fuel JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 11 of 2490

Valve

Co

ver

LH (12.29.43)

Valve

Cover RH (12.29.44)

Valve

Cover Gasket LH (12.29.40)

Valve

Cover Gasket RH (12.29.41)

Valve

Springs LH

Valve

Springs RH

Variable

Camshaft Timing Oil Con

trol Unit LH (12.65.71)

Variable

Camshaft Timing Oil Control Unit RH (12.65.70)

Variable

Camshaft Timing Oil Control Unit Housing LH (12.65.52)

Variable

Camshaft Timing Oil Control Unit Housing RH (12.65.51)

303‐03A : Engine Cooling

Descriptio

n and Operation

Engine Cooling

Diagnosis and Testing

Engine Cooling

Related Faults / Codes

DTC P0116 ECT circuit range / performance problem

DTC P0125 Insufficient coolant temperature for closed loop fuel control

DTC P0117 ECT circuit low input

DTC P0118 ECT circuit high input

DTC P1474 Intercooler coolant pum

p relay malfunction

Pinpoint test A: P0116, P0125

Pinpoint test B: P0117

Pinpoint test C: P0118

Pinpoint test D: P1474

General Procedures

Cooling System Draining, Filling and Bleeding ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 –

AJ27

Cooling System Draining, Filling and Bleeding ‐ 4.0L SC V8 ‐ AJ26

Cooling Sy

stem Draining and Vacuum Filling

Removal and Installation

Removal

Engine ‐ Re m

oval

(12.41.01)

Installation

Engine ‐ Installation (12.41.01)

Page 12 of 2490

Coolant E x

pansion

Tank (26.15.01)

Coolant Outlet Pipe (26.31.08)

Cooling Fan Motor (26.25.24)

Cooling Fan Motor and Shroud (26.25.25)

Cooling Fan Motors (26.25.25)

Cooling Fan Shroud (26.25.30)

Engine Coolant Level Switch (26.40.11)

Radiator (26.40.01) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Radiator (26.40.01) ‐ 4.0L SC V8 ‐ AJ26

Radiator Lower Hose (26.30.07) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Radiator Lower Hose (26.30.07) ‐ 4.0L SC V8 ‐ AJ26

Radiator Upper Ho

se (26.30.01) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Radiator Upper Hose (26.30.01) ‐ 4.0L SC V8 ‐ AJ26

Thermostat (26.45.07) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Thermostat (26.45.07) ‐ 4.0L SC V8 ‐ AJ26

Thermostat Housing Cover (26.

45.22) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Thermostat Housing Cover (26.45.22) ‐ 4.0L SC V8 ‐ AJ26

Thermostat Housing Cover Seal (26.45.20) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Thermostat Housing Cover Seal (26.45.20) ‐ 4.0L SC V8 ‐ AJ26

Water Pump (26.50.

01) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Water Pump (26.50.01) ‐ 4.0L SC V8 ‐ AJ26

Water Pump Pulley (26.50.05) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Water Pump Pulley (26.50.05) ‐ 4.0L SC V8 ‐ AJ26

303‐03B : Supercharger Cooling

Removal and Installation

Water Pump

303‐04: Fu

el Charging and Controls

Diagnosis and Testing

Fuel Charging and Controls

Inspection and Verification

Driver Information Chart

Default mode Definitions

Diagnostic Trouble Code (DTC) index

Pinpoint Tests

Page 13 of 2490

Removal and Installation

Fuel Injection Supply Manifo ld LH

(19.60.05)

Fuel Injection Supply Manifold RH (19.60.04)

Fuel Injection Supply Manifold Pipe (19.41.04)

Fuel Injector Vehicles Without: Supercharger (18.10.01)

Fuel Injector Vehicles With: Supercharger (18.10.01)

Fuel Injectors Vehicles With: Supercharger (18.10.02)

Throttle Body (19.70.04)

Throttle Body Gasket (19.70.07)

303‐05: Accessory Drive

Descriptio

n and Operation

Accessory Drive

Removal and Installation

Accessory Drive Belt (12.10.40) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Accessory Drive Belt (12.10.40) ‐ 4.0L SC V8 ‐ AJ26

