front wheel bearing JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 3 of 2490

Rear Toe Adjustment (57.65. 08)

Whee

l

Bearing Circlip Inspection

Wheel Bearing Inspection

204‐01: Front Suspension

Specification

Description and Operation

Front Suspension

Removal and Installation

Ball Joint (60.15.02)

Rear Lower Arm (60.35.54)

Rear Lower Arm Bushing (60.35.56)

Front Shock Absorber (60.30.04)

Spring

Spring Seat (60.20.03)

Front Sta

bilizer Bar (60.10.01)

Front Stabilizer Bar Bushing (60.10.04)

Front Stabilizer Bar Link (60.10.02)

Upper Arm Bushing

Front Wheel Bearing (60.25.40)

Wheel Hub

Wheel Knuckle (60.25.23)

Wheel Knuckle and Wheel Hub Assembly (60.25.38.90)

Wheel Knuckle and Wheel Hub Assembly Conversion (60.25.43)

204‐02: Rear Suspension

Specif

ication

Description and Operation

Rear Suspension

Removal and Installation

Axle Bump Stop (64.30.15)

Rear Suspension and Axle Assembly (64.25.01)

Rear Shock Absorber (64.30.02)

Shock Absorber Lower Bushing (64.30.39)

Spring (64.20.01)

Rear Stabilizer Bar (64.35.08) ‐ 4.0L SC V8 ‐ AJ26

Rear Stabilizer Bar Bushing (64.35.18) ‐ 4.0L SC V8 ‐ AJ26

Page 70 of 2490

Upper

Wishbones

Each

upper wi

shbone assembly is a on

e-piece steel forging incorporating:

A pres

s-fit ball joint.

Press-fi

t bushes for location of the upper fulcrum bolt.

Lower Wishbones

Each l

o

wer wishbone comprising

forged steel front and rear arms bolted together, incorporates:

A p

ress-fit ball joint in the outer extremity of the rear arm.

Press-f

i

t bushes for location of the lower fulcrum bolts

Locati

on for the shock absor

b

er lower mounting plates.

Vertica l Links

The vertical

links are of forged steel

wi

th integral steering arms. Each is suppo rted between the upper and lower wishbones

by two ball joints and carries:

Front hub

Brake ca

liper and disc shield assembly

ABS se

nsor

.

Front Hub

s

Each f

o

rged steel front hub accommodates sealed for life cartridge

type wheel bearings, and carries:

The brake rotor assembl

y.

A

h

ub nut with toothed, integral ABS rotor.

Su

s

pension spring pi

n locking device.

Front Road

Springs

The road spri

ng

s are of coil type with their

rating dependent upon vehicle specification

Ea

ch spring is installed between the suspension crossbeam location and the lower wishbone spring pan.

Ru

bber seats ar

e installed betw

een the spring and the crossb eam and the spring pan.

Front Shock A

bsorbers

Th

e

shock absorbers are telescopic hydrau

lically operated units. Optional adaptive damping units incorporate a solenoid-

operated control valve at their upper extremity.

Each shoc

k absorber is installed between the lowe

r wishbone rear arm and a recess in the body.

The l

o

wer end of the shock absorber is se

cured to plates on the wishbone by a bolt that also serves as a pivot.

The u

pper en

d of each shock absorber is secured to the body location by a single nut.

Front Sta

b

ilizer Bar

A

front stabil

izer bar installed on all vehicles

is rated according to suspension specification.

Opera

tion

As each road wheel r

i

ses, move

ment is transmitted through the vertical link assembly to the lower wishbone. The resulting

rise of the wishbone compresses the road spring and partially telescopes the shock absorber. During this action, the spring

absorbs associated shocks and the shock absorber minimizes sprin

g os c

illation.

Du

ring cornering, vehicle weight

is transferred to the outer road wheel with a resulting tendency for the inner wheel to lift.

The stabilizer bar assists in minimizing this tendency by transf erring a proportion of potential lift of the inner wheel to the

outer wheel. This result s in enhanced body stability with improved corner ing capabilities.

