set clock JAGUAR X308 1998 2.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1822 of 2490

Ref #12 DEF (resumes the system on at the previous temperature setting).

Button (switch) logic

All buttons with an integral LED state lamp conform to the following operating logic.

When the state lamp is lit the relevant func tion is operational. From this condition, pressing the button will de-activate the

function, confirmed by the LED being de-energized and the pres ence of a single audible 'beep'. A single 'beep' will

accompany the state lamp to confirm function re-selection.

1. 1. ON / OFF and manual fan speed.

Pressing this knob activates the system ON at the last settin g or switches the system OFF. Rotate the knob clockwise to

increase and anti-clockwise to decrease fan speed and thus airflow.

With the system OFF, ram air is available by the selected air di stribution mode (indicated by state lamp). Air flow will NOT

occur unless a manual air distribution mo de is selected, this air being unconditioned and flow dependent upon vehicle

speed.

• NOTE: The blowers are inhibited until the engine coolant te mperature is > 35°C, unless DEFROST, FACE or DEMIST modes

are selected.

2. 2. Manual Air Recirculation

Closes the outside air intakes of the blower asse mblies and recirculates air within the vehicle.

Two options of control are available :

Timed Recirculation. Pressing the button for less than 1.5 seconds lights up the LED (confirmed by a single bleep).

This provides recirculation of interior air for a period of approximately 5 minutes. Pressing the button within five

minutes returns the system to fresh air intake mode.

Continuous Recirculation. Pressing and holding the button for more than 1.5 seconds lights up the LED (confirmed by two beeps). This provides continuous reci rculation of interior air. Pressing the button returns the system to fresh air

intake mode.

• NOTE: Avoid using manual air recirculatio n for prolonged periods in cold weather, this may result in interior misting of

glass.

3. 3. Temperature Scale Selection

Press the appropriate button to display temperatures in degrees Celsius or Fahrenheit.

4. 4. Manual Fan Speed

Rotating the fan speed control knob (to vary fan speed) will di splay a proportional number of horizontal bars on the LCD.

There are total of eleven manual fan speeds available.

5. 5. Temperature Display

Indicator of internal demand temperatur e or external ambient temperature. The external ambient is updated every 4

seconds when the road speed > 25 km / h.

6. 6. Scale

Selected temperature scale, Celsius or Fahrenheit.

