key JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2388 of 2490

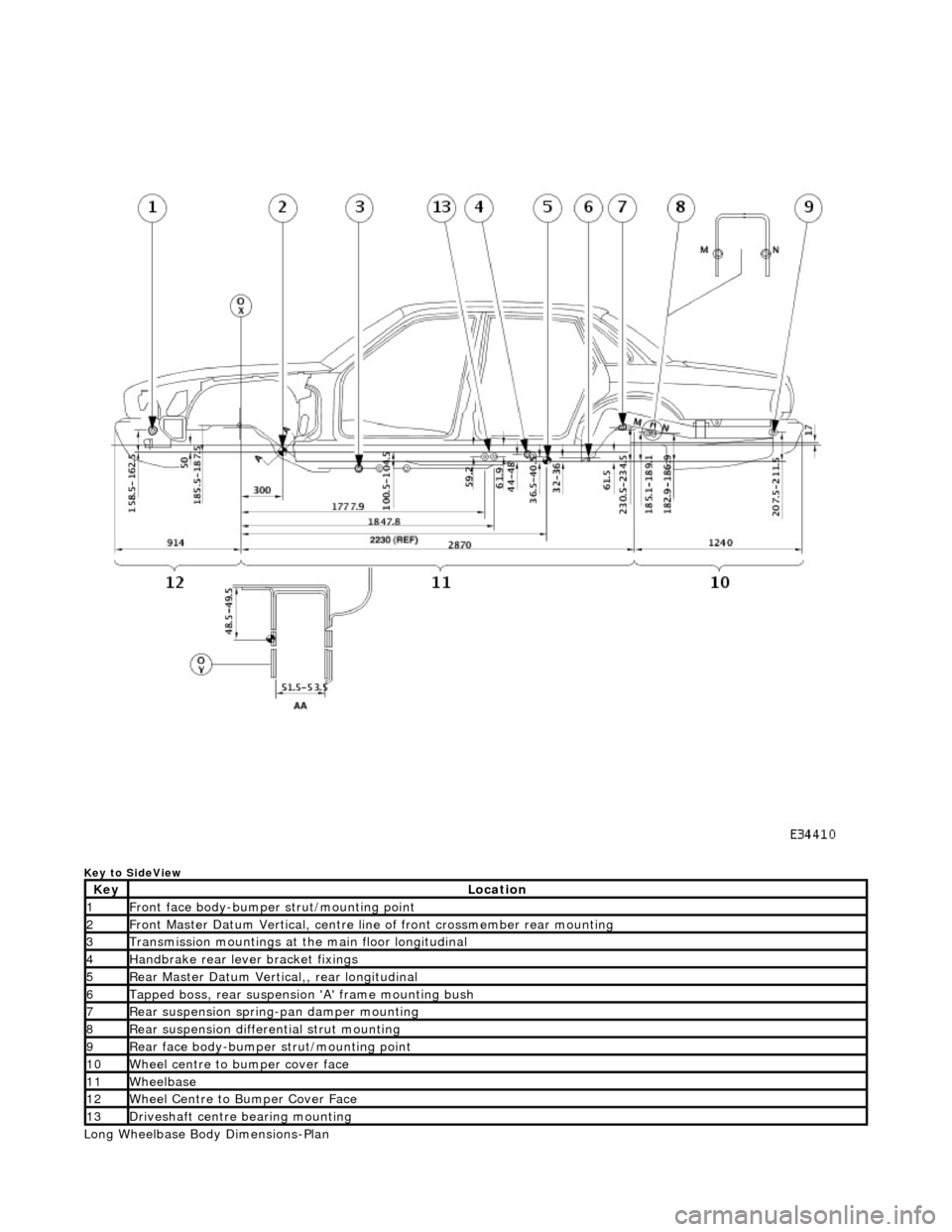

Key to SideView

Long Wheelbase Body Dimensions-Plan

KeyLocation

1Front face body-bumper strut/mounting point

2Front Master Datum Vertical, centre line of front crossmember rear mounting

3Transmission mountings at the main floor longitudinal

4Handbrake rear lever bracket fixings

5Rear Master Datum Vertical,, rear longitudinal

6Tapped boss, rear suspensi on 'A' frame mounting bush

7Rear suspension spring-pan damper mounting

