Wipe JAGUAR X308 1998 2.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2194 of 2490

Glass, Frames and Mechanisms - Rear Door Window Glass Weatherstrip

Removal and Installation

Removal

Installation

1.

Pull seal out of door frame channelling and discard seal.

2. Clean channelling ensuring that any residual adhesive is

removed.

1. Avoiding adhesive at ends, apply a suitable dry lubricant to

seal.

2. Commencing at front of frame, feed seal into channelling

ensuring it is uniformly tensioned and free from kinks.

3. Wipe residual lubricant fro m adhesive contact areas.

4. Remove protective tape from en ds and press adhesive firmly

onto frame.

5. Clean any excess lubricant from external surfaces and check

that door shuts correctly.

Page 2201 of 2490

Installation

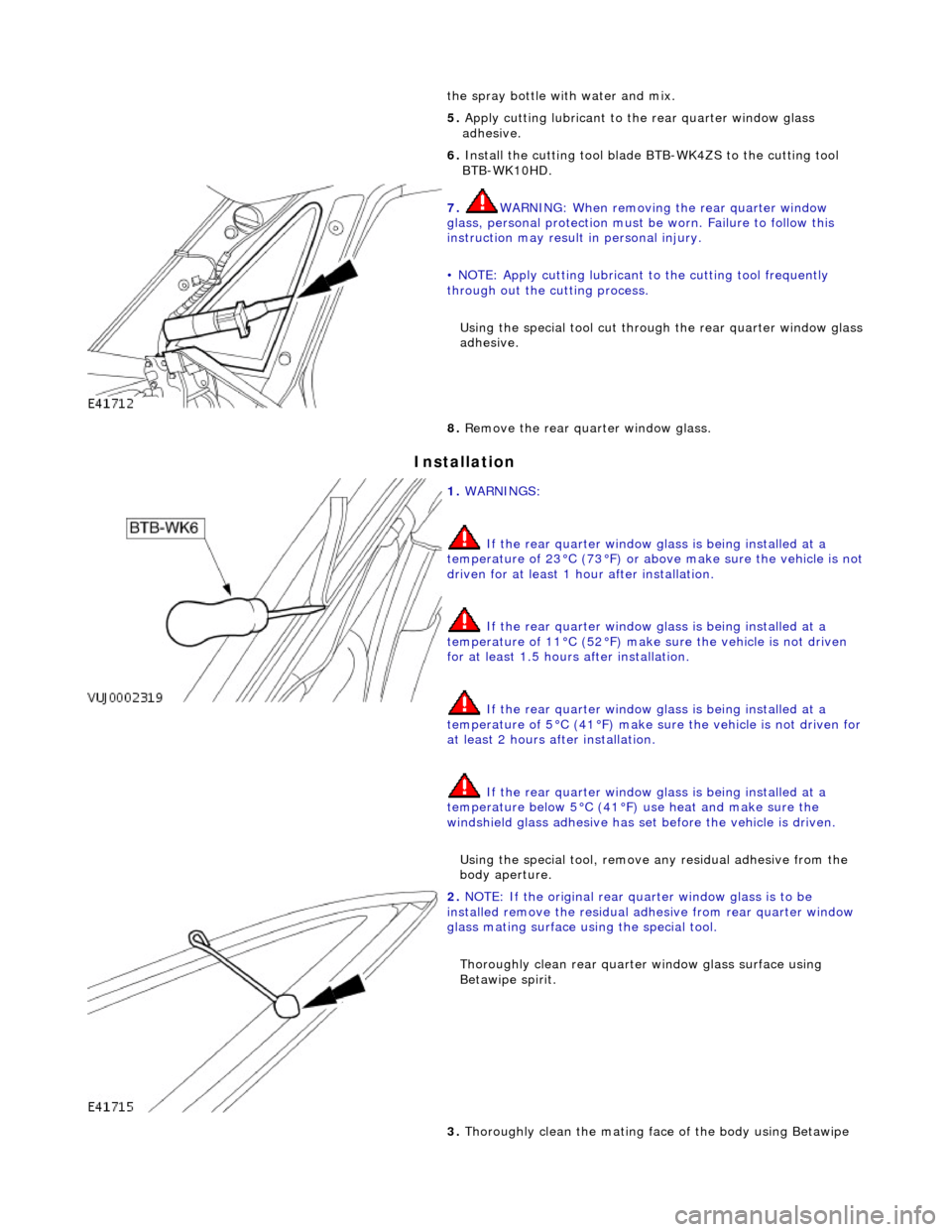

the spray bottle with water and mix.

5. Apply cutting lubricant to the rear quarter window glass

adhesive.

6. Install the cutting tool blade BTB-WK4ZS to the cutting tool

BTB-WK10HD.

7. WARNING: When removing the rear quarter window

glass, personal protec tion must be worn. Failure to follow this

instruction may result in personal injury.

• NOTE: Apply cutting lubricant to the cutting tool frequently

through out the cutting process.

Using the special tool cut throug h the rear quarter window glass

adhesive.

