Relays and fuses JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1920 of 2490

Direction indicator and side marker lamps

Each front direction indicator and side marker lamp is retained in the bumper cover by a lug at one end and a spring clip at

the other end. The side marker lamps are not electrically connected for certain markets.

The side repeater lamps are secured by sp ring clips on the lower edge of the lamp unit. In certain markets Jaguar leaper

badges are substituted for side repeater lamps.

Fog lamps

The fog lamps are located in recesses in the front bump er and secured by three screws. The la mps which are not

interchangeable left to right, are accessed from the rear of the bumper.

Operation

All lamps are controlled by the BPM which provides an appropriate output in response to an input received when a selected

switch is operated.

All lamps receive an input direct from th e BPM with the exception of the main be am, dip beam and front fog lamps which

receive an input from the BPM vi a the respective relays and fuses; refer to section 418-01.

Fault analysis must be undertaken using the PDU. Refer to Diagnosis and Testing.

Consult the relevant Electrical Guid e for details of circuit operation.

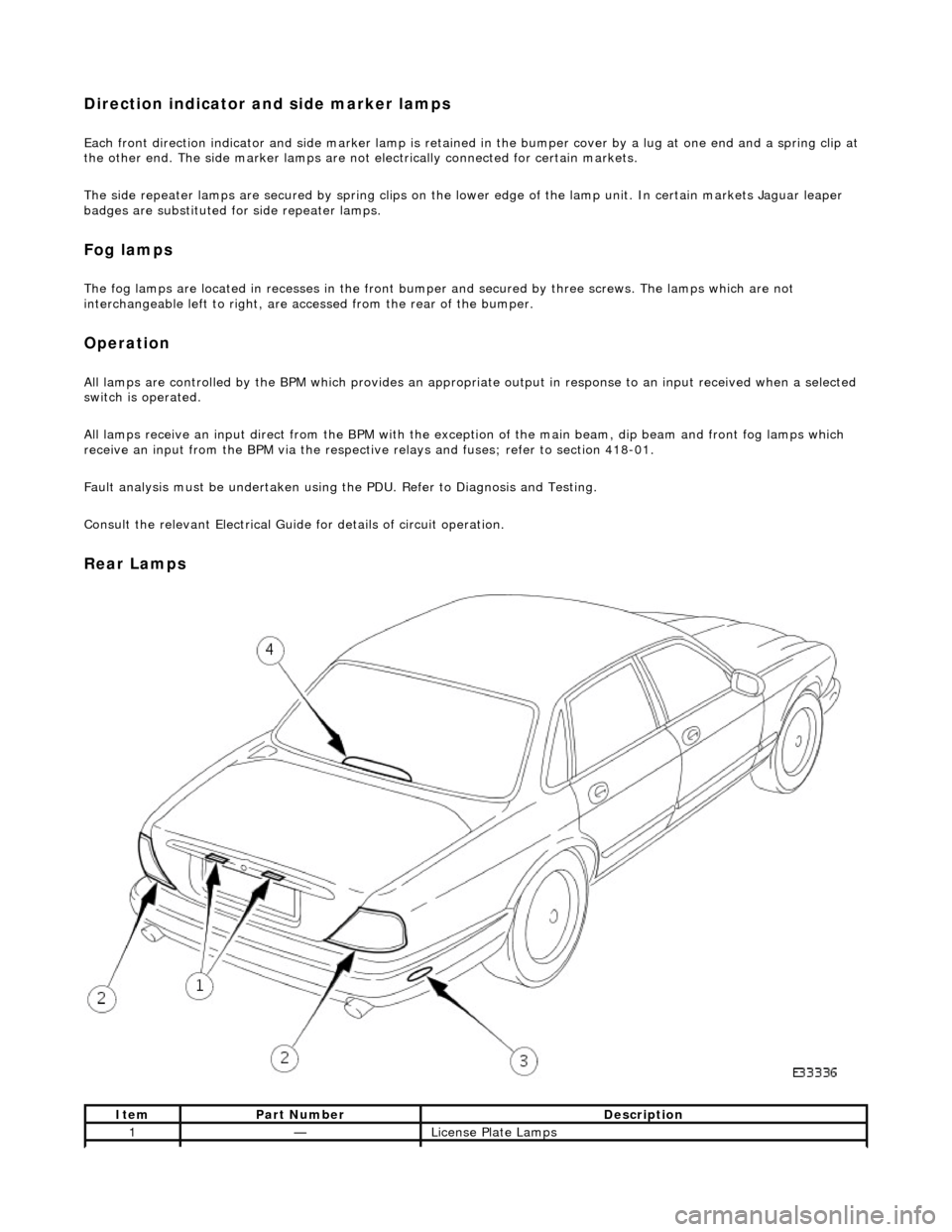

Rear Lamps

ItemPart NumberDescription

1—License Plate Lamps

Page 1973 of 2490

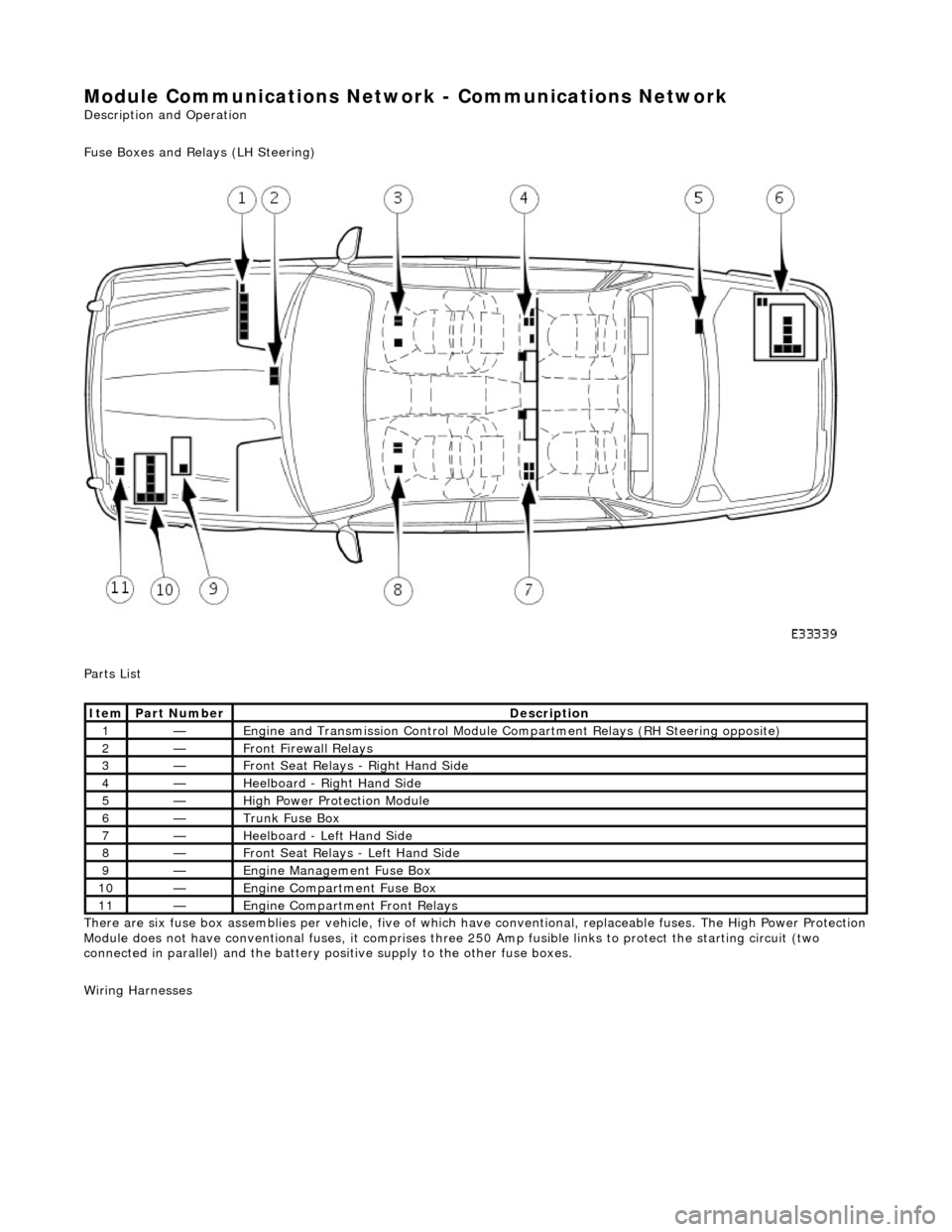

Module Communications Network - Communications Network

Description and Operation

Fuse Boxes and Relays (LH Steering)

Parts List

There are six fuse box assemblies per vehicle, five of which have conventional, replaceable fuses. The High Power Protection

Module does not have conventional fuses, it comprises three 250 Amp fusible links to protect the starting circuit (two

connected in parallel) and the battery positive supply to the other fuse boxes.

