automatic transmission fluid JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 16 of 2490

В В В В В В В В В В В В В В В В В В В В KnockВ Sensor В (KS) В RH В (18.30.93) В

В В В В В В В В В В В В В В В В В В В В

VariableВ Camshaft В Timing В (VCT) В Oil В Co ntrol

В

Solenoid В (18.30.90) В

В

В В В В В В В В

307: В Automatic В Transmission/Transaxle В

В

В В В В В В В В В В В В 307‐01A :В Automatic В Transmission/Transaxle  ‐ 3.2L В NA В V8  ‐ AJ26/4.0LВ NAВ V8  ‐ AJ27 В

В В В В В В В В В В В В В В В В Specification В

В В В В В В В В В В В В В В В В Description В and В Operation В

В В В В В В В В В В В В В В В В В В В В TransmissionВ DescriptionВ

В В В В В В В В В В В В В В В В Diagnosis В and В Testing В

В В В В В В В В В В В В В В В В В В В В DiagnosticВ Strategy В

В В В В В В В В В В В В В В В В GeneralВ Procedures В

В В В В В В В В В В В В В В В В В В В В TransmissionВ FluidВ Drain В and В Refill В (44.24.02) В

In‐Ve

hicle В Repair В

В В В В В В В В В В В В В В В В В В В В ElectronicВ PressureВ ControlВ (EPC)В Solenoid В (44.15.51) В

В В В В В В В В В В В В В В В В В В В В ExtensionВ Housing В Seal В (44.20.18) В

В В В В В В В В В В В В В В В В В В В В ExtensionВ Housing В O ‐Ring В Seal В (44.20.19) В

В В В В В В В В В В В В В В В В В В В В MainВ ControlВ ValveВ BodyВ (44.40.01) В

В В В В В В В В В В В В В В В В В В В В OutputВ Shaft В Speed В (OSS) В Sensor В (44.15.41) В

В В В В В В В В В В В В В В В В В В В В ShiftВ Solenoids В (SS) В (44.15.50) В

В В В В В В В В В В В В В В В В В В В В TransmissionВ ControlВ Module В (TCM) В (44.15.32) В

В В В В В В В В В В В В В В В В В В В В TransmissionВ FluidВ Filter В (44.24.07) В

В В В В В В В В В В В В В В В В В В В В TransmissionВ Fl

uid В Pan В (44.24.04) В

В В В В В В В В В В В В В В В В В В В В TransmissionВ FluidВ Pan В Gasket В (44.24.05) В

В В В В В В В В В В В В В В В В В В В В TransmissionВ InternalВ Wiring В Harness В (44.15.35) В

В В В В В В В В В В В В В В В В В В В В TransmissionВ InternalВ Wiring В Harness В Electrical В ConnectorВ O‐Ring В SealsВ В

В В В В В В В В В В (44.24.20)В

В В В В В В В В В В В В В В В В В В В В TransmissionВ RangeВ (TR)В Sensor В

В В В В В В В В В В В В В В В В В В В В TransmissionВ SupportВ InsulatorВ (12.45.04) В

В В В В В В В В В В В В В В В В В В В В TurbineВ Shaft В Speed В (TSS) В Sensor В (44.15.40) В

В В В В В В В В В В В В В В В В RemovalВ

В В В В В В В В В В В В В В В В В В В В TransmissionВ (44.20.01)В

В В В В В В В В В В В В В В В В Disassembly В and В AssemblyВ ofВ Subassemblies В

В В В В В В В В В В В В В В В В В В В В InputВ Sh

aft В Seal В (44.32.07) В

В В В В В В В В В В В В В В В В В В В В TorqueВ Converter В (44.17.07) В

В В В В В В В В В В В В В В В В Installation В

В В В В В В В В В В В В В В В В В В В В TransmissionВ (44.20.01)В

Mass

В

Airflow

В

Sen s

or

В

Knock

В Sensor

В (KS)

В LH

В (18.30.92)

В

Page 17 of 2490

В

307‐01B : A u

tomatic

В Transmission/Transaxle  ‐ 4.0L В SCВ V8 ‐ AJ26 В

В В В В В В В В В В В В В В В В Specification В

В В В В В В В В В В В В В В В В Description В and В Operation В

В В В В В В В В В В В В В В В В В В В В TransmissionВ DescriptionВ

В В В В В В В В В В В В В В В В Diagnosis В and В Testing В

В В В В В В В В В В В В В В В В В В В В DiagnosticВ Strategy В

В В В В В В В В В В В В В В В В GeneralВ Procedures В

В В В В В В В В В В В В В В В В В В В В TransmissionВ FluidВ Drain В and В Refill В (44.24.02) В

В В В В В В В В В В В В В В В В In‐Vehicle В Repair В

В В В В В В В В В В В В В В В В В В В В ExtensionВ Housing В Seal В (44.20.18) В

В В В В В В В В В В В В В В В В В В В В MainВ ControlВ ValveВ BodyВ (44.40.01) В

В В В В В В В В В В В В В В В В В В В В TransmissionВ FluidВ Filter В (44.24.07) В

В В В В В В В В В В В В В В В В В В В В TransmissionВ Fl

uid В Pan В Gasket В (44.24.05) В

В В В В В В В В В В В В В В В В В В В В TransmissionВ InternalВ Wiring В Harness В Electrical В ConnectorВ O‐Ring В SealsВ В

В В В В В В В В В В (44.24.20)В

В В В В В В В В В В В В В В В В В В В В TransmissionВ SupportВ InsulatorВ (12.45.04) В

В В В В В В В В В В В В В В В В RemovalВ

В В В В В В В В В В В В В В В В В В В В TransmissionВ (44.20.01)В

В В В В В В В В В В В В В В В В Disassembly В and В AssemblyВ ofВ Subassemblies В