8. Remove the rear quarter window glass.

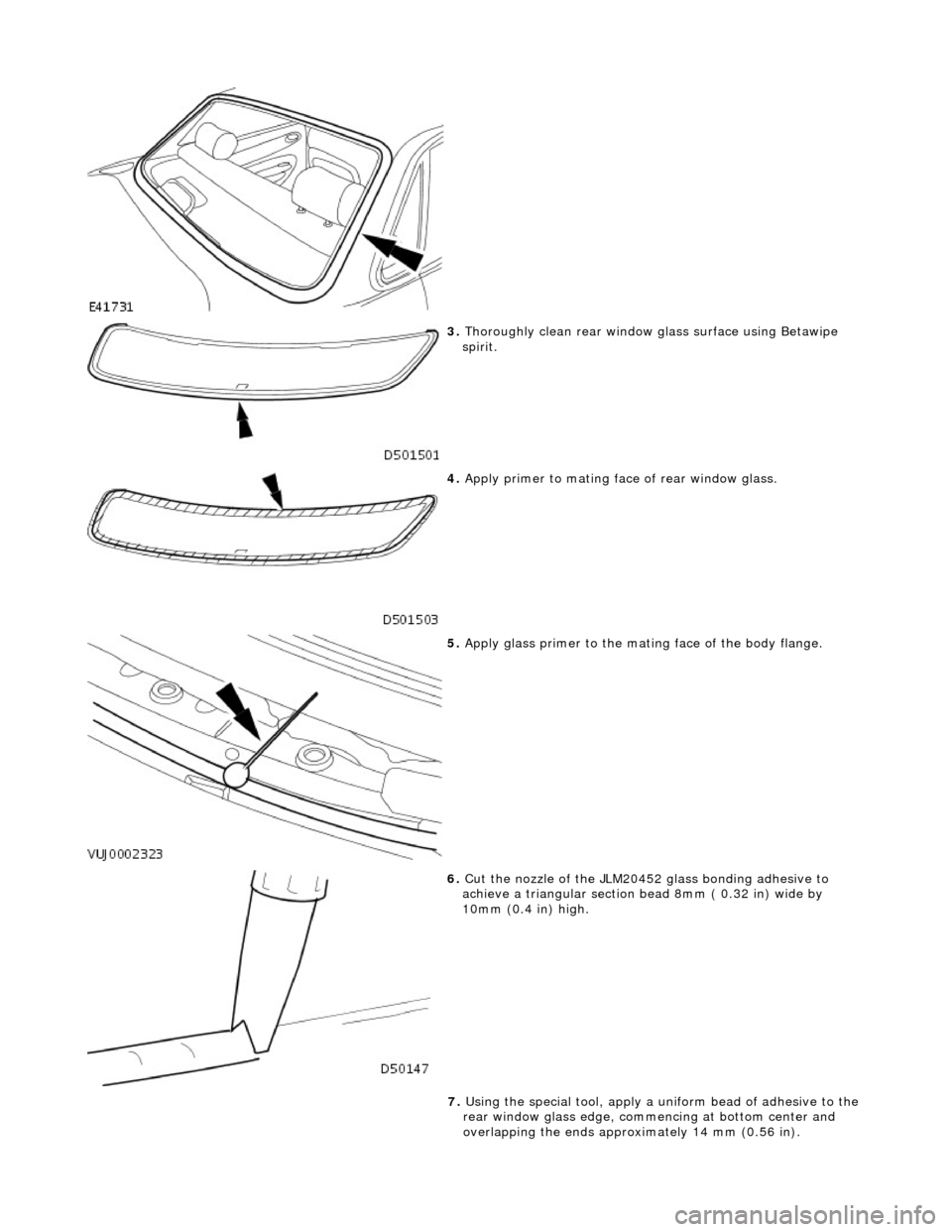

1. WARNINGS:

If the rear quarter window glass is being installed at a

temperature of 23°C (73°F) or abov e make sure the vehicle is not

driven for at least 1 hour after installation.

If the rear quarter window glass is being installed at a

temperature of 11°C (52°F) make sure the vehicle is not driven

for at least 1.5 hours after installation.

If the rear quarter window glass is being installed at a

temperature of 5°C (41°F) make su re the vehicle is not driven for

at least 2 hours after installation.

If the rear quarter window glass is being installed at a

temperature below 5°C (41°F) use heat and make sure the

windshield glass adhesive has set before the vehicle is driven.

Using the special tool, remove any residual adhe sive from the

body aperture.

2. NOTE: If the original rear qu arter window glass is to be

installed remove the residual ad hesive from rear quarter window

glass mating surface using the special tool.

Thoroughly clean rear quarte r window glass surface using

Betawipe spirit.

