low oil pressure JAGUAR X308 1998 2.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1754 of 2490

WARNING: NEVER USE A CFC 12 ANALYZ

ER OR NAKED FLAME TYPE.

Leak tests should be carried out with a UV spot lamp or an electronic analyzer which is dedicated to HFC 134A refrigerant.

Handling Lubricati

ng Oil

Av

oid breathing lubricant mist; it can cau

s

e irritation to the respiratory system.

Always use fresh oil from a sealed containe r and do not leave oil exposed to the atmosphere for any reason other than to fill

or empty a system. PAG oil is very hygr oscopic (absorbs water) and will rapidly become contaminated by atmospheric

moisture.

PAG oil is NOT compatible with previously used mineral based oi ls and must NEVER be mixed. Do not re-use oil when it has

been separated from refrigerant, following a re covery cycle. Dispose of used oil safely.

System Maintenance

Plug pipes an

d units immediatel

y after disconnection an d do not remove the plugs until immediately before making the

connection. Do not leave the system open to atmosphere.

The receiver drier must be renewed if the compressor has failed or if it is susp ected that debris may be present in the

system.

It is not always necessary to renew th e receiver drier if the correct procedur es have been followed. However, if a

component or part of the system is left dismantled for more than five minutes, it may be advisable to renew the receiver

drier. This guidance is based on UK average humidity levels; lo cations with lower humidity levels will be less critical to

moisture contamination. It must be stressed however th at there is not a safe period for work to be carried out in.

Do not use any replacement parts su pplied without transit plugs and seals - return them to the supplier.

Diagnostic equipment for pres sure, mass and volume should be calibrated regularly and certified by a third party

organization.

Use extreme care when handling and securi ng aluminum fittings; always use a backing spanner and take special care when

handling the evaporator.

Use only the correct or re commended tools for the job and apply the manufacturer's torque specifications.

