rear lever bracket fixings

6Rear Master Datum Plan, rear longitudinal

7Tapped boss, rear suspension 'A' frame mounting bush

8Rear suspension spring-pan damper mounting

9Rear suspension differential strut mounting

10Rear face body-bumper strut/mounting point

11Driveshaft centre bearing mounting

Page 2390 of 2490

Key to SideView

KeyLocation

1Front face body-bumper strut/mounting point

2Front Master Datum Vertical, centre line of front crossmember rear mounting

3Transmission mountings at the main floor longitudinal

4Handbrake rear lever bracket fixings

5Rear Master Datum Vertical,, rear longitudinal

6Tapped boss, rear suspensi on 'A' frame mounting bush

7Rear suspension spring-pan damper mounting

8Rear suspension differential strut mounting

9Rear face body-bumper strut/mounting point

10Wheel centre to bumper cover face

11Wheelbase

12Wheel Centre to Bumper Cover Face

13Driveshaft centre bearing mounting

Page 2416 of 2490

Replacement bumper cover assemblies includer side armatures, which should be removed from discarded bumper

assemblies and rout ed for recycling.

BODY SIDE MOULDINGS

Description

Two types of moulding are fitted to the standard wheelbase sedan. The lower mouldings are positioned on the body / door

lower feature lines. Where applicable, the upper mouldings are positioned using the lower mouldings as data. Replacement

lower mouldings are supplied in a primed condition and must be finished as detailed in this section.

Side Moulding Positions

Body Closures

Clearances and Alignments

When any panel, closure or body component is renewed, refitted or reset, the specified clearances and alignments must be

restored. This ensures that vehicle appearance and operation fully satisfy design intent and the customer.

Clearances

Gaps should be uniform around body panel contours and must be parallel to within 1mm in a 400mm linear measurement.

LocationFinishApplicationFixing method

UpperPolished stainless steelDaimler / VDPSelf adhesive

LowerBody colorAll modelsSelf adhesive

1Adhesive tape

2Moulding, Daimler/VDP

3Moulding all models

Page 2422 of 2490

8. Remove generator front cooling duct.

Remove bolt.

Move duct rearwards to rele ase tang from undertray.

Release front duct from rear vertical duct.

9. Remove scrivets or screws se curing undertray to bumper

cover. Discard scrivets.

10. Remove and discard tiestrap securing undertray to body

brace.

