end float JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 5 of 2490

Rear Drive Axle and Diffe rential

General Procedures

Differential Output Shaft End Float Check (51.10.24)

In‐Vehicle Repair

Axle Shaft (47.10.01)

Differential Output Shaft Bearing (51.10.22)

Drive Pinion Flange and Drive Pinion Seal (51.20.01)

Removal and Installation

Axle Assembly (51.25.13)

206: Brake System

206‐00: Brake System ‐ Gen

eral Information

Specification

Description and Operation

Brake System

Diagnosis and Testing

Brake System

General Procedures

Brake System Bleeding (70.25.03) ‐ Vehicles With: Standard Brakes

Brake System Bleeding (70.25.03) ‐ Vehicles With: High Performance Brakes

Front Brake Disc Runout Check ‐ Vehicles With: Standard Brakes

Front Brake Disc Runout Chec

k ‐ Vehicles With: High Performance Brakes

Rear Brake Disc Runout Check (70.12.36) ‐ Vehicles With: Standard Brakes

Rear Brake Disc Runout Check (70.12.36) ‐ Vehicles With: High Performance

Brakes

206‐03: Front Disc Brake

Specification

Description and Operation

Front Disc Brake

Removal and Installation

Brake Caliper (70.55.02) ‐ Vehicles With: Standard Brakes

Brake Caliper (70.55.02) ‐ Vehicles With: High Perfo

rmance Brakes

Brake Disc (70.10.10) ‐ Vehicles With: Standard Brakes

Brake Disc (70.10.10) ‐ Vehicles With: High Performance Brakes

Brake Pads (70.40.02) ‐ Vehicles With: Standard Brakes

Page 66 of 2490

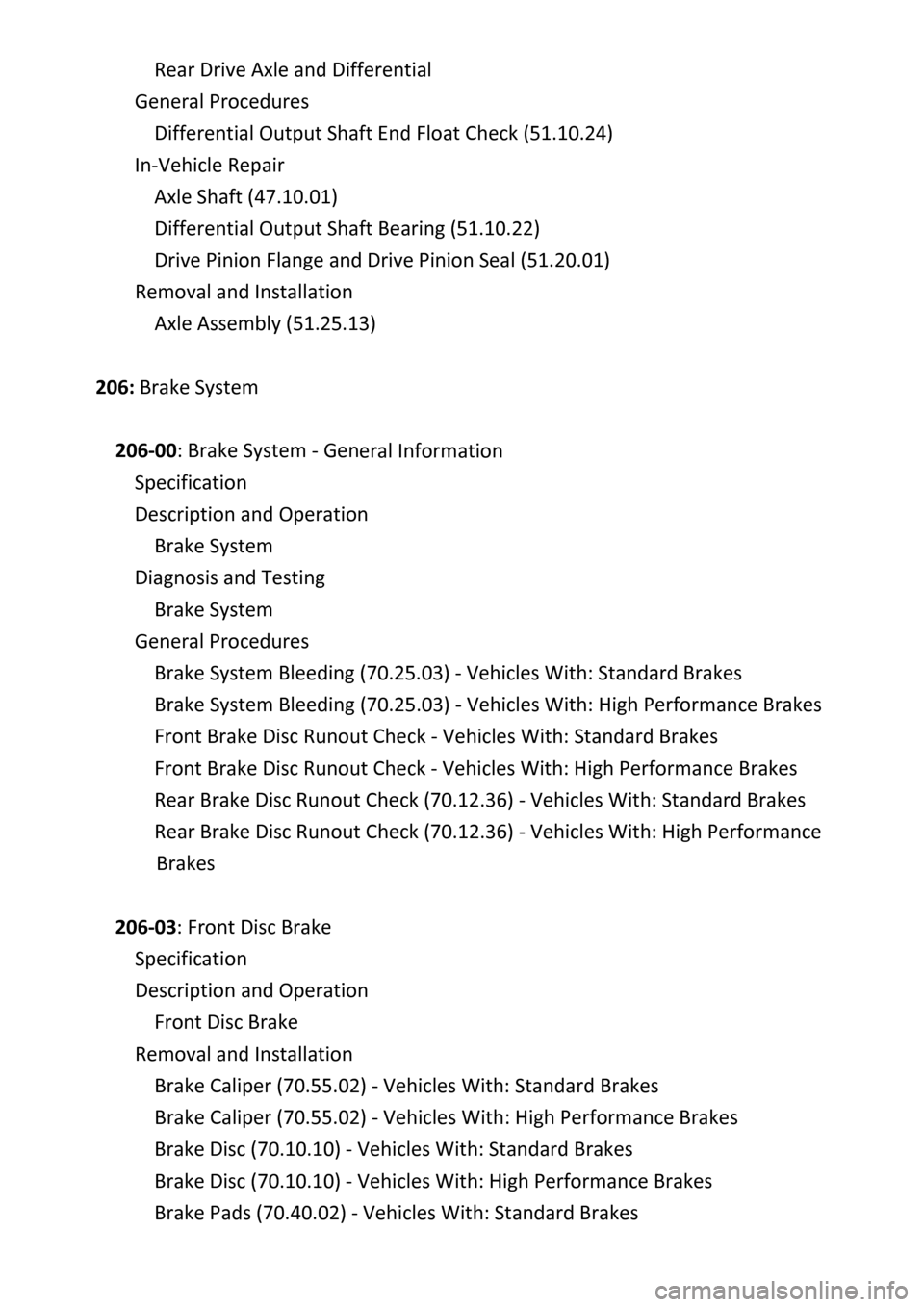

Suspension System - General Information - Wheel Bearing Inspection

Gene

ral Procedures

1.

Dur

ing use, a small amount of surplus grease may appear

around the bearing seal, this does not indicate a failed bearing

or seal. The grease should not be removed as this will act as an

additional barrier to the ingress of water or foreign matter.

Excessive end float or bearing ru mble will indicate a failed

bearing; for maximum permissibl e end float see specification

section. Take care not to confuse suspension ball joint or upper

or lower fulcrum bu sh movement for bearing end float.

If the hub is removed for any reason, a new bearing assembly

must be installed. Never at tempt to re-use a bearing.