В В В В В В В В В В В В В В В В В В В В InputВ Shaft В Seal В (44.32.07) В

В В В В В В В В В В В В В В В В В В В В TorqueВ Converter В (44.17.07) В

В В В В В В В В В В В В В В В В Installation В

В В В В В В В В В В В В В В В В В В В В TransmissionВ (44.20.01)В

В

307‐02A : Transmission/Transaxle  Cooling  ‐ 3.2L  NA  V8  ‐ AJ26/4.0L  NA  V8  ‐ AJ

27 В

В В В В В В В В В В В В В В В В Description В and В Operation В

В В В В В В В В В В В В В В В В В В В В TransmissionВ CoolingВ

В

В В В В В В В В В В В В 307‐02B :В Transmission/Transaxle В Cooling  ‐ 4.0L В SCВ V8 ‐ AJ26 В

В В В В В В В В В В В В В В В В Description В and В Operation В

В В В В В В В В В В В В В В В В В В В В TransmissionВ CoolingВ

В

В В В В В В В В В В В В 307‐05A :В Automatic В Transmission/Transaxle В External В Controls  ‐ 3.2L В NA В V8  – В

В В В В В В В В В В AJ26/4.0LВ NA В V8  ‐ AJ27 В

В В В В В В В В В В В В В В В В Description В and В Operation В

В В В В В В В В В В В В В В В В В В В В ExternalВ Controls В

Page 40 of 2490

irri

tation and dermatitis. In addition, used engine oil contains potentially harmful contaminants which may cause skin

cancer. Washing facilities and adequate means of skin protection should be provided.

Observe these recommendations:

пЃ¬Wear pro t

ective clothing and impe

rvious gloves when necessary.

пЃ¬Do not put oily

rags in pockets. Avoid contaminat

ing clothes, particularly underwear, with oil.

пЃ¬Overal

ls must be cleaned re

gularly; discard oil impregna ted clothing and footwear wh ich cannot be washed or

cleaned.

пЃ¬Fi rst

Aid treatment should be obtained

immediately for open cuts or wounds.

пЃ¬Use barrier

creams, applying before each work period, to en

able easier removal of dirty oil and grease from the skin.

пЃ¬Wa

sh with soap and water to ensure th

at all oil is removed (skin cleaner and a nail brush will help). The use of

preparations containing lanolin will help to replace the natural skin oils which have been removed.

пЃ¬Do

not use petrol, kerosene, gas oil, th

inners or solvents for washing skin.

пЃ¬If

skin disorders develop, obtain medical advice immediately.

пЃ¬Wh

ere prac

ticable, degrease components prior to handling.

пЃ¬W

h

ere there is a risk of fluids coming into contact with th

e eyes, suitable eye protection should be worn - goggles or

face shield. An eye wash facility should be provided.

пЃ¬Ensure that a

dequate ventilation is provided when volatile degreasing agents are being used.

E

n

vironmental Protection

In so

m

e countries it is illegal to pour used oil onto the ground

, down sewers or drains, or into water courses. The burning of

used engine oil in small space heaters or boilers is not reco mmended unless emission control equipment is fitted. Dispose of

used oil through authorized waste disposal contractors, to licensed waste disposal sites or to the waste oil reclamation

trade. If in doubt, contact the Local Authority for advice on disposal facilities.

On-Board Diagnostics (OBD)

Ve

hicles use programmed electronic control systems to prov

ide engine management and emission regulation, automatic

transmission operation and anti -lock braking control. These control systems ha ve an integral On-Board Diagnostics (OBD)

facility for use in conjunction with either Jaguar diagnostic equipment or a scan t ool which is capable of retrieving DTCs,

PIDs and performing active commands.

The OBD information in this manual provid es diagnostic and rectification procedures for emission related electrical and

mechanical systems. The informat ion is intended to facilitate fault diagnosis and the subsequent rectification of vehicles

without recourse to the portab le diagnostic unit (PDU).

OBD related information can be fo und in the following sections:

пЃ¬General Information

пЃ¬Engine M

anagement System

пЃ¬Auto

matic Transmission

пЃ¬Anti-lock Br

aking System

Where appropriate a section comprises the following sub-sections:

Description and Operation

пЃ¬A ge

neral illustration and parts list to help the identi

fication of the particular system or component.

пЃ¬A b

rief description of the system operating characteristics and monitoring procedure

accompanied by a component

illustration.

пЃ¬Addi ti

onal information, where appropriat

e, is provided in the form of component calibrations, characteristics and

cross sectional views.

пЃ¬A localized circui

t diagram is included to provide circuit iden

tification and details of connectors, splices, fuses, wire

gauge and colors. See Circuit Diagrams.

Diagnosis and Testing (dedicated to fault analysis and rectification)

пЃ¬Recommended special tools. пЃ¬Symptom chart; a ch

art contai

ning all relevant Diagnostic Trouble Code s (DTC), their possible causes and an

indication of the appropriate test.

пЃ¬Sp

ecific pinpoint test(s), de

signed so that fault diagnosis can be carr ied out in a logical and efficient manner.