11. At each side of vehicle, remo ve and discard scrivet securing undertray to wheelarch liner.

12. Remove undertray from vehicle.

13. Remove both front road wheels. Refer to Section 100-02.

14. Remove both front road springs. Refer to 60. 20.02.

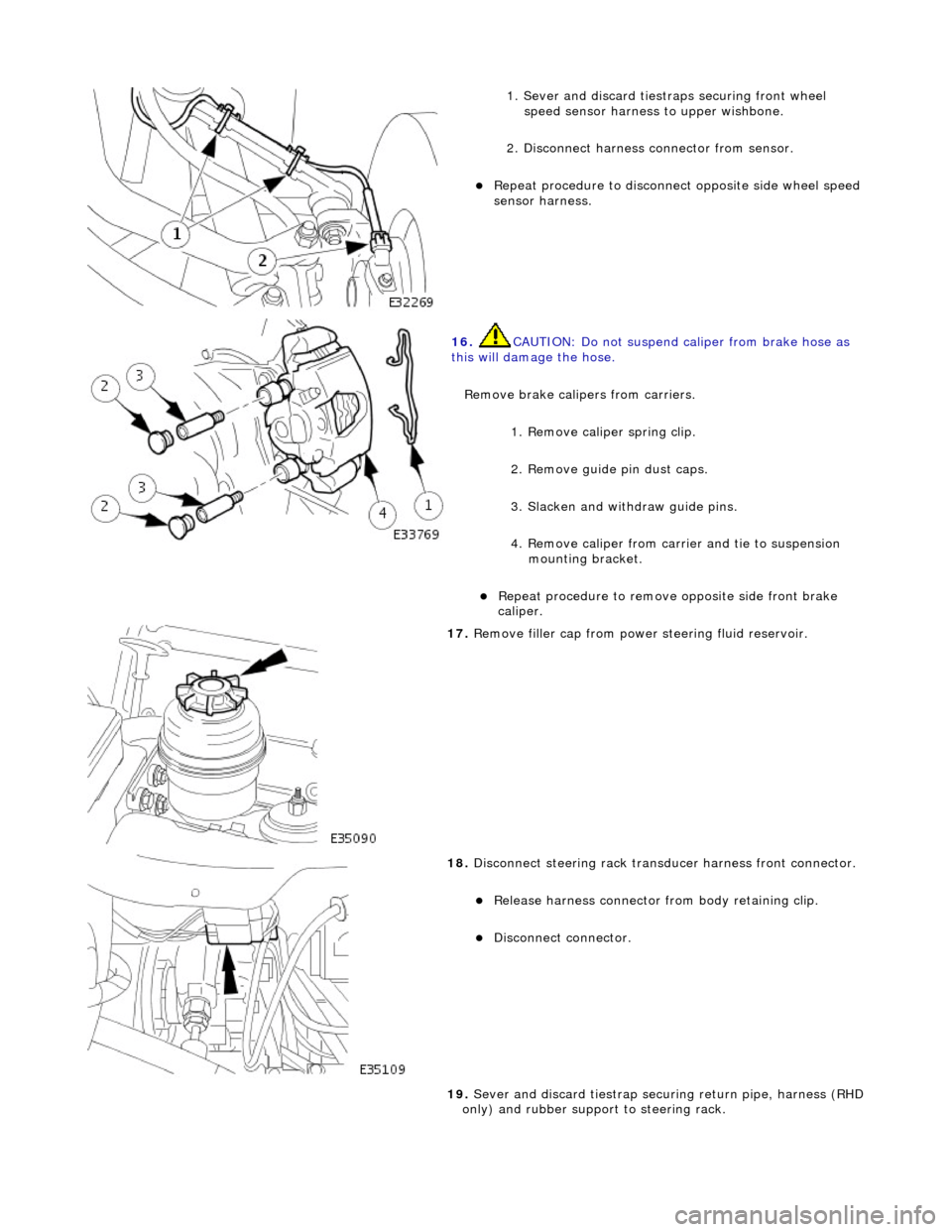

15. Disconnect wheel speed sensor harness connectors.

Page 2423 of 2490

1. Sever and discard tiestraps securing front wheel

speed sensor harness to upper wishbone.

2. Disconnect harness connector from sensor.

Repeat procedure to disconnect opposite side wheel speed

sensor harness.

16. CAUTION: Do not suspend caliper from brake hose as

this will damage the hose.

Remove brake calipers from carriers.

1. Remove caliper spring clip.

2. Remove guide pin dust caps.

3. Slacken and withdraw guide pins.

4. Remove caliper from carrier and tie to suspension mounting bracket.

Repeat procedure to remove opposite side front brake

caliper.

17. Remove filler cap from power steering fluid reservoir.

18. Disconnect steering rack transducer harness front connector.

Release harness connector from body retaining clip.

Disconnect connector.

19. Sever and discard tiestrap secu ring return pipe, harness (RHD

only) and rubber support to steering rack.

