clock JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 22 of 2490

Ambient Air Temperature Sensor (82.20. 02)

Cold Ai

r

Bypass Blend Door Actuator (82.20.86)

Defrost Vent/Register Blend Door Actuator (82.20.84)

Footwell Vent/Duct Blend Door Actuator (80.20.20 or 82.20.85)

Instrument Panel Blend Door Actuator (82.20.83)

Remote Climate Control Module LHD (82.20.65)

Remote Climate Control Module RHD (82.20.65)

413: Instrumentation and Warning Sy

stems

413‐00: Instrument Cluster and Panel Illumination

Description and Operation

Instrument Cluster and Panel Illumination

Removal and Installation

Instrument Panel Dimmer Switch (86.65.07)

413‐01: Instrument Cluster

Description and Operation

Instrument Cluster

Diagnosis and Testing

Instrument Cluster

Removal and Installation

Instrument Clust

er (88.20.01)

413‐06: Horn

Description and Operation

Horn

Diagnosis and Testing

Horn

413‐07: Clock

Description and Operation

Clock

Diagnosis and Testing

Clock

Removal and Installation

Clock (88.15.07)

Page 55 of 2490

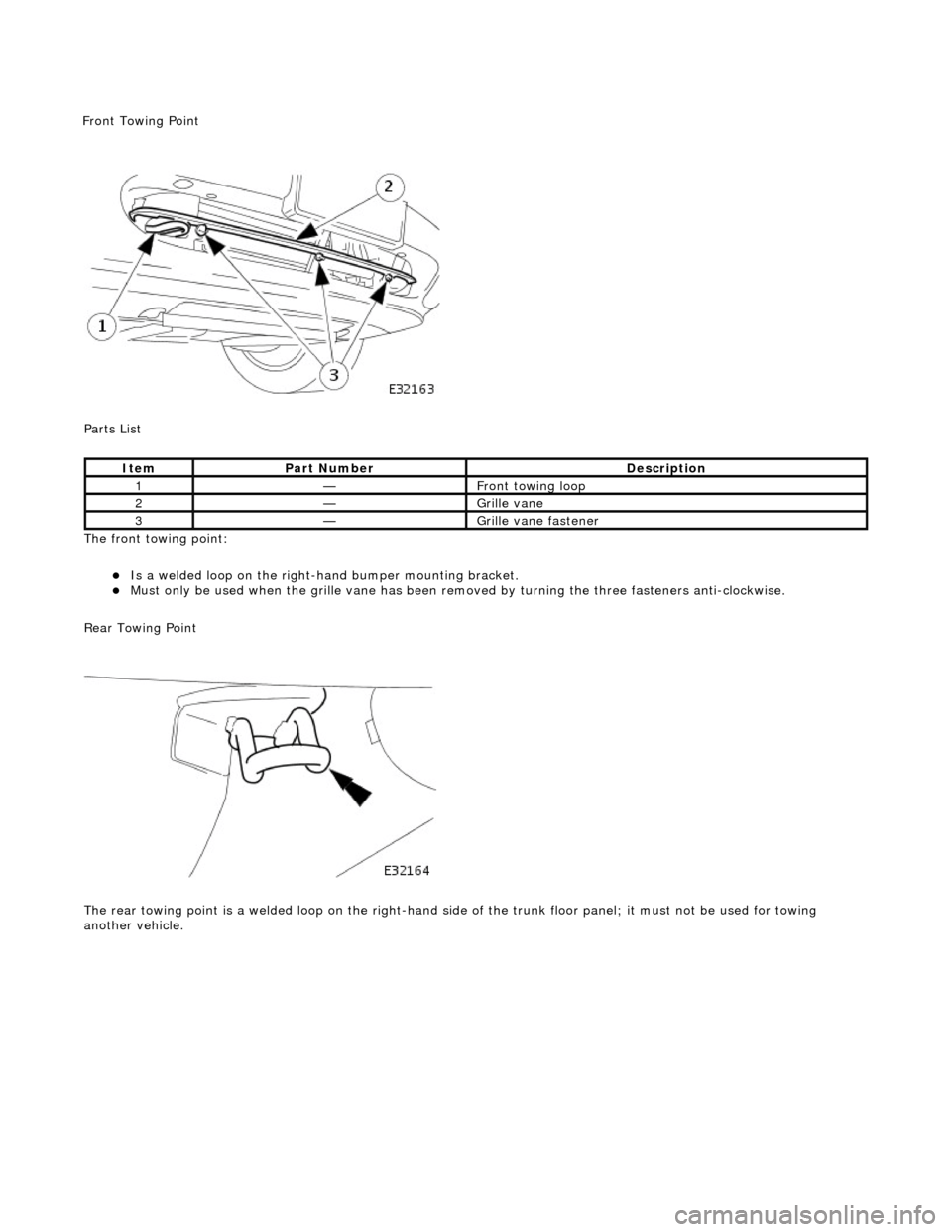

P

arts List

The front towing point:

Is a welded loop on the ri

ght-ha

nd bumper mounting bracket.

Mus

t only be used when the grille

vane has been removed by turning the three fasteners anti-clockwise.

Rear Towing Point