Page 230 of 2490

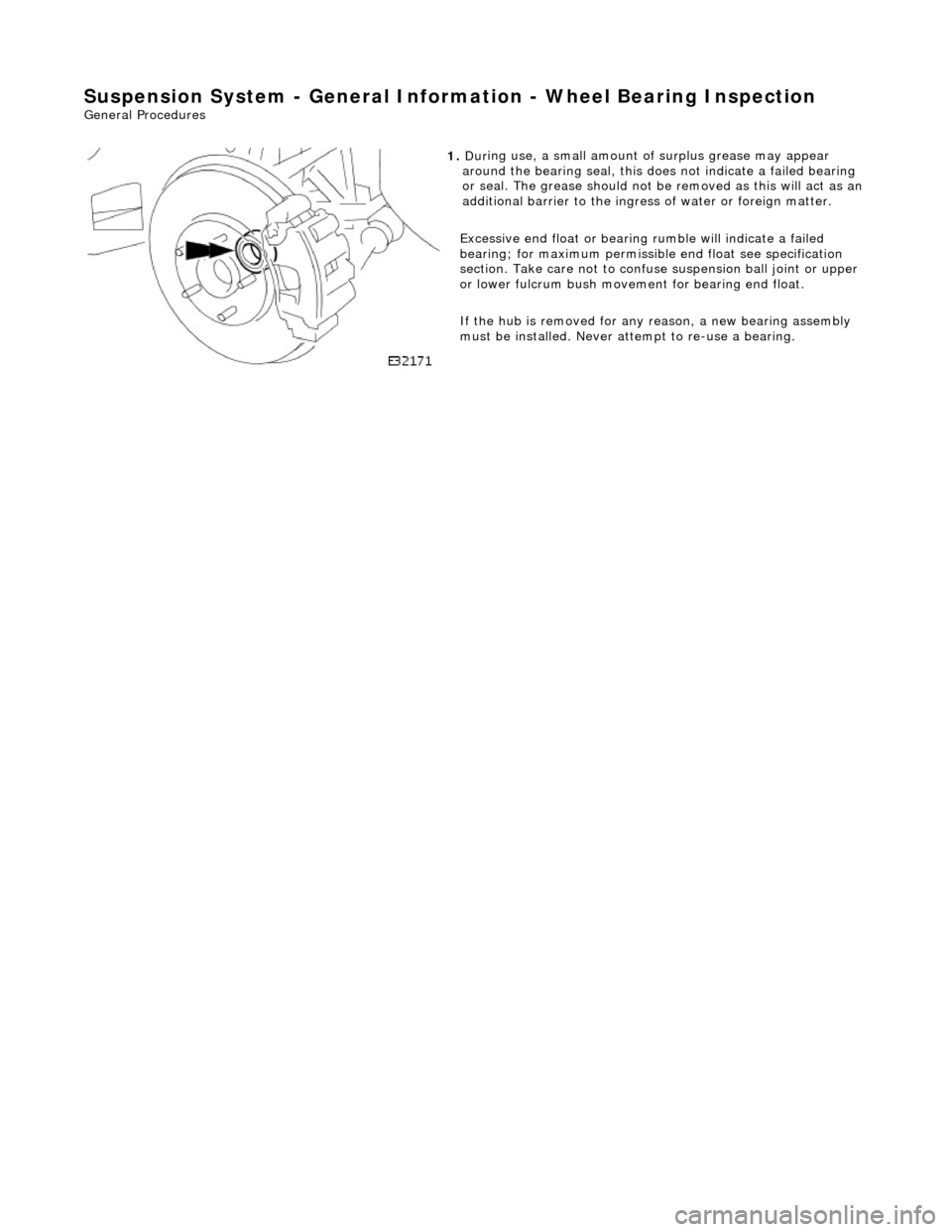

1.

Position hub carrier on block of wood.

2. Position ABS-rotor sensor to hub.

Ali g

n assembly to press-ram, and operate press to install

ABS-sensor rotor to hub.

10 . CAUTI

ON: Do not use excessive force when levering

hub.

Measure hub end-float.

Secure hub carri er in vi

ce.

Inst

al

l special tool JD15 to hub.

1. Install dial gauge JD 13A on hub carrier.

2. Using two levers, measure and record hub end-float.

R e

move special tools from hub carrier.

11

. Using h

ydraulic pr

ess, remove hub and outer bearing

assembly from carrier.

1. Position large section of special tool JD132 on press bed, with recess in tool upper most.

2. Position hub carrier on tool, ensuring parking brake cable housing locates in tool recess.

3. Position small section of special tool JD132 on hub.

Alig

n assembly to press-ram, and operate press to remove

hub from hub carrier.

12 . R

emove ABS rotor and inner bearing from hub carrier.

R

e

move ABS rotor.

R

e

move inner bearing.

13. Remove outer bearing assembly from hub.

Remove bearing shim.

Page 231 of 2490

Re

move bearin

g spacer.

Remove ou

ter bearing.

14. Pack new inner and outer bear ings with Shell Retinax 'A'

grease.

15

.

Install outer bearing and usin g special tool 205-234, fully

seat seal in hub carrier.

16

.

Using a press, install hub in carrier/bearing assembly.

17

.

Install inner bearing assembly.

1. Install bearing spacer.

2. Install bearing shim.

3. Install inner bearing.

18. Determine hub end float.

Measure an

d record end-float as a datum.

Calculating from datum, select

a sh

im that will achieve a

0.076 mm end-float.