8Rear suspension differential strut mounting

9Rear face body-bumper strut/mounting point

10Wheel centre to bumper cover face

11Wheelbase

12Wheel Centre to Bumper Cover Face

13Driveshaft centre bearing mounting

Page 2389 of 2490

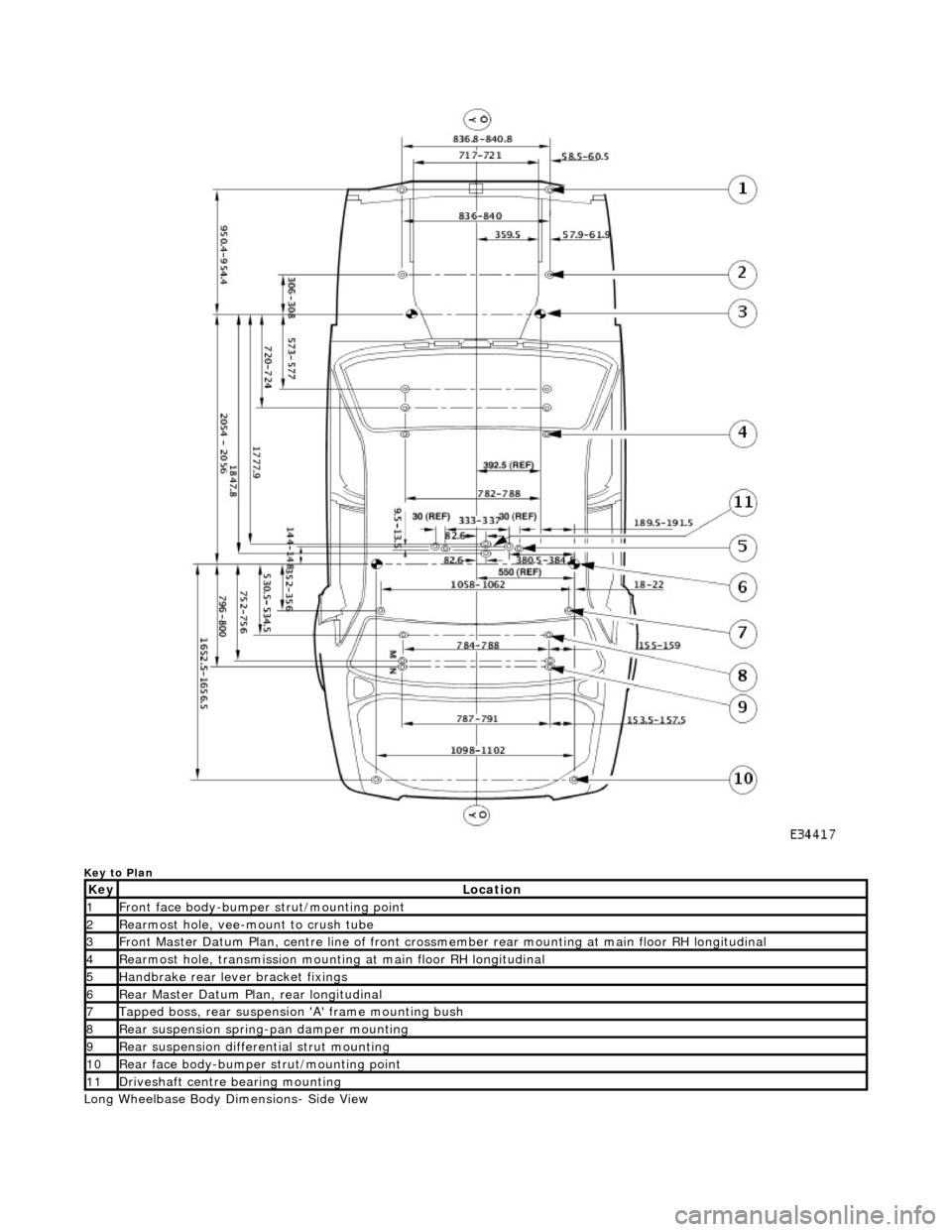

Key to Plan

Long Wheelbase Body Dimensions- Side View

KeyLocation

1Front face body-bumper strut/mounting point

2Rearmost hole, vee-mount to crush tube

3Front Master Datum Plan, centre line of front crossmember rear mount ing at main floor RH longitudinal

