body processor module JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 42 of 2490

General Information - Terminology Glossary

Description an

d Operation

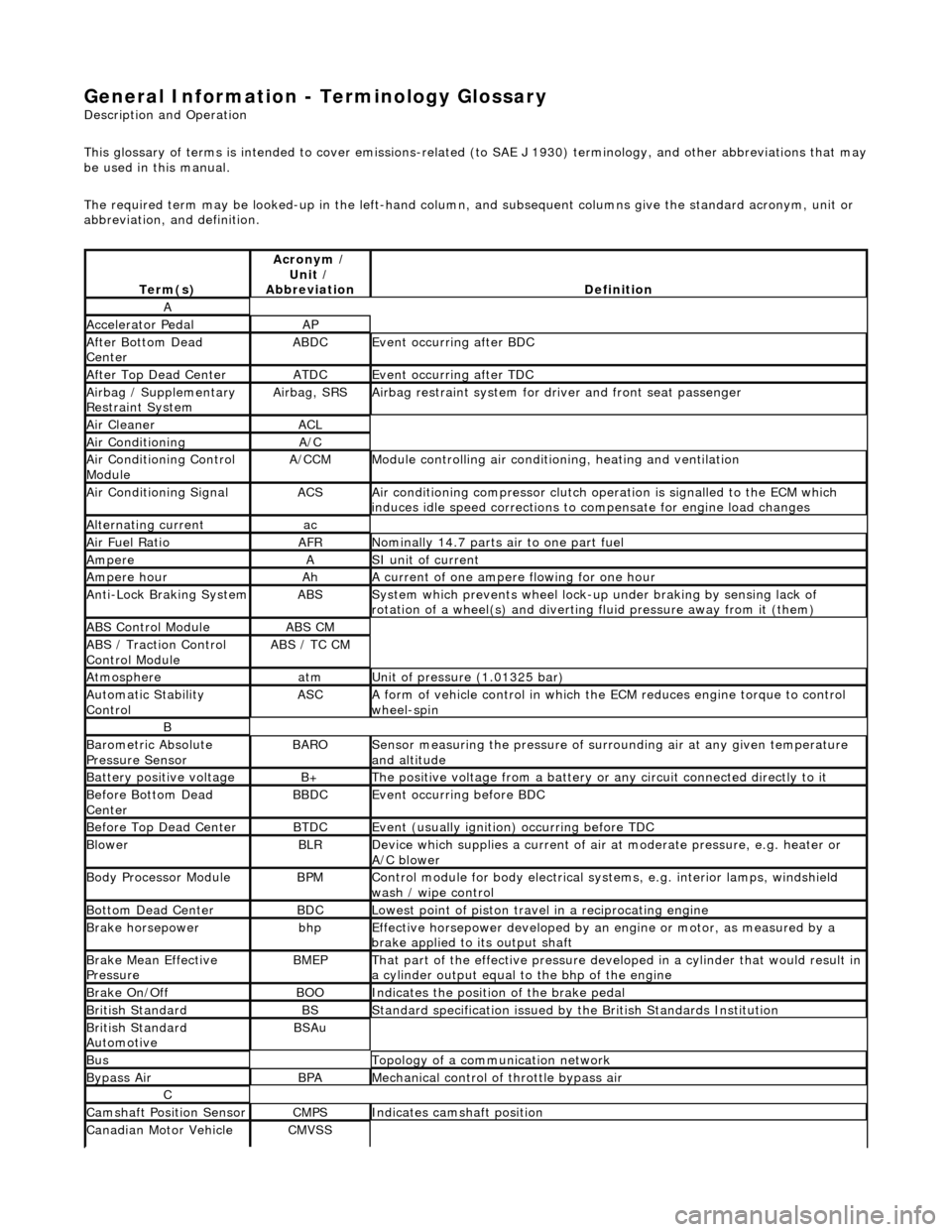

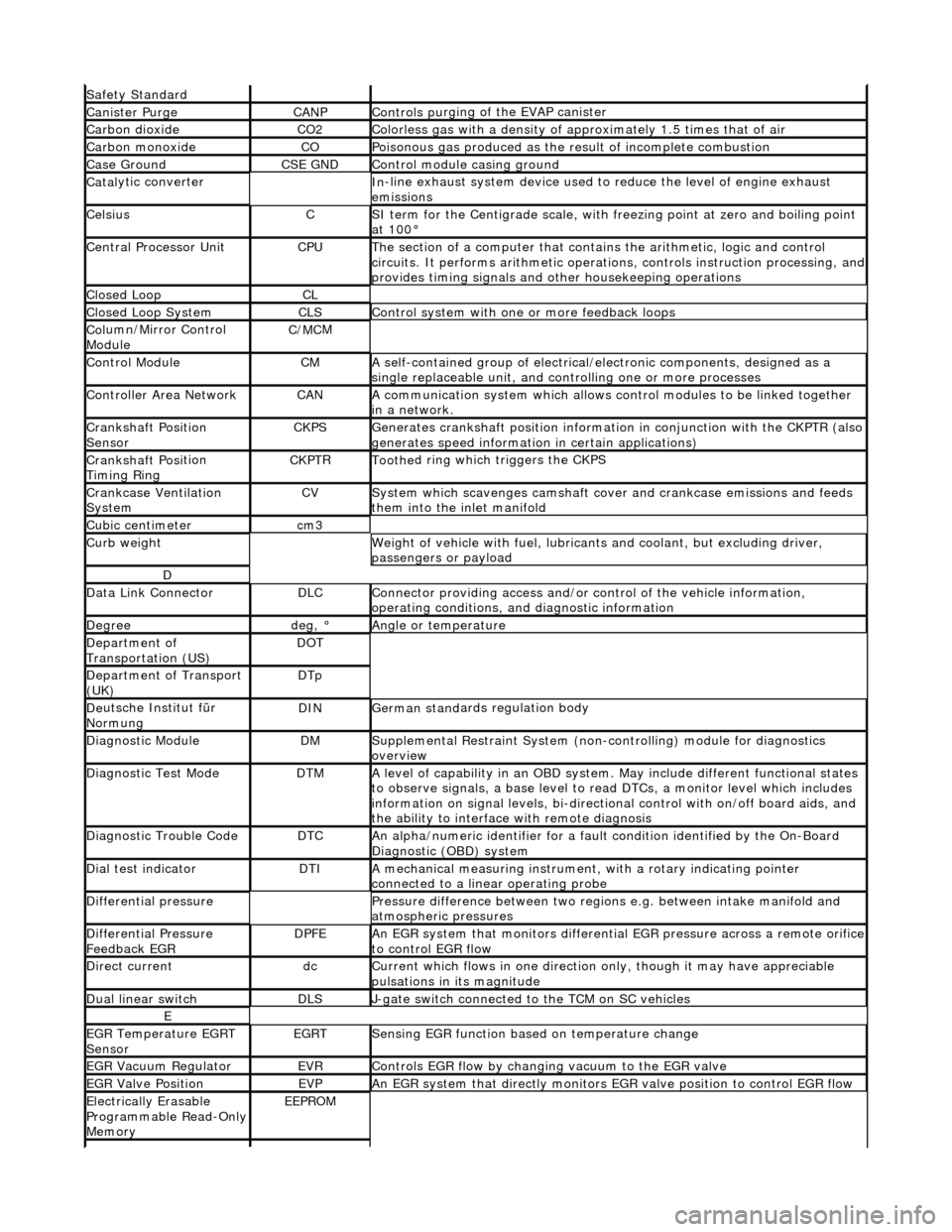

This glossary of terms is intended to cover emissions-related (to SAE J 1930) term inology, and other abbreviations that may

be used in this manual.

The required term may be looked-up in th e left-hand column, and subsequent columns give the standard acronym, unit or

abbreviation, and definition.

Te rm

(s)

Acr

ony

m /

Unit /

Abbreviation

De fi

nition

A

Accel

e

rator Pedal

AP

Af

ter Botto

m Dead

Center

ABDCEvent occurri ng after

BDC

Af

ter Top Dead CenterATDCEvent occurri ng after

TDC

Ai

rbag /

Supplementary

Restraint System

Airbag, SRSAi rbag restraint system for

dr

iver and front seat passenger

Air Cleane rACL

Air ConditioningA/C

Air Conditioning Con t

rol

Module

A/CCMModule c

ontrolling air conditioning, heating and ventilation

Air Conditioning SignalACSA

i

r conditioning compressor clutch operation is signalled to the ECM which

induces idle speed corrections to co mpensate for engine load changes

Alternating cu

rrent

ac

Ai

r Fuel R

atio

AFRN

omi

nally 14.7 parts air to one part fuel

Ampe

reASI unit of current

Ampere hourAhA current of one ampere

fl

owing for one hour

Anti-Lock Braking SystemABSS

y

stem which prevents wheel lock-up

under braking by sensing lack of

rotation of a wheel(s) and divertin g fluid pressure away from it (them)

ABS Control Mo

dule

ABS CM

ABS /

T

raction Control

Control Module

ABS / T

C CM

Atmosph

e

re

atmU

n

it of pressure (1.01325 bar)

Au

to

matic Stability

Control

ASCA form of vehicle

control

in which the ECM reduces en gine torque to control

wheel-spin

B

Baro me

tric Absolute

Pressure Sensor

BAR OSensor measuring the pressure of surr ou

nding air at any given temperature

and altitude

Bat t

ery positive voltage

B+The posi

ti

ve voltage from a battery or

any circuit connected directly to it

Before Bottom Dead

CenterBBDCEvent occurri ng before BD

C

Before Top Dead

Center

BTD

CEvent (usual ly

ignition) occurring before TDC