3. Thoroughly clean the mating face of the body using Betawipe

Page 2209 of 2490

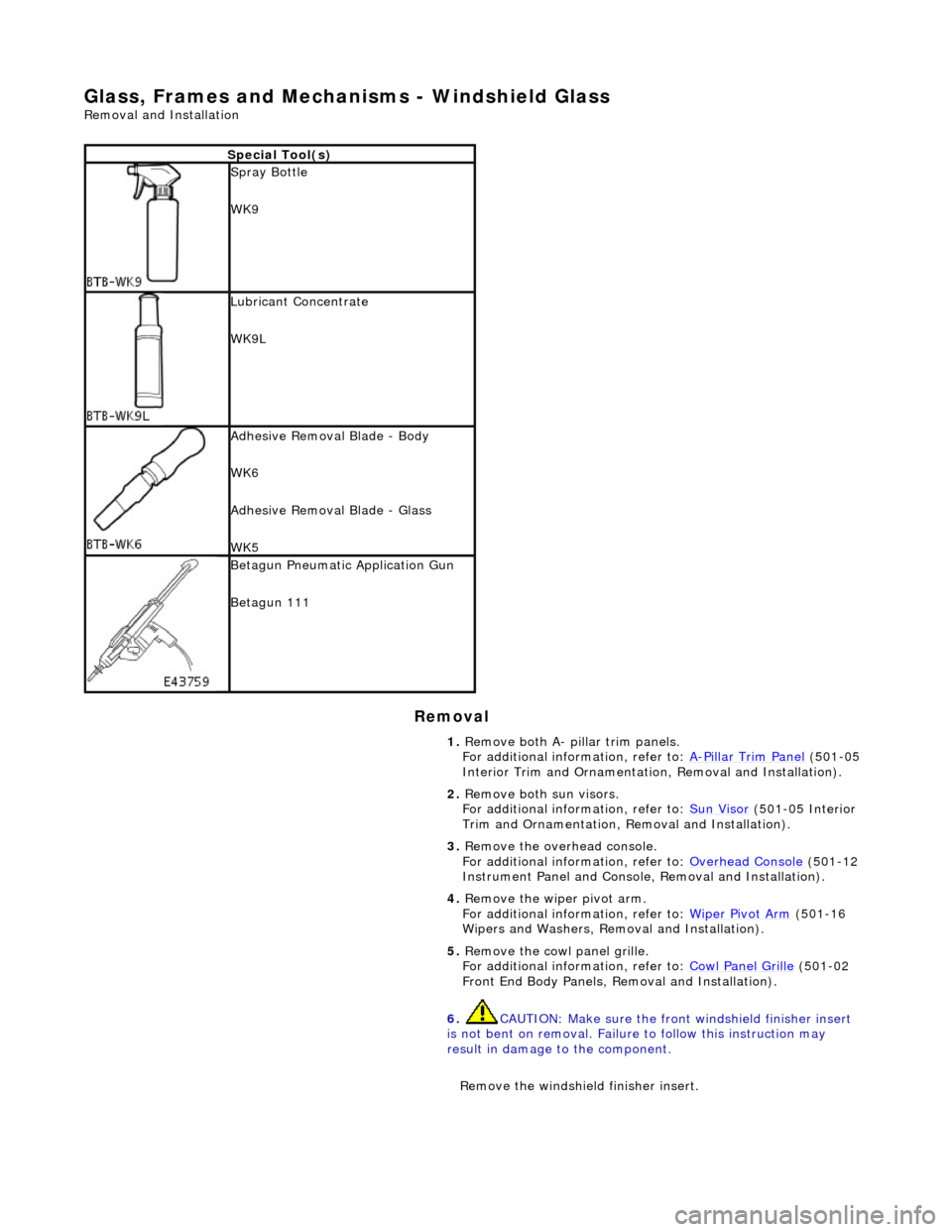

3. Thoroughly clean rear window glass surface using Betawipe

spirit.

4. Apply primer to mating face of rear window glass.

5. Apply glass primer to the mating face of the body flange.

6. Cut the nozzle of the JLM20452 glass bonding adhesive to

achieve a triangular section bead 8mm ( 0.32 in) wide by

10mm (0.4 in) high.

7. Using the special tool, apply a uni form bead of adhesive to the

rear window glass edge, commen cing at bottom center and

overlapping the ends approximately 14 mm (0.56 in).