Graph - High S

ide Pressure against Ambient Temperature

Page 1756 of 2490

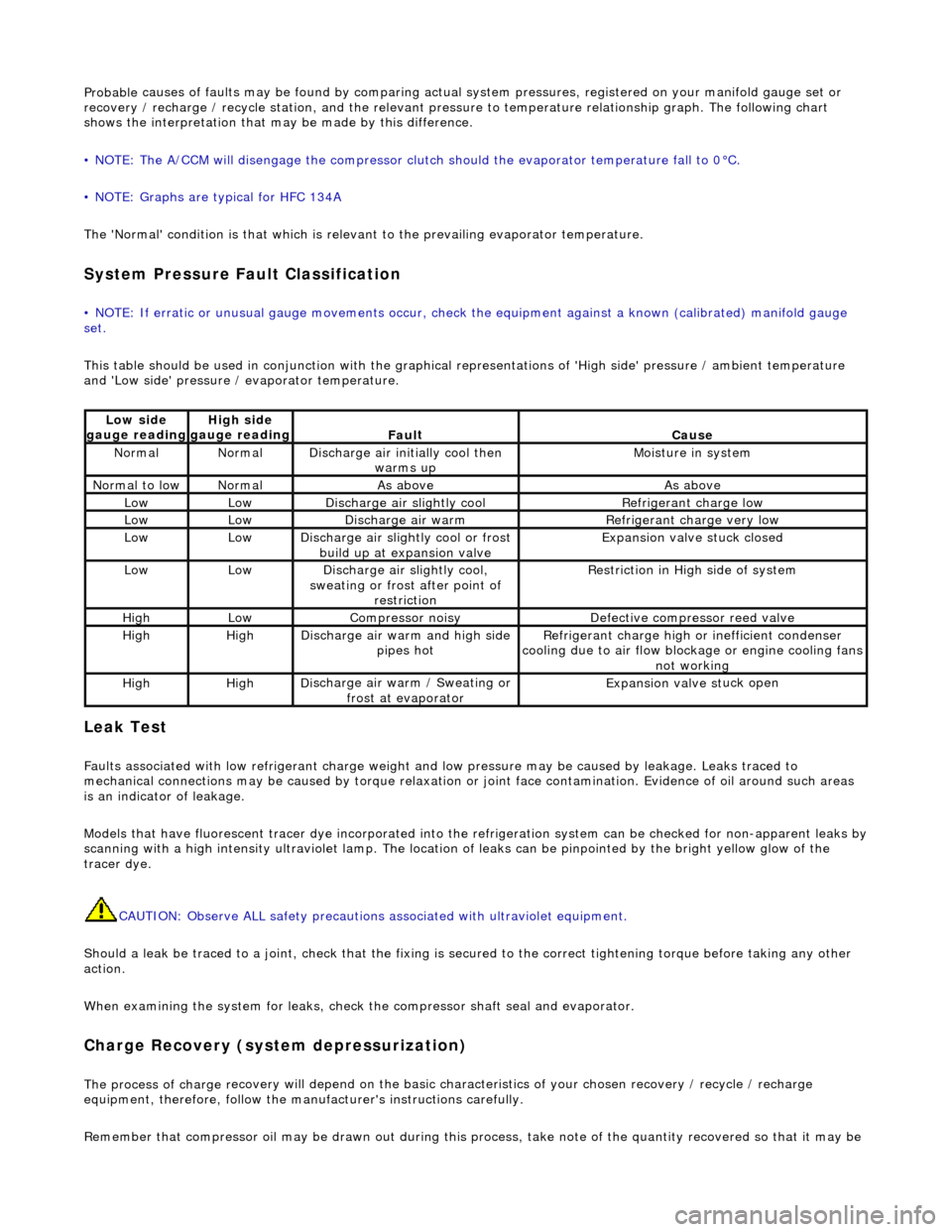

Probable

causes of faults may be found by comparing actual

system pressures, registered on your manifold gauge set or

recovery / recharge / recycle station, and the relevant pressure to temperature relationship graph. The following chart

shows the interpretation that ma y be made by this difference.

• NOTE: The A/CCM will disengage the compressor clutch should the evaporator temperature fall to 0°C.

• NOTE: Graphs are typical for HFC 134A

The 'Normal' condition is that which is relevant to the prevailing evaporator temperature.

System Pressure Fault Classification

• NOTE

: If erratic or unusual gauge move

ments occur, check the equipment against a known (calibrated) manifold gauge

set.

This table should be used in conjunction with the graphical representations of 'High side' pressure / ambient temperature

and 'Low side' pressure / evaporator temperature.

Leak

Test

F

a

ults associated with low re

frigerant charge weight and low pressure ma y be caused by leakage. Leaks traced to

mechanical connections may be caused by to rque relaxation or joint face contamination. Evidence of oil around such areas

is an indicator of leakage.

Models that have fluorescent tracer dye incorporated into the refrigeration system can be checke d for non-apparent leaks by

scanning with a high intensity ultraviolet lamp. The location of leaks can be pinpointed by the bright yellow glow of the

tracer dye.

CAUTION: Observe ALL safety precautions associated with ultraviolet equipment.

Should a leak be traced to a joint, check that the fixing is secured to the correct tightening torque before taking any other

action.

When examining the system for leaks, chec k the compressor shaft seal and evaporator.

Charge Re

covery (system depressurization)

The process of

charge r

ecovery will depe

nd on the basic characteristics of your chosen recovery / recycle / recharge

equipment, therefore, follow the manu facturer's instructions carefully.

Remember that compressor oil may be drawn out during this process, take note of the quantity recovered so that it may be

