Wipe JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 681 of 2490

Whilst applying the opposing force to the sprocket and

chain, tighten the sprocket securing bolt to 115-125 Nm.

Remove the chain tensioning tool.

6. Remove the tape and steel stri p from the timing cover upper

face. Wipe any residue of tape from the joint face.

7. Remove the camshaft locking tool.

8. Install the Cam Cover to Bank 1. Refer to Operation 12.29.44.

9. Raise the vehicle on the ramp.

10. Remove the crankshaft setting tool 303-531.

11. Install the crankshaft position sensor.

1. Install the sensor to the flywheel housing and fit the

securing bolt. Tighten to 8-12 Nm.

2. Install the access grommet to the housing.

12. Lower the ramp.

13. Remove the paint protection sheets and close the engine

compartment cover.

14. Connect the battery and in stall the battery cover.

Refer to the Battery Reconnection Procedure 86.15.15.

Page 750 of 2490

Engine - Oil Pan

In-vehicle Repair

Removal

Installation

1. Open the engine compartment and fit paintwork protection

sheets.

2. Raise the vehicle on a ramp.

3. Drain the engine oil.

1. Position the waste oil bowser.

2. Remove the oil pan drain plug and drain the engine

oil.

Wipe the drain plug and refit it, to prevent oil dripping.

Move the oil bowser away from the vehicle.

4. Remove the oil pan.

1. Remove the eighteen bolt s which secure the oil pan

to the oil pan body.

2. Remove the oil pan from the oil pan body.

3. Remove the gasket from the oil pan body assembly.

5. Clean and inspect the sealing faces on the oil pan body

assembly.

Clean and inspect the new oil pan mating face.

1. Fit the oil pan gasket to the oil pan body assembly.

Insert the seal into the locating positions in the groove,

working around from a corner.

Press in the remainder of th e seal, following the same

procedure.

2. Fit the oil pan to the oil pan body.

1. Position and align the oil pan.

2. Fit, but do not tighten, all eighteen bolts which secure

the oil pan.

Page 752 of 2490

Engine - Oil Pan Gasket

In-vehicle Repair

Removal

Installation

1. Open the engine compartment and fit paintwork protection

sheets.

2. Raise the vehicle on a ramp.

3. Drain the engine oil.

1. Position the waste oil bowser.

2. Remove the drain plug and drain the engine oil.

Fit a new sealing washer to the drain plug.

Wipe the drain plug and refit it to the oil pan to prevent oil

dripping.

Move the oil bowser away from the vehicle.

4. Remove the oil pan.

1. Remove the eighteen bolt s which secure the oil pan.

2. Remove the oil pan.

3. Remove the gasket.

5. Clean and inspect the sealing face s on the oil pan. and mating

faces.

1. Fit the oil pan gasket to the cylinder block adaptor body.

Insert the seal into the locating positions in the groove,

working around from a corner.

Press in the remainder of th e seal, following the same

procedure.

2. Fit the oil pan.

1. Position and align the oil pan.

2. Fit, but do not tighten, all eighteen bolts which secure

the oil pan.

Page 813 of 2490

2. With the wire in position, press the piston fully into the tensioner body.

Remove the wire.

3. Install the chain tensioner between the chain path.

1. Reposition the sprocket, still captive in the chain, upwards for access.

2. Install the chain tensioner between the sprockets.

Position the cam sprocket, chain and tensioner assembly

into position and locate the sprocket onto the camshaft

spigot.

4. Install the chain tensioner to the engine.

1. Fully seat the sprocket onto the camshaft and install the securing bolt, hand tight.

2. Install the two bolts which secure the tensioner and tighten to 10-14 Nm.

5. Install the cams haft sprocket.

Install the chain tensioner tool 303-532 to the sprocket

holes.

Apply force to the tool in an anti-clockwise direction to

tension the chain on its drive side.

Whilst applying the opposing force to the sprocket and

chain, tighten the sprocket securing bolt to 115-125 Nm.

Remove the chain tensioning tool.

6. Remove the tape and steel stri p from the timing cover upper

face. Wipe any residue of tape from the joint face.

7. Remove the camshaft locking tool.

8. Install the Cam Cover to Bank 2. Refer to Operation 12.29.43.

9. Raise the vehicle on the ramp.

10. Remove the crankshaft setting tool 303-531.

Page 819 of 2490

Whilst applying the opposing force to the sprocket and

chain, tighten the sprocket securing bolt to 115-125 Nm.