Page 47 of 2490

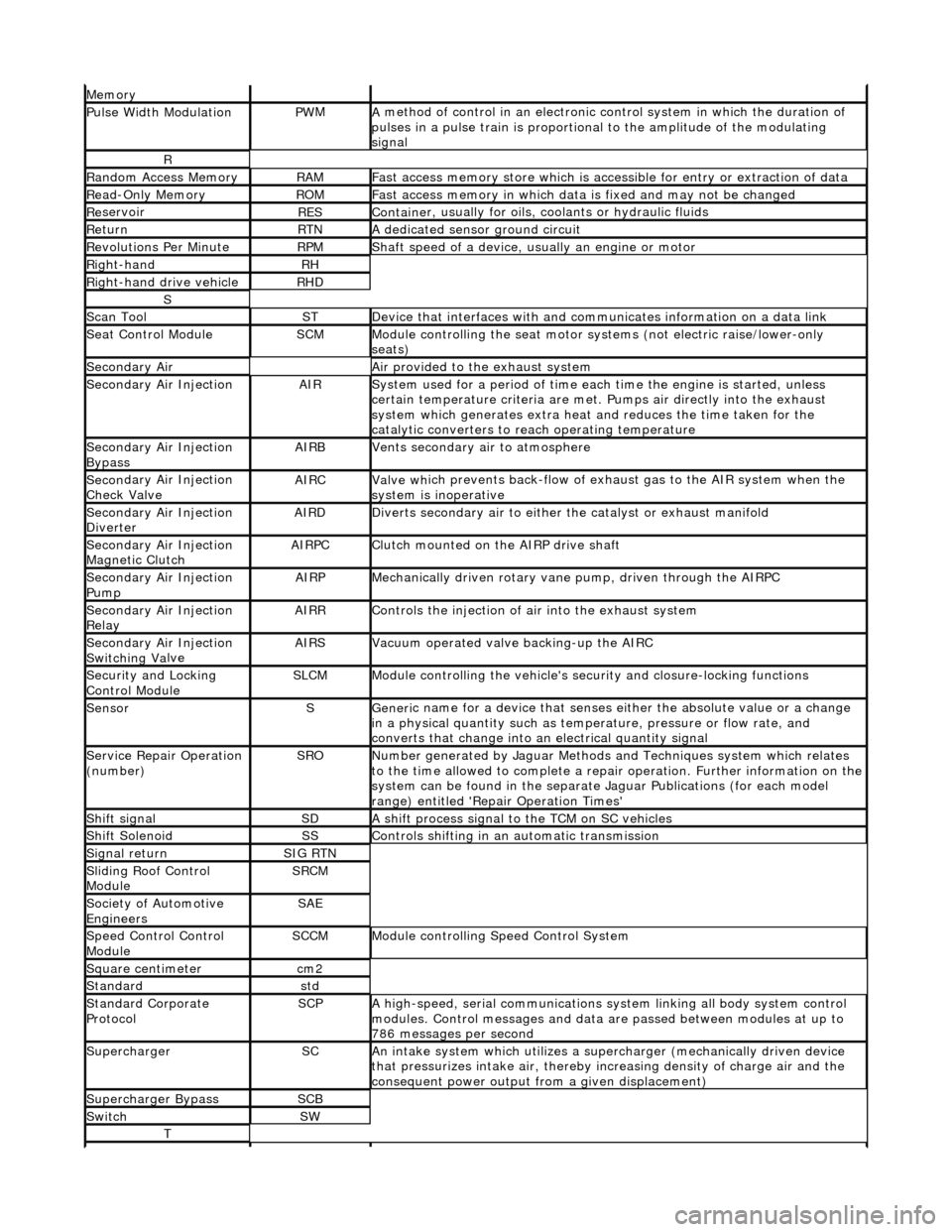

Mem

ory

Pulse Width ModulationPW

M

A

method of control in an electronic co

ntrol system in which the duration of

pulses in a pulse train is proportional to the amplitude of the modulating

signal

R

Ran

dom Access Memory

RAMF

ast access memory store which is accessible for entry or extraction of data

Re

ad-Only Memory

RO

M

F

ast access memory in which data

is fixed and may not be changed

Re

servoir

RESContaine

r, usually for oils,

coolants or hydraulic fluids

Re

turn

RTNA

dedicated sensor ground circuit

R

evolutions Per Minute

RP

M

Shaft speed o

f a device, us

ually an engine or motor

R

ight-hand

RH

Right-hand drive veh

icle

RHD

S

Scan T

ool

STDe

vice that interfaces with and comm

unicates information on a data link

Se

at Control Module

SCMModule

controlling the seat motor systems (not electric raise/lower-only

seats)

Secon

dary Air

Air pro

vided to the exhaust system

Secon

dary Air Injection

AIRSy

stem used for a period of time each

time the engine is started, unless

certain temperature criter ia are met. Pumps air directly into the exhaust

system which generates extra heat and reduces the time taken for the

catalytic converters to reach operating temperature

Secon

dary Air Injection

Bypass

AIRBVents secon

dary air to atmosphere

Secon

dary Air Injection

Check Valve

AIRCValve wh

ich prevents back-flow of exhaust gas to the AIR system when the

system is inoperative

Secon

dary Air Injection

Diverter

AIRDD

iverts secondary air to either

the catalyst or exhaust manifold

Secon

dary Air Injection

Magnetic Clutch

AIRP

C

Clu

tch mounted on the AIRP drive shaft

Secon

dary Air Injection

Pump

AIRPMe

chanically driven rotary vane

pump, driven through the AIRPC

Secon

dary Air Injection

Relay

AIRRCont

rols the injection of air into the exhaust system

Secon

dary Air Injection

Switchin

g Va

lve

AIRSV

acuum operated valve backing-up the AIRC

Secu

rity and Locking

Control Module

SLCMModul

e controlling the vehicle's security and closure-locking functions

SensorSGeneri

c name for a device

that senses either the absolute value or a change

in a physical quantity su ch as temperature, pressure or flow rate, and

converts that change into an electrical quantity signal

Servic

e Repair Operation

(number)

SRONu

mber generated by Jaguar Methods

and Techniques system which relates

to the time allowed to complete a repair operation. Further information on the

system can be found in the separate Jaguar Publications (for each model

range) entitled 'Repair Operation Times'