The rear towing point is a welded loop on the right-hand side of the trunk floor panel; it must not be used for towing

another vehicle.

It

em

Par

t Number

De

scription

1—Fr

ont towing loop

2—Gr

ille vane

3—Gr

ille vane fastener

F

ront Towing Point

Page 377 of 2490

Remove brake

pads from caliper housing.

Discard

brake pads.

7. R

emove caliper carrier from hub carrier.

Re

move bolts.

R

emove carrier.

8. Ali

gn brake disc access hole

with parking brake adjuster.

R

emove plug from access hole.

Rotate

brake disc until ac

cess hole is aligned with

adjuster.

9. Slacken parking brake adju

ster.

Rot

ate adjuster clockwise.

10. Remove brake disc from wheel studs.

Page 381 of 2490

6. CAUTI

ONS:

Only remove the bolts securi ng the caliper anchor bracket

to the hub carrier. Refer to caution above for more information.

Do not allow the caliper to hang on the hydraulic hose, as

this will damage the hose.

Remove caliper from hub carrier.

Re

move bolts.

Re

move and tie caliper aside.

7.

Ali

gn brake disc access hole

with parking brake adjuster.

R

emove plug from access hole.

Rotate

brake disc until ac

cess hole is aligned with

adjuster.

8. Slacken parking brake adju

ster to

allow for the removal of the

brake disc.

Rot

ate adjuster clockwise.