Blowe

rBLRDe

vice which supplies a current of air at

moderate pressure, e.g. heater or

A/C blower

Body Processor M

odule

BPMControl modu

le

for body electrical systems, e.g. interior lamps, windshield

wash / wipe control

Bott om D

ead Center

BD

CLowest poin t of piston

travel in a reciprocating engine

Brake hors

epowe

r

bhpEffecti

ve horsepower devel

oped by an

engine or motor, as measured by a

brake applied to its output shaft

Brake Mean Effective

Pres sureBME PThat p

art of the effective

pressure developed in a cyli nder that would result in

a cylinder output equal to the bhp of the engine

Brake On/ O

ff

BOOIn

dic

ates the position of the brake pedal

Br

it

ish Standard

BSStan

dar

d specification issued by the British Standards Institution

Br

it

ish Standard

Automotive

BSAu

BusTopology of a commu n

ication network

Bypass

AirBPAMechanica l

control of throttle bypass air

C

Camshaft Posit

i

on Sensor

CMPSIndi

cat

es camshaft position

Canadian Motor

V

ehicle

CMVSS

Page 43 of 2490

Safety Standard

Canister PurgeCANPControls pu

rging of the EVAP canister

Carbon dioxideCO2Colorless gas with

a density of a

pproximately 1.5 ti mes that of air

Carbon mon

oxide

COPoi

sonous gas produced as the re

sult of incomplete combustion

Case G

round

CSE GNDControl modu

le casing ground

Catal

ytic converter

In

-line exhaust system device used to reduce the level of engine exhaust

emissions

Ce

lsius

CSI ter

m for the Centigrade scale, with

freezing point at zero and boiling point

at 100°

Central

Processor Unit

CPUTh

e section of a computer that contai

ns the arithmetic, logic and control

circuits. It performs arithm etic operations, controls instruction processing, and

provides timing signals and other housekeeping operations

Cl

osed Loop

CL

Cl

osed Loop System

CLSControl

system with one

or more feedback loops

Col

umn/Mirror Control

Module

C/MC

M

Control ModuleCMA

self-contained group of electrical/electronic components, designed as a

single replaceable un it, and controlling one or more processes

Controll

er Area Network

CANA

communication system which allows control modules to be linked together

in a network.