Shif

t signal

SDA

shift process signal to the TCM on SC vehicles

Shif

t Solenoid

SSControls shi

fting in an automatic transmission

Si

gnal return

SIG RTN

Slidin

g Roof Control

Module

SRCM

Society of Automotive

Engineers

SAE

Speed

Control Control

Module

SCCMModule con

trolling Speed Control System

Square c

entimeter

cm

2

Stan

dard

std

Stan

dard Corporate

Protocol

SCPA

high-speed, serial communications system linking all body system control

modules. Control messages and data ar e passed between modules at up to

786 messages per second

SuperchargerSCAn in

take system which utilizes a supercharger (mechanically driven device

that pressurizes intake air, thereby in creasing density of charge air and the

consequent power output from a given displacement)

Supercharger

Bypass

SCB

SwitchSW

T

Page 48 of 2490

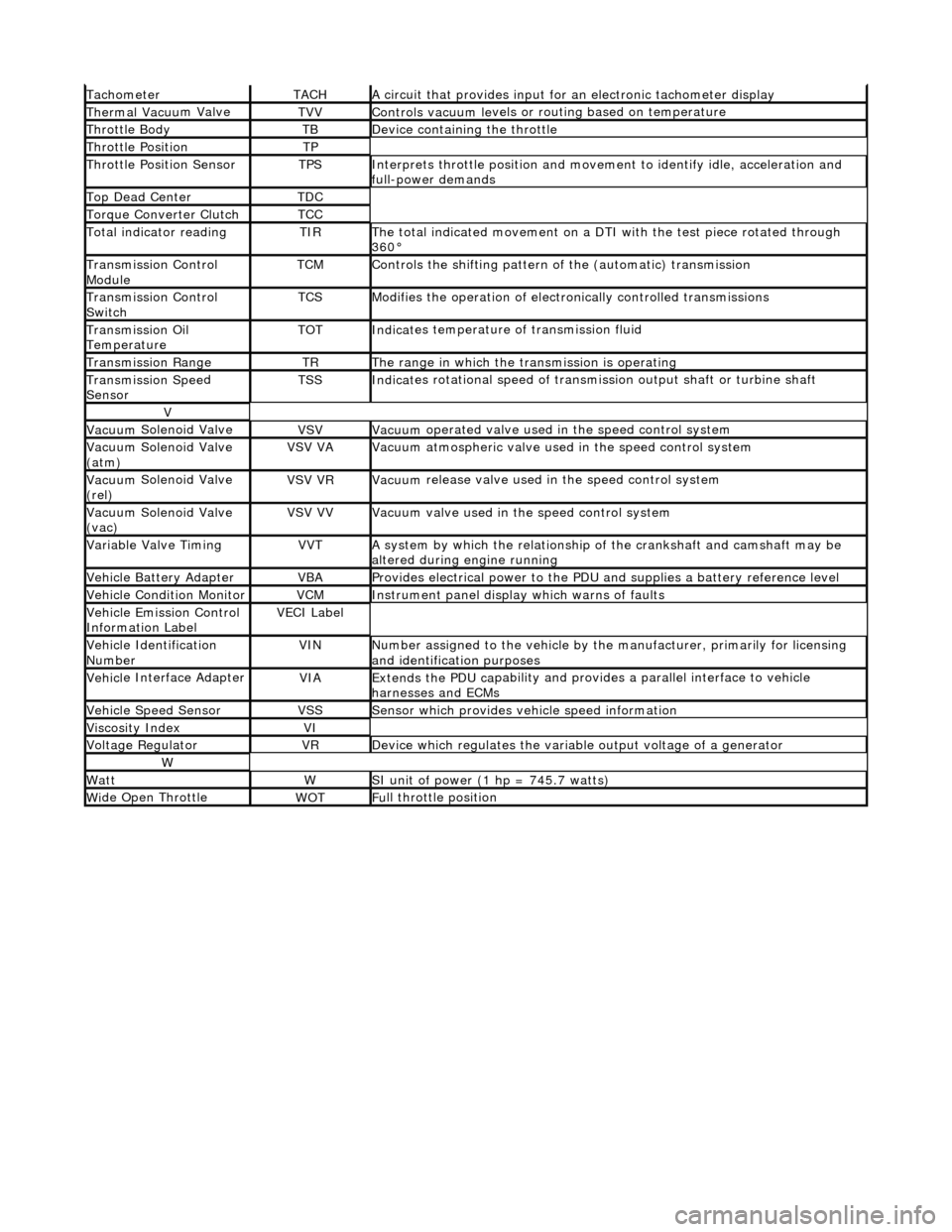

Tacho

meter

TACHA

ci

rcuit that provides input for

an electronic tachometer display

Thermal Vacuu

m Valve

TVVControls vacuum l

e

vels or

routing based on temperature

Throttle

Body

TBDe

vi

ce containing the throttle

Throttl

e

Position

TP

Throttl

e

Position Sensor

TPSInterprets throttl

e

position and movement to iden tify idle, acceleration and

full-power demands

Top Dead CenterTDC

Torque Converter C

lutch

TCC

To

tal

indicator reading

TIRThe t

o

tal indicated movement on a DTI with the test piece rotated through

360В°

Transm

ission Control

Module

TCMControls

the shifting pattern

of the (automatic) transmission

Transm

ission Control

Switch

TCSModifi es

the operation of electronically controlled transmissions

Transmission Oil

TemperatureTOTIndi

cat

es temperature of transmission fluid

Transmission RangeTRThe ran

g

e in which the transmission is operating

Transmission Spe

e

d

Sensor

TSSIndi cat

es rotational speed of transmission output shaft or turbine shaft

V

Vacuu

m

Solenoid Valve

VSVVacuu

m

operated valve used in the speed control system

Vacuu

m

Solenoid Valve

(atm)