Accessory Drive Belt Idler Pulley (12.10.43) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Accessory Drive Belt Idler Pulle

y (12.10.43) ‐ 4.0L SC V8 ‐ AJ26

Accessory Drive Belt Tensioner (12.10.41) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Accessory Drive Belt Tensioner (12.10.41) ‐ 4.0L SC V8 ‐ AJ26

Supercharger Belt (18.50.08)

Supercharger Belt Idler Pulley (18.50.09)

Supercharger Belt Tensioner (18.50.24)

303‐06: Starting System

Description and Operati

on

Starting System

Diagnosis and Testing

Starting System

Inspection and Verification

Diagnostic Trouble Code (DTC) Index

Pinpoint Tests

Removal and Installation

Starter Motor (86.60.01)

Page 15 of 2490

Superchar

ger

Outlet Pipe (18.50.16)

Supercharger Outlet Pipe Gasket (18.50.17)

Throttle Body Elbow (19.70.28)

Throttle Body Elbow Gasket (19.70.29)

303‐13: Evaporative Emissions

Diagnosis and Testing

Evaporative Emissions

Preliminary

Inspection

Diagnostic

Drive Cycles

Diagnostic

Trouble Code (DTC) index/Symptom Chart

Pinpoint

Tests

Removal

and Installation

Evaporative

Emission Canister (17.15.13)

Evaporative

Emission Canister Purge Valve (17.15.30)

Fuel

Tank Press

ure Sensor (19.55.31)

Fuel

Vapor Vent Valve Housing (19.55.24)

Fuel

Vapor Vent Valve Housing Seal (19.55.25)

303

‐14: Electronic Engine Controls

Description

and

Diagnosis

and Testing

Electronic

Engine Con

trols

Inspection

and Verification

Driver

Information Chart

Default

mode Definitions

Diagnostic

Trouble Code (DTC) Index

Pinpoint

Tests

Removal

and Installation

Catalyst

Monitor Sensor LH (18.30.81)

Catalyst

Monitor Sensor RH (18.30.80)

Heated Oxygen Sensor (HO2S) LH (18.30.79)

Heated Oxygen Sensor (HO2S) RH (18.30.78)

Camshaft

Position

Sen s

or

ECM

Position

Sensor

Crankshaft

Removal

Engine

Coolant Temperature

Sensor

Operation

Intake Air Temperature (IAT) Sensor (18.

30.52)

Page 19 of 2490

309: Exhaust Syst

em

309‐00: Exhaust System

Specification

Description and Operation

Exhaust System

Diagnosis and Testing

Exhaust System

Removal and Installation

Catalytic Converter LH (17.50.15) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Catalytic Converter LH (17.50.15) ‐ 4.0L SC V8 ‐ AJ26, Vehicles With:

Supercharger

Catalytic Converter RH (17.50.16) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Catalyt

ic Converter RH (17.50.16) ‐ 4.0L SC V8 ‐ AJ26, Vehicles With:

Supercharger

Catalytic Converter Gasket LH (17.50.06) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Catalytic Converter Gasket LH (17.50.06) ‐ 4.0L SC V8 ‐ AJ26

Catalytic Converter Gasket RH (17.50.07) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Catalyt

ic Converter Gasket RH (17.50.07) ‐ 4.0L SC V8 ‐ AJ26

Front Muffler (30.10.18) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Front Muffler (30.10.18) ‐ 4.0L SC V8 ‐ AJ26

Intermediate Muffler LH (30.10.15) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Intermediate Muffler LH (30.10.15) ‐ 4.0L SC V8 ‐ AJ

26

Intermediate Muffler RH (30.10.16) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Intermediate Muffler RH (30.10.16) ‐ 4.0L SC V8 ‐ AJ26

Muffler and Tailpipe LH (30.10.22)

Muffler and Tailpipe RH (30.10.52)

310: Fuel System

310‐00: Fuel System ‐ General Information

General Procedures

Fuel System Pressure Check

Fuel Tank Draining

Fuel Sy stem Pres

sure

Release

Page 20 of 2490

310‐01: Fu el Tank and Lines

Removal and Installation

Fuel Level Sensor (88.25.32)

Fuel Pump (19.45.08)

Fuel Tank (19.55.01)

310‐02

:

Acceleration Control

General Procedures

Accelerator Cable Adjustment (12.20.05)

Removal and Installation

Accelerator Cable (19.20.06)