Lo

w side

gauge reading

High s i

de

gauge reading

Fau l

t

Cause

No

r

mal

No

r

mal

Di

sc

harge air initially cool then

warms up

Mois

ture in system

N

ormal

to low

No

r

mal

As aboveAs above

LowLowD

i

scharge air slightly cool

Ref

r

igerant charge low

LowLowDi

scharge air warm

Refr

igerant charge very low

LowLowDi

scharge air slightly cool or frost

build up at expansion valve

Expansion valve st

uck closed

LowLowDi

scharge air slightly cool,

sweating or frost after point of restriction

Restri

ction in High side of system

HighLowCompressor noisyDe

fe

ctive compressor reed valve

HighHighD

i

scharge air warm and high side

pipes hot

Refri

gerant charge high or inefficient condenser

cooling due to air flow blockage or engine cooling fans

not working

HighHighD i

scharge air warm / Sweating or

frost at evaporator

Expans ion valve st

uck open

Page 1759 of 2490

Sym

ptom #2

Sy

mptom #2

Sym

ptom #3

Sy

mptom #3

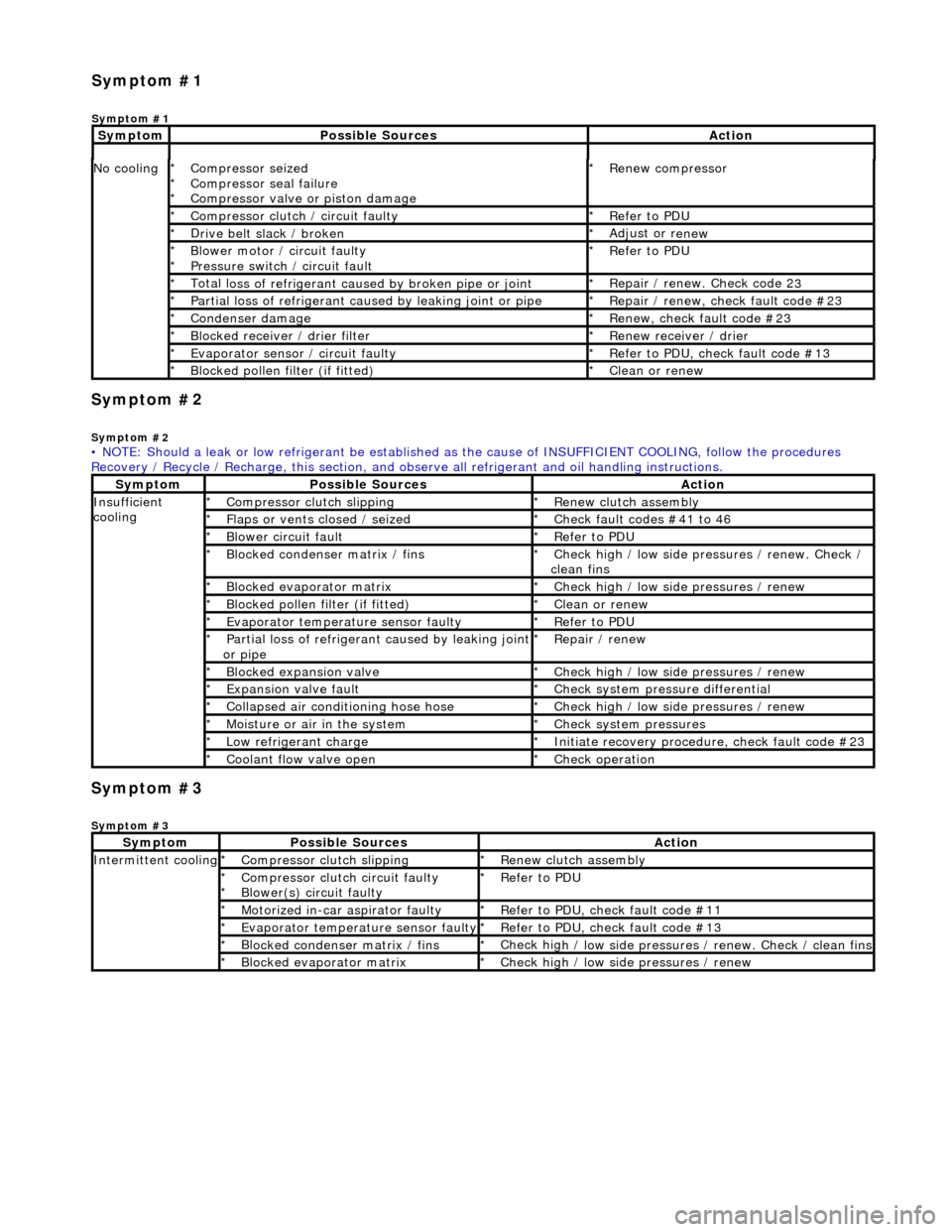

No

cooling

Compressor sei

zed

Compressor seal failure

Compressor valve or piston damage

*

*

*

R

enew compressor

*

Compressor cl

utch / circuit faulty

*

R

efer to PDU

*

D

rive belt slack / broken

*

Adjust or r

enew

*

B

lower motor / circuit faulty

Pressure switch / circuit fault

*

*

R

efer to PDU

*

Total l

oss of refrigerant caused by broken pipe or joint

*

Repair / renew. Check code 2

3

*

P

artial loss of refrigerant caused by leaking joint or pipe

*

R

epair / renew, check fault code #23

*

Conden

ser damage

*

Re

new, check fault code #23

*

Bl

ocked receiver / drier filter

*

R

enew receiver / drier

*

Evaporator senso

r / circuit faulty

*

R

efer to PDU, check fault code #13

*

Bl

ocked pollen filter (if fitted)

*

Cle

an or renew

*

• NOTE: Should a leak or low refrigerant be established as the cause of INSUFFICIENT COOL ING, follow the procedures

Recovery / Recycle / Recharge, this section, and ob serve all refrigerant and oil handling instructions.