Page 135 of 2490

Front Suspension - Front Wheel Bearing

Re

moval and Installation

S

pecial Tool(s)

Hub Remover

204-193 (JD 224)

Hub Removal Collets

2

04-194 (JD 225)

Hub Holdin

g Tool

204-195 (JD 227)

Hub Replacer

2

04-196 (JD 236)

Wh

eel Bearing Remover

204-197 (JD 237)

Wh

eel Bearing Replacer

204-198 (JD 238)

ABS Rotor Nut Socket

20

6-066A

Ci

rclip Pliers

Page 141 of 2490

Front Susp

ension - Wheel Hub

Re

moval and Installation

S

pecial Tool(s)

Hub Remover

204-193 (JD 224)

Hub Removal Collets

2

04-194 (JD 225)

Hub Holdin

g Tool

204-195 (JD 227)

Hub Replacer

2

04-196 (JD 236)

Wh

eel Bearing Remover

204-197 (JD 237)

Wh

eel Bearing Replacer

204-198 (JD 238)

ABS Rotor Nut Socket

20

6-066A

Ci

rclip Pliers

Page 147 of 2490

Front Suspension - Wheel Knuckle

Re

moval and Installation

S

pecial Tool(s)

Hub Remover

204-193 (JD 224)

Hub Removal Collets

2

04-194 (JD 225)

Hub Holdin

g Tool

204-195 (JD 227)

Hub Replacer

2

04-196 (JD 236)

Wh

eel Bearing Remover

204-197 (JD 237)

Wh

eel Bearing Replacer

204-198 (JD 238)

ABS Rotor Nut Socket

20

6-066A

Ci

rclip Pliers

Page 313 of 2490

Do t

he disc brake caliper pistons

and pins bind, leak or stick?

Yes INSTALL new calipers as necessary. TE ST the system for normal operation.

No GO to C4

.

C4: INSPECT BR

AKE DISCS

Check the brake discs fo

r excess

ive damage, thickness variatio n or runout. For additional

information, refer to General Procedures in this section.

1

D

oes excessive damage or runout exist?

Yes INSTALL new brake discs and brak e pads as necessary. TEST the system for normal operation.

No GO to C5

.

C5: INSPECT THE FRONT HU

B AND WHEEL BEARING ASSEMBLY

Check the fr

ont hub and wheel bearing assembly.

For additional information, refer toSection 204

-00

Su

spension System

- General

Information

. 1

Are th

e wheel bearings OK?

Yes GO to C6

.

No

INSTALL new wheel bearings. For additional inform ation, refer toSection 204

-01

Front Suspension

.

TEST the system

for normal operation.

C

6: CHECK SUSPENSION BUSHES AND BALL JOINTS.

Chec

k all suspension bu

shes and ball joints.

1

Are th

e suspension bushes and ball joints OK?

Yes Vehicle is OK.

No INSTALL new front suspension bushes and ball joints as required. For additional information, refer

toSection 204

-01

Front Suspension

. INSTALL n

ew rear suspension bush

es and ball joints as required.

For additional informat ion, refer toSection 204

-0

2 Rear Suspension

.

P

INPOINT TEST D : THE PEDAL FEELS SPONGY

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

D

1: CHECK FOR SPONGY PEDAL (ENGINE OFF)

Check f

or a firm brake pedal.

1

Is th

e brake pedal effort an

d brake pedal travel normal?

Yes Vehicle is OK.

No GO to D2

.

D2:

CHECK BRAKE PEDAL RESERVE (ENGINE OFF)

Pump th

e brake pedal 10 times and

hold on the final application.

1

Does th

e brake pedal feel fi

rm on final application?

Yes GO to D3

.

No

BLEED the brake system. For additional information, re fer to General Procedures in this section. TEST

the system for normal operation.

D3:

CHECK BRAKE PEDAL RESERVE (ENGINE ON)

Engine is

idle.