19. Install new bearing shim.

Page 287 of 2490

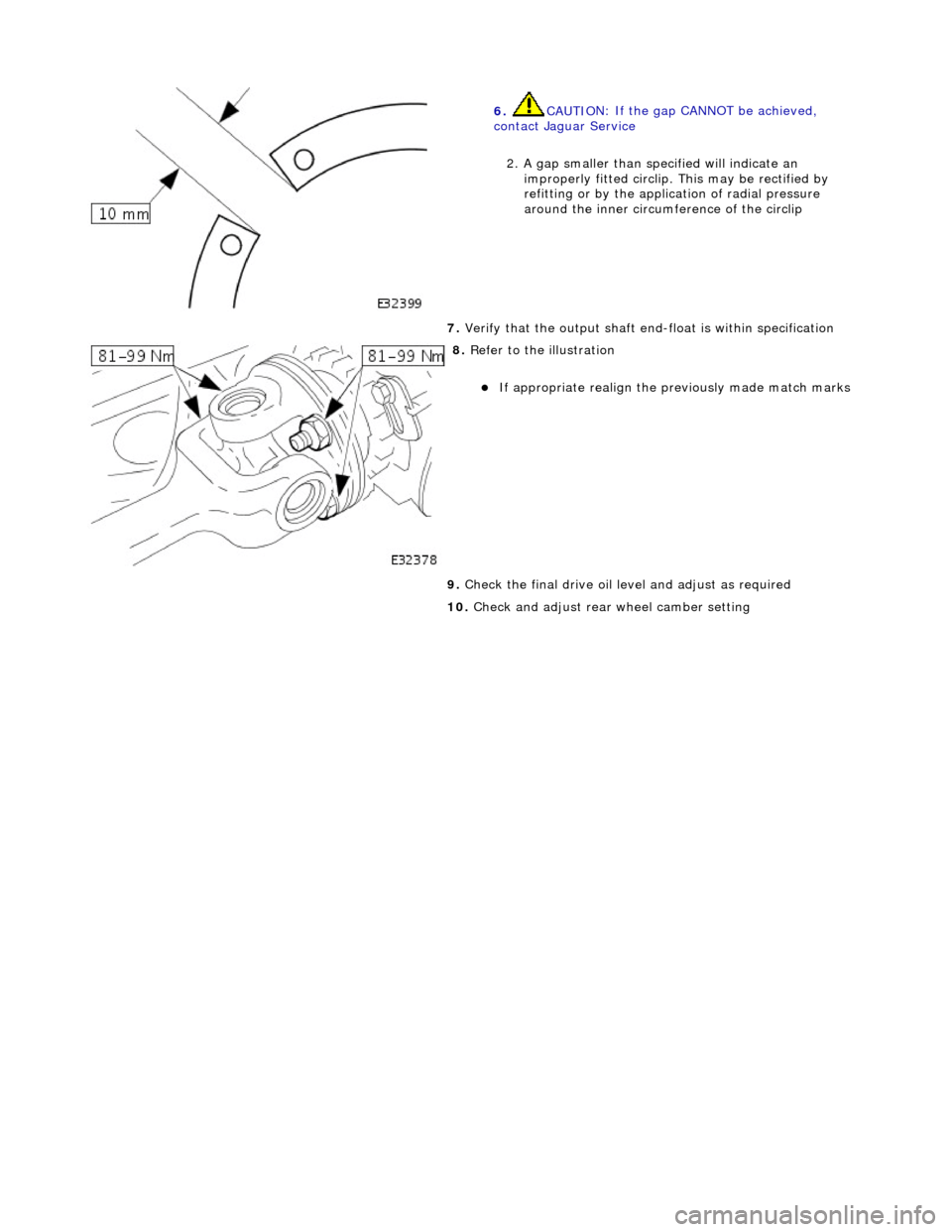

R

ear Drive Axle/Differential - Differ

ential Output Shaft End Float Check

Gen

eral Procedures

1.