Sy

mptom

Possib

le Sources

Acti

on

Insuffi

cient

cooling

Compre

ssor clutch slipping

*

R

enew clutch assembly

*

Fl

aps or vents closed / seized

*

Check f

ault codes #41 to 46

*

Bl

ower circuit fault

*

R

efer to PDU

*

Bl

ocked condenser matrix / fins

*

Check hig

h / low side pr

essures / renew. Check /

clean fins

*

Bl

ocked evaporator matrix

*

Check hig

h / low side

pressures / renew

*

Bl

ocked pollen filter (if fitted)

*

Cle

an or renew

*

Evaporator temp

erat

ure sensor faulty

*

R

efer to PDU

*

P

artial loss of refrigerant caused by leaking joint

or pipe

*

R

epair / renew

*

Blocked expan

sion valve

*

Check hig

h / low side

pressures / renew

*

Expans

ion valve fault

*

Chec

k system pres

sure differential

*

C

ollapsed air conditioning hose hose

*

Check hig

h / low side

pressures / renew

*

Moi

sture or air in the system

*

Chec

k system pressures

*

Low r

efrigerant charge

*

Initiate recovery

procedure, check fault code #23

*

Coo

lant flow valve open

*

Chec

k operation

*

Sy

mptom

Possib

le Sources

Acti

on

Int

ermittent cooling

Compre

ssor clutch slipping

*

R

enew clutch assembly

*

Compressor cl

utch circuit faulty

Blower(s) circuit faulty

*

*

R

efer to PDU

*

Motorized in-car aspirator faulty

*

R

efer to PDU, check fault code #11

*

Evaporator temp

erature sensor faulty

*

R

efer to PDU, check fault code #13

*

Bl

ocked condenser matrix / fins

*

Check hig

h / low side pressures / renew. Check / clean fins

*

Bl

ocked evaporator matrix

*

Check hig

h / low side

pressures / renew

*

Sym

ptom #1

Sy

mptom #1

Sy

mptom

Possib

le Sources

Acti

on

Page 1760 of 2490

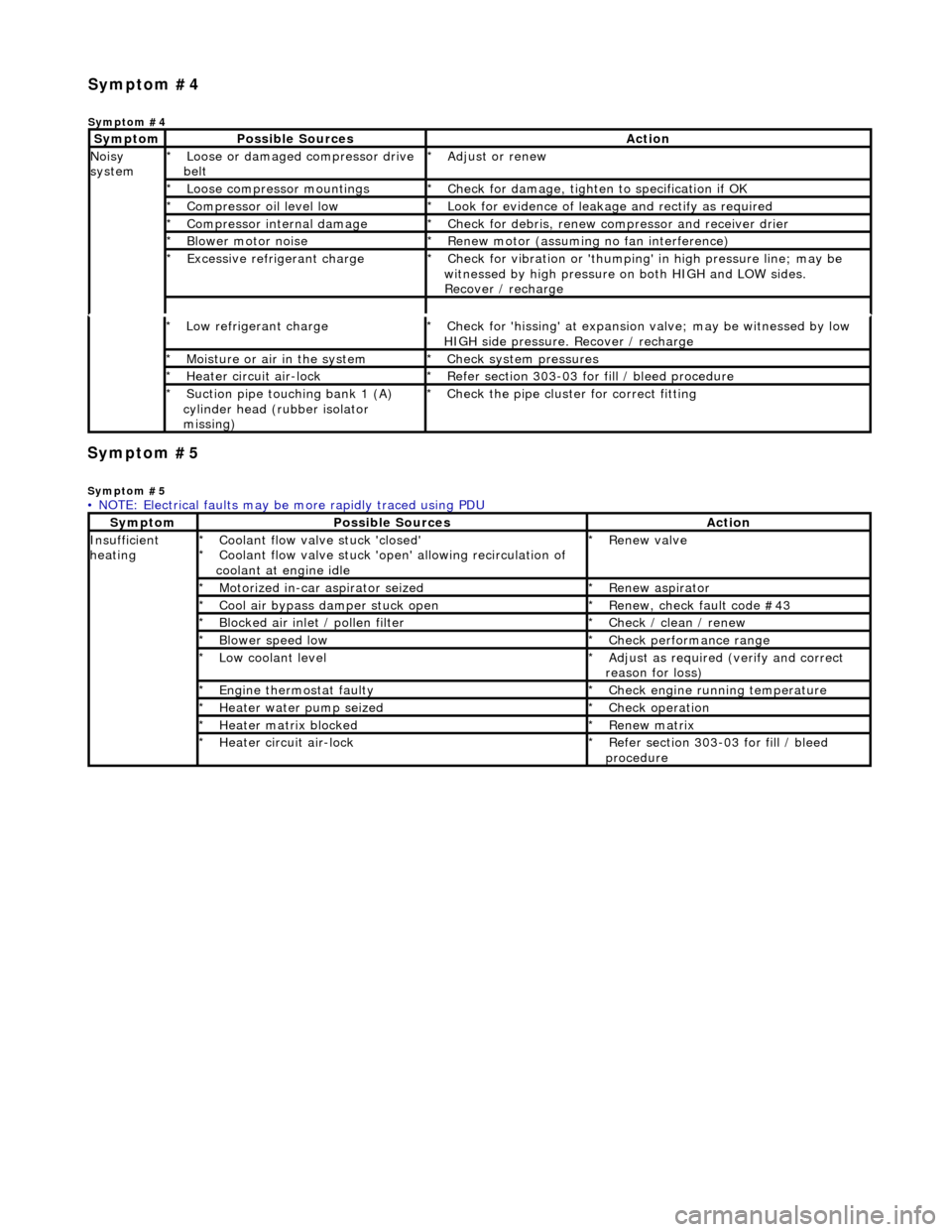

Symp

tom #5

Sy

m

ptom #5

Low r

e

frigerant charge

*

Check f or 'hissi

ng' at expansion

valve; may be witnessed by low

HIGH side pressure. Recover / recharge

*

Moi

s

ture or air in the system

*

Chec k syst

em pressures

*

Heat er ci

rcuit air-lock

*

R e

fer section 303-03 for fill / bleed procedure

*

Suct ion

pipe touching bank 1 (A)

cylinder head (rubber isolator

missing)

*

Check the pi

pe cluster for correct fitti

ng

*

• NOTE: Electrical faults may be more rapidly traced using PDU

Sym

ptom

Possib

l

e Sources

Acti

o

n

Insuffi

ci

ent

heating

Coo l

ant flow valve stuck 'closed'

Coolant flow valve stuck 'open' allowing recirculation of

coolant at engine idle

*

*

Re

new v

alve

*

Motorized in-car aspirator sei zed

*R e

new aspirator

*

Coo l

air bypass damper stuck open

*

Re new,

check fault code #43

*

B l

ocked air inlet / pollen filter

*

Chec k / cl

ean / renew

*

B l

ower speed low

*

Check performance range

*

Low cool ant

level

*

Adjust as req u

ired (verify and correct