1

Apply the brake pedal ligh

tl

y three or four times.

2

W

ait 15 seconds for the vacuum to recover.

3

Push down on

the brake pedal until it stops moving

downward or an increased resistance to the brake

pedal travel occurs.

4

Hol

d the brake pedal in the applied position while increasing the engine speed to 2000 revs/min.

5

Re

lease the accelerator pedal.

6

Does th

e brake pedal move downward as

the engine speed returns to idle?

Yes GO to D4

.

No

CHECK the vacuum to brake booster. For additional information, refer toSection 206

-0

7 Power Brake

Actuation.

Page 317 of 2490

Yes

Vehicle is OK.

No GO to J2

.

J

2: CHECK BRAKE FLUID LEVEL

Check the brake master cyli

nder reservoir fluid level.

1

Is the fl

uid level OK?

Yes GO to J3

.

No

CHECK brake master cylinder reservoir sealing points. For additional information, refer to Brake

Master Cylinder in this section. ADD brake fl uid and BLEED the brake system. For additional

information, refer to General Proc edures in this section. TEST the system for normal operation.

REPEAT road test if necessary.

J

3: CHECK BRAKE PEDAL RESERVE

Engine is

idle.

1

Apply the brake pedal ligh

tl

y three or four times.

2

W

ait 15 seconds for the vacuum to replenish.

3

Push down on

the brake pedal until it stops moving

downward or an increased resistance to the brake

pedal travel occurs.

4

Hol

d the brake pedal in the applied position while increasing the engine speed to 2000 revs/min.

5

Re

lease the accelerator pedal.

6

Does th

e brake pedal move downward as

the engine speed returns to idle?

Yes GO to J4

.

No

CHECK the vacuum to the brake booster. Fo r additional information, refer toSection 206

-0

7 Power

Brake Ac

tuation

.

J

4: CHECK THE FRONT HUB AND BEARING ASSEMBLY

Check the fr

ont hub and bearing assembly. Fo

r additional information, refer toSection 204

-01

Front

Suspe

nsion

. 1

Are th

e front wheel bearings loose?

Yes INSTALL a new front wheel bearin g if damaged. For additional information, refer toSection 204

-01

F

ront Suspension

. TEST

the system for normal operation.

No CHECK the front brake discs for thickness variances. For additional information, refer to General

Procedures in this section.

PINPO

INT TEST K : SLOW OR INCOMPLETE BRAKE PEDAL RETURN

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

K1: C

HECK FOR BRAKE PEDAL RETURN

Ru

n the engine at fast idle while

making several brake applications.

1

Pull the

brake pedal rearward with approximately 44.5 N (10lb) force.

2

Relea

se the brake pedal and measure

the distance to the toe board.

3

Make a hard brake

application.

4

Relea

se the brake pedal and measure the brake

pedal to toe board distance. The brake pedal

should return to its original position.

5

Does th

e brake pedal return

to its original position?

Yes Vehicle is OK.

No GO to K2

.

K

2: CHECK FOR BRAKE PEDAL BINDING

Check the brake pedal to make

s

ure it is operating freely.

1

Is th

e brake pedal operating freely?

Yes INSTALL a new brake booster. For addi tional information, refer toSection 206

-0

7 Power Brake

Actuation. TEST

the system for normal operation.

No REPAIR or INSTALL new brake pedal. TE ST the system for normal operation.