7. 7. External temperature

Symbol indicates when this option is selected

Page 1836 of 2490

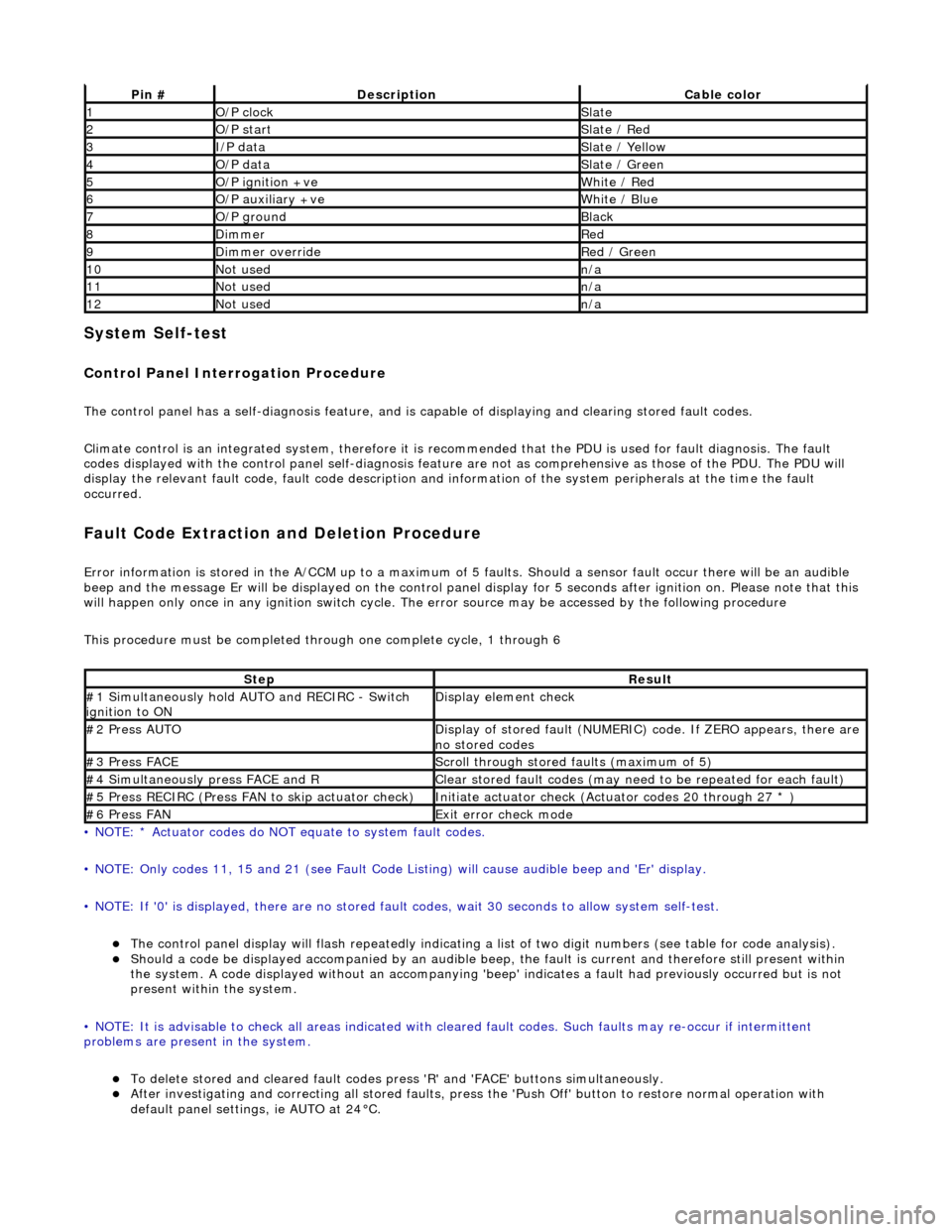

System Self-test

Control Panel Interrogation Procedure

The control panel has a self-diagnosis feature, and is capable of displaying and clearing stored fault codes.

Climate control is an integrated system, therefore it is recommended that the PDU is used for fault diagnosis. The fault

codes displayed with the control panel self -diagnosis feature are not as comprehensive as those of the PDU. The PDU will

display the relevant fault code, fault co de description and information of the system peripherals at the time the fault

occurred.

Fault Code Extraction and Deletion Procedure

Error information is stored in the A/CCM up to a maximum of 5 faults. Should a sensor fault occur there will be an audible

beep and the message Er will be displayed on the control panel display for 5 seco nds after ignition on. Please note that this

will happen only once in any ignition switch cycle. The error source may be accessed by the following procedure

This procedure must be completed through one complete cycle, 1 through 6

• NOTE: * Actuator codes do NOT equate to system fault codes.

• NOTE: Only codes 11, 15 and 21 (see Fault Code List ing) will cause audible beep and 'Er' display.

• NOTE: If '0' is displayed, there are no stored faul t codes, wait 30 seconds to allow system self-test.

The control panel display will flash repeatedly indicating a list of two digit numbers (see table for code analysis). Should a code be displayed accompanied by an audible beep, the fault is current and therefore still present within

the system. A code displayed without an accompanying 'bee p' indicates a fault had previously occurred but is not

present within the system.

• NOTE: It is advisable to check all areas indicated with cleared fault codes. Such faults may re-occur if intermittent

problems are present in the system.

To delete stored and cleared fault codes press 'R' and 'FAC E' buttons simultaneously. After investigating and correcting all stored faults, press the 'Push Off' button to restore normal operation with

default panel settings, ie AUTO at 24°C.