Crankshaft Posi

tion

Sensor

CKPSGenerates crankshaft positi on informa

tion in conjunct

ion with the CKPTR (also

generates speed information in certain applications)

Crankshaft Posi

tion

Timing Ring

CKPT

R

Toothe

d ring which

triggers the CKPS

Crankcase Ventila

tion

System

CVSys

tem which scavenges camshaft cover and crankcase emissions and feeds

them into the inlet manifold

Cubic ce nt

imeter

cm

3

Curb weightWe

ight of vehicle with fuel, lubrican

ts and coolant, but excluding driver,

passengers or payload

D

Dat

a Link Connector

DLCConne

ctor providing access and/or control of the vehicle information,

operating conditions, and diagnostic information

De

gree

deg, °Angle or tempe

rature

D

epartment of

Transportation (US)

DO

T

D

epartment of Transport

(UK)

DTp

De

utsche In

stitut für

Normung

DINGerman stand

ards regulation body

Di

agnostic Module

DMSuppl

emental Restraint System (non-c

ontrolling) module for diagnostics

overview

Di

agnostic Test Mode

DTMA le

vel of capability in an OBD system.

May include different functional states

to observe signals, a base level to re ad DTCs, a monitor level which includes

information on signal levels, bi-directional control with on /off board aids, and

the ability to interface with remote diagnosis

Diagnostic Trouble CodeDTCAn al

pha/numeric identifier for a fault

condition identified by the On-Board

Diagnostic (OBD) system

D

ial test indicator

DTIA mechan

ical measuring

instrument, with a rotary indicating pointer

connected to a linear operating probe

D

ifferential pressure

Pressure di

fference betwee

n two regions e.g. between intake manifold and

atmospheric pressures

D

ifferential Pressure

Feedback EGR

DP

FE

An

EGR system that monito

rs differential EGR pressure across a remote orifice

to control EGR flow

D

irect current

dcCurrent which f

lows in on

e direction only, though it may have appreciable

pulsations in its magnitude

Du

al linear switch

DLSJ

-gate switch connected to the TCM on SC vehicles

E

EGR

Temperature EGRT

Sensor

EGRTSens

ing EGR function based on temperature change

EGR Vacu

um Regulator

EVRControls EGR

flow by changi

ng vacuum to the EGR valve

EGR Valve

Position

EVPAn EGR

system that direct

ly monitors EGR valve position to control EGR flow

Electrically E

rasable

Programmable Read-Only

Memory

EEP

ROM

Page 528 of 2490

Speed an

d load

Coo

l

ant temperature

Ti

me el

apsed from start up

Cl

osed l

oop fuelling

Determination of the vapour concentration is made by stepped opening of the EVAP valve and subsequent monitoring of the

fuelling correction. This function is performed prior to purging, so that at the onse t of purging the EVAP valve can be set to

the optimum position. Should the ECM be unable to determine the concentration before purging, a default value is

employed, which is then modified whilst purging is in progress.

When the purging process is operational th e ECM modifies the basic fuelling calculation to maintain the correct air / fuel

ratio.

Purging is inhibited during fuel cut-off and stability / traction control intervention.

Coolant Temperature Sen

sor

Th

e

sensor outputs a voltage to the ECM which decreases as temperature increases.

Cooling Fans

In response to engi

ne coolant temperat

u

re and climate control system demand, the ECM will energize the cooling fans.

Climate Control Compressor

The E

C

M will allow the compressor clutch to be engaged if th

e engine temperature and load demand are normal. Should the

driver require maximum engine powe r or the coolant temperature be high, the request will be denied.

Cranking Signal

The ECM reacts to a signal fr

om th

e Body Processor Module (BPM) when the starter motor relay is energi

zed. This signal is

used to trigger starting, fu el and ignition strategies.

Engine Speed and Cranksh

aft Position

Engine

speed and cran

k position are moni

tored by a sensor which is mounted on the cylinder block (flywheel housing)

behind the crankshaft drive plat e. It indicates rotational speed to the ECM in the form of 12 pulses per crank revolution.

Engine speed is used for synchronization of fuel an d ignition systems, as well as other functions.

Camshaft Position

The ca

mshaft position sensor is mounted at

the rear of Bank 2 cylinder head on the inlet side and provides one signal every

720 degrees of crankshaft rotation. The signal, in conjunction with the signal from the crankshaft position sensor, indicates

to the ECM that the piston of cylinder 1A is approaching TDC on the compression stroke.

Variable Valve

Timing (Where Fitted)

By energi

si

ng a solenoid to allow the pass

age of pressurized oil on each of the inle t camshaft drives, the ECM can vary by a

single stepped amount, the relati ve timing of the inlet valves.

Ign

ition

Ignit

i

on spark is produced by

individual on-plug coil units.