9. Remove brake disc from hub.

Page 394 of 2490

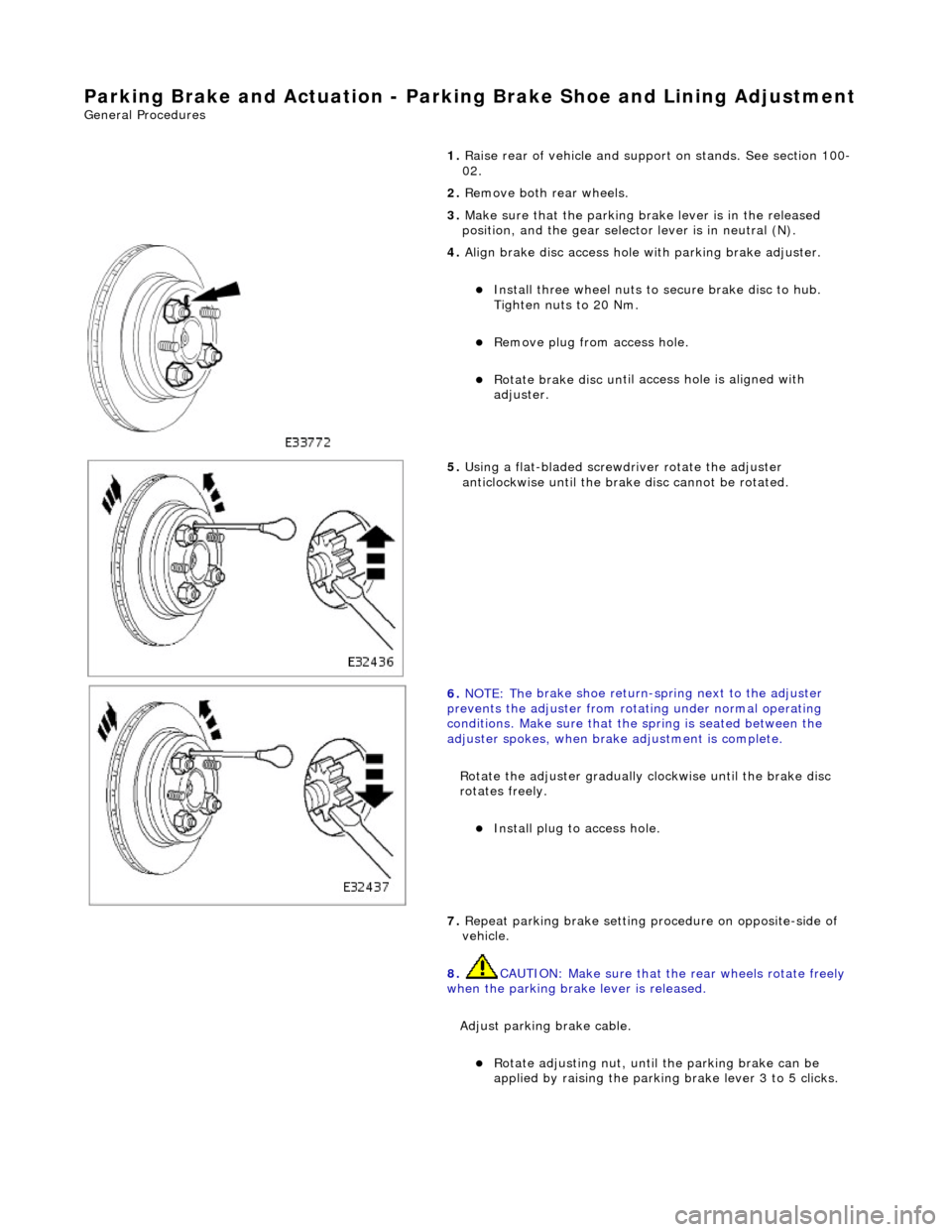

Parking Brake and Actuation - P

arking Brake Shoe

and Lining Adjustment

Gene

ral Procedures

1. Raise rear of vehicle and support on stands. See section 100-

02.

2. Remove both rear wheels.

3. Make sure that the parking br ake lever is in the released

position, and the gear selector lever is in neutral (N).

4. Alig

n brake disc access hole

with parking brake adjuster.

Instal

l three wheel nuts to secure brake disc to hub.

Tighten nuts to 20 Nm.

R e

move plug from access hole.

Rotate

brake disc un

til ac

cess hole is aligned with

adjuster.

5. Using a flat-bladed screwdriv er rotate the adjuster

anti

clockwise until the brake disc cannot be rotated.

6. NOTE : Th

e brake shoe return-spring next to the adjuster

prevents the adjuster from rota ting under normal operating

conditions. Make sure that the spring is seated between the

adjuster spokes, when brake adjustment is complete.

Rotate the adjuster gradually clockwise until the brake disc

rotates freely.

Inst al

l plug to access hole.

7. Repeat parking brake setting pr ocedure on opposite-side of

vehicle.

8. CAUTION: Make sure that th e rear wheels rotate freely

when the parking brake lever is released.

Adjust parking brake cable.

Ro

tate adjusting nut, until the parking brake can be

applied by raising the parking brake lever 3 to 5 clicks.