Page 324 of 2490

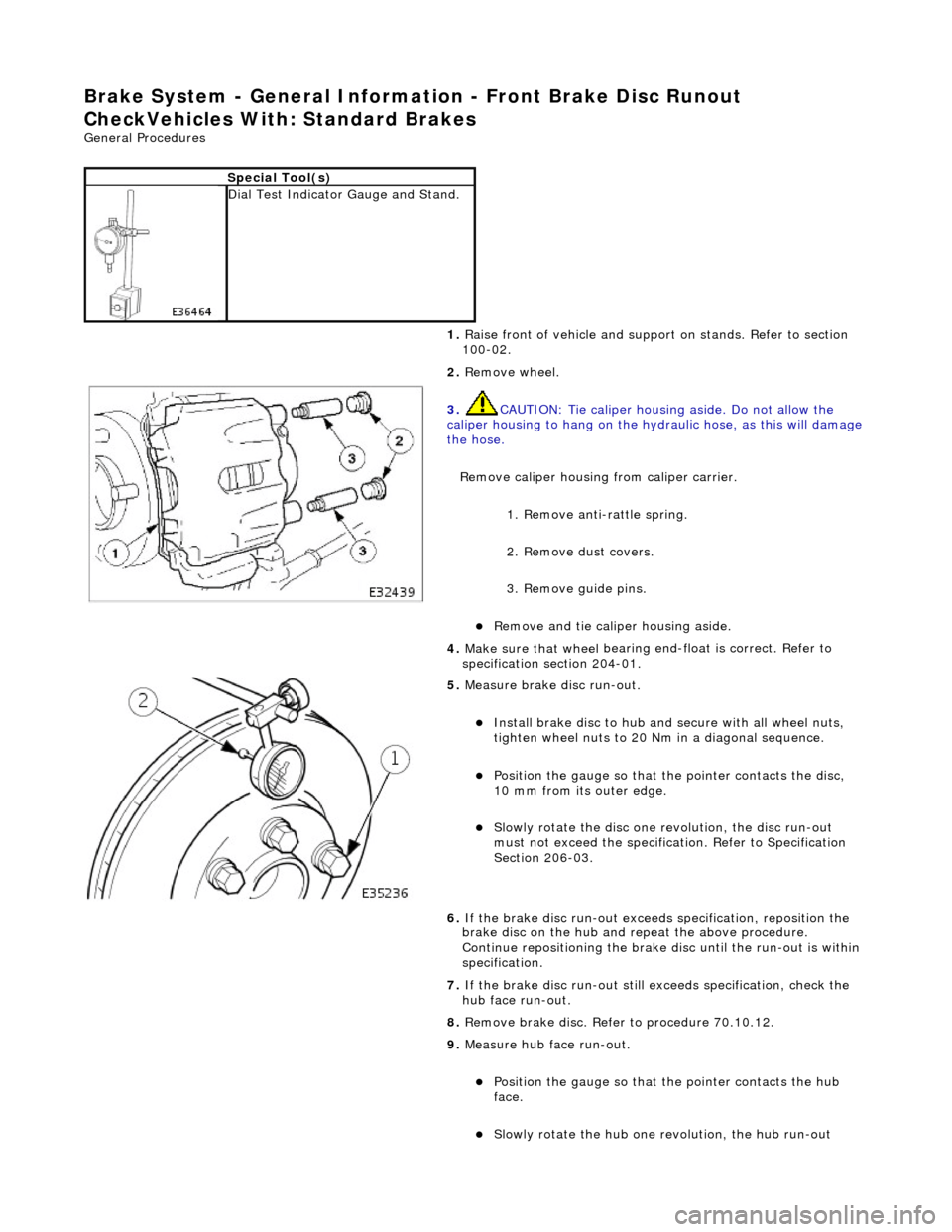

Brake System - Gener

al Information - Front Brake Disc Runout

CheckVehicles With: Standard Brakes

Gen e

ral Procedures

S

p

ecial Tool(s)

Dial Test Indicator

G

auge and Stand.

1. Raise front of vehicle and support on stands. Refer to section

100-02.

2. Remove wheel.

3. CAUT

ION: Tie caliper housing aside. Do not allow the

caliper housing to hang on the hydraulic hose, as this will damage

the hose.

Remove caliper housing from caliper carrier.

1. Remove anti-rattle spring.

2. Remove dust covers.

3. Remove guide pins.

Remove an

d tie caliper housing aside.

4.