There are two ignition amplifiers; module #1 drives coils 1A, 2B, 3B and 4A, whilst module #2 drives coils 1B, 2A, 3A and

4B. The ECM controls the amplifiers.

Page 1064 of 2490

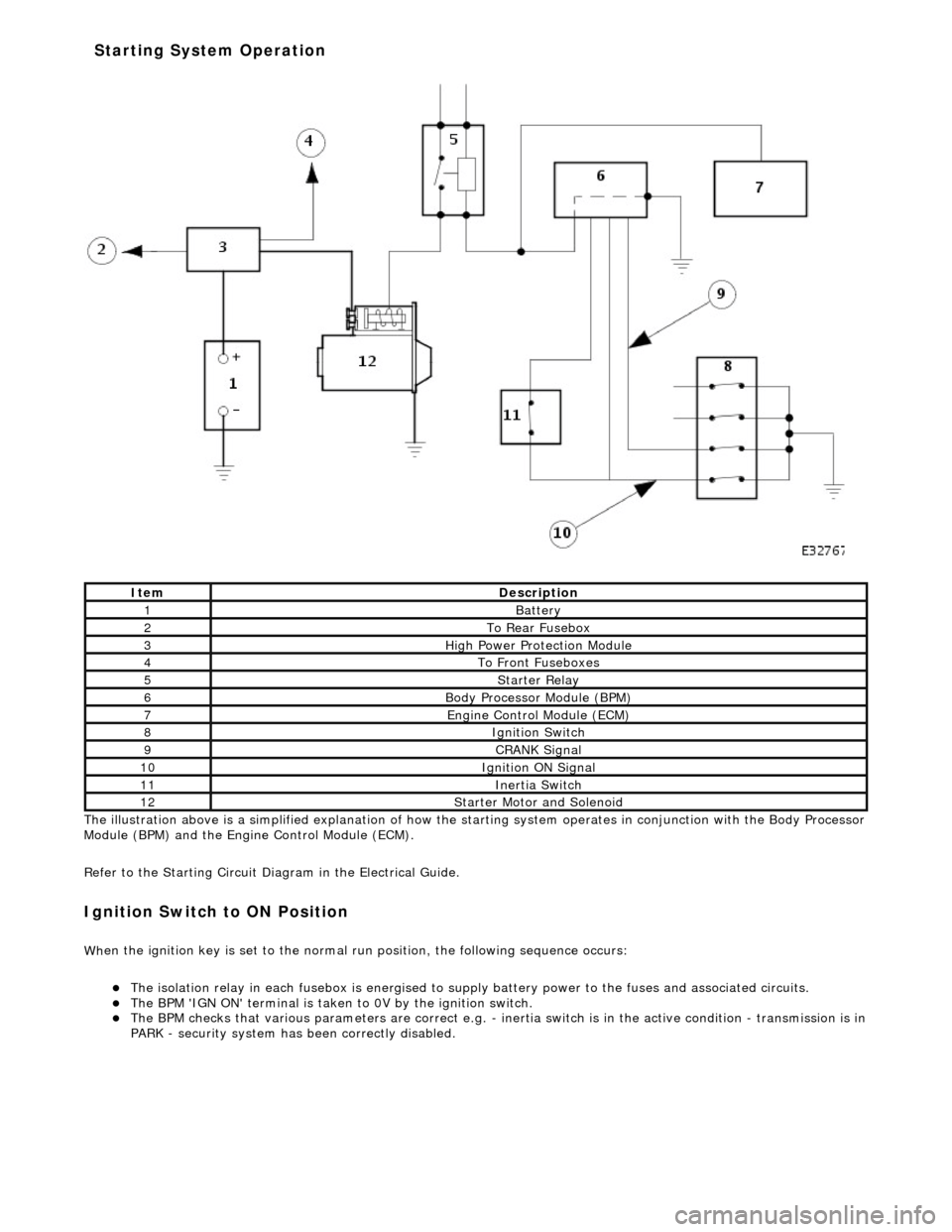

The il

lustration above is a simplified expl

anation of how the starting system operates in conjunction with the Body Processor

Module (BPM) and the Engine Control Module (ECM).

Refer to the Starting Circuit Diagram in the Electrical Guide.

I g

nition Switch to ON Position

W

h

en the ignition key is set to the normal run position, the following sequence occurs:

The

is

olation relay in each fusebox is

energised to supply battery power to the fuses and associated circuits.

The BPM 'IGN

ON' terminal

is taken to 0V by the ignition switch.

The BPM

checks that various parameters are correct e.g. -

inertia switch is in the active condition - transmission is in

PARK - security system has been correctly disabled.

It e

m

De

scr

iption

1Batt

ery

2To Re ar

Fusebox

3Hi

gh Power Pr

otection Module

4To Front

Fu

seboxes

5Starter Re

lay

6Body Processor M

odule (BPM)

7Engine

C

ontrol Module (ECM)