Wiring Harnesses

ItemPart NumberDescription

1—Engine and Transmission Cont rol Module Compartment Relays (RH Steering opposite)

2—Front Firewall Relays

3—Front Seat Relays - Right Hand Side

4—Heelboard - Right Hand Side

5—High Power Protection Module

6—Trunk Fuse Box

7—Heelboard - Left Hand Side

8—Front Seat Relays - Left Hand Side

9—Engine Management Fuse Box

10—Engine Compartment Fuse Box

11—Engine Compartment Front Relays

Page 1983 of 2490

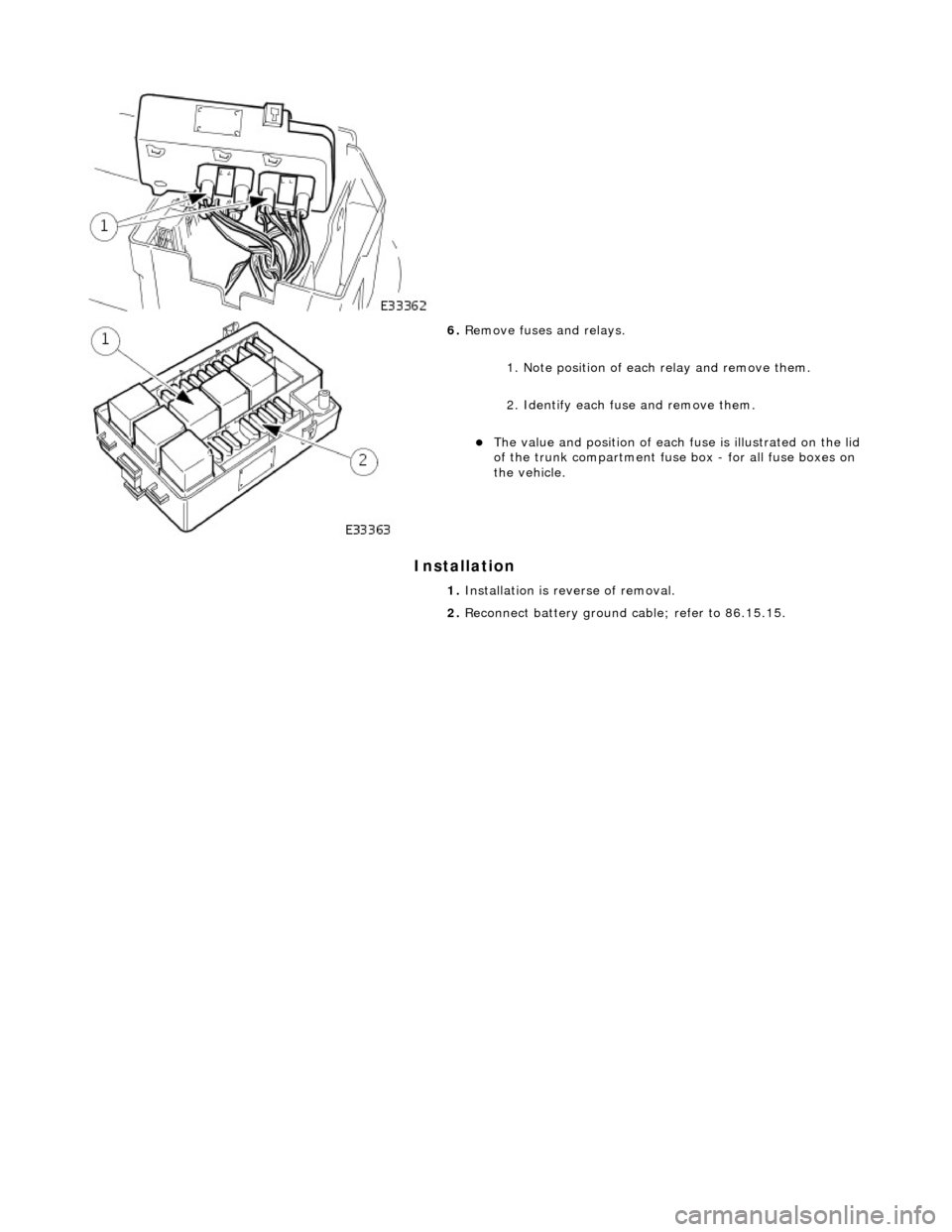

Installation

6. Remove fuses and relays.

1. Note position of each relay and remove them.

2. Identify each fu se and remove them.

The value and position of each fuse is illustrated on the lid

of the trunk compartment fuse box - for all fuse boxes on

the vehicle.