Make sure that wheel

bearing en

d-float is correct. Refer to

specification section 204-01.

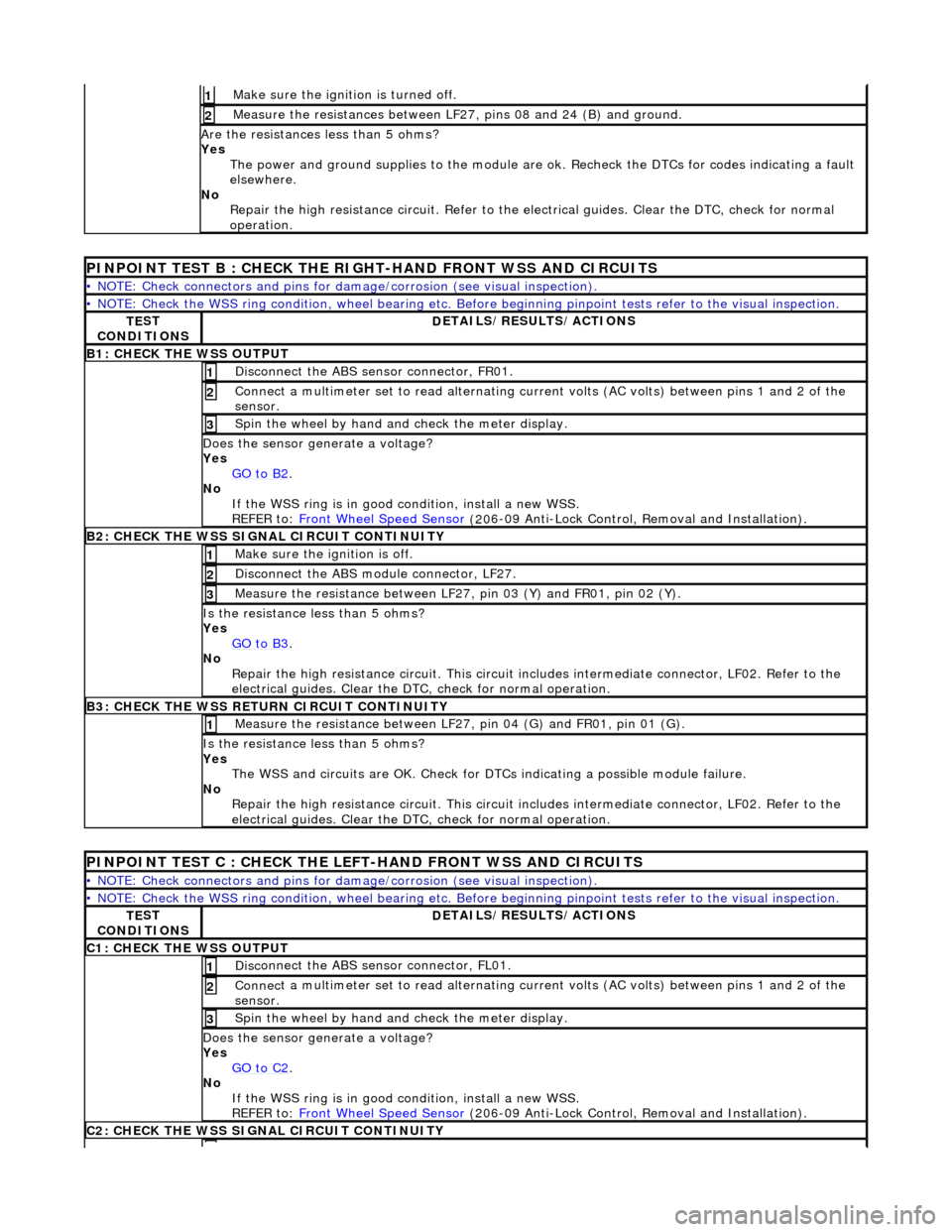

5. Measure brake d

isc run-out.

Inst

al

l brake disc to hub and secure with all wheel nuts,

tighten wheel nuts to 20 Nm in a diagonal sequence.