4Rearmost hole, transmission mounting at main floor RH longitudinal

5Handbrake rear lever bracket fixings

6Rear Master Datum Plan, rear longitudinal

7Tapped boss, rear suspension 'A' frame mounting bush

8Rear suspension spring-pan damper mounting

9Rear suspension differential strut mounting

10Rear face body-bumper strut/mounting point

11Driveshaft centre bearing mounting

Page 2390 of 2490

Key to SideView

KeyLocation

1Front face body-bumper strut/mounting point

2Front Master Datum Vertical, centre line of front crossmember rear mounting

3Transmission mountings at the main floor longitudinal

4Handbrake rear lever bracket fixings

5Rear Master Datum Vertical,, rear longitudinal

6Tapped boss, rear suspensi on 'A' frame mounting bush

7Rear suspension spring-pan damper mounting

8Rear suspension differential strut mounting

9Rear face body-bumper strut/mounting point

10Wheel centre to bumper cover face

11Wheelbase

12Wheel Centre to Bumper Cover Face

13Driveshaft centre bearing mounting

Page 2411 of 2490

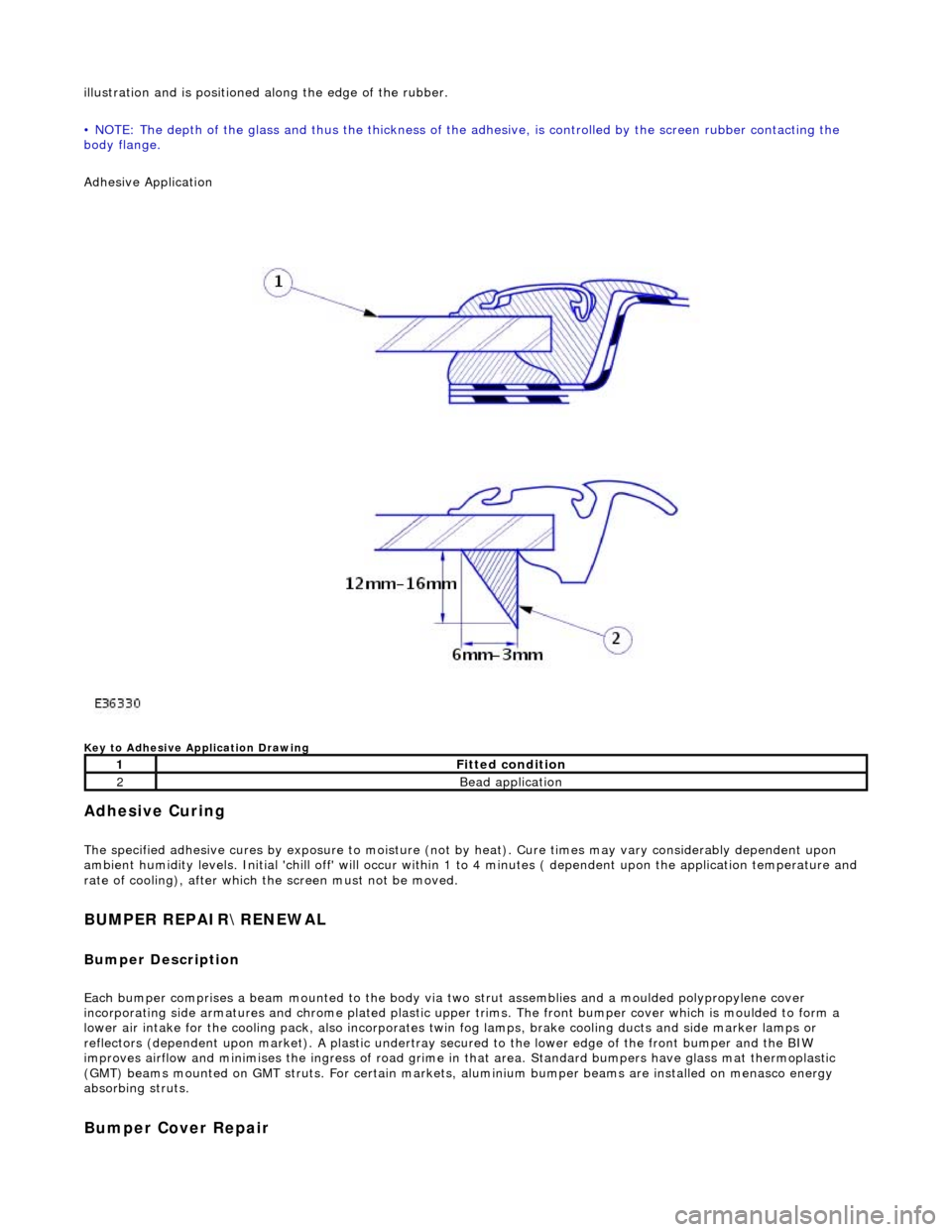

illustration and is positioned along the edge of the rubber.

• NOTE: The depth of the glass and thus the thickness of the ad hesive, is controlled by the screen rubber contacting the

body flange.

Adhesive Application

Key to Adhesive Application Drawing

Adhesive Curing

The specified adhesive cures by exposure to moisture (not by heat). Cure times may vary considerably dependent upon

ambient humidity levels. Initial 'chill off' will occur within 1 to 4 minutes ( dependent upon the application temperature and

rate of cooling), after which the screen must not be moved.

BUMPER REPAIR\RENEWAL

Bumper Description

Each bumper comprises a beam mounte d to the body via two strut assemblies and a moulded polypropylene cover

incorporating side armatures and chrome plated plastic upper trims. The front bumper cover which is moulded to form a

lower air intake for the cooling pack, also incorporates twin fog lamps, brake cooling ducts and side marker lamps or

reflectors (dependent upon market). A plastic undertray secured to the lower edge of the front bumper and the BIW

improves airflow and minimises the ingres s of road grime in that area. Standard bumpers have glass mat thermoplastic

(GMT) beams mounted on GMT struts. For certain markets, aluminium bumper beams are installed on menasco energy

absorbing struts.