Page 2212 of 2490

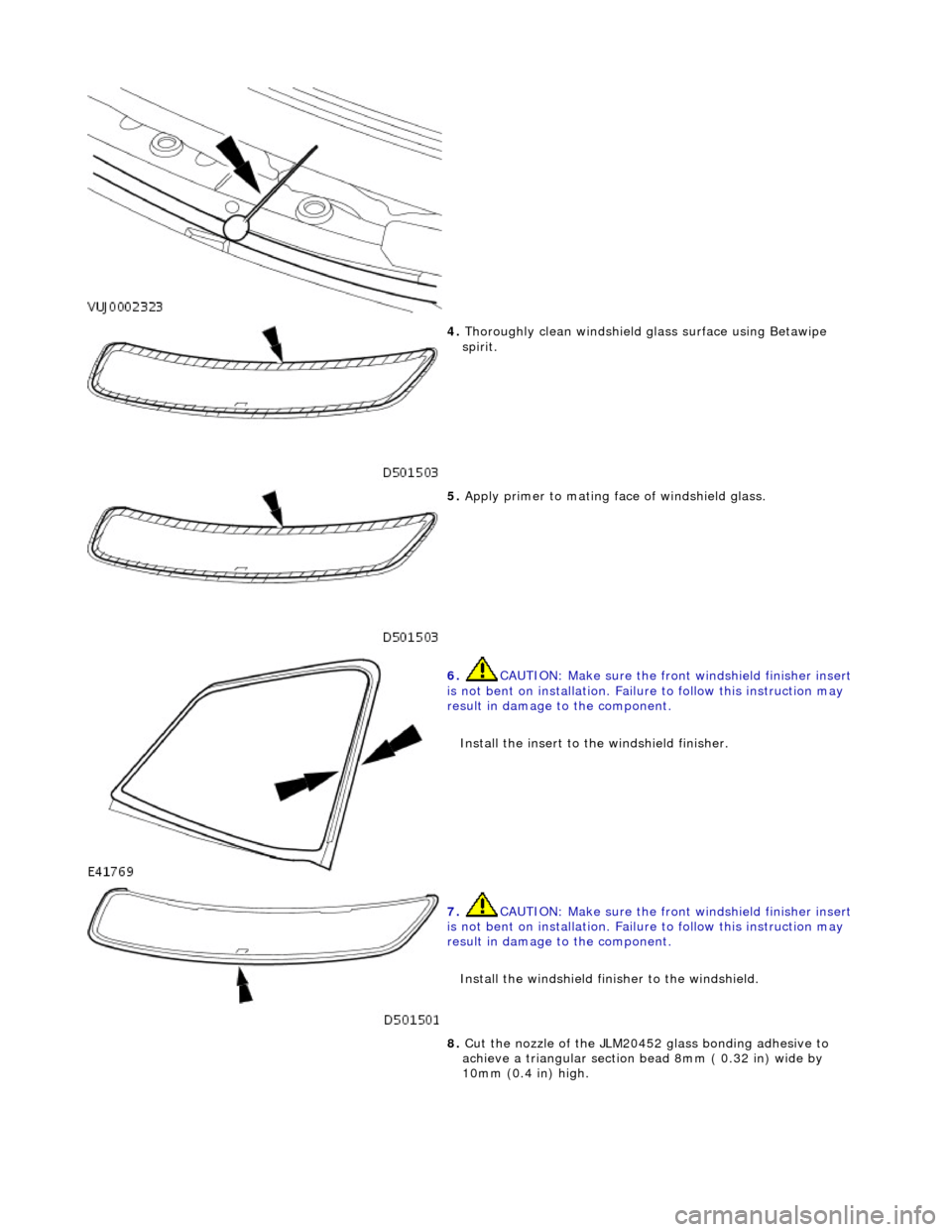

Glass, Frames and Mechanisms - Windshield Glass

Removal and Installation

Removal

Special Tool(s)

Spray Bottle

WK9

Lubricant Concentrate

WK9L

Adhesive Removal Blade - Body

WK6

Adhesive Removal Blade - Glass

WK5

Betagun Pneumatic Application Gun

Betagun 111

1. Remove both A- pill ar trim panels.

For additional information, refer to: A

-Pillar Trim Panel (501-05

Interior Trim and Ornamentatio n, Removal and Installation).

2. Remove both sun visors.

For additional information, refer to: Sun Visor

(501-05 Interior

Trim and Ornamentation, Re moval and Installation).

3. Remove the overhead console.

For additional information, refer to: Overhead Console

(501-12

Instrument Panel and Console, Removal and Installation).

4. Remove the wiper pivot arm.

For additional information, refer to: Wiper Pivot Arm

(501-16

Wipers and Washers, Remo val and Installation).

5. Remove the cowl panel grille.

For additional information, refer to: Cowl Panel Grille

(501-02

Front End Body Panels, Removal and Installation).

6. CAUTION: Make sure the front windshield finisher insert

is not bent on removal. Failure to follow this instruction may

result in damage to the component.

Remove the windshield finisher insert.

Page 2216 of 2490

4. Thoroughly clean windshield glass surface using Betawipe

spirit.

5. Apply primer to mating fa ce of windshield glass.

6. CAUTION: Make sure the front windshield finisher insert

is not bent on installation. Failure to follow this instruction may

result in damage to the component.

Install the insert to the windshield finisher.

7. CAUTION: Make sure the front windshield finisher insert

is not bent on installation. Failure to follow this instruction may

result in damage to the component.

Install the windshield finisher to the windshield.

8. Cut the nozzle of the JLM20452 glass bonding adhesive to

achieve a triangular section bead 8mm ( 0.32 in) wide by

10mm (0.4 in) high.