Remove the chain tensioning tool.

6. Remove the tape and steel stri p from the timing cover upper

face. Wipe any residue of tape from the joint face.

7. Remove the camshaft locking tool.

8. Install the Cam Cover to Bank 2. Refer to Operation 12.29.43.

9. Raise the vehicle on the ramp.

10. Remove the crankshaft setting tool 303-531.

11. Install the crankshaft position sensor.

1. Install the sensor to the flywheel housing and fit the

securing bolt. Tighten to 8-12 Nm.

2. Install the access grommet to the housing.

12. Lower the ramp.

13. Remove the paint protection sheets and close the engine

compartment cover.

14. Connect the battery and in stall the battery cover.

Refer to the Battery Reconnection Procedure 86.15.15.

Page 823 of 2490

2. With the wire in position, press the piston fully into the tensioner body.

Remove the wire.

3. Install the chain tensioner between the chain path.

1. Reposition the sprocket, still captive in the chain, upwards for access.

2. Install the chain tensioner between the sprockets.

Position the cam sprocket, chain and tensioner assembly

into position and locate the sprocket onto the camshaft

spigot.

4. Install the chain tensioner to the engine.

1. Fully seat the sprocket onto the camshaft and install the securing bolt, hand tight.

2. Install the two bolts which secure the tensioner and tighten to 10-14 Nm.

5. Install the cams haft sprocket.

Install the chain tensioner tool 303-532 to the sprocket

holes.

Apply force to the tool in an anti-clockwise direction to

tension the chain on its drive side.

Whilst applying the opposing force to the sprocket and

chain, tighten the sprocket securing bolt to 115-125 Nm.

Remove the chain tensioning tool.

6. Remove the tape and steel stri p from the timing cover upper

face. Wipe any residue of tape from the joint face.

7. Remove the camshaft locking tool.

8. Install the Cam Cover to Bank 1. Refer to Operation 12.29.44.

9. Raise the vehicle on the ramp.

10. Remove the crankshaft setting tool 303-531.

Page 829 of 2490

Whilst applying the opposing force to the sprocket and

chain, tighten the sprocket securing bolt to 115-125 Nm.

Remove the chain tensioning tool.

6. Remove the tape and steel stri p from the timing cover upper

face. Wipe any residue of tape from the joint face.

7. Remove the camshaft locking tool.

8. Install the Cam Cover to Bank 1. Refer to Operation 12.29.44.

9. Raise the vehicle on the ramp.

10. Remove the crankshaft setting tool 303-531.

11. Install the crankshaft position sensor.

1. Install the sensor to the flywheel housing and fit the

securing bolt. Tighten to 8-12 Nm.

2. Install the access grommet to the housing.

12. Lower the ramp.

13. Remove the paint protection sheets and close the engine

compartment cover.

14. Connect the battery and in stall the battery cover.

Refer to the Battery Reconnection Procedure 86.15.15.