310‐03: Speed Control

Diagnosis and Testing

Speed Con

trol

4: Electrical

412: Climate Control System

412‐00: Climate Control System ‐ General Information

Specification

Description and Operation

Climate Control System

Diagnosis and Testing

Climate Control System

General Procedures

Air Conditioning (A/C) System Check ‐ Retail Procedure

Air Conditioning (A/C) System Recovery, Evacuation and Charging (82.30.30)

Contaminated Refrigerant Ha

ndling

Manifold Gauge Set Connection

Refrigerant Adding (82.30.02)

Refrigerant Oil Adding

Refrigerant System Tests

412‐01: Air Distribution and Filtering

Description and Operation

Page 28 of 2490

Removal and Installation

Door (76. 28.04)

Front Doo

r

Opening Weatherstrip (76.40.01)

Fuel Filler Door (76.10.25)

Hood (76.16.01)

Hood Hinge (76.16.12)

Hood Striker (76.16.24)

Hood Strut (76.16.15)

Luggage Compartment Lid Hinge (76.19.28)

Luggage Compartment Lid Opening Weatherstrip (76.19.06)

Luggage Compartment Lid Striker (76.19.12)

Luggage Compartment Lid Strut (76.19.27)

Rear Door Opening Weathe

rstrip (76.40.02)

501‐05: Interior Trim and Ornamentation

Description and Operation

Interior Trim

Removal and Installation

A‐Pillar Trim Panel (76.13.31)

B‐Pillar Trim Panel (76.13.28)

Cowl Side Trim Panel (76.13.30)

C‐Pillar Trim Panel (76.13.73)

Door Window Control Switch Finish Pane

l (76.47.33)

Engine Cover (76.11.35)

Floor Covering (76.49.08)

Folding Tray (76.47.31)

Folding Tray Finish Panel (76.47.32)

Front Door Armrest (76.34.22)

Front Door Trim Panel Finish Panel (76.47.11)

Front Door Stowage Compartment (76.34.27)

Front Door Trim Panel (76.34.01)

Headliner (76.64.01)

Luggage Compartment Front Trim Panel (76.19.31)

Luggage Compart

ment Lid Trim Panel (76.19.05)

Luggage Compartment Rear Trim Panel (76.19.44)

Luggage Compartment Side Trim Panel (76.19.22)

Overhead Console Finish Panel (76.47.41)

Page 38 of 2490

Torque Specifications

Torque sp

ecifications are shown in maintenance procedure illustra

tions and also in the torque specifications chart located at

the front of the relevant section.

Disconnecting/Connecting the Battery

Ow ing t

o the electronic components used on the vehicle, it is important that the battery is disconnected when specified in a

maintenance procedure.

When the battery is connected, the specified procedure must be followed, to ensure the correct operation of all vehicle

systems; refer to Section 414-01.

Use of Control Modules

Control modu les may

only be used on the ve

hicle to which they were originally fitted. Do not attempt to use or test a control

module on any other vehicle.

Function

al Test

On

completion of a maintenance procedure, a thorough test should be carried out, to ensu

re that the relevant vehicle

systems are working correctly.

Protecting the Vehicle

Al ways

fit covers to protect

the fenders before commencing work in the engi ne compartment. Cover the seats and carpets,

wear clean overalls and wash hands or wear gloves before working inside the vehicle. Avoid spilling hydraulic fluid,

antifreeze or battery acid on the paintwork. In the event of spillage, wash off with water imme diately. Use polythene sheets

in the trunk to protect carpets. Always use the recommended service tool, or a satisfactory equivalent, where specified.

Protect temporarily exposed screw thread s by replacing nuts or fitting caps.

Preparation

Before disassembly, clean the surrounding ar ea

as thoroughly as possible. When co

mponents have been removed, blank off

any exposed openings using grease-proof paper and masking tape. Immediately seal fuel, oil and hydraulic lines when

separated, using plastic caps or plugs, to prevent loss of fluid and the entry of dirt. Close the open ends of oilways, exposed

by component removal, with tapered hardw ood plugs or readily visible plastic plugs. Immediately a component is removed,

place it in a suitable container; use a se parate container for each component and its associated pa rts. Before dismantling a

component, clean it thoroughly with a recommended cleaning agent; check that the agent will not damage any of the

materials within the component. Clean the bench and obtain ma rking materials, labels, containers and locking wire before

dismantling a component.