8Ignition Switch

9CRANK Signal

10Ignition ON Signal

11Inertia Switch

12St

arte

r Motor and Solenoid

Starting System Operation

Page 1066 of 2490

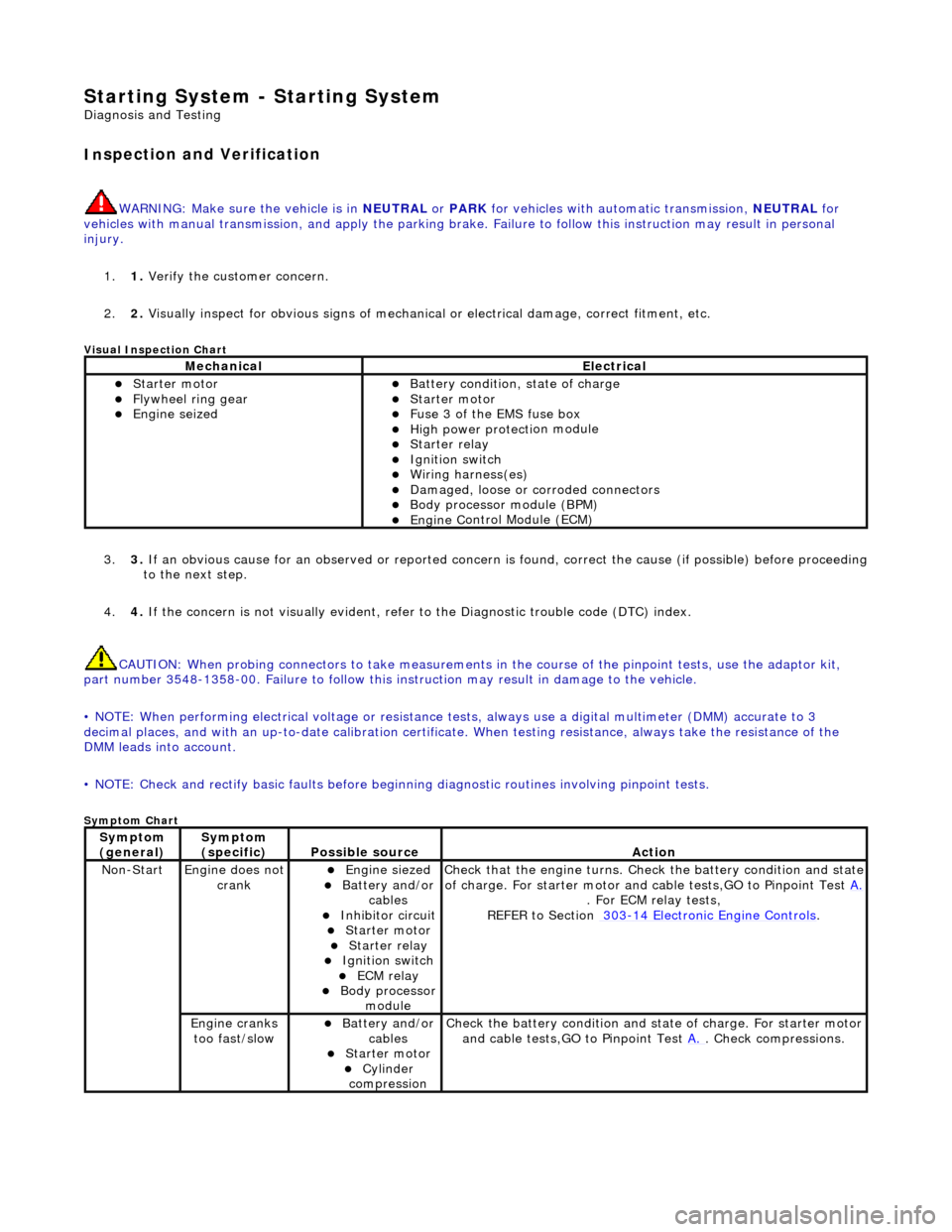

Starting System - Starting System

Diagn

osis and Testing

I

n

spection and Verification

W

A

RNING: Make sure

the vehicle is in NEUTRAL or PARK for vehicles with au tomatic transmission, NEUTRAL for

vehicles with manual transmissi on, and apply the parking brake. Failure to foll ow this instruction may result in personal

injury.

1. 1. Verify the customer concern.

2. 2. Visually inspect for obvious signs of mechanical or electrical damage, correct fitment, etc.

Vi

sual Inspection Chart

3.

3. If an obvi

ous cause for an observed or

reported concern is found, correct th e cause (if possible) before proceeding

to the next step.

4. 4. If the concern is not visually evident, refer to the Diagnostic trouble code (DTC) index.

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit,

part number 3548-1358-00. Failure to follow this in struction may result in damage to the vehicle.

• NOTE: When performing electrical voltag e or resistance tests, always use a digital multimeter (DMM) accurate to 3

decimal places, and with an up-t o-date calibration certificate. When testing resistance, always take the resistance of the

DMM leads into account.

• NOTE: Check and rectify basic faults before beginning diagnostic ro utines involving pinpoint tests.

Sym

ptom Chart

MechanicalElectrical

Starte

r motor

Flywheel

ring gear

Engine

s

eized

Batter

y condition, state of charge

Starte

r motor

F

u

se 3 of the EMS fuse box

High

power protec ti

on module

Starter relay Ignition switc

h

W

i

ring harness(es)

Damaged, loose or corroded connector

s

Body processor module (B

PM)

Engine

C

ontrol Module (ECM)

Sy

m

ptom

(

gene r

al)

Sy

m

ptom

(specific)

Possib l

e source

Acti

o

n

No

n

-Start

Engine does

not

crankEngine s

iezed

Batt

ery and

/or

cables

Inhibitor circuit St arte

r motor

Starter relay Ignition switc

h

ECM relay Body processor

modu le

Check that

the engine turns. Check the battery condition and state

of charge. For starter motor and ca ble tests,GO to Pinpoint Test A.

. For ECM relay

tests,

REFER to Section 303

-14

Electronic Engine Controls

.

Engine

c

ranks

too fast/slow

Batt ery and

/or

cables

St arte

r motor

Cy

linder

com

pression

Check the battery con

dition

and st

ate of charge. For starter motor

and cable tests,GO to Pinpoint Test A.