Page 2217 of 2490

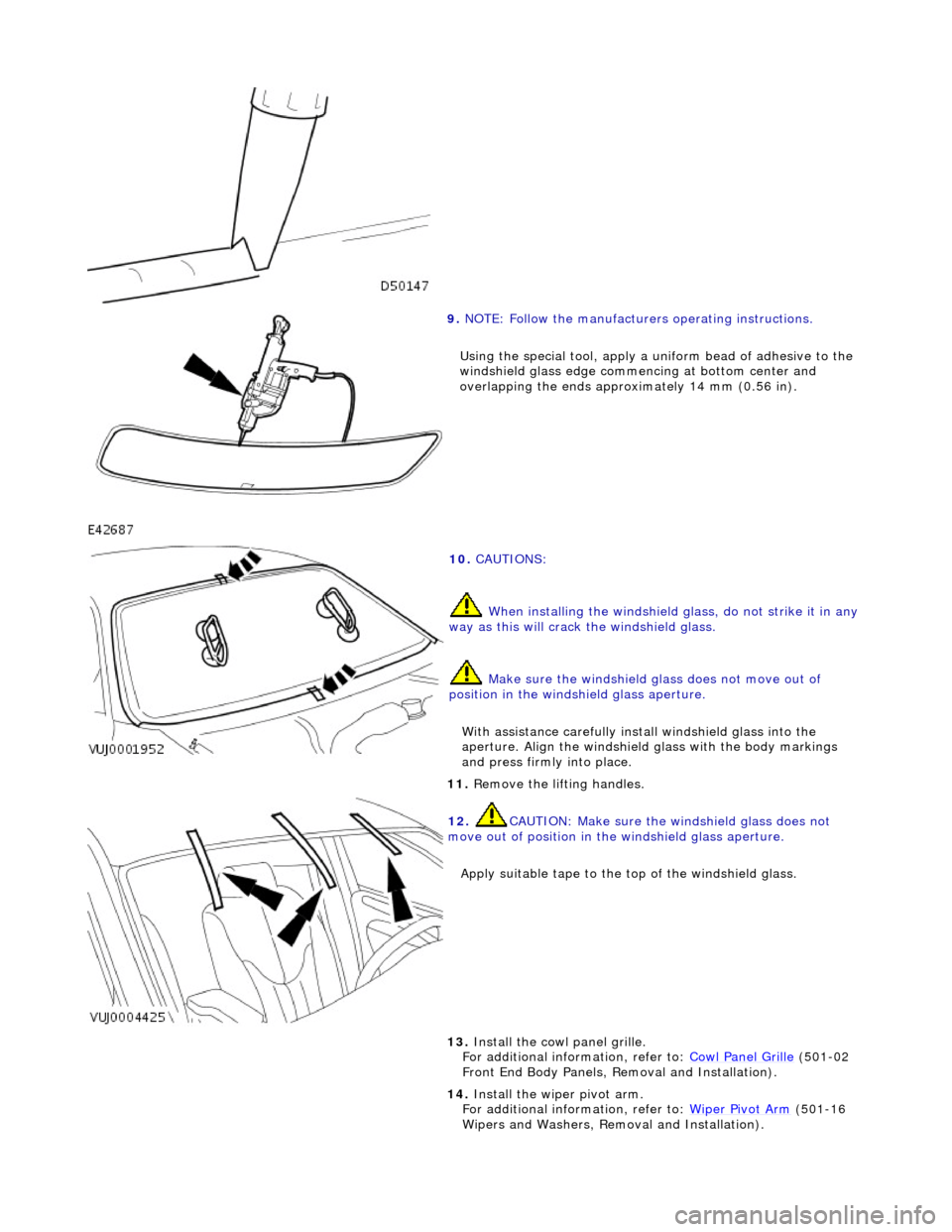

9. NOTE: Follow the manufacturers operating instructions.

Using the special tool, apply a uni form bead of adhesive to the

windshield glass edge commenc ing at bottom center and

overlapping the ends approximately 14 mm (0.56 in).