Pin #DescriptionCable color

1O/P clockSlate

2O/P startSlate / Red

3I/P dataSlate / Yellow

4O/P dataSlate / Green

5O/P ignition +veWhite / Red

6O/P auxiliary +veWhite / Blue

7O/P groundBlack

8DimmerRed

9Dimmer overrideRed / Green

10Not usedn/a

11Not usedn/a

12Not usedn/a

StepResult

#1 Simultaneously hold AU TO and RECIRC - Switch

ignition to ONDisplay element check

#2 Press AUTODisplay of stored fault (NUMERIC) code. If ZERO appears, there are

no stored codes

#3 Press FACEScroll through stored faults (maximum of 5)

#4 Simultaneously press FACE and RClear stored fault codes (may need to be repeated for each fault)

#5 Press RECIRC (Press FAN to skip actuator check)Initiate actuator check (Actuator codes 20 through 27 * )

#6 Press FANExit error check mode

Page 1877 of 2490

Battery, Mounting and Cables - Battery Connect

General Procedures

1.

NOTE: Whether one, or both, cables are disconnected, a

minimum of 30 seconds MUST elapse between disconnection of

the FIRST cable and reconnection of the LAST cable. A clean final

connection must be made; do not allow temporary contact.

Connect the batter y terminal(s).

2. Reset the clock.

3. Enter the radio security code. If necessary, refer to the Sound

System Handbook.