Dismantling

O b

serve scrupulous cleanliness when dismantling components,

particularly when parts of the brake, fuel or hydraulic

systems are being worked on. A particle of dirt or a fragment of cloth could caus e a dangerous malfunction if trapped in

these systems. Clean all tapped holes, crev ices, oilways and fluid passages with compressed air. Do not permit compressed

air to enter an open wound. Always use ey e protection when using compressed air.

Ensure that any O-rings used for sealing are correctly refitted or renewed if disturbed. Mark mating parts to ensure that

they are replaced as dismantled. Whenever possible use markin g materials which avoid the possibilities of causing distortion

or the initiation of cracks, which could occur if a center pu nch or scriber were used. Wire together mating parts where

necessary to prevent accidental interchange (e.g roller bearing components). Tie labels on to all parts to be renewed and to

parts requiring further inspection before being passed fo r reassembly. Place labelled parts and other parts for rebuild in

separate containers. Do not disc ard a part which is due for renewal until it ha s been compared with the new part, to ensure

that the correct part has been obtained.

Page 39 of 2490

Before inspecting a component for wear or per

forming a dimensional check,

ensure that it is absolutely clean; a slight smear

of grease can conceal an incipient failure. When a component is to be checked dimensionally against figures quoted for it,

use the correct equipment (surface plates, micrometers, dial gauges etc.) in serviceable condition. The use of makeshift

equipment can be dangerous. Reject a component if its dimensio ns are outside the limits quoted, or if damage is apparent.

A part may be refitted if its critical di mension is exactly to the limit size and it is otherwise satisfactory. Use Plastigauge 12

Type PG-1 for checking bearing surface clearance, e.g. big end bearing shell to crank jour nal. Instructions for the use of

Plastigauge and a scale giving bearing clearances in steps of 0.0025 mm (0.0001 in) are supplied with the package.

Safety

Precautions

• WAR

NINGS:

WORKING ON THE FUEL SYSTEM RESULTS IN FUEL AND FUEL VAPOUR BEING PRESENT IN THE ATMOSPHERE. FUEL

VAPOUR IS EXTREMELY FLAMMABLE, HENCE GREAT CARE MUST BE TAKEN WHILST WORKING ON THE FUEL SYSTEM.

ADHERE STRICTLY TO THE FOLLOWING PRECAUTIONS:

DO

NOT SMOKE IN THE WORK AREA.

DISP

LAY 'NO SMOKING' SIGNS AROUND THE AREA.

DISCONNECT TH

E BATTERY BEFORE WORKING ON THE FUEL SYSTEM.

DO NOT CONNEC

T/DISCONNECT ELECTRICAL CIRCUITS

, USE ELECTRICAL EQUIPMENT OR OTHER TOOLS OR

ENGAGE IN WORKING PRACTICES WHICH IN ANY WAY MAY RESULT IN THE PRODUCTION OF SPARKS.

ENS

URE THAT A CO2 FIRE EXTINGUISHER IS CLOSE AT HAND.

ENS

URE THAT DRY SAND IS AVAILABLE TO SOAK UP ANY FUEL SPILLAGE.

EMP

TY FUEL USING SUITABLE FIRE PROOF EQUIPMENT IN

TO AN AUTHORIZED EXPLOSION PROOF CONTAINER.

DO NOT EMP

TY FUEL WHILE WORKING IN A WORKSHOP OR A PIT.

ENS

URE THAT WORKING AREA IS WELL VENTILATED.

ENS

URE THAT ANY WORK ON THE FUEL SYSTEM IS ON

LY CARRIED OUT BY EXPERIENCED AND WELL QUALIFIED

MAINTENANCE PERSONNEL.

ENS

URE THAT FUME EXTRACTION EQUIPMENT IS USED WHERE APPROPRIATE.

FUME EXTRACTION EQUIPMENT MUST BE IN OPERATION WHEN SOLVENTS ARE USED E.G. TRICHLOROETHANE,

WHITE SPIRIT, SBP3, METHYLENE CHLORIDE, PERCHLORETHY LENE. DO NOT SMOKE IN THE VICINITY OF VOLATILE

DEGREASING AGENTS.