Page 831 of 2490

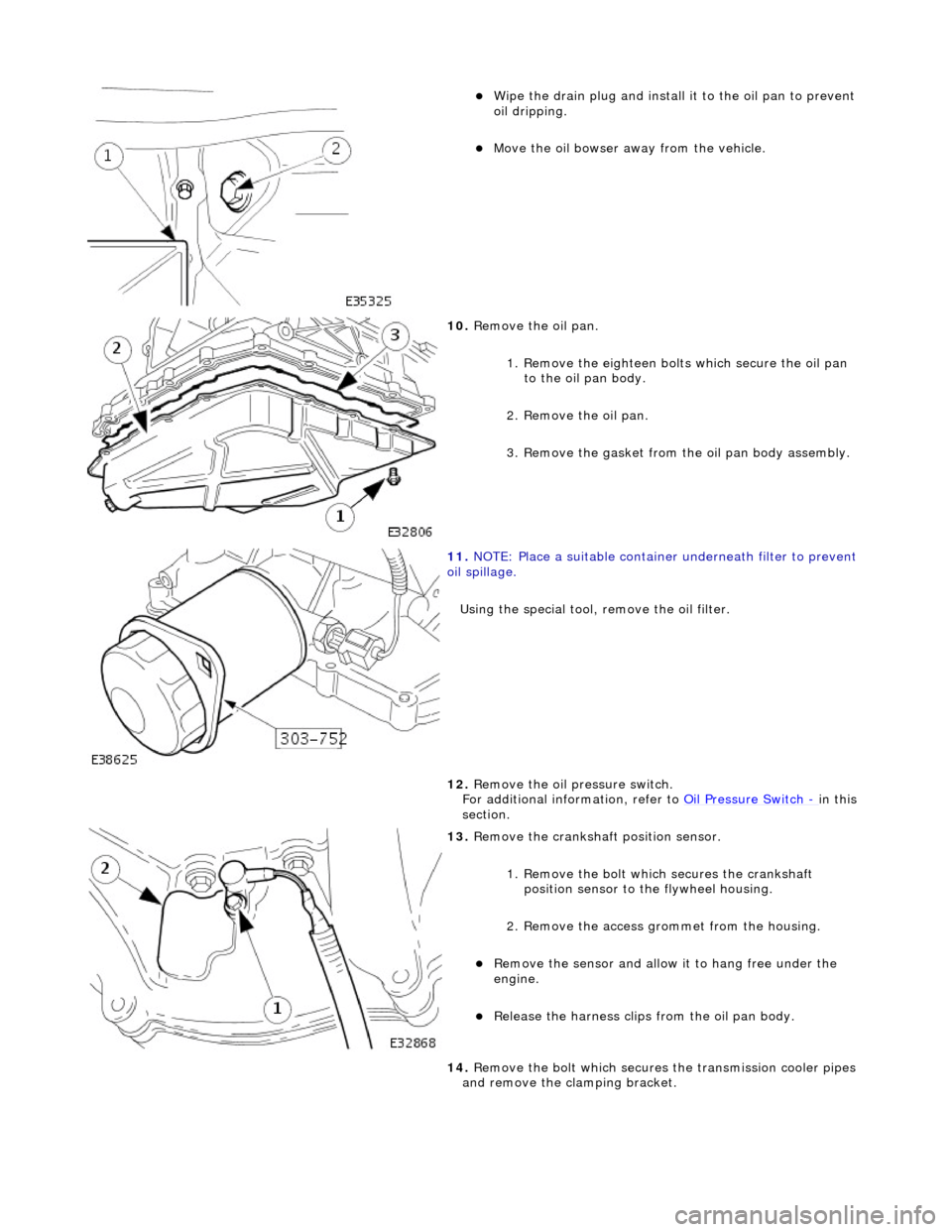

Wipe the drain plug and install it to the oil pan to prevent

oil dripping.

Move the oil bowser away from the vehicle.

10. Remove the oil pan.

1. Remove the eighteen bolt s which secure the oil pan

to the oil pan body.

2. Remove the oil pan.

3. Remove the gasket from the oil pan body assembly.

11. NOTE: Place a suitable container underneath filter to prevent

oil spillage.

Using the special tool, remove the oil filter.

12. Remove the oil pressure switch.

For additional information, refer to Oil Pressure Switch

- in this

section.

13. Remove the crankshaft position sensor.

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

2. Remove the access grommet from the housing.

Remove the sensor and allow it to hang free under the

engine.

Release the harness clips from the oil pan body.

14. Remove the bolt which secures the transmission cooler pipes

and remove the clamping bracket.

Page 840 of 2490

Wipe the drain plug and install it to the oil pan to prevent

oil dripping.

Move the oil bowser away from the vehicle.

10. Remove the oil pan.

1. Remove the eighteen bolt s which secure the oil pan

to the oil pan body.

2. Remove the oil pan.

3. Remove the gasket from the oil pan body assembly.

11. NOTE: Place a suitable container underneath filter to prevent

oil spillage.

Using the special tool, remove the oil filter.

12. Remove the oil pressure switch.

For additional information, refer to Oil Pressure Switch

- in this

section.

13. Remove the crankshaft position sensor.

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

2. Remove the access grommet from the housing.

Remove the sensor and allow it to hang free under the

engine.

Release the harness clips from the oil pan body.

14. Remove the bolt which secures the transmission cooler pipes

and remove the clamping bracket.