reason for loss)

*

Engine

t

hermostat faulty

*

Check engine r u

nning temperature

*

Heater water pump seized

*Chec k op

eration

*

Heater ma trix

blocked

*

Re new m

atrix

*

Heater circui t

air-lock

*

R e

fer section 303-03 for fill / bleed

procedure

*

Sym

p

tom #4

Sym

ptom #4

Sy

m

ptom

Possib

l

e Sources

Acti

o

n

No

i

sy

system

Loose or damaged compressor drive

belt

*Adjust or r

e

new

*

Loose compressor mountings

*Check f o

r damage, tighten to specification if OK

*

Compressor oil level l

ow

*

Look for evidence of l

eakag

e and rectify as required

*

Compressor internal dama ge

*Check f o

r debris, renew compressor and receiver drier

*

B l

ower motor noise

*

Re new m

otor (assuming no fan interference)

*

Excessive refrige rant charge

*Check f o

r vibration or 'thumping'

in high pressure line; may be

witnessed by high pressure on both HIGH and LOW sides.

Recover / recharge

*

Page 1761 of 2490

Climate Co

ntrol System - General In

formation - Air Conditioning (A/C)

System Check - Re tail Procedure

Gen

eral Procedures

E

vacuating the Manifold Gauge Set

Connecting the Manifold Gauge Set

C

AUTION: Only use hoses with connectors wh

ich are dedicated to HFC 134A charge ports.

Stabilizing the System

1.

At

tach the center (service) hose to a vacuum pump and start

the pump. Open fully both high and low valves and allow the

vacuum to remove air and mois ture from the manifold set for

at least five minutes.

CAUTION: It is imperative th at the vacuum pump is not

subjected to a positi ve pressure of any degree. Therefore the

pump must be fitted wi th an isolation valve at the center (service

hose) connection and this valve mu st be closed before the pump

is switched off. This operation replaces the 'purge' procedure used

on previous systems. Observe the manufacturer's

recommendation with regard to vacuum pump oil changes.

Turn the vacuum pump off and isol ate it from the center service

hose but do not open the hose to atmosphere.

1. Att

achment of the hose quick release connectors to the high

and low side system ports is stra ightforward, provided that the

high and low valves are closed and the system is NOT

operational.

WARNING: UNDER NO CIRCUMSTANCES SHOULD THE

CONNECTIONS BE MADE WITH THE SYSTEM IN OPERATION OR

THE VALVES OPEN. SHOULD THE VALVES BE OPEN AND A

VACUUM PUMP OR REFRIGERANT CONTAINER ATTACHED, AN

EXPLOSION COULD OCCUR AS A RESULT OF HIGH PRESSURE

REFRIGERANT BEING FORCED BACK INTO THE VACUUM PUMP OR

CONTAINER.

Assessment of system operating efficiency and fault

classification may be achieved by using the facilities on your

Recovery / Recharging / Recycling station, follow the

manufacturer's instructions implicitly and observe all safety

considerations.