Di

sconnect the battery ground lead

2. Raise the vehicle for access

3. Mo

unt a dial test indicator (DTI

) to the differential housing with

the probe resting on the axle sh aft flange (the DTI probe must

be parallel to the output shaf t center line and NOT the axle

shaft)

4. Chec

k the end float

Pus

h the wheel / shaft assembly INWARDS

Zero the DTI

P

ull the wheel / shaft assembly OUTWARDS

N

ote the reading

5. Check the specification

0 t

o 0,15 mm GOOD

0,

15 mm + NOT GOOD; Renew the output shaft bearing

Page 294 of 2490

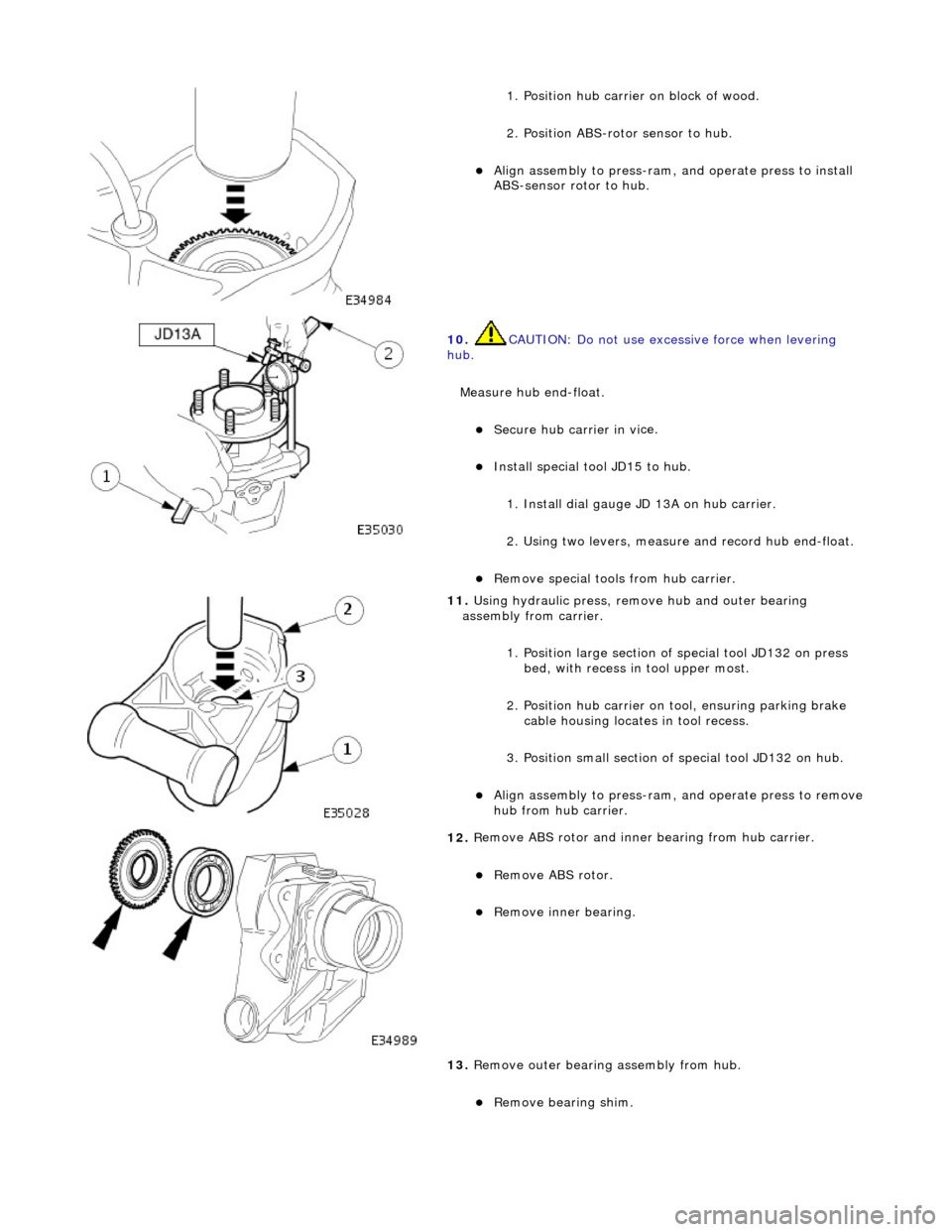

6.