Bumper Cover Repair

1Fitted condition

2Bead application

Page 2439 of 2490

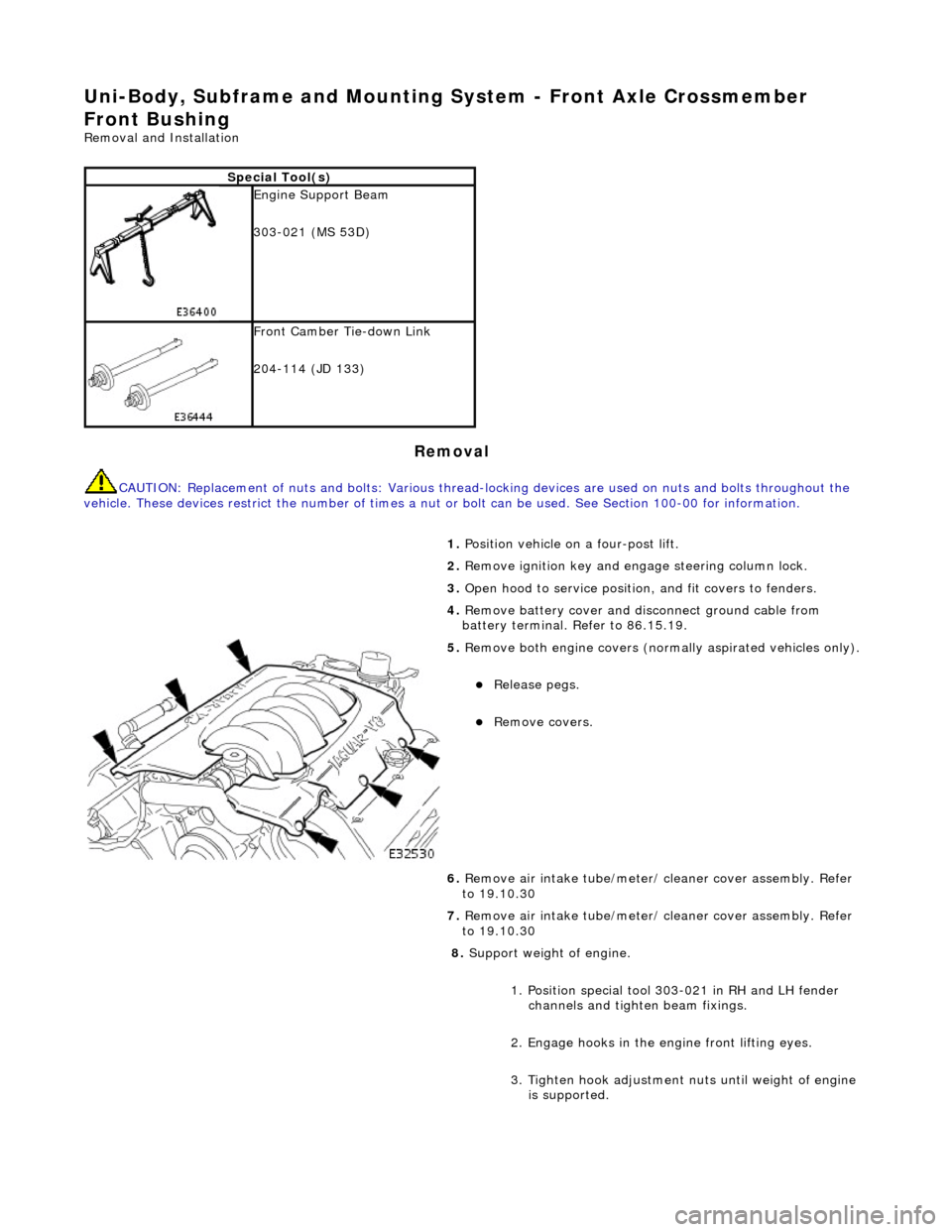

Uni-Body, Subframe and Mounting System - Front Axle Crossmember

Front Bushing

Removal and Installation

Removal

CAUTION: Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See Section 100-00 for information.

Special Tool(s)

Engine Support Beam

303-021 (MS 53D)

Front Camber Tie-down Link

204-114 (JD 133)

1. Position vehicle on a four-post lift.

2. Remove ignition key and en gage steering column lock.

3. Open hood to service position, and fit covers to fenders.

4. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

5. Remove both engine covers (nor mally aspirated vehicles only).

Release pegs.

Remove covers.

6. Remove air intake tube/meter/ cleaner cover assembly. Refer

to 19.10.30

7. Remove air intake tube/meter/ cleaner cover assembly. Refer

to 19.10.30

8. Support weight of engine.

1. Position special tool 303-021 in RH and LH fender channels and tighte n beam fixings.

2. Engage hooks in the en gine front lifting eyes.

3. Tighten hook adjustment nuts until weight of engine is supported.

Page 2450 of 2490

Uni-Body, Subframe and Mounting System - Front Axle Crossmember

Front Bushing Heat Shield

Removal and Installation

Removal

CAUTION: Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See Section 100-00 for information.

Special Tool(s)

Engine Support Beam

303-021 (MS 53D)

Front Camber Tie-down Link

204-114 (JD 133)

1. Position vehicle on a four-post lift.

2. Remove ignition key and en gage steering column lock.

3. Open hood to service position, and fit covers to fenders.

4. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to section 86.15.15.