Page 849 of 2490

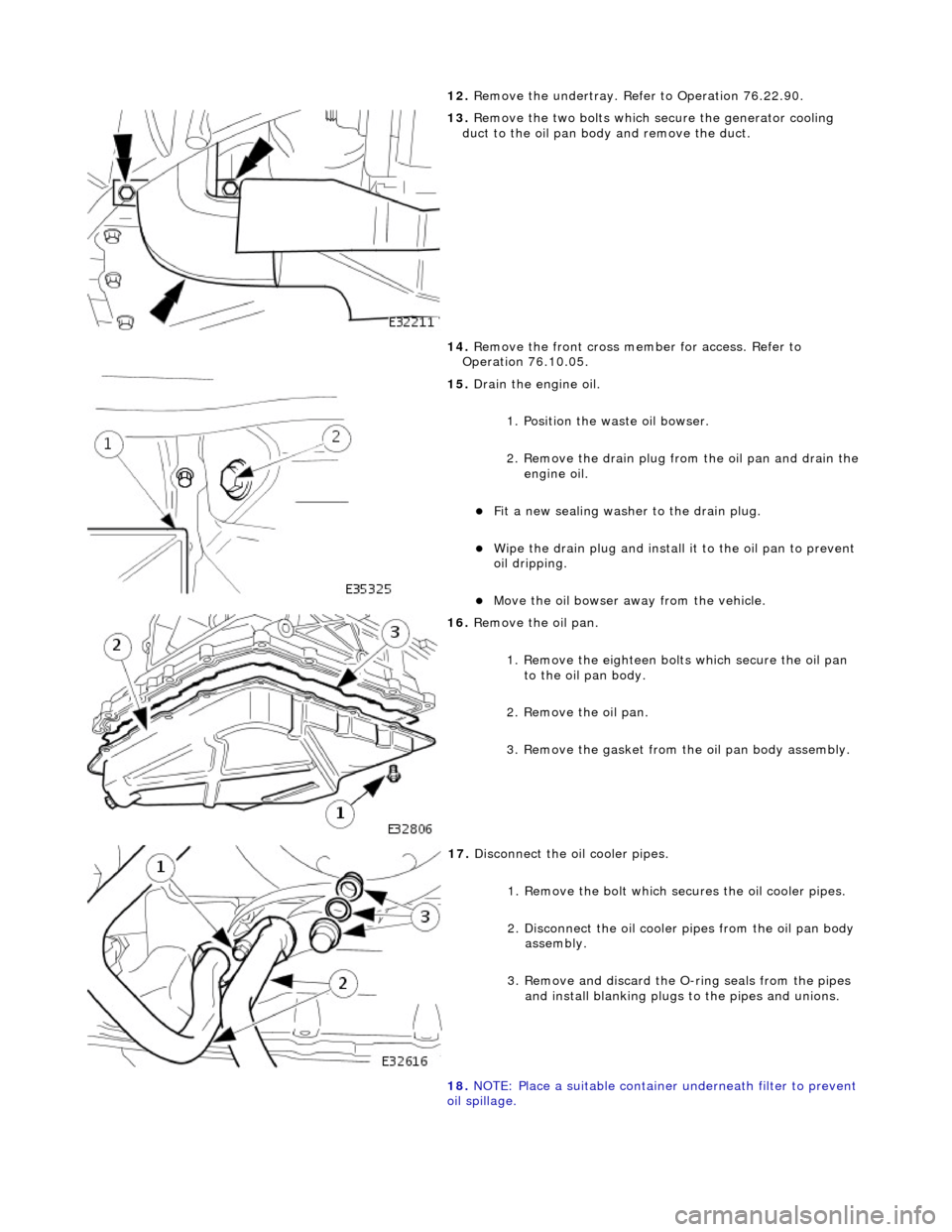

12. Remove the undertray. Re fer to Operation 76.22.90.

13. Remove the two bolts which se cure the generator cooling

duct to the oil pan body and remove the duct.

14. Remove the front cross member for access. Refer to

Operation 76.10.05.

15. Drain the engine oil.

1. Position the waste oil bowser.

2. Remove the drain plug from the oil pan and drain the engine oil.

Fit a new sealing washer to the drain plug.

Wipe the drain plug and install it to the oil pan to prevent

oil dripping.

Move the oil bowser away from the vehicle.

16. Remove the oil pan.

1. Remove the eighteen bolt s which secure the oil pan

to the oil pan body.

2. Remove the oil pan.

3. Remove the gasket from the oil pan body assembly.

17. Disconnect the oil cooler pipes.

1. Remove the bolt which secures the oil cooler pipes.

2. Disconnect the oil cooler pipes from the oil pan body

assembly.

3. Remove and discard the O-ring seals from the pipes

and install blanking plugs to the pipes and unions.

18. NOTE: Place a suitable container underneath filter to prevent

oil spillage.