. Chec

k compressions.

Page 1465 of 2490

The Drive-to-fourth switch:

Detects when the gear selector lever is moved from Drive to Fourth. Is hard-wired to the transmission control module.

The Neutral position switch:

Is hard-wired to the body processor module. Detects when the gear selector lever is moved to the Neutral position.

The Park position switch:

Is hard-wired to the body processor module. Detects when the gear selector leve r is moved to the Park position.

The gear selector module:

Provides illumination of the gear sele ctor surround, which is dimmable via a CA N signal from the instrument cluster. Provides red illumination, on the gear selector surround, of the gear selected, by CAN signals from the instrument

cluster.

Illuminates the security system Active LED on the gear se lector surround, in response to an input from the body

processor module.

Is connected to the fascia harness via a 12-way connector. Refer to Connec tor Pins Identification, 307-01A.

The gear selector interlock solenoid:

Prevents the gear selector lever from be ing moved from the Park position, unless th e ignition switch is in position II,

and the brake pedal is depressed.

Is controlled by an input from the body processor module.

The seven gear selector positions are:

P : The transmission is mechanically locked (starting available). R : Reverse gear. N : No power to the rear wh eels (starting available). D : All 5 forward gears available. 4 : Upshift to 4th gear only. 3 : Upshift to 3rd gear only. 2 : Upshift to 2nd gear only.

Performance Mode Pushbutton

The performance mode pushbutton:

Is mounted on the gear selector surround. Selects Normal or Sport mode when pressed by the driver. Is illuminated when Sport mode is selected.

Page 1855 of 2490

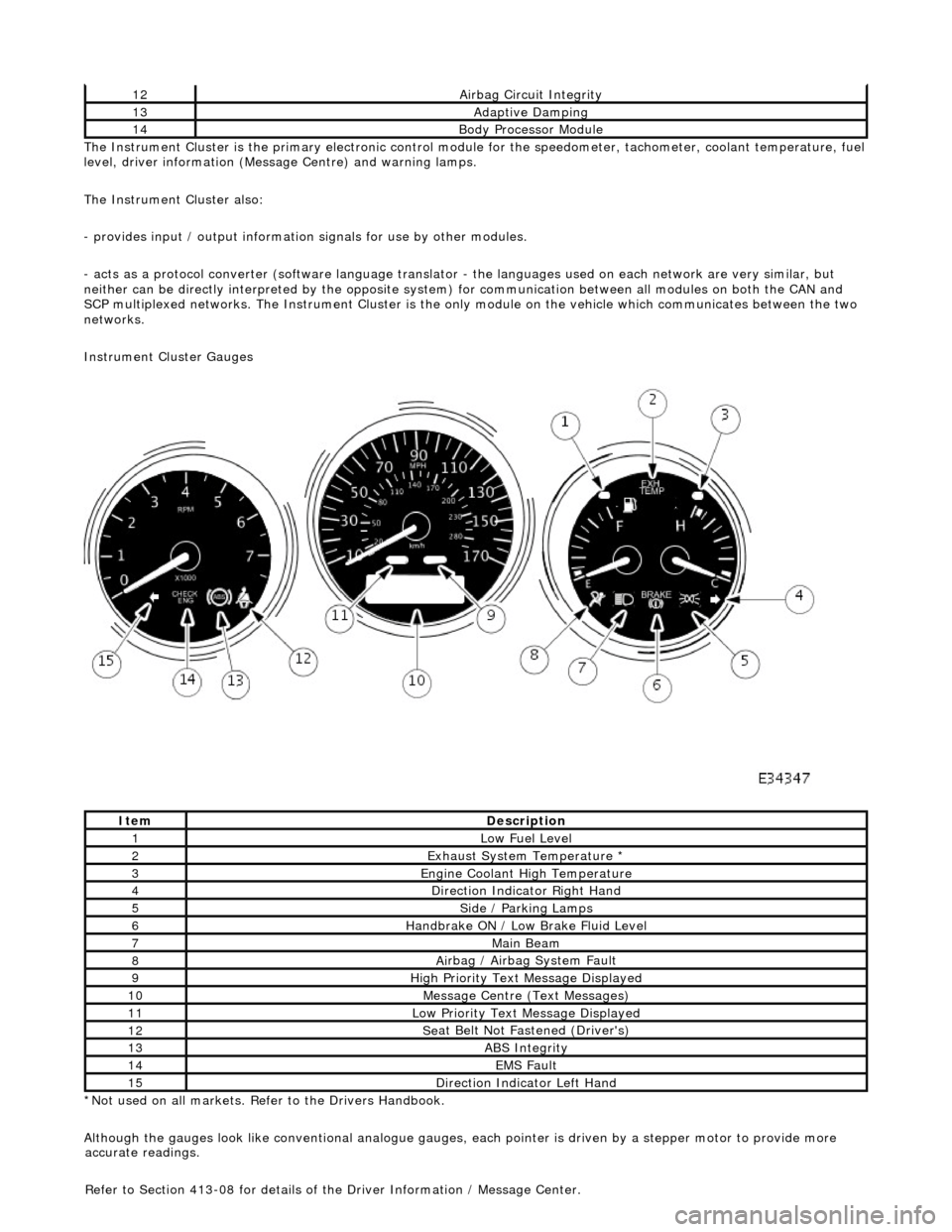

The In

strument Cluster is the primary electronic control module for the speedomete

r, tachometer, coolant temperature, fuel

level, driver information (Message Centre) and warning lamps.

The Instrument Cluster also:

- provides input / output informatio n signals for use by other modules.