Page 1893 of 2490

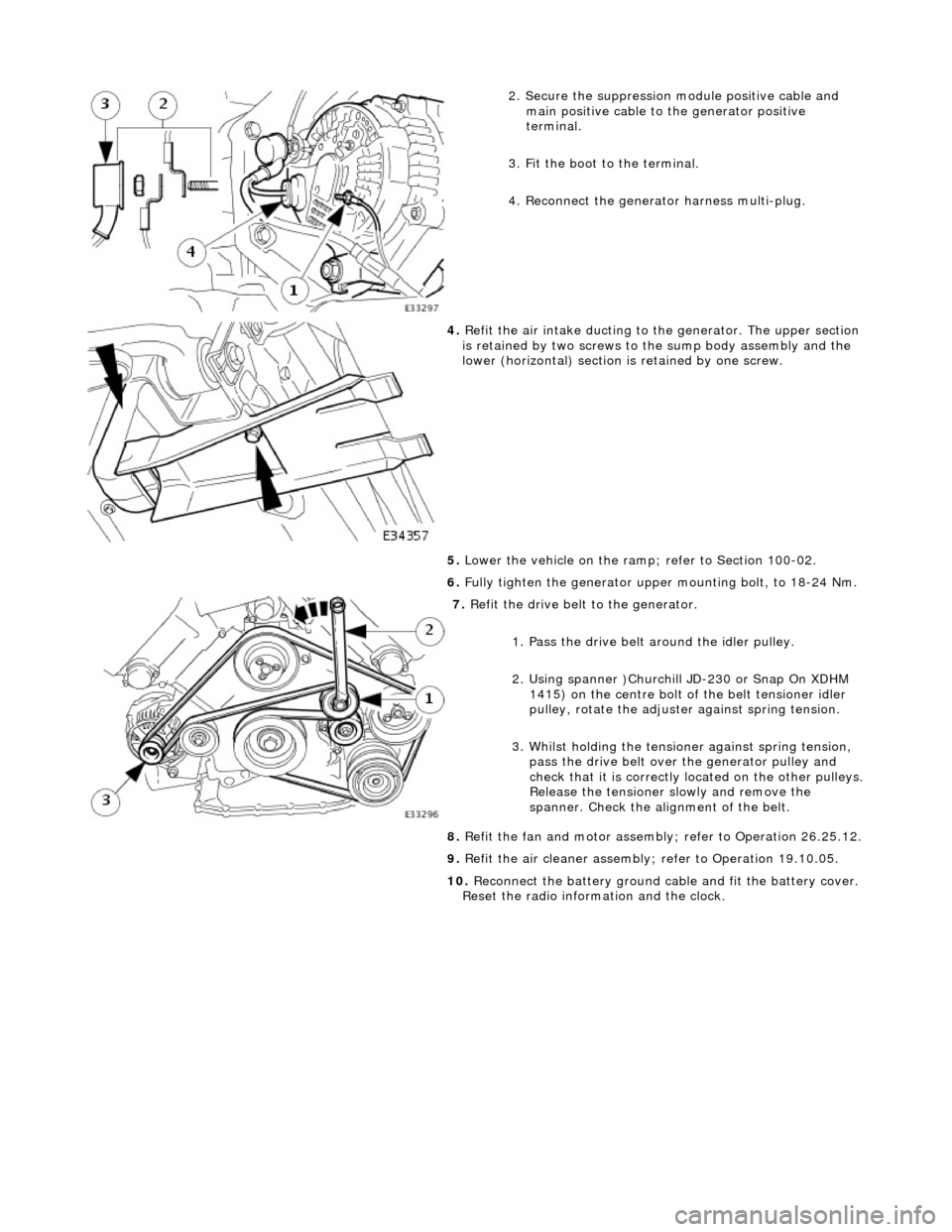

2. Secure the suppression module positive cable and

main positive cable to the generator positive

terminal.

3. Fit the boot to the terminal.

4. Reconnect the generator harness multi-plug.

4. Refit the air intake ducting to the generator. The upper section

is retained by two screws to the sump body assembly and the

lower (horizontal) section is retained by one screw.