Page 518 of 2490

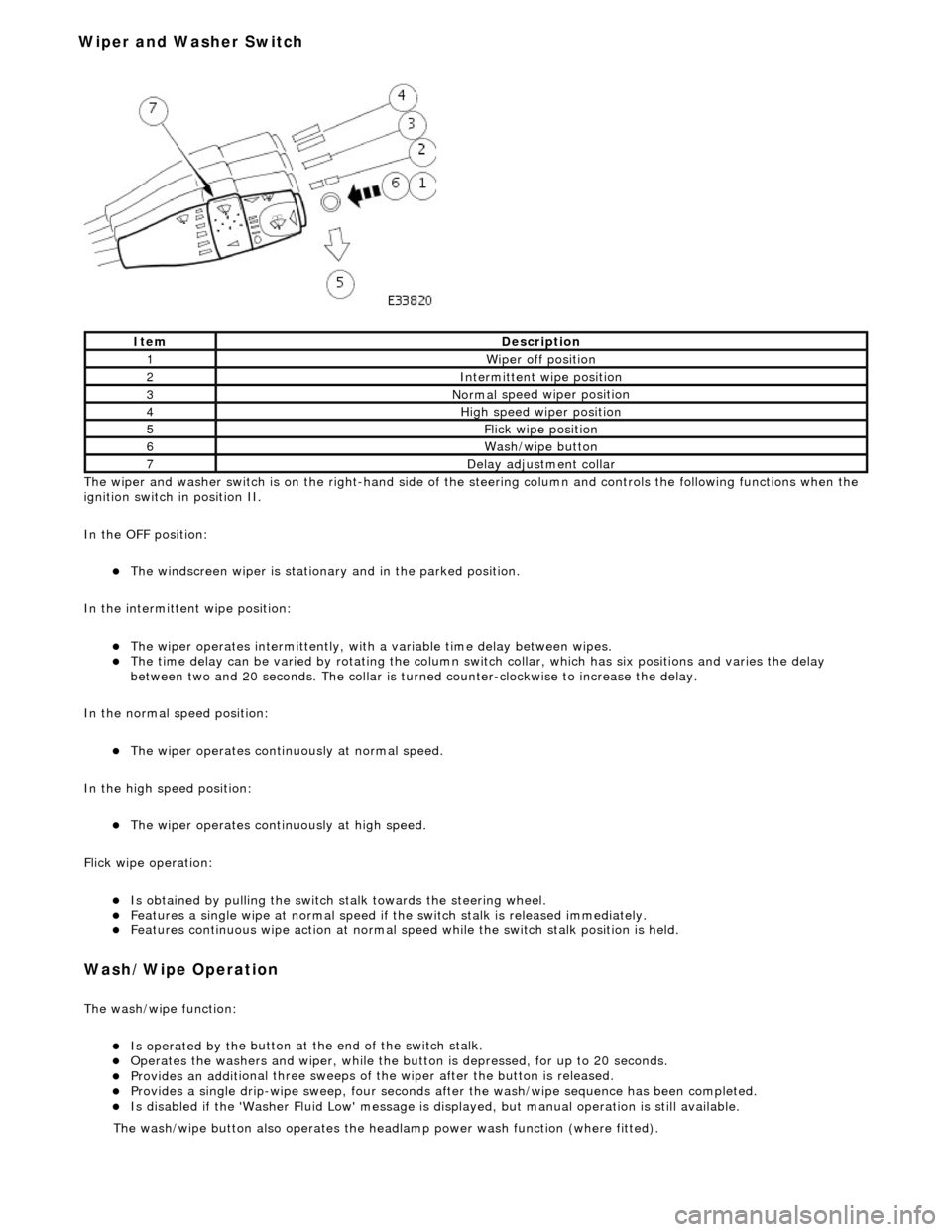

The wiper and washer switch i s

on the righ

t-hand side of the steering column and controls the fo llowing functions when the

ignition switch in position II.

In the OFF position:

The windscreen wiper is stationary and in the parked positio

n.

In the intermittent wipe position:

The wi per ope

rates intermittently, with

a variable time delay between wipes.

The time del

ay can be varied by rotating the column sw

itch collar, which has six positions and varies the delay

between two and 20 seconds. The collar is turned counter-clockwise to increase the delay.

In the normal speed position:

The wiper oper a

tes continuously at normal speed.

In the high speed position:

The wiper ope r

ates continuously at high speed.

Flick wipe operation:

Is obt

ained by pulling the switch

stalk towards the steering wheel.

F

e

atures a single wipe at normal speed if

the switch stalk is released immediately.

Fe

atures continuous wipe action

at normal speed while the swit ch stalk position is held.

Wash/W

ipe Operation

Th

e

wash/wipe function:

Is operat

ed by th

e button at the end of the switch stalk.

Op

erate

s the washers and wiper, while the butt

on is depressed, for up to 20 seconds.

Provides an addit

ional three sweeps of

the wiper after the button is released.

Provid

es a single drip-wipe sweep, four seconds af

ter the wash/wipe sequence has been completed.

Is disabled if the 'Washer Flu

id Low' message is di

splayed, but manual operat ion is still available.