VSV VAVacuu m

atmospheric valve used in the speed control system

Vacuu

m

Solenoid Valve

(rel)

VSV VRVacuu m

release valve used in the speed control system

Vacuu

m

Solenoid Valve

(vac)

VSV VVVacuu m

valve used in the speed control system

Variable Valve TimingVVTA

s

ystem by which the relationship of the crankshaft and camshaft may be

altered during engine running

Vehi cl

e Battery Adapter

VBAProvide

s

electrical power to the PDU

and supplies a battery reference level

Vehicl

e Condition Monitor

VCMInst

rum

ent panel display which warns of faults

Ve

hic

le Emission Control

Information Label

VECI Label

Vehi cl

e Identification

Number

VINN u

mber assigned to the vehicle by the manufacturer, primarily for licensing

and identification purposes

Vehi cl

e Interface Adapter

VIAExtends the

PDU ca

pability and provid

es a parallel interface to vehicle

harnesses and ECMs

Vehicle Spe e

d Sensor

VSSSens

or which provides ve

hicle speed information

Viscosity In

dexVI

Voltage RegulatorVRDe

vice which regulates the variable output voltage of a generator

W

Wat

tWSI unit of power (1 hp = 7

45.7 watts)

W

i

de Open Throttle

WO

TFu

ll throttle position

Page 977 of 2490

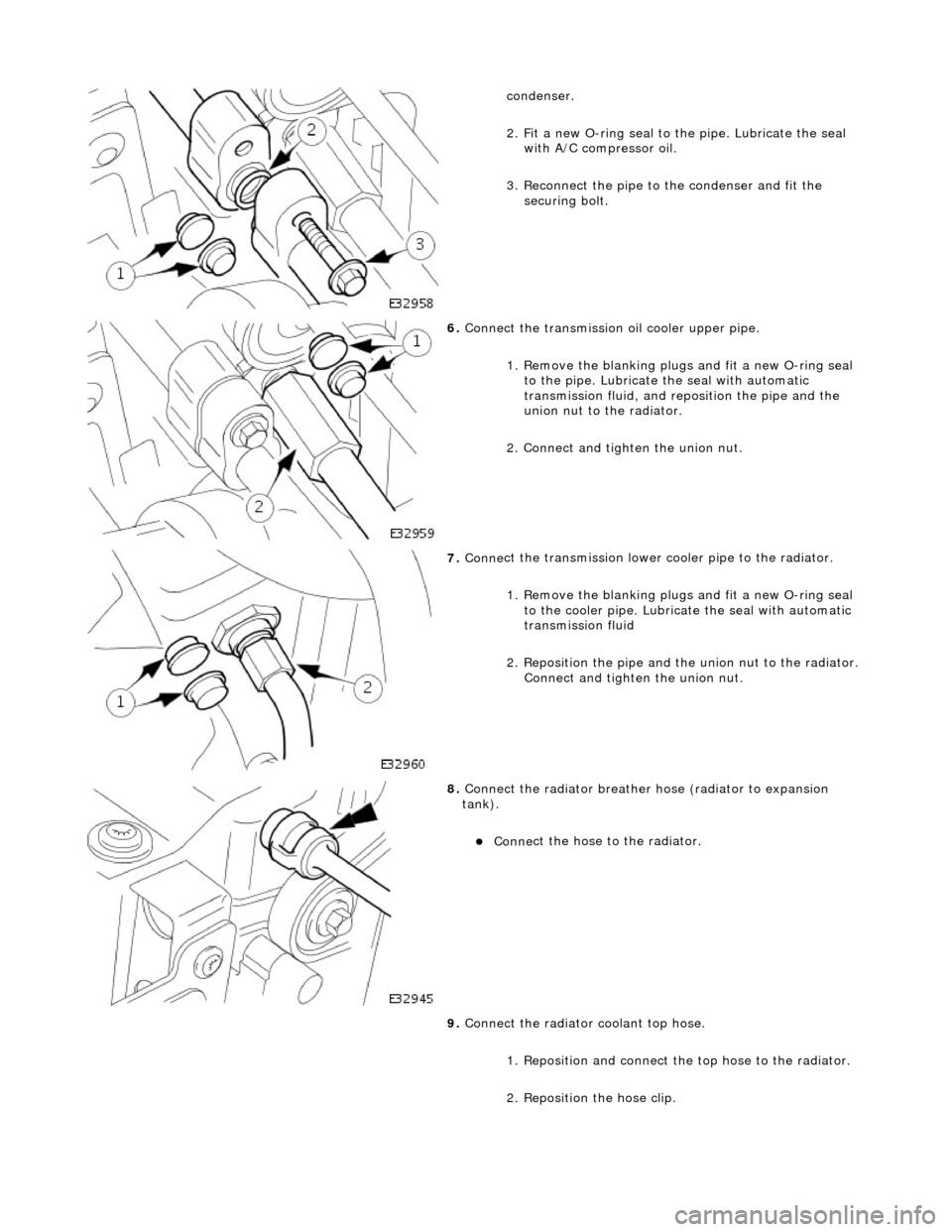

conde

nser.

2. Fit a new O-ring seal to the pipe. Lubricate the seal with A/C compressor oil.

3. Reconnect the pipe to the condenser and fit the securing bolt.

6. Conne

ct the transmission

oil cooler upper pipe.

1. Remove the blanking plugs and fit a new O-ring seal to the pipe. Lubricate the seal with automatic

transmission fluid, and re position the pipe and the

union nut to the radiator.