5. Lower the vehicle on the ramp ; refer to Section 100-02.

6. Fully tighten the generator upper mounting bolt, to 18-24 Nm.

7. Refit the drive belt to the generator.

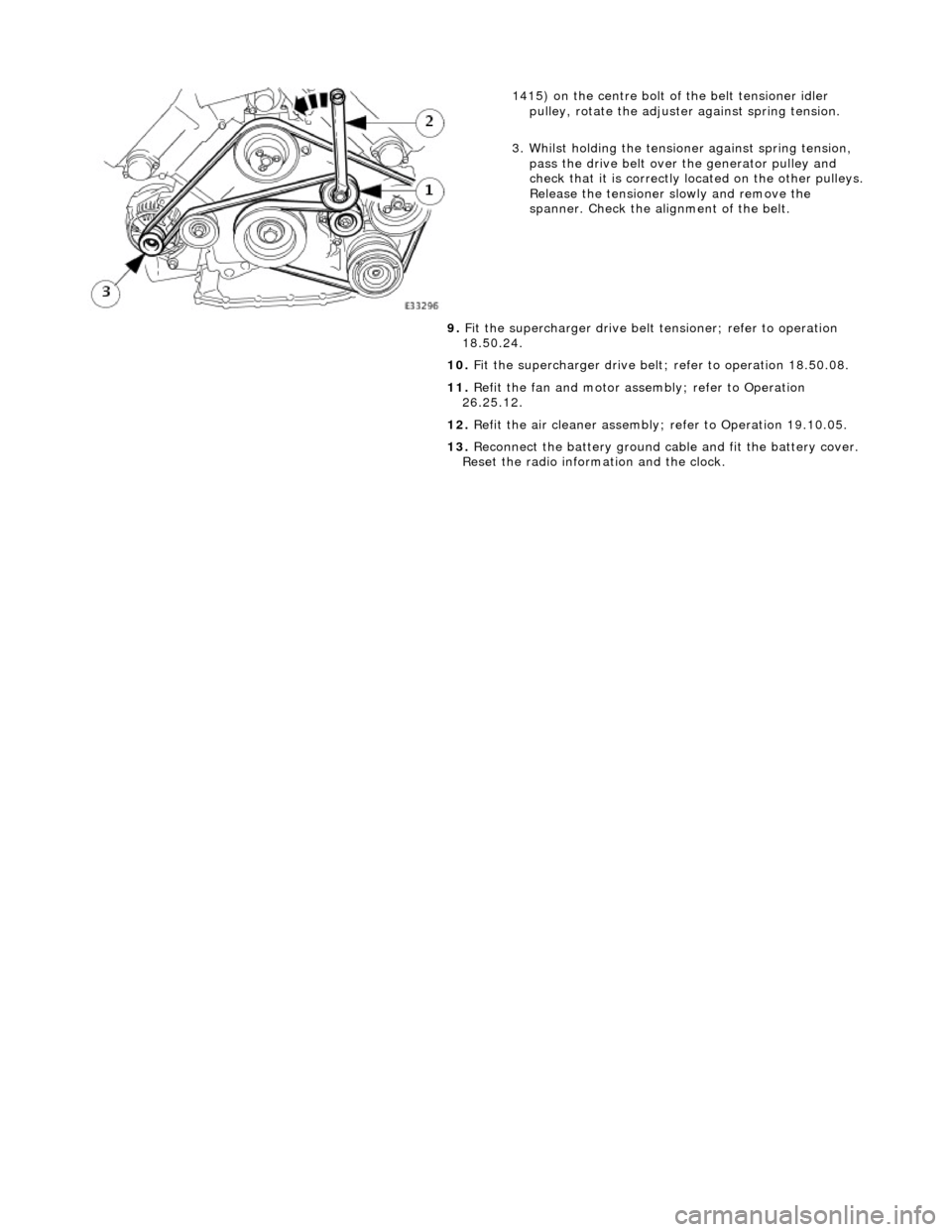

1. Pass the drive belt around the idler pulley.

2. Using spanner )Churchill JD-230 or Snap On XDHM 1415) on the centre bolt of the belt tensioner idler

pulley, rotate the adjuster against spring tension.

3. Whilst holding the tensioner against spring tension, pass the drive belt over the generator pulley and

check that it is correctly located on the other pulleys.

Release the tensioner slowly and remove the

spanner. Check the alignment of the belt.

8. Refit the fan and motor assembly ; refer to Operation 26.25.12.

9. Refit the air cleaner assembly; refer to Operation 19.10.05.

10. Reconnect the battery ground cable and fit the battery cover.

Reset the radio inform ation and the clock.

Page 1898 of 2490

1415) on the centre bolt of the belt tensioner idler

pulley, rotate the adjuster against spring tension.

3. Whilst holding the tensioner against spring tension, pass the drive belt over the generator pulley and

check that it is correctly located on the other pulleys.

Release the tensioner slowly and remove the

spanner. Check the alignment of the belt.

9. Fit the supercharger drive belt tensioner; refer to operation

18.50.24.

10. Fit the supercharger drive belt ; refer to operation 18.50.08.

11. Refit the fan and motor asse mbly; refer to Operation

26.25.12.

12. Refit the air cleaner assembly; refer to Operation 19.10.05.

13. Reconnect the battery ground cable and fit the battery cover.

Reset the radio inform ation and the clock.