Ite

m

De

scr

iption

1W

i

per off position

2Intermittent

wipe position

3Normal

speed wiper position

4High

speed wiper position

5Flick wipe position

6Wa

sh/wipe button

7D

e

lay adjustment collar

The was

h

/wipe button also operates the head

lamp power wash function (where fitted).

Wiper and Washer Switch

Page 572 of 2490

2. Fi

t the retaining / pivot bolt and tighten it to 12 - 16

Nm.

5. Refi

t the primary chain tensione

r assembly. Refer to Operation

12.65.55 in this Section.

U s

e a wedge 303 - 533 (or two if required) between the

primary chain tensioner and te nsioner blade, to take up

the slack in the chain.

6. Tigh te

n the exhaust camshaft

sprocket securing bolt.

1. Fit the chain tensioner tool 303 - 532 to the sprocket holes.

1. Apply force to the to

ol in

an anti-clockwise direction

to tension the chain on its drive side.

2 .

Whilst applying the opposing force to the sprocket

and chain, tighten the sprock et securing bolt to 115 -

125 Nm.

7. Tigh te

n the VVT unit securing bolt.

1. Whilst still applying the opposing force to the

sprocket and chain (using 303 - 532), check that the

wedges are still in place, tighten the VVT unit

securing bolt to 115 - 125 Nm.

Re

move the chain tensioning

tool and the wedge(s).

8. Remove the camshaft locking tool 303 - 530 and transfer it to

the A-Bank camshafts, aligning the shafts slightly as necessary.