2. Connect and tighten the union nut.

7. Conne

ct the transmission lower cooler pipe to the radiator.

1. Remove the blanking plugs and fit a new O-ring seal to the cooler pipe. Lubricate the seal with automatic

transmission fluid

2. Reposition the pipe and th e union nut to the radiator.

Connect and tighten the union nut.

8. Connect

the radiator breather

hose (radiator to expansion

tank).

пЃ¬Conne

ct the hose to the radiator.

9. Connect the radiator coolant top hose.

1. Reposition and connect the top hose to the radiator.

2. Reposition the hose clip.

Page 984 of 2490

conden

ser.

2. Fit a new O-ring seal to the pipe. Lubricate the seal with A/C compressor oil.

3. Reconnect the pipe to the condenser and fit the securing bolt.

6. Conne ct

the transmission

oil cooler upper pipe.

1. Remove the blanking plugs and fit a new O-ring seal to the pipe. Lubricate the seal with automatic

transmission fluid, and re position the pipe and the

union nut to the radiator.

2. Connect and tighten the union nut.

7. Conne ct

the transmission lower cooler pipe to the radiator.

1. Remove the blanking plugs and fit a new O-ring seal to the cooler pipe. Lubricate the seal with automatic

transmission fluid

2. Reposition the pipe and th e union nut to the radiator.

Connect and tighten the union nut.

8. Connect the radiator br

eather

hose (radiator to expansion

tank).

пЃ¬Conne ct

the hose to the radiator.

9. Connect the radiator coolant top hose.

1. Reposition and connect the top hose to the radiator.

2. Reposition the hose clip.

Page 1260 of 2490

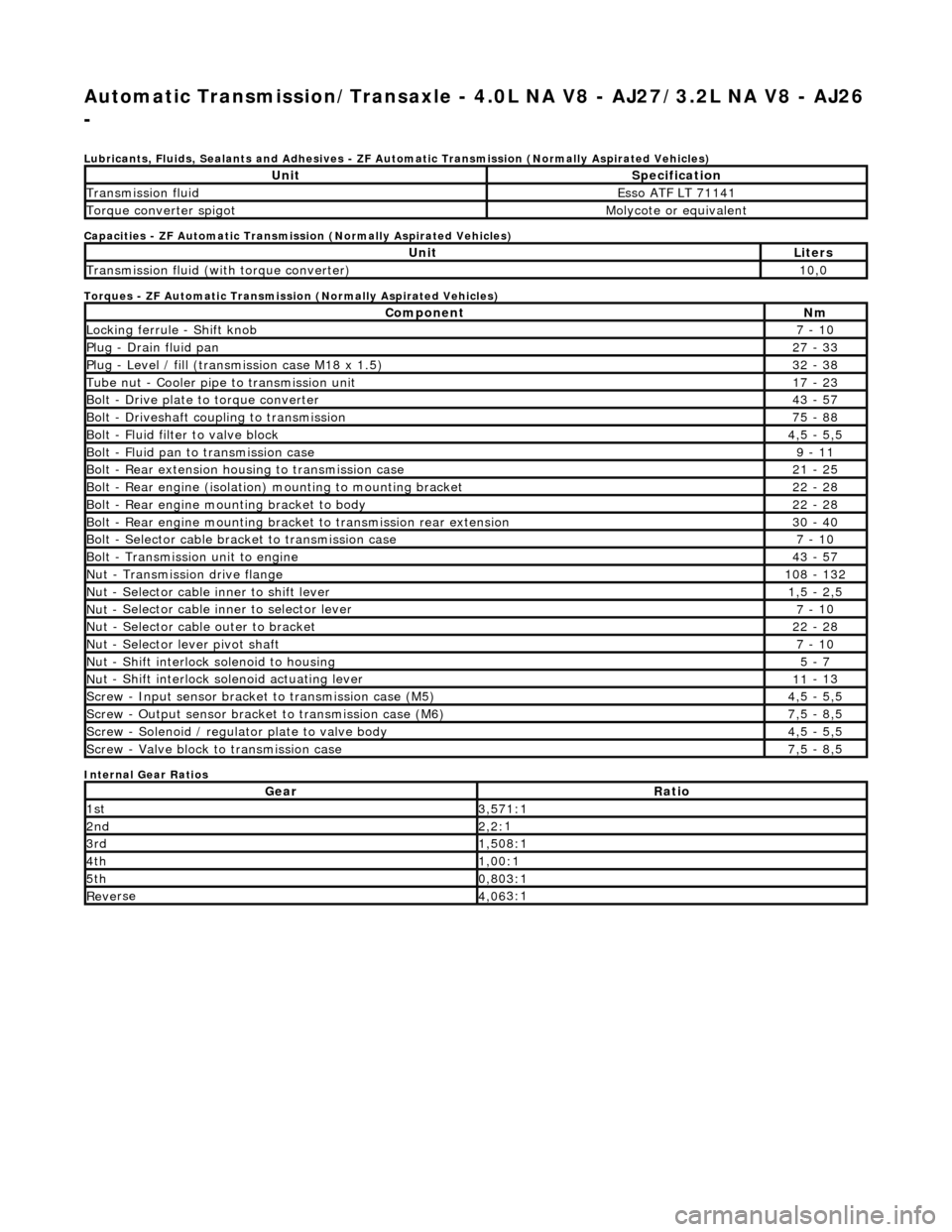

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

-

Lubri c

ants, Fluids, Sealants and Adhesives - ZF Au

tomatic Transmission (Normally Aspirated Vehicles)

Capacities - ZF Automatic Transmission (Normally Aspirated Vehicles)

Torques - ZF Automatic Transmission (Normally Aspirated Vehicles)