1. Installation is reverse of removal.

2. Reconnect battery ground cable; refer to 86.15.15.

Page 1985 of 2490

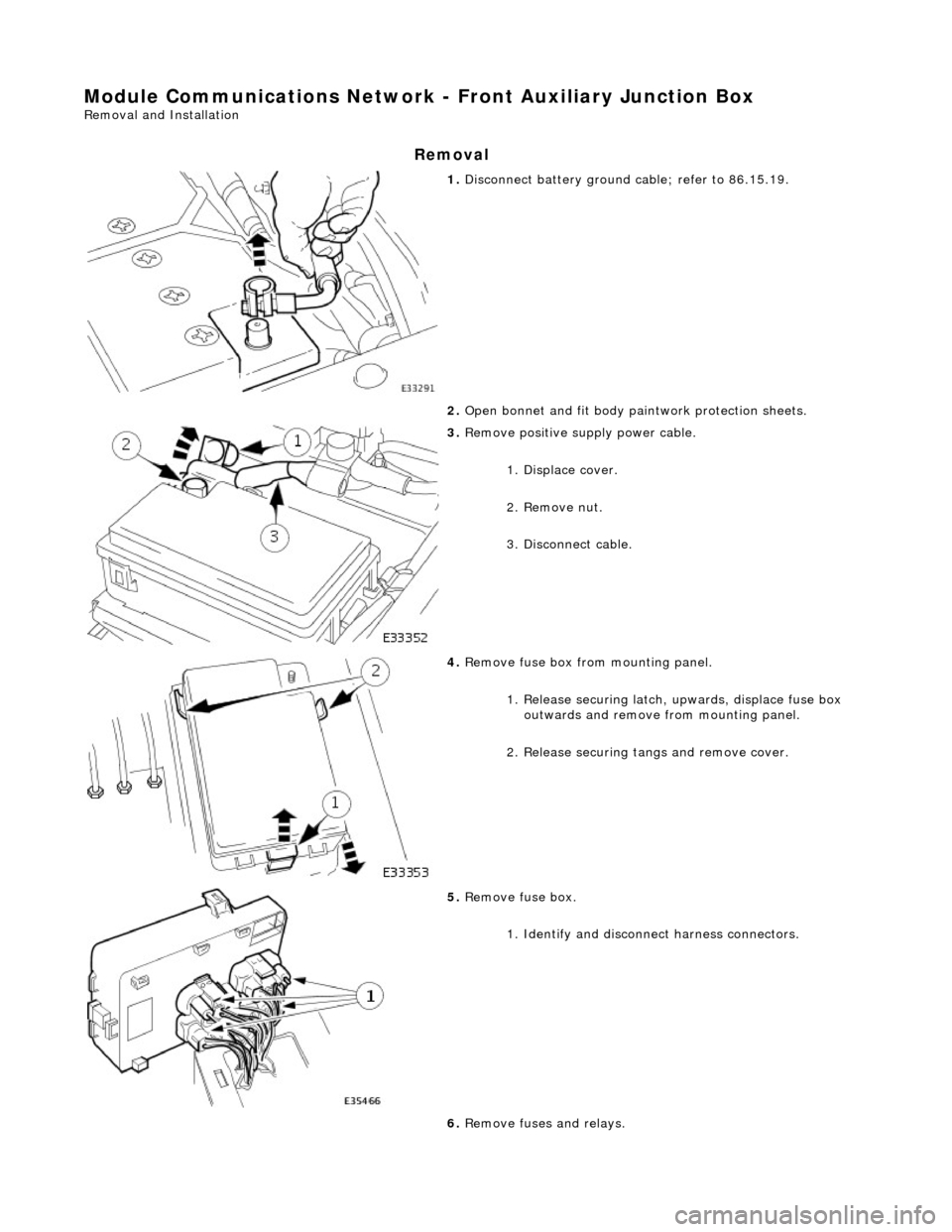

Module Communications Network - Front Auxiliary Junction Box

Removal and Installation

Removal

1. Disconnect battery ground cable; refer to 86.15.19.

2. Open bonnet and fit body pa intwork protection sheets.

3. Remove positive supply power cable.

1. Displace cover.

2. Remove nut.

3. Disconnect cable.

4. Remove fuse box fro m mounting panel.

1. Release securing latch, upwards, displace fuse box

outwards and remove from mounting panel.