Page 1907 of 2490

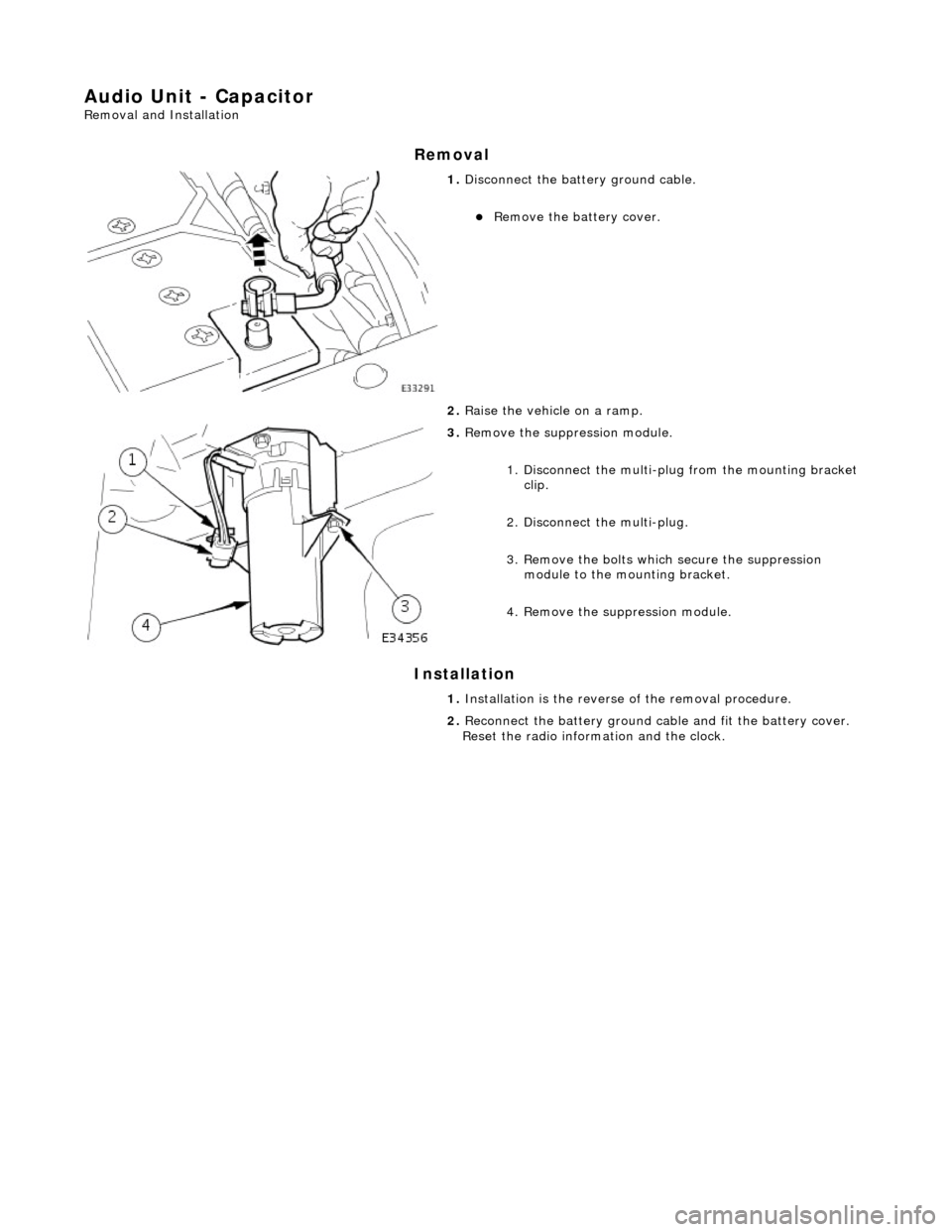

Audio Unit - Capacitor

Removal and Installation

Removal

Installation

1. Disconnect the batt ery ground cable.

Remove the battery cover.

2. Raise the vehicle on a ramp.

3. Remove the suppr ession module.

1. Disconnect the multi-plug from the mounting bracket clip.

2. Disconnect the multi-plug.

3. Remove the bolts which secure the suppression module to the mounting bracket.

4. Remove the su ppression module.

1. Installation is th e reverse of the re moval procedure.

2. Reconnect the battery ground cable and fit the battery cover.

Reset the radio inform ation and the clock.

Page 2054 of 2490

Interior Trim and Ornamentation - Interior Trim

Description and Operation

Carpets

The passenger compartment carpet is a one piece moulded constr uction with integral sound deadening material, heel mats

and driver's footrest. The carpet is attach ed to the vehicle floor by plastic clips fitted below the door treadplates. Removal of the carpet necessitates re moval of the front seats, lifting of the centre console rear extens ion and removal of the heelboard

carpet.