Internal Gear Ratios

UnitS p

ecification

Transmissi

on fluidEsso

ATF LT 71141

Torque converter spigotMolyc

o

te or equivalent

UnitLi

t

ers

Transmissi

on fluid (with

torque converter)

10

,0

Com p

onent

Nm

Locki

n

g ferrule - Shift knob

7 -

10

P

l

ug - Drain fluid pan

27

-

33

P

l

ug - Level / fill (transmission case M18 x 1.5)

32

-

38

Tu

be

nut - Cooler pipe to transmission unit

17

-

23

B

o

lt - Drive plate to torque converter

43

-

57

B

o

lt - Driveshaft coupling to transmission

75

-

88

Bo

lt

- Fluid filter to valve block

4,

5 -

5,5

Bolt

-

Fluid pan to transmission case

9 -

11

B

o

lt - Rear extension housing to transmission case

21

-

25

Bolt

-

Rear engine (isolation) mounting to mounting bracket

22

-

28

Bolt -

Rear engine moun

ting bracket to body

22

-

28

Bolt

-

Rear engine mounting bracke

t to transmission rear extension

30 -

40

B

o

lt - Selector cable bracket to transmission case

7 -

10

Bolt

-

Transmission unit to engine

43

-

57

Nu

t -

Transmission drive flange

1

08 -

132

Nu

t -

Selector cable inner to shift lever

1,

5 -

2,5

Nu

t -

Selector cable inner to selector lever

7 -

10

Nu

t -

Selector cable outer to bracket

22

-

28

Nu

t

- Selector lever pivot shaft

7 -

10

Nu

t -

Shift interlock solenoid to housing

5 -

7

Nut -

Shift interlock solenoid actuating lever

11

-

13

Sc

re

w - Input sensor bracket to transmission case (M5)

4,

5 -

5,5

Screw

-

Output sensor bracket to transmission case (M6)

7,

5 -

8,5

Screw

-

Solenoid / regulator plate to valve body

4,

5 -

5,5

Sc

re

w - Valve block to transmission case

7,

5 -

8,5

GearRatio

1s

t3,57

1:1

2n

d2,2:

1

3r

d1,50

8:1

4t

h1,00

:1

5t

h0,80

3:1

Re

ve

rse

4,

06

3:1

Page 1261 of 2490

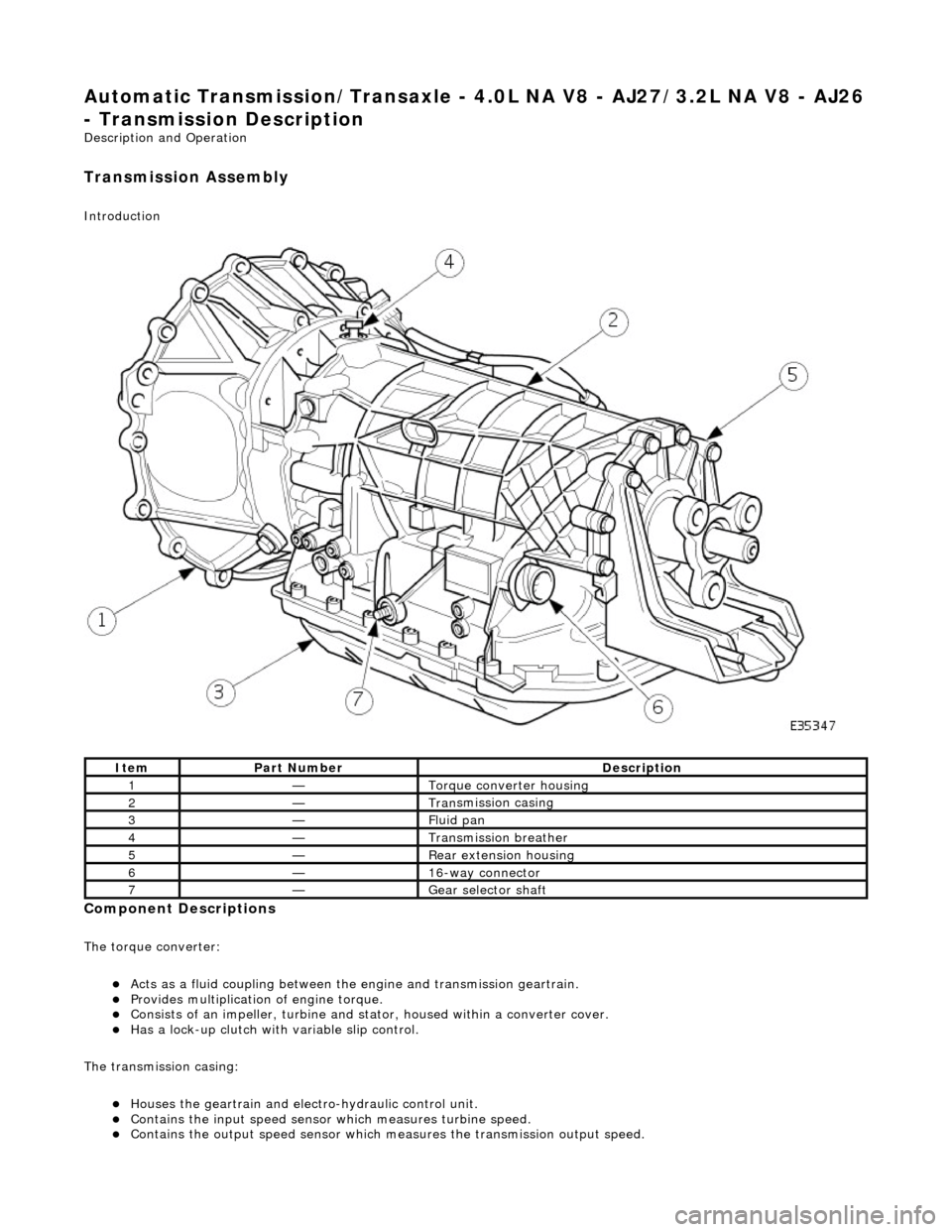

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Transmission Descriptio

n

Description an

d Operation

Transmission As

sembly

Int

roduction

Compon

ent Descriptions

The t

orque converter:

пЃ¬Acts as a fluid

coupling between the

engine and transmission geartrain.