CAUTIO

N: If the gap CANNOT be achieved,

contact Jaguar Service

2. A gap smaller than specified will indicate an improperly fitted circlip. This may be rectified by

refitting or by the application of radial pressure

around the inner circum ference of the circlip

7. Verify t

hat the output shaft end-float is within specification

8. Re

fer to the illustration

If

app

ropriate realign the pr

eviously made match marks

9. Check the final drive oil level and adjust as required

10. Check and adjust rear wheel camber setting

Page 328 of 2490

R

emove and tie caliper aside.

5. Make sure that wheel bearing end-float is within specification. Refer to specification section <<204-01>>.

6.

Measure brake disc run-out.

1. Install brake disc to hub and secure with all wheel nuts, tighten wheel nuts to 20 Nm in a diagonal sequence.

2. Position the gauge so that the pointer contacts the disc, between the disc's outer drill holes and the disc's outer edge.

Slowly rotate the disc one revolution, the disc run-out must not exceed the specification. Refer to

Specification Section <<206-03>>.

7. If the brake disc run-out exceeds specification, reposition the brake disc on the hub and repeat the above

procedure. Continue repositioning the brake disc until the run-out is within specification.

8. If the brake disc run-out still exceeds specification, check the hub face run-out.

9. Remove brake disc.

Page 332 of 2490

Me

asurement of the brake disc run-out, must be carried-out with the disc and hub parking-brake

adjuster-holes aligned.

Make sure that wheel bearing end-float is correct. Refer to specification section <<204-02>>.

5.

Measure brake disc run-out.

Install brake disc to hub and secure with all wheel nuts, tighten wheel nuts to 20 Nm in a diagonal

sequence.

Position the gauge so that the pointer contacts the disc 10 mm from its outer edge.

Slowly rotate the disc one revolution, the disc run-out must not exceed the specification. Refer to

specifications in section <<206-04>>.

6. If the brake disc run-out exceeds specification, check the hub face run-out.

7. Remove brake discs. Refer to procedure 70.10.13.

8.

Measure hub face run-out.

Page 336 of 2490

5.

Make sure that wheel bearing end-float is within specification. Refer to specification section

<<204-02>>.

6.

NOTE:

Measurement of the brake disc run-out, must be carried-out with the disc and hub access holes aligned.

7.

Measure brake disc run-out.

1. Install brake disc to hub and secure with all wheel nuts, tighten wheel nuts to 20 Nm in a diagonal sequence.

2. Position the gauge so that the pointer contacts the disc, between the disc's outer drill holes and the disc's outer edge.

Slowly rotate the disc one revolution, the disc run-out must not exceed the specification. Refer to

specifications in section <<206-04>>.

8. If the brake disc run-out exceeds specification, check the hub face run-out.

Page 1157 of 2490

The OR

VR system features are :

N

arrow fuel filler pipe and tank check valve.

Fue

l level vent valve (FLVV) fitted to the evaporative flan

ge and consisting of a two stage shut-off valve with rollover

protection and a pressure relief valve.

Grade ven

t valve with rollover protection, fitted to the ev

aporative flange and with an outlet pipe connected to the

FLVV vapour outlet pipe.

Large bore vapour vent pipes.