2. Release securing tangs and remove cover.

5. Remove fuse box.

1. Identify and disconne ct harness connectors.

6. Remove fuses and relays.

Page 2023 of 2490

sliding roof finisher and clips. Carpet covered trims line the trunk and are secured by fir tree fasteners to the sides and fro nt inner panel.

Rear View Mirrors

The.interior rear view mirror is an electrochromic unit that automatically da rkens to prevent glare from following vehicle

lights. This automatic function is selected by pressing the switch at the bottom of the mirror. Pressing the switch again

cancels this function. An LED then illuminates when automatic dipping is operative. The light sensing unit for the Night

Sentinel automatic lamp operating system is also incorporated in the mirror casing.

The door mirrors are cheater mounted, colo r-keyed units, remote electrically adjustable and heated. Adjustment of both

mirrors is carried out from the driver's door switchpack.A slider switch selects the mirror to be adjusted, and a disc switch

adjusts the selected mirror to the required position. Mirror ad justment can only be made when the ignition switch is in

position I or II or the driver's door is open, and the selector switch is moved from the central position. The door mirrors also

automatically darken under control of the electrochromic interior rear view mirror. Mirror heating elements operate on

selection of backlight heating.

Automatic dipping of passenger door mirror for kerb view when reversing, is fitted as part of the memory pack. With the

ignition switch in position II, the mirror selector switch in the left or right position and reverse gear selected, automatic

dipping is initiated by moving the mirror toggle switch rearwards and releasing. On receipt of the dip signal, the passenger

door mirror is driven downwards either 7 degrees, bottom of travel, or 4,5 to 5,5 seconds, whichever occurs first.

Subsequent rearward movement of the toggle switch achieves further dipping of the mirror in the same increments and

sequence. The mirror can be manu ally returned to the normal memorised positi on by moving the toggle switch forward with

reverse gear selected. The mirror will auto matically return to memorised position on deselection of reverse gear, or moving

ignition switch from position II.

Door mirror fold-back where fitted, to facilitate parking in conf ined spaces, can be initiated when the ignition switch is in

position I or II, the mirror selector switch is in the centra l position and vehicle speed is below 19 km/h (12 mph). Mirror

fold-back is then initiated by moving the toggle switch rear wards and releasing it. The door mirrors are returned to the

normal driving position by agai n moving toggle switch rearwards. There is no speed constraint on this operation. In the

event of a fold-back mirror becoming 'out of position' due to acci dental impact, it must only be re-positioned by initiating

the fold-back sequence.

Loss of power supplies will result in loss of mirror fold-back memory. In the event of such a memory loss with mirrors in the

normal position, fold-back will operate on second movement of the toggle swit ch. On loss of memory with mirrors in the

fold-back position, they will return to the no rmal position on next fold-back operation.

Bumpers

Each bumper comprises a beam mounted to the body via two strut assemblies, and a moulded polypropylene cover

incorporating side armatures and chrome plated blades. Each strut is secured to the BIW by three bolts and supports the

beam on a single bolt/height adjuster. The front bumper cover which is moulded to form a lo wer air intake for the cooling

pack, also incorporates left and right handed twin fog lamps, brake coolin g ducts. Side marker lamps fitted for some

markets serve only as reflectors for UK and Europe. A plastic undertray secured to the lower edge of the front bumper,

improves airflow and minimises the ingres s of road grime in that area. Standard bumpers have glass mat thermoplastic

(GMT) beams mounted on GMT struts. For certain markets, aluminium bumper beams are installed on menasco energy

absorbing struts. Whilst both types of front bumper provide a fu lly integrated 'soft front end' that satisfies bumper impact

requirements, the energy absorbing front and rear bumpers are further designed to withstand 5mph (8kph) impacts with no

visible damage sustained. Side markers/re flectors, and direction indicators are designed for ease of ac cess from the outside

of the bumper. For adjustment and bulb change, the fog lamps are accessed from th e bumper interior. The bumper covers

are body coloured and matched. Replacement covers are supplied complete with side armatures and are finished in primer

Trunk

The trunk houses the spare wheel, the battery, an electrical carrier containing electrical fuses, relays and modules and a

compact disc auto-changer attached to body bracketry. The trun k is fitted with push-fit liners to the sides and front inner

panel.The carpet covered floor is in two removable sections, one covering the spare wheel and wheel changing equipment,

the other covering the battery and electrical carrier. The front and rear edges of the floor board loca te in blocks on the fuel

tank backboard and the rear of the body , which provide two height settings to accommodate the difference in thickness

between the space saver and full sized spare wheels. A moulded finisher covering the rear of the trunk below the sill is

secured to the rear panel by tabs and fir tree fasteners. Finisher panels fitted over the rear lamp units provide for access

from the trunk. Finisher panels fitted to the rear lamp units provide trunk inte rior access to the lamps. The trunk lid

underside is fitted with a removable mo ulded liner and two trunk illumination light s. Trunk locking is based on a central

latch and striker, operated electrically through the central lo cking system by an adjacent actuator or by key in a barrel lock

Page 2024 of 2490

located behind the trunk lid badge.