Page 574 of 2490

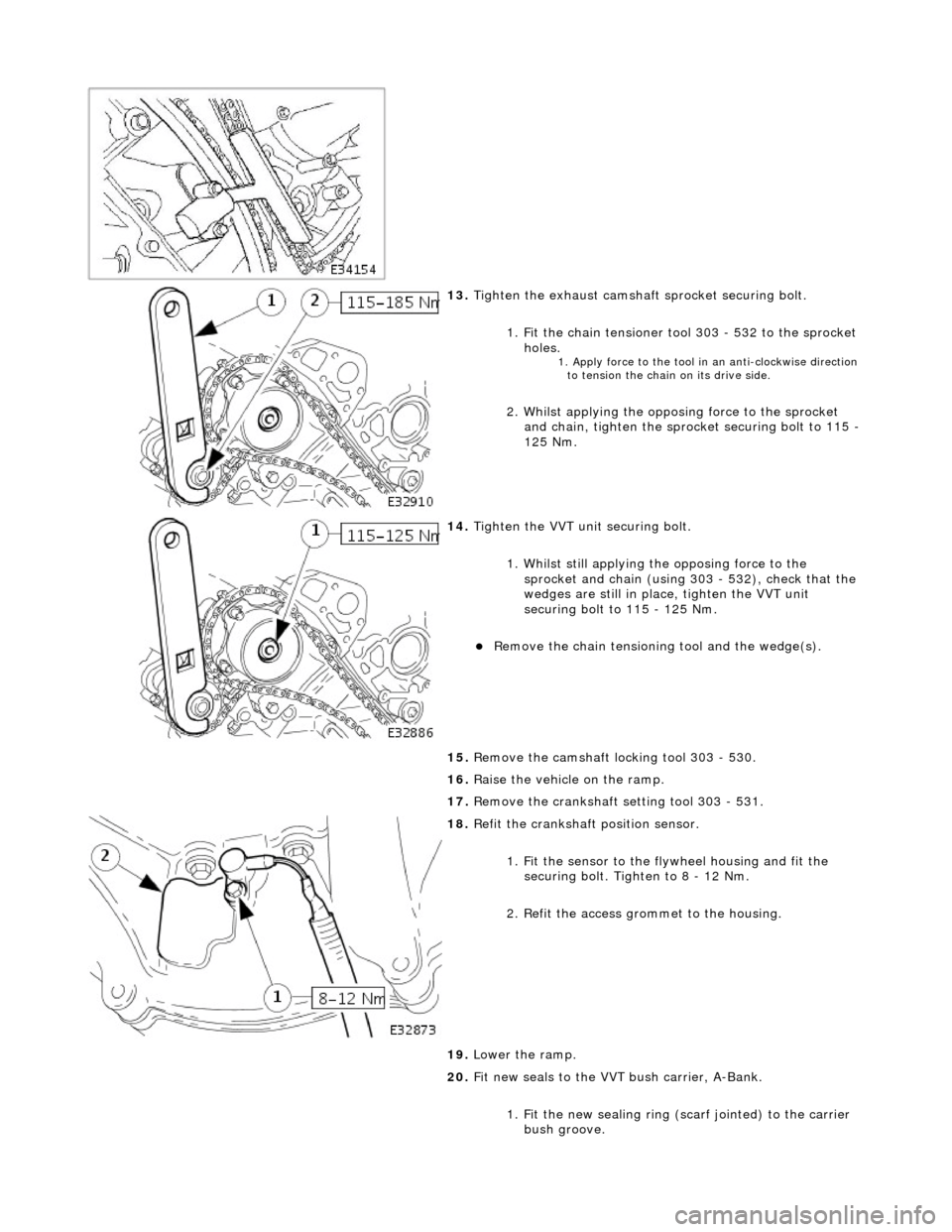

13. Tigh

ten the exhaust camshaft

sprocket securing bolt.

1. Fit the chain tensioner tool 303 - 532 to the sprocket holes.

1. Apply force to the to

ol in

an anti-clockwise direction

to tension the chain on its drive side.

2 .

Whilst applying the opposing force to the sprocket

and chain, tighten the sprock et securing bolt to 115 -

125 Nm.

14 . Tigh

ten the VVT unit securing bolt.

1. Whilst still applying the opposing force to the

sprocket and chain (using 303 - 532), check that the

wedges are still in place, tighten the VVT unit

securing bolt to 115 - 125 Nm.

R e

move the chain tensioning

tool and the wedge(s).

15. Remove the camshaft locking tool 303 - 530.

16. Raise the vehicle on the ramp.

17. Remove the crankshaft setting tool 303 - 531.

18 . R

efit the crankshaft position sensor.

1. Fit the sensor to the fl ywheel housing and fit the

securing bolt. Tighten to 8 - 12 Nm.

2. Refit the access grommet to the housing.

19. Lower the ramp.

20. Fit new seals to the VVT bush carrier, A-Bank.

1. Fit the new sealing ring ( scarf jointed) to the carrier

bush groove.

Page 582 of 2490

2.

Install the retaining / pivo

t bolt and tighten it to 12-

16 Nm.

5. Install the primary ch

ain te

nsioner assembly. Refer to

Operation 12.65.55.

Use a wedge 3 03-5

33 (or two if required) between the

primary chain tensioner and te nsioner blade, to take up

the slack in the chain.

6. Tigh te

n the exhaust camshaft

sprocket securing bolt.

1. Install the chain tensioner tool 303-532 to the sprocket holes.

Appl y force

to the tool in an

anti-clockwise direction to

tension the chain on its drive side.

2. Whilst applying the opposing force to the sprocket and chain, tighten the sprock et securing bolt to 115-

125 Nm.

7. Tigh te

n the intake camshaft

sprocket securing bolt.

1. Whilst still applying the opposing force to the

sprocket and chain (using 303-532), check that the

wedges are still in place, ti ghten the securing bolt to

115-125 Nm.

R e

move the chain tensioning

tool and the wedge(s).

8. Remove the camshaft locking t ool 303-530 and transfer it to

Bank 1 camshafts, aligning the shafts slightly as necessary.