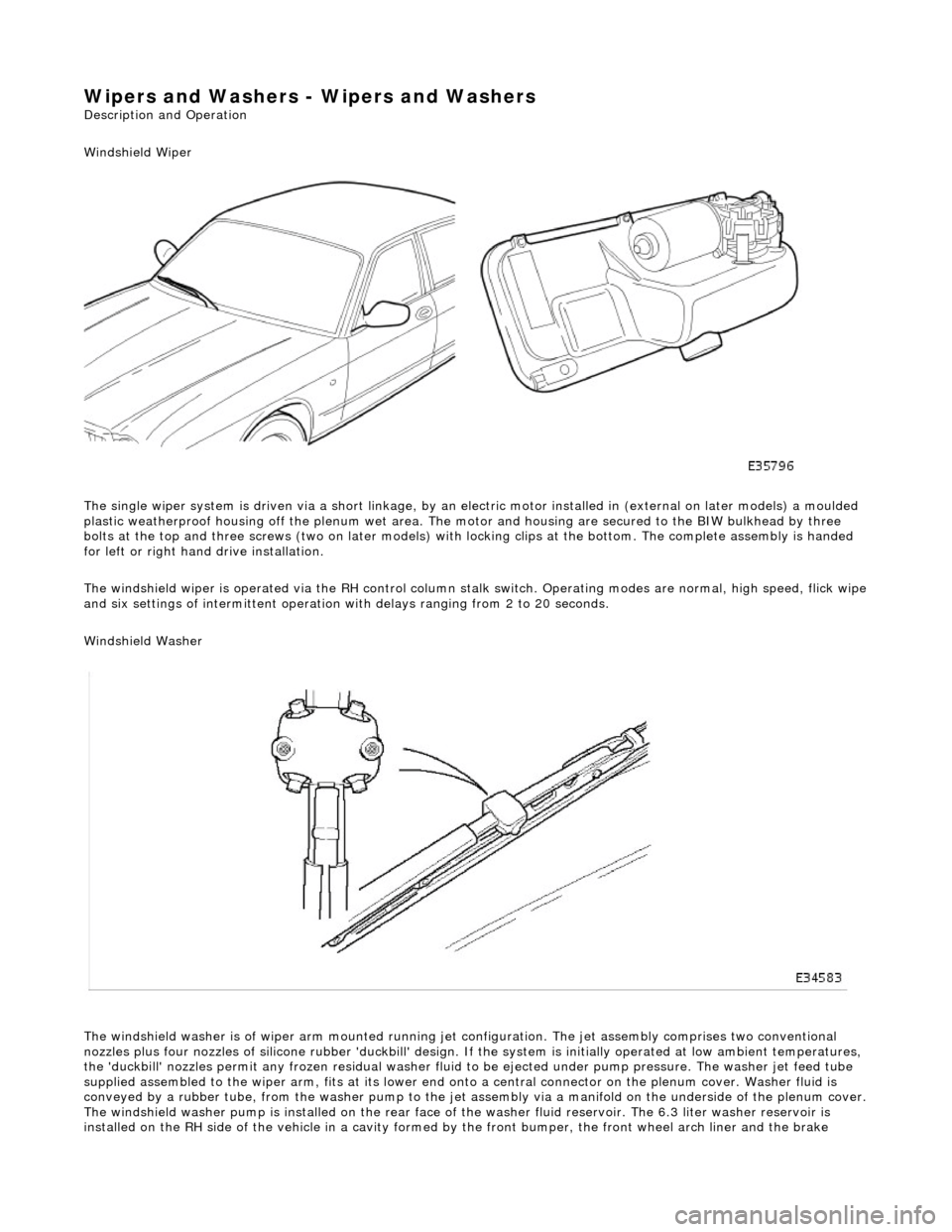

10. CAUTIONS:

When installing the windshield glass, do not strike it in any

way as this will crack the windshield glass.

Make sure the windshield glass does not move out of

position in the windshield glass aperture.

With assistance carefully install windshield glass into the

aperture. Align the windshield glass with the body markings

and press firmly into place.

11. Remove the lifting handles.

12. CAUTION: Make sure the windshield glass does not

move out of position in the windshield glass aperture.

Apply suitable tape to the to p of the windshield glass.

13. Install the cowl panel grille.

For additional information, refer to: Cowl Panel Grille (501-02

Front End Body Panels, Removal and Installation).

14. Install the wiper pivot arm.

For additional information, refer to: Wiper Pivot Arm

(501-16

Wipers and Washers, Remo val and Installation).

Page 2242 of 2490

Instrument Panel and Console - Instrument Panel

Removal and Installation

Removal

1. Turn ignition switch to position II.

2. Motor driver and front passenger seats rearward.

3. Position steering wheel in stra ight ahead position and fully

lower and extend steering column.

4. Turn ignition switch to position O.

5. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

6. Remove 'J' gate finish er. Refer to 76.25.24.

7. Remove 'J' gate finisher retain ing panel. Refer to 76.25.26.

8. Remove centre console veneer panel. Refer to 76.47.26.

9. Disconnect and remove radio.

10. Remove centre console switch module. Refer to 86.80.32.

11. Remove centre console. Refer to 76.25.01.

12. Slacken and remove centre cons ole vent duct rear securing

screw and withdraw duct assemb ly from air conditioning unit

manifold.

13. WARNING: BEFORE ANY AIRBAG/SRS SERVICE IS

PERFORMED, AT LEAST ONE MINUTE MUST ELAPSE AFTER

DISCONNECTION OF THE BATTERY CABLE, TO ALLOW

DISSIPATION OF BACK-UP POWER SUPPLY ENERGY.

Remove driver airbag. Refer to 76.73.39.

14. Remove steering wheel. Refer to Section 211-04.

15. Remove steering column lo wer cowl. Refer to 76.46.03.

16. Remove steering column u pper cowl. Refer to 76.46.02.

17. Remove driver side unders cuttle. Refer to 76.46.11.

18. Remove combined windshield wiper/washer switch and

audible warning speaker assembly. Refer to 86.65.42.

19. Remove glovebox. Refer to 76.52.03.

20. Remove 'A' post lower trim pads. refer to 76.13.30.

21. Carefully withdraw driver stowage bin trim, remove bin

securing screw and remove bin from facia.