General workshop practices:

Disc

onnect the grounded termin

al of the vehicle battery.

D

o not apply heat in an attempt to free seized nuts or fitt

ings; as well as causing damage to protective coatings,

there is a risk of damage from stray heat to electronic equipment and brake lines.

Keep oils and solven

ts away from naked flames and other sour

ces of ignition.

Adhere str

ictly to handling and safety inst

ructions given on containers and labels.

E

nsure that a suitab

le form of fire extinguisher is conveniently located.

Wh

en using electrical tools and equipment, inspect the power

lead for damage and check that it is properly earthed.

D

o not leave tools, equipment, spilt oil etc. around the work area.

Working beneath a vehicle:

Wh

enever possible, use a ramp or

pit in preference to jacking.

Posit

ion chocks at the wheels as we

ll as applying the parking brake.

N

ever rely on a jack alone to support a

vehicle; use axle stands, or blocks care fully placed at the jacking points, to

provide a rigid location.

Ch

eck that any lifting equipment used has adeq

uate capacity and is fully serviceable.

Working on air conditioning systems:

D

o not disconnect any pipes of the refrigeration system

unless you are trained and instructed to do so; a refrigerant

is used which can cause blindness if allowed to come into contact with the eyes.

Health Protection

P

rolonged and repeated contact with mineral oil will result in the removal of natural oils from the skin, leading to dryness,