пЃ¬P

rovides multiplication of engine torque.

пЃ¬Cons

ists of an impeller, turbine and stat

or, housed within a converter cover.

пЃ¬Has a l

ock-up clutch with variable slip control.

The transmission casing:

пЃ¬Houses the geartrain and elec t

ro-hydraulic control unit.

пЃ¬Contains

the input speed sensor which measures turbine speed.

пЃ¬Contai

ns the output speed sensor which measures the transmission output speed.

It

em

Par

t Number

De

scription

1—Torque c

onverter housing

2—Tran

smission casing

3—Fluid pan

4—Transmission bre

ather

5—Re

ar extension housing

6—16

-way connector

7—Gear s

elector shaft

Page 1335 of 2490

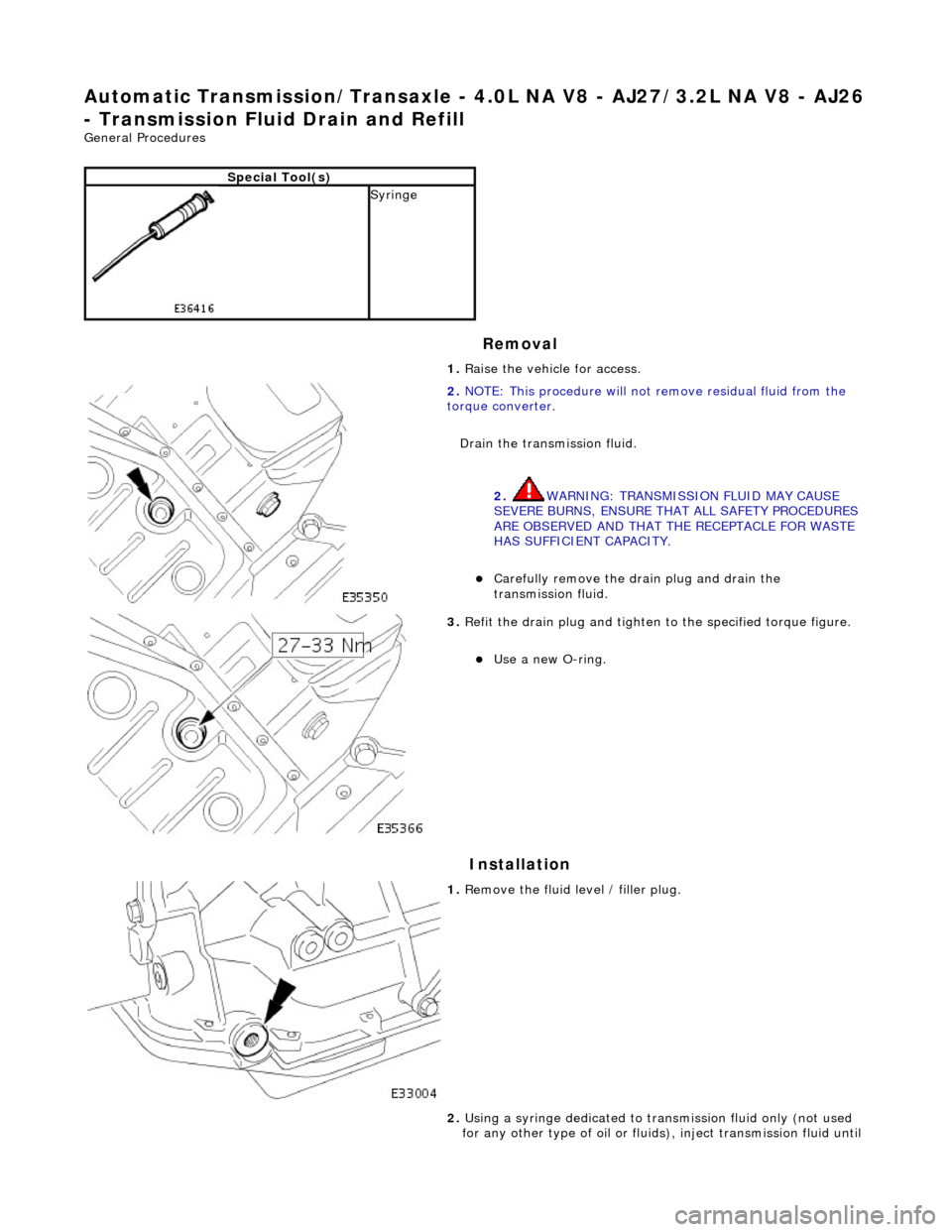

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Transmission Fluid Drain and Refill

General Procedures

Removal

Installation

Special Tool(s)

Syringe 1. Raise the vehicle for access.

2. NOTE: This procedure will not re move residual fluid from the

torque converter.

Drain the transmission fluid.

2. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED AND THAT THE RECEPTACLE FOR WASTE

HAS SUFFICIENT CAPACITY.

пЃ¬Carefully remove the drain plug and drain the

transmission fluid.

3. Refit the drain plug and tighten to the specified torque figure.

пЃ¬Use a new O-ring.

1. Remove the fluid level / filler plug.

2. Using a syringe dedicated to tran smission fluid only (not used

for any other type of oil or fluids ), inject transmission fluid until