Page 2306 of 2490

Wipers and Washers - Wipers and Washers

Description and Operation

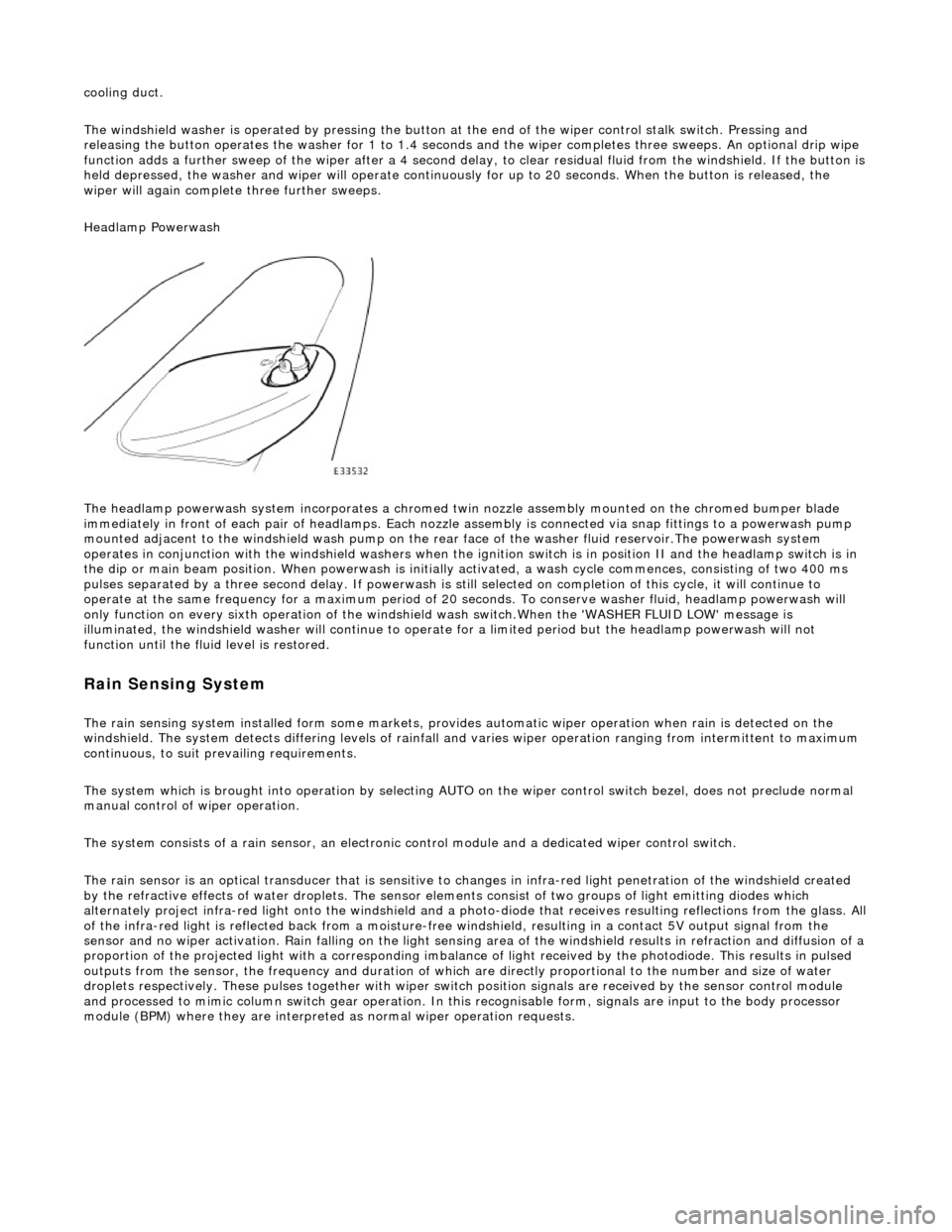

Windshield Wiper

The single wiper system is driven via a sh ort linkage, by an electric motor installed in (external on later models) a moulded

plastic weatherproof housing o ff the plenum wet area. The motor and housing are secured to the BIW bulkhead by three

bolts at the top and three screws (two on later models) with locking clips at the bottom. The complete assembly is handed

for left or right hand drive installation.

The windshield wiper is operated via the RH control column stalk switch. Operating modes are normal, high speed, flick wipe

and six settings of intermittent operation with delays ranging from 2 to 20 seconds.

Windshield Washer

The windshield washer is of wiper arm mounted running jet configuration. The je t assembly comprises two conventional

nozzles plus four nozzles of silicone rubbe r 'duckbill' design. If the system is initially operated at low ambient temperatures ,

the 'duckbill' nozzles permit an y frozen residual washer fluid to be ejected un der pump pressure. The washer jet feed tube

supplied assembled to the wiper ar m, fits at its lower end onto a central connector on the pl enum cover. Washer fluid is

conveyed by a rubber tube, from the washer pump to the jet assembly via a manifold on the underside of the plenum cover.

The windshield washer pump is installed on the rear face of the washer fluid reservoir. The 6.3 liter washer reservoir is

installed on the RH side of th e vehicle in a cavity formed by the front bu mper, the front wheel arch liner and the brake

Page 2307 of 2490

cooling duct.

The windshield washer is operated by pressing the button at the end of the wiper control stalk switch. Pressing and

releasing the button operates the washer for 1 to 1.4 seconds and the wiper completes three sweeps. An optional drip wipe

function adds a further sweep of the wiper after a 4 second delay, to clear residual fluid from the windshield. If the button is

held depressed, the washer and wiper will operate continuous ly for up to 20 seconds. When the button is released, the

wiper will again complete three further sweeps.

Headlamp Powerwash

The headlamp powerwash system incorporates a chromed twin nozzle assembly mounted on the chromed bumper blade

immediately in front of each pair of he adlamps. Each nozzle assembly is connected via snap fittings to a powerwash pump

mounted adjacent to the windshield wash pump on the rear face of the washer fluid reservoir.The powerwash system

operates in conjunction with the windshield washers when the ignition switch is in position II and the headlamp switch is in

the dip or main beam position. When powerwash is initially activated, a wash cycle commences, consisting of two 400 ms

pulses separated by a three second delay. If powerwash is still selected on completion of this cycle, it will continue to

operate at the same frequency for a maximum period of 20 se conds. To conserve washer fluid, headlamp powerwash will

only function on every sixth operation of the windshie ld wash switch.When the 'WASHER FLUID LOW' message is

illuminated, the windshield washer will continue to operat e for a limited period but the headlamp powerwash will not

function until the fluid level is restored.