Fascia

The full width, slush moulded, soft feel PVC fascia is mounted on an injection moulded armature and is faced with wood

veneer. In addition to the air conditioning and central, outer and demisting vents, it accepts instrument packs dedicated to

market requirements and a centrally mounted analogue clock.

Doors

The one-piece door casings are trimmed in UEV to match the seating, with wood veneer at the waistline and a carpet insert

at the front lower corner. Each casing is secured to the door inner panel by fir tree press fast eners along the lower section,

two armrest fixings at the centre and vene er panel dowels and fixings at the top. The armrests which are common to front

and rear doors, are trimmed in matching leather or UEV according to specification. The door switchpacks, dedicated to

driver and front or rear passenger, are in corporated in the armrests. A speaker is in stalled in the lower section of each door

and a tweeter is incorporated behind each interior door handle escutcheon. Where premium ICE is fitted, the front tweeters

are installed in the upper A posts.

A, B, C and D Posts

On each side,a grained UEV finisher trimmed to match the headlining is secured to the 'A' post and cantrail by fir tree

fasteners locating in BIW apertures. The upper 'D' post finisher is trimmed and secured in the same manner. The single

piece'B/C' post finishers, also finished in grained matching UEV, each have a front se at belt exit aperture and are secured to

the BIW by four spring clips and two fir tree fasteners.

Headlining

The one-piece headlining consists of a 6mm thick polyurethane foam membrane covered with suede effect knitted polyester. The headlining is secured to the BIW roof by body tangs, the roof console, sun visors, combined grab handles and coat

hooks, the cantrail finishers and where fitt ed, the sliding roof finisher and clips.

Trunk

Carpet covered trims line the trunk and are secured by fir tr ee fasteners to the sides and front inner panel. The carpet

covered, two-section, removable trunk fl oor provides access to the spare wheel and wheel changing equipment, the battery

and electrical carrier. The floor board rests on the spare wheel, with the front and rear edges locating in blocks on the fuel

tank backboard and the rear of the body. The support blocks provide for two floor he ight settings to accommodate either a

space saver or full size spare wheel.A moulded finisher covering the rear of the trunk below the sill is secured to the rear

panel by tabs and fir tree fasteners. Finish er panels fitted to the rear lamp units provide trunk interior access to the lamps.

The trunk lid underside is fitted with a removabl e moulded liner and two trunk illumination lights.