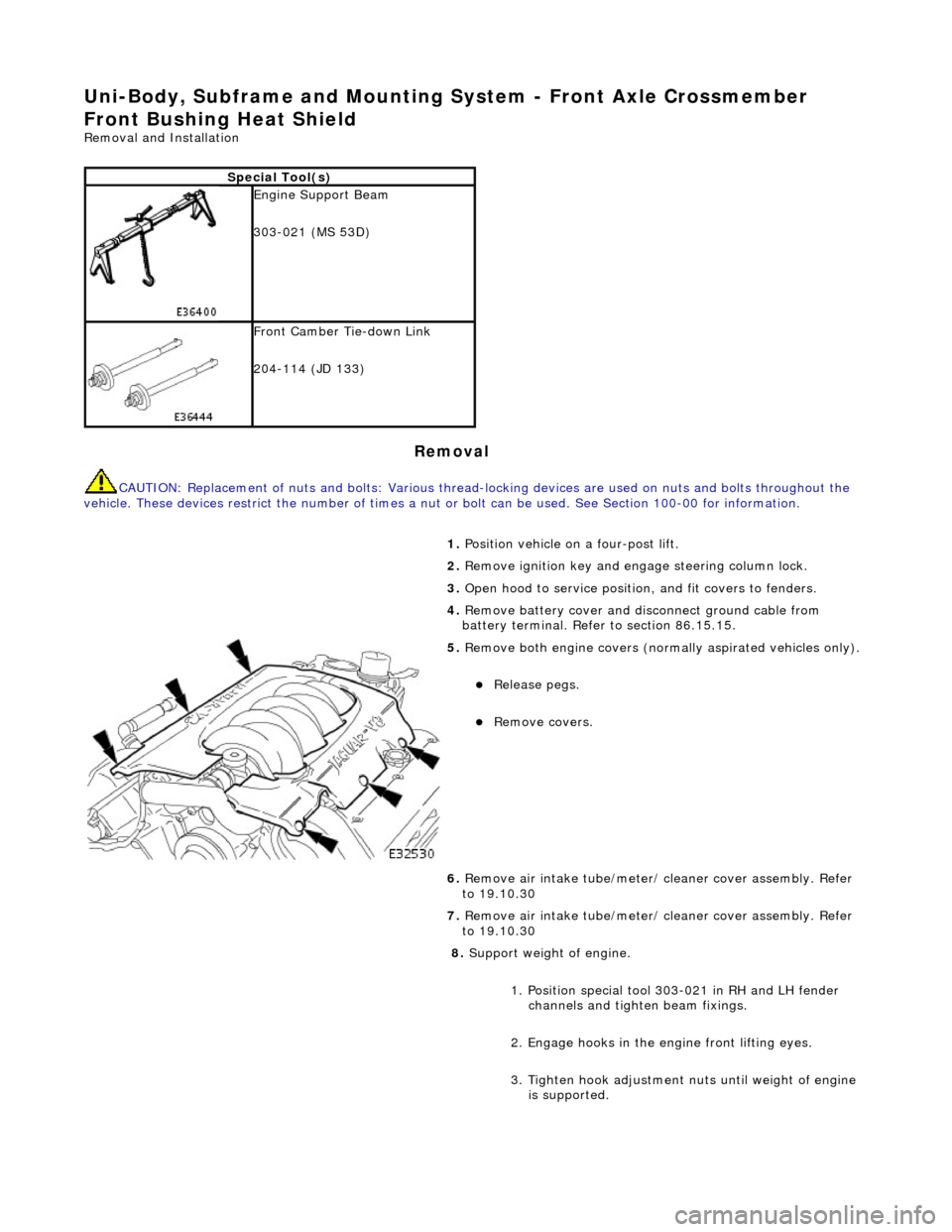

5. Remove both engine covers (nor mally aspirated vehicles only).

Release pegs.

Remove covers.

6. Remove air intake tube/meter/ cleaner cover assembly. Refer

to 19.10.30

7. Remove air intake tube/meter/ cleaner cover assembly. Refer

to 19.10.30

8. Support weight of engine.

1. Position special tool 303-021 in RH and LH fender channels and tighte n beam fixings.

2. Engage hooks in the en gine front lifting eyes.

3. Tighten hook adjustment nuts until weight of engine is supported.