- acts as a protocol converter (software language translator - the languages used on each network are very similar, but

neither can be directly interp reted by the opposite system) for communication between all modules on both the CAN and

SCP multiplexed networks. The Instrument Cluster is the only module on the vehicle which communicates between the two

networks.

Instrument Cluster Gauges

*Not used on all markets. Refer to the Drivers Handbook.

Although the gauges look like conventional analogue gauges, each pointer is driven by a stepper motor to provide more

12Ai

rbag Circuit Integrity

13Adaptive Damping

14Body Processor

Module

It

em

De

scription

1Low Fu

el Level

2Exhaus

t System Temperature *

3E

ngine Coolant High Temperature

4Di

rection Indicator Right Hand

5Side

/ Parking Lamps

6Handbrake ON / Low

Bra

ke Fluid Level

7Main

Beam

8Ai

rbag / Airbag System Fault

9Hi

gh Priority Text

Message Displayed

10M

essage Centre (Text Messages)

11Low Pri

ority Text Message Displayed

12Se

at Belt Not Fa

stened (Driver's)

13ABS Integrity

14EMS Fault

15D

irection Indicator Left Hand

accu

rate readings.

Refer to Section 413-08 for details of the Driver Information / Message Center.

Page 1859 of 2490

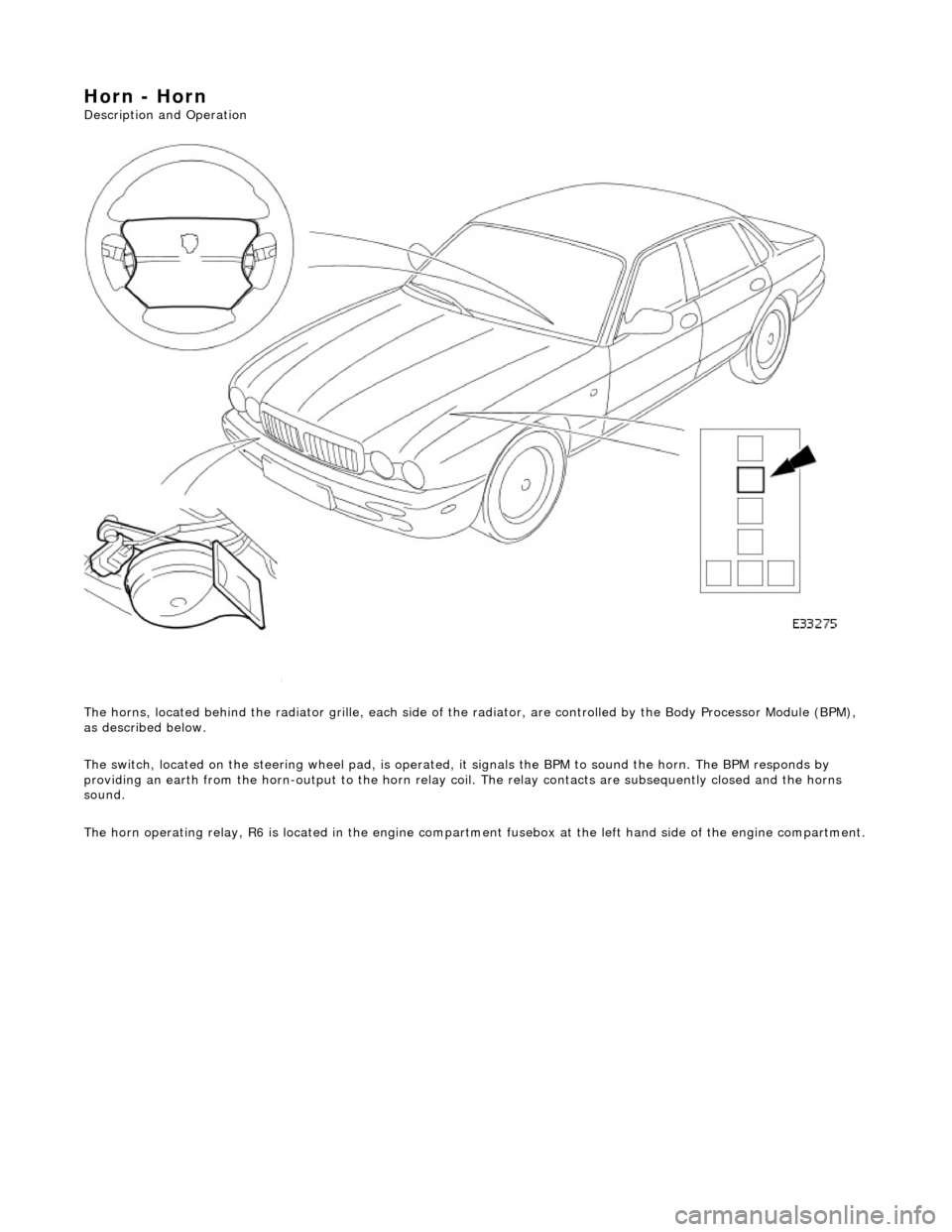

Horn - Horn

Description and Operation

The horns, located behind the radiator gril le, each side of the radiator, are controlled by the Body Processor Module (BPM),

as described below.

The switch, located on the steering wheel pad, is operated, it signals the BPM to sound the horn. The BPM responds by

providing an earth from the horn-output to the horn relay coil. The relay contacts are subsequently closed and the horns

sound.

The horn operating relay, R6 is located in the engine compartm ent fusebox at the left hand side of the engine compartment.