In

spection

Page 42 of 2490

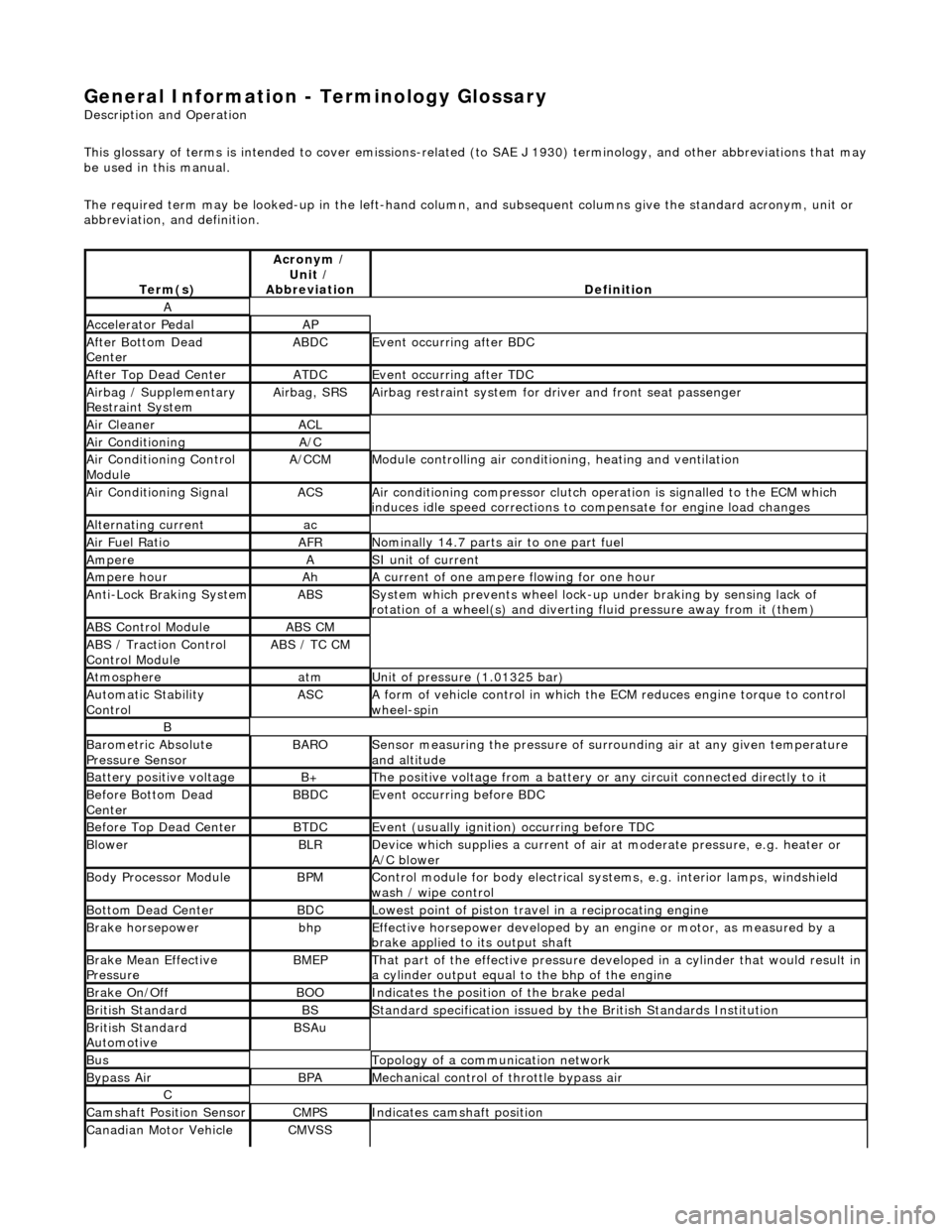

General Information - Terminology Glossary

Description an

d Operation

This glossary of terms is intended to cover emissions-related (to SAE J 1930) term inology, and other abbreviations that may

be used in this manual.

The required term may be looked-up in th e left-hand column, and subsequent columns give the standard acronym, unit or

abbreviation, and definition.

Te rm

(s)

Acr

ony

m /

Unit /

Abbreviation

De fi

nition

A

Accel

e

rator Pedal

AP

Af

ter Botto

m Dead

Center

ABDCEvent occurri ng after

BDC

Af

ter Top Dead CenterATDCEvent occurri ng after

TDC

Ai

rbag /

Supplementary

Restraint System

Airbag, SRSAi rbag restraint system for

dr

iver and front seat passenger

Air Cleane rACL

Air ConditioningA/C

Air Conditioning Con t

rol

Module

A/CCMModule c

ontrolling air conditioning, heating and ventilation

Air Conditioning SignalACSA

i

r conditioning compressor clutch operation is signalled to the ECM which

induces idle speed corrections to co mpensate for engine load changes

Alternating cu

rrent

ac

Ai

r Fuel R

atio

AFRN

omi

nally 14.7 parts air to one part fuel

Ampe

reASI unit of current

Ampere hourAhA current of one ampere

fl

owing for one hour

Anti-Lock Braking SystemABSS

y

stem which prevents wheel lock-up

under braking by sensing lack of

rotation of a wheel(s) and divertin g fluid pressure away from it (them)

ABS Control Mo

dule

ABS CM

ABS /

T

raction Control

Control Module

ABS / T

C CM

Atmosph

e

re

atmU

n

it of pressure (1.01325 bar)

Au

to

matic Stability

Control

ASCA form of vehicle

control

in which the ECM reduces en gine torque to control

wheel-spin

B

Baro me

tric Absolute

Pressure Sensor

BAR OSensor measuring the pressure of surr ou

nding air at any given temperature

and altitude

Bat t

ery positive voltage

B+The posi

ti

ve voltage from a battery or

any circuit connected directly to it

Before Bottom Dead

CenterBBDCEvent occurri ng before BD

C

Before Top Dead

Center

BTD

CEvent (usual ly

ignition) occurring before TDC

Blowe

rBLRDe

vice which supplies a current of air at

moderate pressure, e.g. heater or

A/C blower

Body Processor M

odule

BPMControl modu

le

for body electrical systems, e.g. interior lamps, windshield

wash / wipe control

Bott om D

ead Center

BD

CLowest poin t of piston

travel in a reciprocating engine

Brake hors

epowe

r

bhpEffecti

ve horsepower devel

oped by an

engine or motor, as measured by a

brake applied to its output shaft

Brake Mean Effective

Pres sureBME PThat p

art of the effective

pressure developed in a cyli nder that would result in

a cylinder output equal to the bhp of the engine

Brake On/ O

ff

BOOIn

dic

ates the position of the brake pedal

Br

it

ish Standard

BSStan

dar

d specification issued by the British Standards Institution

Br

it

ish Standard

Automotive

BSAu

BusTopology of a commu n

ication network

Bypass

AirBPAMechanica l

control of throttle bypass air

C

Camshaft Posit

i

on Sensor

CMPSIndi

cat

es camshaft position

Canadian Motor

V

ehicle

CMVSS