1. Accurate test gauge data wi

ll on

ly be attained if the system

temperatures and pressures are stabilized.

пЃ¬E

nsure that equipment and hoses cannot come into

contact with engine moving parts or sources of heat.

пЃ¬It is recommended th at a free standing air

mover is placed

in front of the vehicle to provide air flow through the

condenser / cooling system.

пЃ¬St

art the engine, allow it to attain normal working

temperature and set at fast idle (typically 1200 to 1500

rpm).

пЃ¬Select full

air condit

ioning performance.

пЃ¬With

all temperatures and pres

sures stable, or displaying

symptoms of faults; begin relevant test procedures.

Page 1837 of 2490

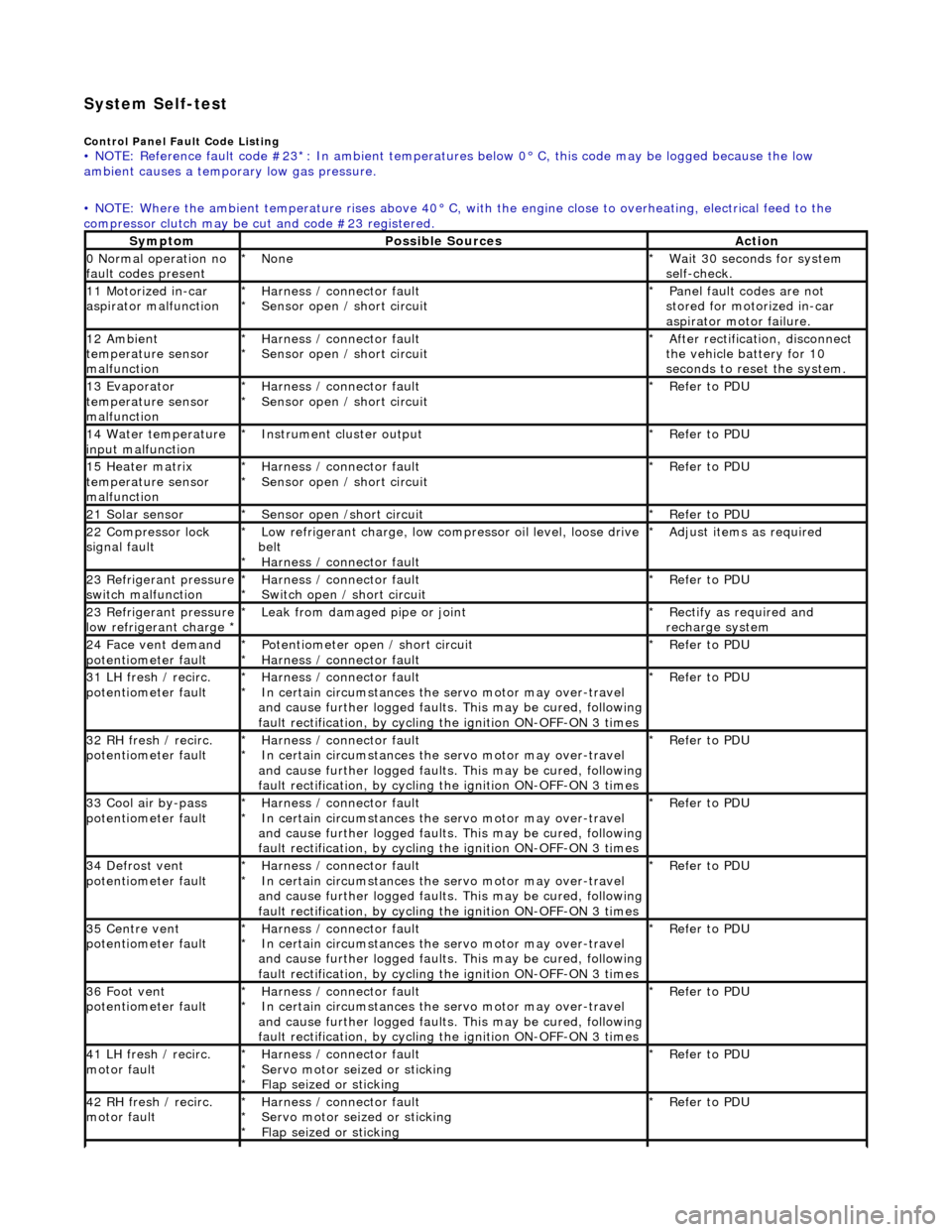

System Self-test

Control Panel Fault Code Listing • NOTE: Reference fault code #23*: In ambient temperatures below 0° C, this code may be logged because the low

ambient causes a tempor ary low gas pressure.