Page 1919 of 2490

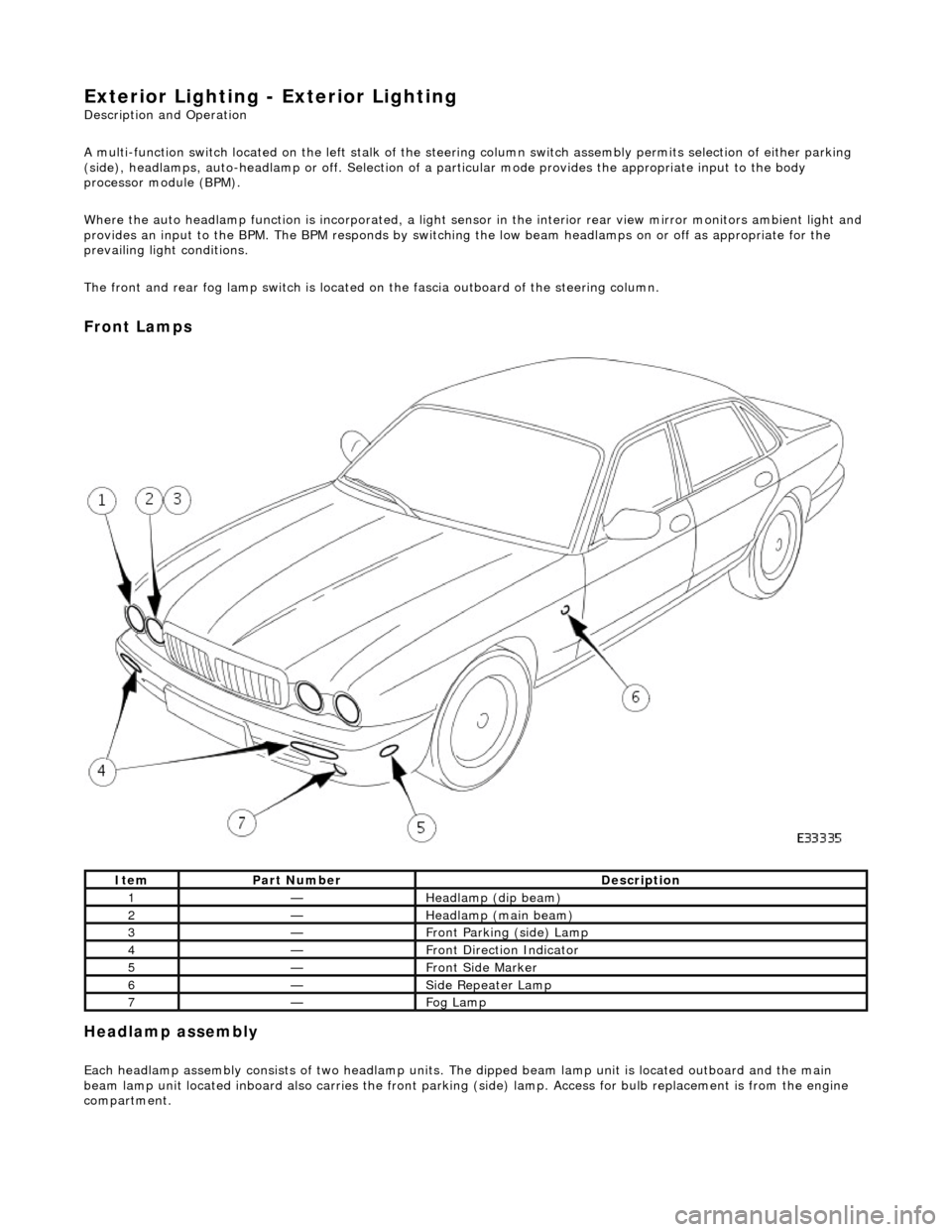

Exterior Lighting - Exterior Lighting

Description and Operation

A multi-function switch located on the left stalk of the steering column switch assembly permits selection of either parking

(side), headlamps, auto-headlamp or off. Selection of a particular mode provides the appropriate input to the body

processor module (BPM).

Where the auto headlamp function is incorporated, a light sensor in the interior rear view mirror monitors ambient light and

provides an input to the BPM. The BPM responds by switching the low beam headlamps on or off as appropriate for the

prevailing light conditions.

The front and rear fog lamp switch is located on the fascia outboard of the steering column.

Front Lamps

Headlamp assembly

Each headlamp assembly consists of tw o headlamp units. The dipped beam lamp unit is located outboard and the main

beam lamp unit located inboard also carries the front parking (side) lamp. Access for bulb replacement is from the engine

compartment.

ItemPart NumberDescription

1—Headlamp (dip beam)

2—Headlamp (main beam)

3—Front Parking (side) Lamp

4—Front Direction Indicator

5—Front Side Marker

6—Side Repeater Lamp

7—Fog Lamp

Page 1922 of 2490

Exterior Lighting - Exterior Lighting

Diagnosis and Testing

Tests Using the Portable Diagnostic Unit

Refer to PDU User Guide

The complexity of the electronics involved with the various Electronic Control Modules and the multiplexed communication

networks, preclude the use of workshop general electrical test equipment. Therefore, reference should be made to the PDU

User Guide for detailed inst ructions on testing the exterior lamps and circuits.

The PDU systematically tests and analyses the lamp assemblies, the bulbs and the electrical connections to them. It should

be noted that the lamps are not wired direct ly to the switches. Actuation of a switch provides an input signal to the Body

Processor which interpre ts the signal as a request to switch output from the Bo dy Processor, either directly or indirectly to a

specific lamp.

Where a fault involving a lamp is indicated by the PDU, befo re replacing the component, some basic diagnostic methods

may be necessary to confirm that connections are good and that wiring is not damaged.