Page 584 of 2490

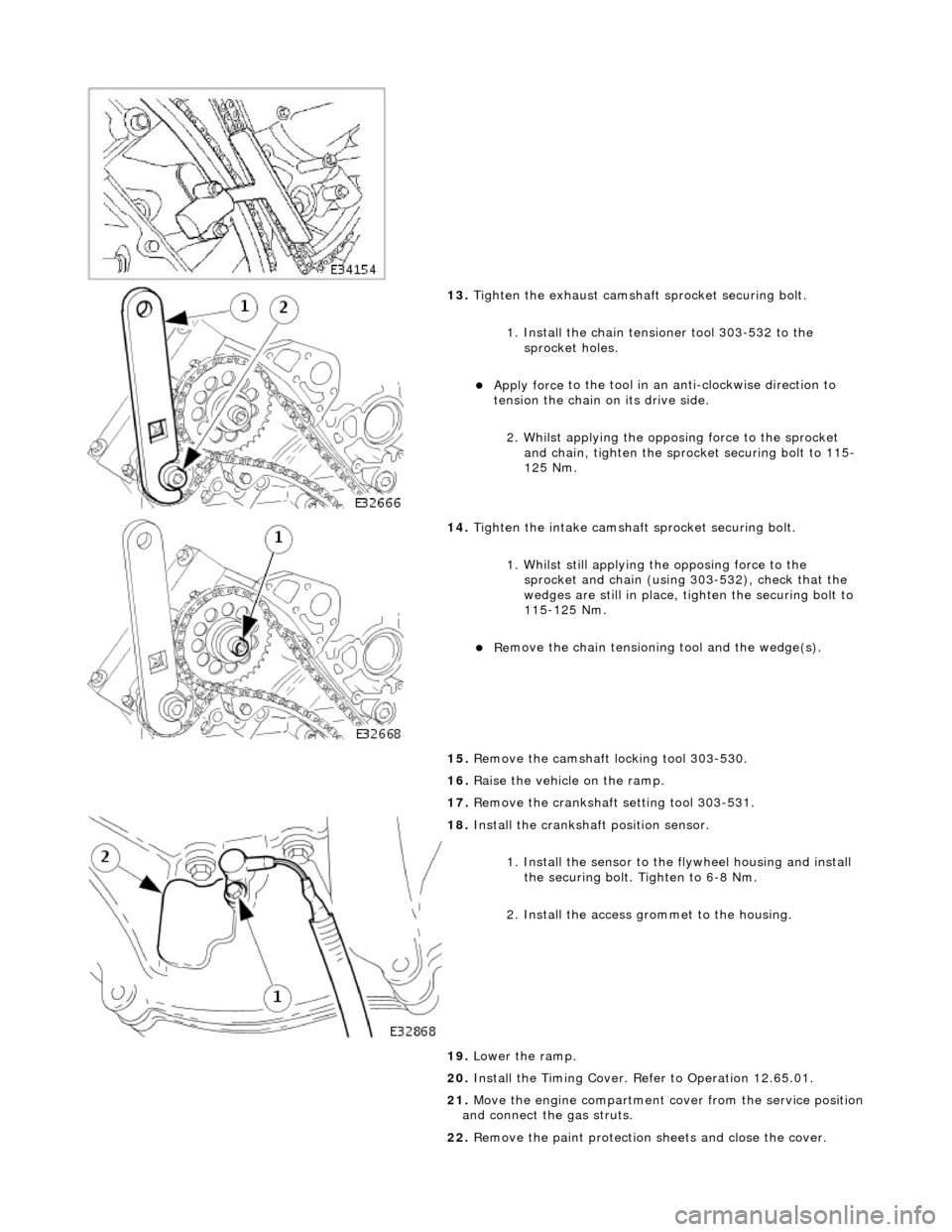

13. Tigh

ten the exhaust camshaft

sprocket securing bolt.

1. Install the chain tensioner tool 303-532 to the sprocket holes.

Appl y force

to the tool in an

anti-clockwise direction to

tension the chain on its drive side.

2. Whilst applying the opposing force to the sprocket and chain, tighten the sprock et securing bolt to 115-

125 Nm.

14 .

Tigh

ten the intake camshaft

sprocket securing bolt.

1. Whilst still applying the opposing force to the

sprocket and chain (using 303-532), check that the

wedges are still in place, ti ghten the securing bolt to

115-125 Nm.

R e

move the chain tensioning

tool and the wedge(s).

15. Remove the camshaft locking tool 303-530.

16. Raise the vehicle on the ramp.

17. Remove the crankshaft setting tool 303-531.

18 . Inst

all the crankshaft position sensor.

1. Install the sensor to the flywheel housing and install

the securing bolt. Tighten to 6-8 Nm.

2. Install the access grommet to the housing.

19. Lower the ramp.

20. Install the Timing Cover. Refer to Operation 12.65.01.

21. Move the engine compartment cover from the service position

and connect the gas struts.

22. Remove the paint protection sheets and close the cover.