• NOTE: Where the ambient temperature rises above 40° C, with the engine close to overheating, electrical feed to the

compressor clutch may be cut and code #23 registered.

SymptomPossible SourcesAction

0 Normal operation no

fault codes presentNone

*Wait 30 seconds for system

self-check.

*

11 Motorized in-car

aspirator malfunctionHarness / connector fault

Sensor open / short circuit

*

*Panel fault codes are not

stored for motorized in-car

aspirator motor failure.

*

12 Ambient

temperature sensor

malfunctionHarness / connector fault

Sensor open / short circuit

*

*After rectification, disconnect

the vehicle battery for 10

seconds to reset the system.

*

13 Evaporator

temperature sensor

malfunctionHarness / connector fault

Sensor open / short circuit

*

*Refer to PDU

*

14 Water temperature

input malfunctionInstrument cl uster output

*Refer to PDU

*

15 Heater matrix

temperature sensor

malfunctionHarness / connector fault

Sensor open / short circuit

*

*Refer to PDU

*

21 Solar sensorSensor open /short circuit

*Refer to PDU

*

22 Compressor lock

signal faultLow refrigerant charge, low compressor oil level, loose drive

belt Harness / connector fault

*

*Adjust items as required

*

23 Refrigerant pressure

switch malfunctionHarness / connector fault

Switch open / short circuit

*

*Refer to PDU

*

23 Refrigerant pressure

low refrigerant charge * Leak from damaged pipe or joint

*Rectify as required and

recharge system

*

24 Face vent demand

potentiometer faultPotentiometer open / short circuit

Harness / connector fault

*

*Refer to PDU

*

31 LH fresh / recirc.

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

32 RH fresh / recirc.

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

33 Cool air by-pass

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

34 Defrost vent

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

35 Centre vent

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

36 Foot vent

potentiometer faultHarness / connector fault

In certain circumstances the servo motor may over-travel

and cause further logged faults. This may be cured, following

fault rectification, by cycling the ignition ON-OFF-ON 3 times

*

*Refer to PDU

*

41 LH fresh / recirc.

motor faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

42 RH fresh / recirc.

motor faultHarness / connector fault

Servo motor seized or sticking

Flap seized or sticking

*

*

*Refer to PDU

*

Page 2381 of 2490

The body is pre-treated to ensure high resistance to corrosion and stone chip dama ge. Prior to the first major pre-treatment process, the body shell is high-pressure washed to remove any metal dust and residual oil.

The first major pre-treatment process consists of phosphate and electro-paint deposition, which together with zinc coating,

forms the basis of the corrosion protection. This process includes high pressure knock-off, alkali de-greasing, zinc phosphate

conversion of body steel (dissolving iron and coating with zinc phosphate crystals), trivalent chrome rinsing and

demineralized water rinsing, seal ing all chemicals and impurities.

Both dip and spray techniques are employed and the bodies are submerged to the waistline during the first and third rinses

of the main phosphate clean. Chemical strengths and soluti on temperatures are continuously monitored and accurately

controlled throughout the process.

An 80% water primer is then cathodic elec tro-deposition applied to the thoroughly cleansed bodies in a uniform 'sag-free'

film 18 to 32 micron thick. Optimum durabi lity of the electroprimer is achieved by finally curing in a stoving oven at 165 В°C

for a period of 20 minutes.

All underbody seams of the fully primed bo dies are then manually sealed, to prevent water and dust ingress into the vehicle

and to enhance corrosion protection.

An 800 to 1000 g/m2 PVC coating is semi-automatic airless sp ray applied to the underside of the main floor panels, trunk

floor and rear wheel arches (ref. illustration above).

The upper panels of primed and external ly sealed bodyshells are next lightly scuffed to remove imperfections and a PVC

coating is applied to all internal seams by an airless spray technique. A PVC bead seal is also applied to the doors, hood and

trunk clinch joints.

Following anti-corrosion, sealing and primin g treatment, the bodies enter the first stage of 'cosmetic' painting. This consists

of the application of two coats of a highly chip resistant po lyester surfacer, employing high voltage electrostatic 'spinning

bells', to achieve a final film thickness of 35 to 50 micron. Between surfacer coats, a polyurethane coat is automatically

applied to the sills to impart even greater resistance to stone chipping.

All interior panels are then painted us ing a color keyed sealer, wet-on-wet wi th a surfacer material, after which the

bodyshells are stoved at 160 В°C for a period of 20 minutes. Further protection agai nst corrosion is provided by a medium

solids black pigmented wax which is airless spray applied to vehicle undersides.

Wax Injected Box Sections

Critical body box-sections are si milarly protected by spray injecting a high solids wax. This is then re-flowed at 70 to 90 В°C

to achieve optimum seam/joint penetratio n and form a resilient and durable internal coating (ref. illustration above).