Rain Sensing System

The rain sensing system installed form so me markets, provides automatic wiper operation when rain is detected on the

windshield. The system detects differing le vels of rainfall and varies wiper operation ranging from intermittent to maximum

continuous, to suit prevailing requirements.

The system which is brought into operation by selecting AUTO on the wiper control switch bezel, does not preclude normal

manual control of wiper operation.

The system consists of a rain sensor, an electronic control module and a dedicated wiper control switch.

The rain sensor is an optical transducer that is sensitive to changes in infra-red light penetration of the windshield created

by the refractive effects of water drople ts. The sensor elements consist of two groups of light emitting diodes which

alternately project infra-red light onto th e windshield and a photo-diode that receiv es resulting reflections from the glass. A ll

of the infra-red light is reflected back from a moisture-free windshield, resulting in a contact 5V output signal from the

sensor and no wiper activation. Rain falling on the light sensing area of the wi ndshield results in refraction and diffusion of a

proportion of the projected light with a corresponding imbalance of light received by the photodiode. This results in pulsed

outputs from the sensor, the frequency and duration of which are directly proportional to the number and size of water

droplets respectively. These pulses together with wiper switch position signals are received by the sensor control module

and processed to mimic column switch gear operation. In this recognisable form, signals are input to the body processor

module (BPM) where they are interprete d as normal wiper operation requests.

Page 2309 of 2490

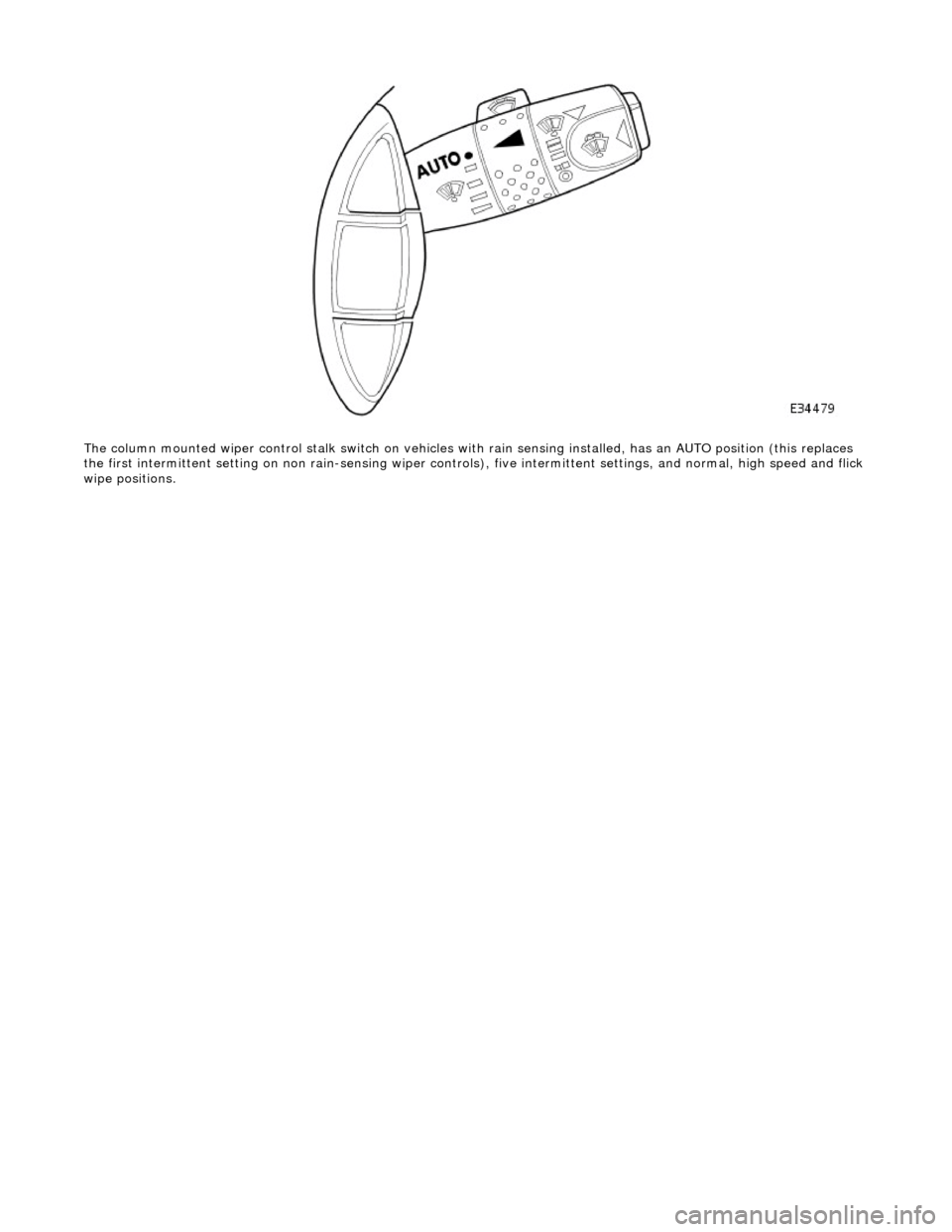

The column mounted wiper control stalk switch on vehicles with rain sensing installed, has an AUTO position (this replaces

the first intermitte nt setting on non rain-sensing wiper controls), five intermittent settings, and normal, high speed and flick

wipe positions.