Page 2436 of 2490

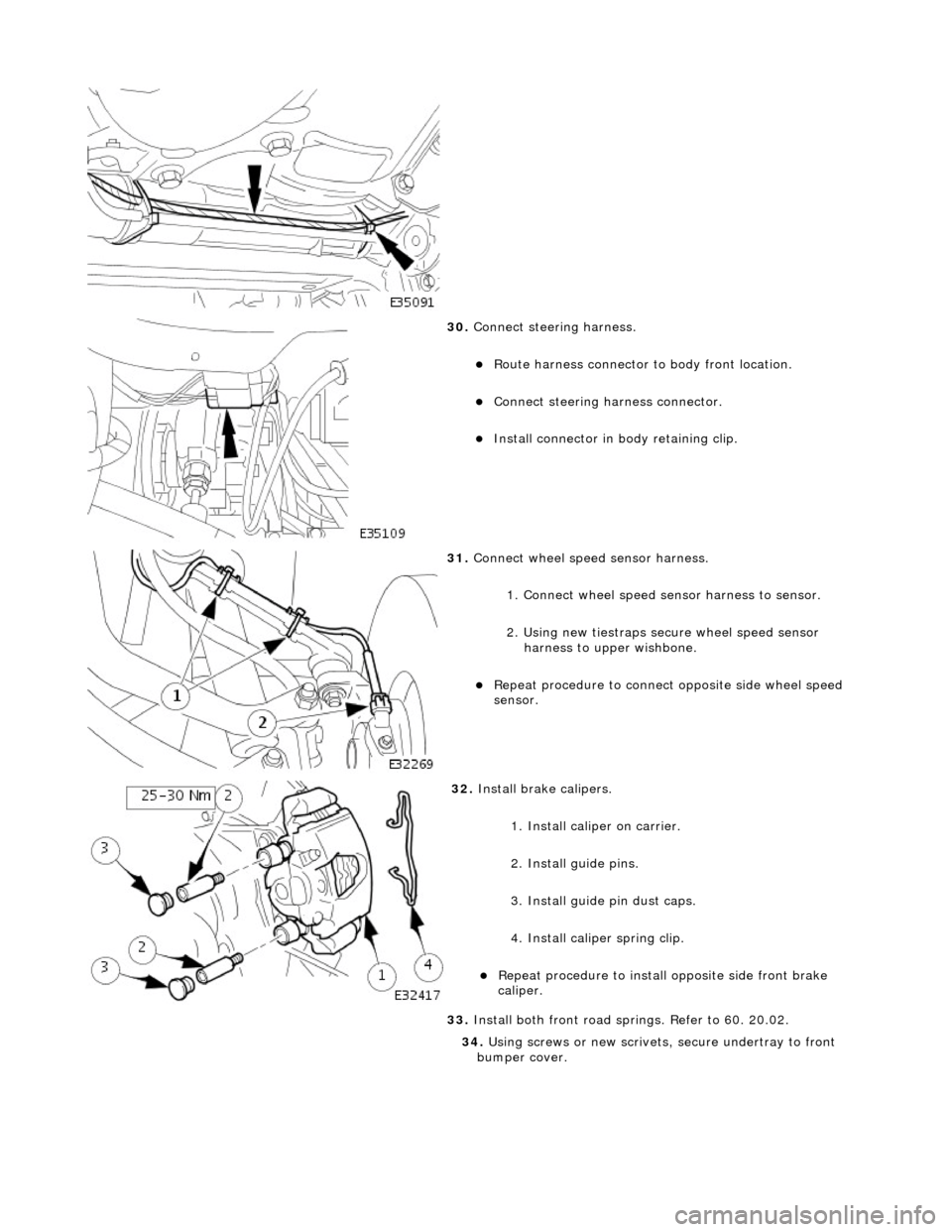

30. Connect steering harness.

Route harness connector to body front location.

Connect steering ha rness connector.

Install connector in body retaining clip.

31. Connect wheel speed sensor harness.

1. Connect wheel speed sensor harness to sensor.

2. Using new tiestraps secure wheel speed sensor harness to upper wishbone.

Repeat procedure to connect opposite side wheel speed

sensor.

32. Install brake calipers.

1. Install caliper on carrier.

2. Install guide pins.

3. Install guide pin dust caps.

4. Install caliper spring clip.

Repeat procedure to install opposite side front brake

caliper.

33. Install both front road sp rings. Refer to 60. 20.02.

34. Using screws or new scrivets , secure undertray to front

bumper cover.