After full wet sanding, rinsing and drying to provide a good su bstrate, a color-keyed semi-matt sealer co at is applied using

electrostatic bells to achieve a film build of 25 to 35 micron . The bodies are then stoved for a further 20 minutes at a

temperature of 145 В°C and subjected to a local 'seek-and-find' de -nib operation prior to the final two coat process. The final

top coat finish is achieved by using poly ester base coat colors and an acrylic sag resistant clear coat. This clear over base

(COB) process produces a high gloss, durabl e paint finish with a film thickness of 50 to 65 micron, which is finally cured at a

temperature of 135В°C for 20 minutes.

The Munsell three dimensional system of color management is em ployed to achieve highly accurate control of vehicle colors.

This system ensures that paint pigmentations are accurately maintained and facilitates vigorous final checking of finished

vehicles for color match. The hu e of individual panels such as trunk lids, doors and hoods is in some instances adjusted to

offset the effects of differing light angles. Where applicable, coachlines are manually applied and radiant heat cured on the

completed and valeted vehicle prior to hand spray applic ation of a protective wax coat.

Introduction

All repairs, whether structural or cosmetic must return the vehicle to the original manufactured condition with regard to

occupant safety, dimensional accuracy, fi nish and corrosion protection, and ensure continuation of the Paint Surface and

Corrosion warranty where applicable.

Similarly, repaired vehicles must be fu lly checked, and where appropriate reset, with regard to steering, suspension,

braking, and occupant restraint systems.

Page 2383 of 2490

Paint

The inhalation of sprays, fumes, or dust during paint application or sanding processes should always be avoided. Ensure

that there is efficient ventilation / extrac tion at all times. Paint spraying should be confined as far as possible to spray

booths. Personnel with a history of asth ma should not be employed in any process involving the use of isocyanates.

Operators working in a spray booth where isocyanate material is present must use air-fed breathing equipment with air

supplied to the visor at the re commended pressure and filtered to remove oil, water, and fumes. Operators involved in

handling mixing or spraying should wear protective clothing including gloves and goggles, to avoid skin and eye contact.

Particle masks or canister type respir atosr should be worn when sanding.

Applied Heat

When welding, flame cutting, brazing etc, the operator shou ld use as appropriate, goggles, mask / fume extractor and

flameproof protective clothing. It is especially important when working with polyurethane compounds to use air-fed

breathing equipment. Appropriat e fire fighting equipment and personnel trai ned in its use must always be available.

Metal Repair

Appropriate eye and hand protection should be worn when sanding, drilling, cutting, chiselling, flatting or welding. Face

masks or air-fed visors should also be wo rn when sanding or flatting either body solder or fillers. On completion of a

soldering operation, swarf must be re moved from the work area and the operat or must wash his hands thoroughly.

GENERAL REPAIR NOTES

The following advice should be noted before any repair work is carried out.

Disconnect the vehicle battery gr ound lead (disconnect the alternator where electric welding is used) and take note of the

reconnection procedures as detailed in 86.15.15.

Where structural parts are straightened or renewed, a body alignment / straightening jig must be used. The application of

heat, especially excessive heat, reduces the strength of steels, where appropriate therefore, structural sections should be

straightened by cold processes.

Repairs may only be carried out successful ly, and any warranties protected, if genuine Jaguar replacement parts and Jaguar

approved materials are used.

The correct tools, procedures and facilities must always be us ed. The quality of the work must not be compromised by using

inappropriate methods or equipment.

All trim and electrical components in the locality of the repair must be removed or disconnected prior to panel removal /

replacement; this is especially important where hollow sectio ns may contain harnesses, tubes or foam, see section A4.3.5.

WARNING: DO NOT WORK IN THE VICINITY OF A LIVE AIR BAG, REMOVE IT COMPLETELY. READ WORKING

PRACTICES AIR BAG, SECTION 20. ANY SEAT BELT WHICH HAS BEEN WORN IN AN ACCIDENT MUST BE RENEWED.

CAUTION: Electric arc welding should not be used on Jaguar vehicles. The high voltages produced by this process will

cause irreparable damage to the electric al control and microprocessor systems.

The following welding and gas processes are the only ones recommended by Jaguar Cars Ltd.

Welding and Gas Processes

Resistance spot welding, MIG welding and all gas processes may only be carried out on bare, unpainted or unplated metal.

The flanges of panels to be welded toge ther, must be clean, corrosion free and tr eated as appropriate, with either weld-

through primer or inter-weld sealer. Only materials and processes specified in the 'Body Sealing and Preservation Manual'

should be used in the relevant application areas detailed in this section. Refer to 'Zinc Coated Panels' Section