Panels centered between two adjacent panels must have equal gaps on either side. For exceptions to this, refer to the

appropriate specification. Gaps between ad jacent panels or components must not expose harnesses, labels, brackets or

visually poor joint or assembly conditions.

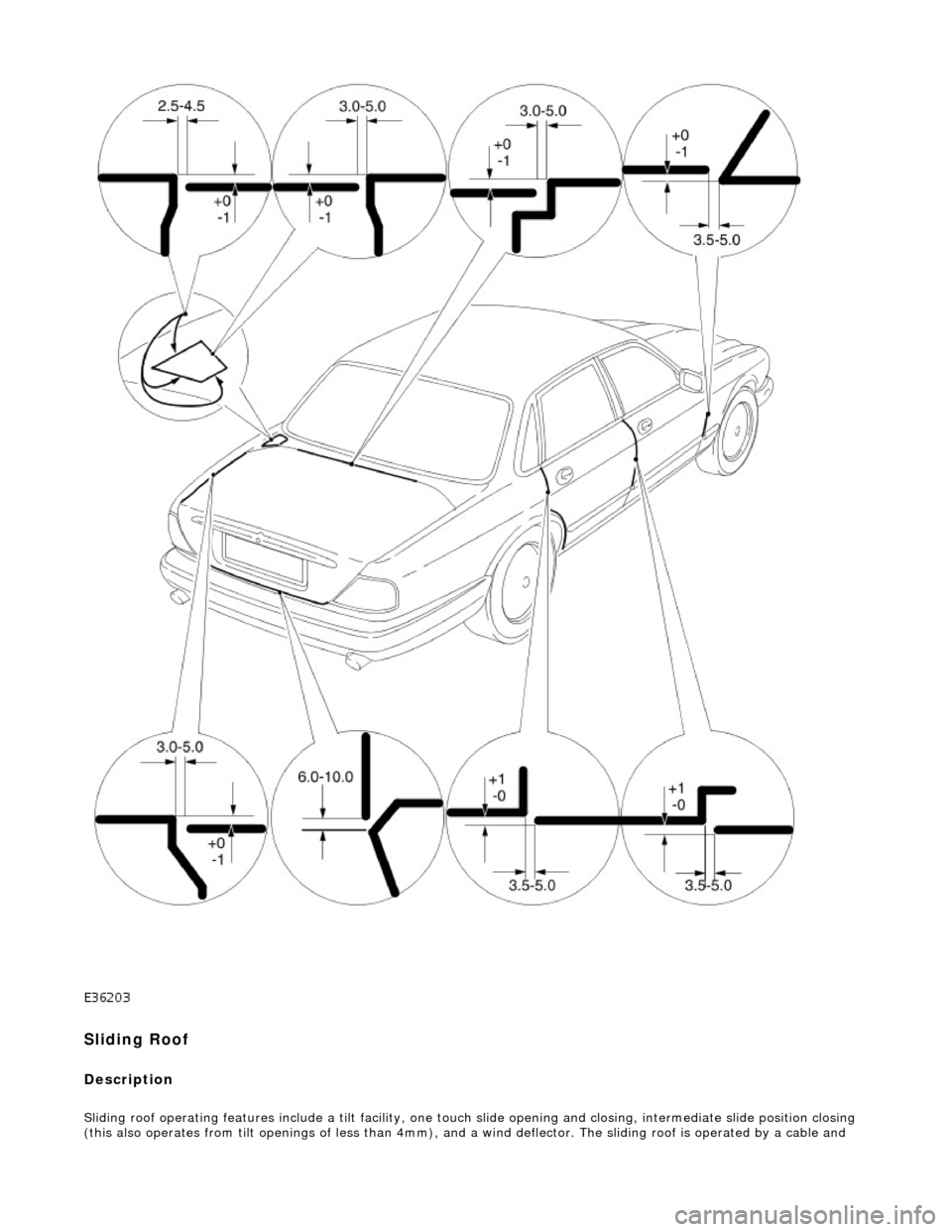

• NOTE: Sliding roof panel clearances are specified without the edge seal installed.

Areas of particular concern are, fuel filler flap, trunk lid to fenders and saddle panels, hood to fenders, grill and headlamps,

sliding roof to main roof panel, door gaps at fenders, B\C posts, roof drip rail an d rocker panel, and bumper cover to fenders

and cross car assemblies

Alignment

Panels must be correctly profiled to maintain cosmetic appearance, and ensure co rrect seating of seals with minimal wind

noise. Areas of particular concern are hood to fenders, trunk lid to fenders and saddle panels, doors to apertures, doors to

fenders and adjacent doors and relationship of the sliding roof panel leading and trailing edges to the main roof panel.

Exterior Fitments

Bezels, trims and lamps must be concentric with apertu res and have equal clearances with adjacent panels.

Areas of particular concern are headlamp to hood, fender and trim panel, exhaust tailpipe trim to bumper cover cut-out,

rear lamp assembly to trunk lid, fender and bumper cover trim, and side feature lines including body side mouldings, fender

to door and door to door.

Exterior Clearances and Alignments-Front

Sliding Roof

Description

Sliding roof operating features include a tilt facility, one touch slide opening and closing, intermediate slide position closing

(this also operates from tilt openings of less than 4mm), and a wind deflector. The sliding roof is operated by a cable and

lever mechanism driven by an electric motor. A sliding roof control module (SRCM) controls the motor in response to

selections made on the roof console switch , or input from the security system for automatic closing. Both the motor and the SRCM are accessed by removing the roof console.In the event of an electrical failure the sliding roof can be manually

operated. This is achieved by inserting a wide bladed screwdriver into a slot in the motor drive gear and turning clockwise to open or counter clockwise to close the sliding roof.

• NOTE: The drive gear becomes disengaged from the motor during manual operation. Before restoring electrical operation

the drive gear must be rotated one quarter turn in the reverse direction to re-engage the motor.

The SRCM is held in position by clips and has two electrical connectors in terfacing with the motor and the roof console

switch/security system. Prior to installing a new SRCM, the sun ro of must be in a neutral closed position. This provides the

SRCM with a sliding roof datum, to ensure accurate and consistent operation. Obstacle sensin g operates on closing in the

slide mode only. If the sliding roof lid encounters an ob struction between 4mm and 200mm from the closed position, the

SRCM detects increased motor load and reve rses the motor, driving the sliding roof to the fully open position. The sliding

roof lid surround seal has a metal inner sect ion which will deform on removal. If removed, this seal must be discarded and a

new seal must be installed on the lid using a Jaguar approved crimping tool.