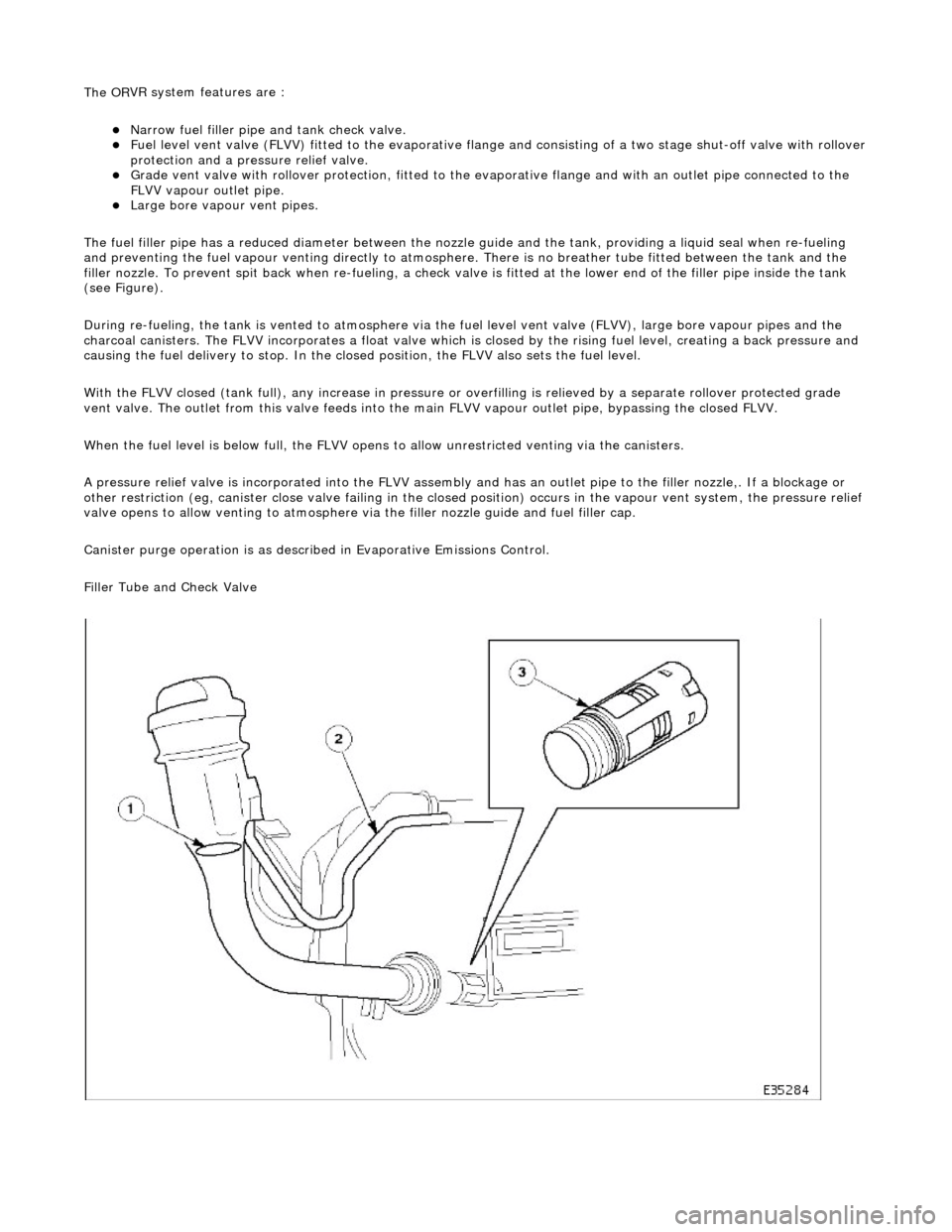

The fuel filler pipe has a reduced diameter between the nozzle guide and the tank, providing a liquid seal when re-fueling

and preventing the fuel vapour venting directly to atmosphere. There is no breather tube fitted between the tank and the

filler nozzle. To prevent spit back when re-fueling, a check valv e is fitted at the lower end of the filler pipe inside the tank

(see Figure).

During re-fueling, the tank is vented to atmosphere via the fuel level vent valv e (FLVV), large bore vapour pipes and the

charcoal canisters. The FLVV incorp orates a float valve which is closed by the rising fuel level, creating a back pressure and

causing the fuel delivery to stop. In the closed position, the FLVV also sets the fuel level.

With the FLVV closed (tank full), any increase in pressure or overfilling is relieved by a separate rollover protected grade

vent valve. The outlet from this valve feeds into the main FLVV vapour outlet pipe, bypassing the closed FLVV.

When the fuel level is below full, the FLVV opens to allow unrestricted venting via the canisters.

A pressure relief valve is incorp orated into the FLVV assembly and has an outlet pipe to the filler nozzle,. If a blockage or

other restriction (eg, canister close valve failing in the closed position) occurs in the vapour vent system, the pressure reli ef

valve opens to allow venting to atmosphere via the filler nozzle guide and fuel filler cap.

Canister purge operation is as described in Evaporative Emissions Control.

Filler Tube and Check Valve