Occupant Restraints

Inertia reel seat belts with electronically controlled pre-tensioners are installed at the front seats. Supplementary occupant

restraint is provided for driver and front seat passenger by front airbags, and side air bags installed in the outer wing of

each front seat. Standard inertia reel type belts are fitted to all three rear seat positions. The front seat belts are provide d

with height adjuster units which are attached one to each of the 'B' posts. Where emergency locking retractor/automatic

locking retractor seat belts are provided, the belts have two operating modes.The inertia reel mode with emergency locking

retractor is for adult passenge r use only and operates to allow the occupant some freedom of tors o movement under normal

travel conditions.. The static reel mode which prevents belt payout and must be used when a ch ild seat is installed, is

activated by fully extending the belt to engage the ratchet me chanism,.then releasing the belt. Operation of the ratchet will

then be felt and the belt w ill become locked in that position. To revert to in ertia reel (adult passenger) mode, pay the belt

back into the reel to th e fully retracted position.

Body Structure

The XJ8 sedan body is produced in monocoque standard and lo ng wheelbase form. 70% of the body panels are zinc coated

to achieve optimum corrosion protection and a further 8% are constructed in high st rength steels to provide high torsional

strength and passenger impact protection.

Doors

Each front and rear door consists of a we lded, mild steel inner frame and an outer panel. The outer panel is welded to the

waist rail and cheater of the inner frame, then bonded and clinched to fo rm the door assembly. Cosmetic PVC bead is

applied to all clinch joints

Hood

The hood consists of one piece inner an d outer panels clinched and bonded toge ther, with cosmetic bead PVC sealant

applied to all clinch joints. The hood pivo ts at the front on two hinges each secured by bolts to the hood front underside and

the BIW front upper crossmember. Two gas struts secured to the hood by pi vot pins and snap-on couplings, support the

hood in the open position.

Trunk

The trunk lid is of similar construction to the hood, consisting of inner and outer panels clinched and bonded together and

PVC bead sealed. The trunk accommodates the spare wheel, the battery, an electrical carrier containing electrical fuses,

relays and modules and where premium ICE is fitted, a compac t disc auto-changer mounted on body bracketry. Carpet

covered trims line the trunk sides and front inner panel and a po lyurethane rear finisher is secured to the rear panel by

spring clips and fir tree fasteners.

B and C Post Reinforcement

Page 2035 of 2490

the BIW front upper crossmember. Two gas struts secured to the hood by pi vot pins and snap-on couplings, support the

hood in the open position. A full width insulating pad is secured by screws to the underside of the hood. A sponge rubber

tubular seal is mounted transversely to wards the front of the hood underside.

Trunk

The trunk lid is of similar construction to the hood, consisting of inner and outer panels clinched and bonded together and

PVC bead sealed. The trunk accommodates the spare wheel, the battery, an electrical carrier containing electrical fuses,

relays and modules and where premium ICE is fitted, a compac t disc auto-changer mounted on body bracketry. Carpet

covered trims line the trunk and are secured by push-fit fasten ers to the sides and front inner panel. The carpet covered,

two-section, removable trunk floor prov ides access to the spare wheel and wheel changing equipment, the battery and

electrical carrier. The floor board rests on the spare wheel, with the front and rear e dges locating in blocks on the fuel tank

backboard and the rear of the body. The support blocks provide for two floor height settings to accommodate either a space

saver or full size spare wheel.A trunk seal retainer covers the re ar of the trunk below the sill. Finisher panels fitted to the

rear lamp units provide for trunk inte rior access to the lamps. The trunk lid underside is fitted with a removable moulded

liner and two trunk illumination lights. Two gas struts fitted between the inner wheel arches and trunk hinges support the

trunk lid in the open position. For some markets, a warning triangle is attached to a bracket on the trunk lid underside. The

trunk is locked by a central latch and stri ker operated by an adjacent electrical actuator, via the central locking system, or

by key operation of a barrel lock located behind the trunk lid badge.

Fuel Filler Flap