Page 2219 of 2490

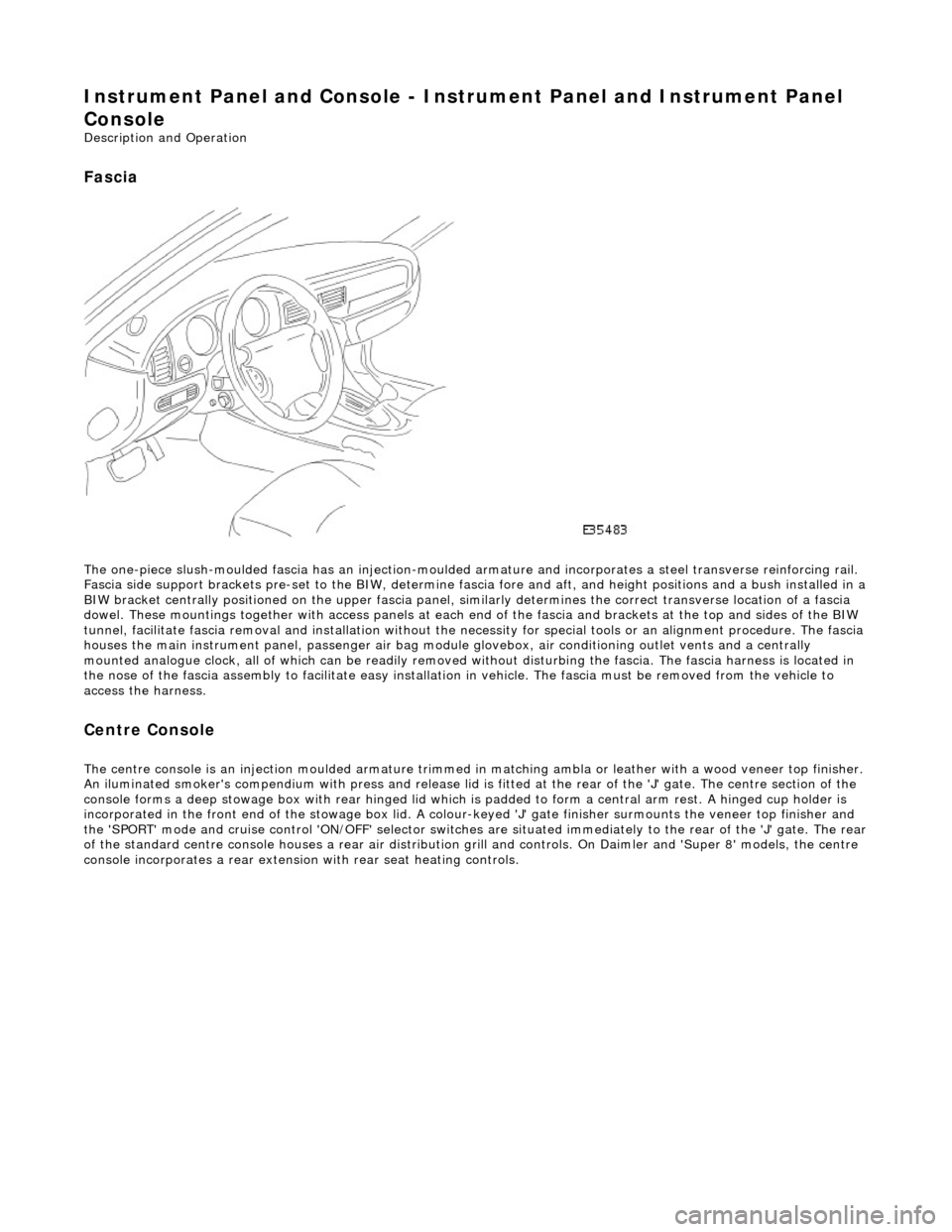

Instrument Panel and Console - Instrument Panel and Instrument Panel

Console

Description and Operation

Fascia

The one-piece slush-moulded fascia has an injection-moulded ar mature and incorporates a steel transverse reinforcing rail.

Fascia side support brackets pre-set to th e BIW, determine fascia fore and aft, and height position s and a bush installed in a

BIW bracket centrally positioned on the upper fascia panel, similarly determines the correct transverse location of a fascia

dowel. These mountings together with access panels at each en d of the fascia and brackets at the top and sides of the BIW

tunnel, facilitate fascia removal and instal lation without the necessity for special tools or an alignment procedure. The fasci a

houses the main instrument panel, pass enger air bag module glovebox, air conditioning outlet vents and a centrally

mounted analogue clock, all of which can be readily removed wi thout disturbing the fascia. The fascia harness is located in

the nose of the fascia assembly to facilitate easy installati on in vehicle. The fascia must be removed from the vehicle to

access the harness.

Centre Console

The centre console is an injection moulded armature trimmed in matching ambla or leather with a wood veneer top finisher.

An iluminated smoker's compendium with pr ess and release lid is fitted at the rear of the 'J' gate. The centre section of the

console forms a deep stowage box with rear hinged lid which is padded to form a central arm rest. A hinged cup holder is

incorporated in the front end of the stowage box lid. A colour-keyed 'J' gate finisher surmounts the veneer top finisher and

the 'SPORT' mode and cruise control 'ON/OFF' selector switches are situated immediately to the rear of the 'J' gate. The rear

of the standard centre console houses a re ar air distribution grill and controls. On Daimler and 'Super 8' models, the centre

console incorporates a rear extensio n with rear seat heating controls.