Posi

tion the gauge so that the pointer contacts the disc,

10 mm from its outer edge.

Slo w

ly rotate the disc one revolution, the disc run-out

must not exceed the specification. Refer to Specification

Section 206-03.

6. If the brake disc run-out exceeds specification, reposition the

brake disc on the hub and re peat the above procedure.

Continue repositioning the brake di sc until the run-out is within

specification.

7. If the brake disc run-out still exceeds specification, check the

hub face run-out.

8. Remove brake disc. Refer to procedure 70.10.12.

9. Measure hub face run-out.

Posi

tion the gauge so that the pointer contacts the hub

face.

Slo w

ly rotate the hub one revolution, the hub run-out

Page 437 of 2490

Make sure the ignition is turned off. 1

Meas

ure the resistances between LF27,

pins 08 and 24 (B) and ground.

2

Are

the resistances less than 5 ohms?

Yes The power and ground supplies to the module are ok . Recheck the DTCs for codes indicating a fault

elsewhere.

No Repair the high resistance circui t. Refer to the electrical guides. Clear the DTC, check for normal

operation.

PINPOINT TE

ST B : CHECK THE RIGHT-HAND FRONT WSS AND CIRCUITS

•

NOTE: Check connectors and pins for damage/corrosion

(see visual inspection).

•

NOTE: Check the WSS ring condition, whee

l bearing etc. Before beginning pinpoint test s refer to the visual inspection.

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

B1: CHECK

THE WSS OUTPUT

Disc

onnect the ABS sensor connector, FR01.

1

Connec

t a multimeter set

to read alternating curr ent volts (AC volts) between pins 1 and 2 of the

sensor.

2

Spin

the wheel by hand and check the meter display.

3

Doe

s the sensor generate a voltage?

Yes GO to B2

.

No

If the WSS ring is in good condition, install a new WSS.

REFER to: Front Wheel Speed Sensor

(20

6-09 Anti-Lock Control, Removal and Installation).

B2:

CHECK THE WSS SIGNAL CIRCUIT CONTINUITY

Make sure the ignition is off. 1

Di

sconnect the ABS module connector, LF27.

2

Meas

ure the resistance between LF27

, pin 03 (Y) and FR01, pin 02 (Y).

3

I

s the resistance less than 5 ohms?

Yes GO to B3

.

No

Repair the high resistance circui t. This circuit includes intermediate connector, LF02. Refer to the

electrical guides. Clear the DTC, check for normal operation.

B3:

CHECK THE WSS RETURN CIRCUIT CONTINUITY

Meas

ure the resistance between LF27

, pin 04 (G) and FR01, pin 01 (G).

1

I

s the resistance less than 5 ohms?

Yes The WSS and circuits are OK. Check for DTCs indicating a possible module failure.

No Repair the high resistance circui t. This circuit includes intermediate connector, LF02. Refer to the

electrical guides. Clear the DTC, check for normal operation.

P

INPOINT TEST C : CHECK THE LEFT-HAND FRONT WSS AND CIRCUITS

•

NOTE: Check connectors and pins for damage/corrosion

(see visual inspection).

•

NOTE: Check the WSS ring condition, whee

l bearing etc. Before beginning pinpoint test s refer to the visual inspection.

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

C1

: CHECK THE WSS OUTPUT

Disc

onnect the ABS sensor connector, FL01.

1

Connec

t a multimeter set

to read alternating curr ent volts (AC volts) between pins 1 and 2 of the

sensor.

2

Spin

the wheel by hand and check the meter display.

3

Doe

s the sensor generate a voltage?

Yes GO to C2

.

No

If the WSS ring is in good condition, install a new WSS.

REFER to: Front Wheel Speed Sensor

(20

6-09 Anti-Lock Control, Removal and Installation).

C2

: CHECK THE WSS SIGNAL CIRCUIT CONTINUITY

Page 552 of 2490

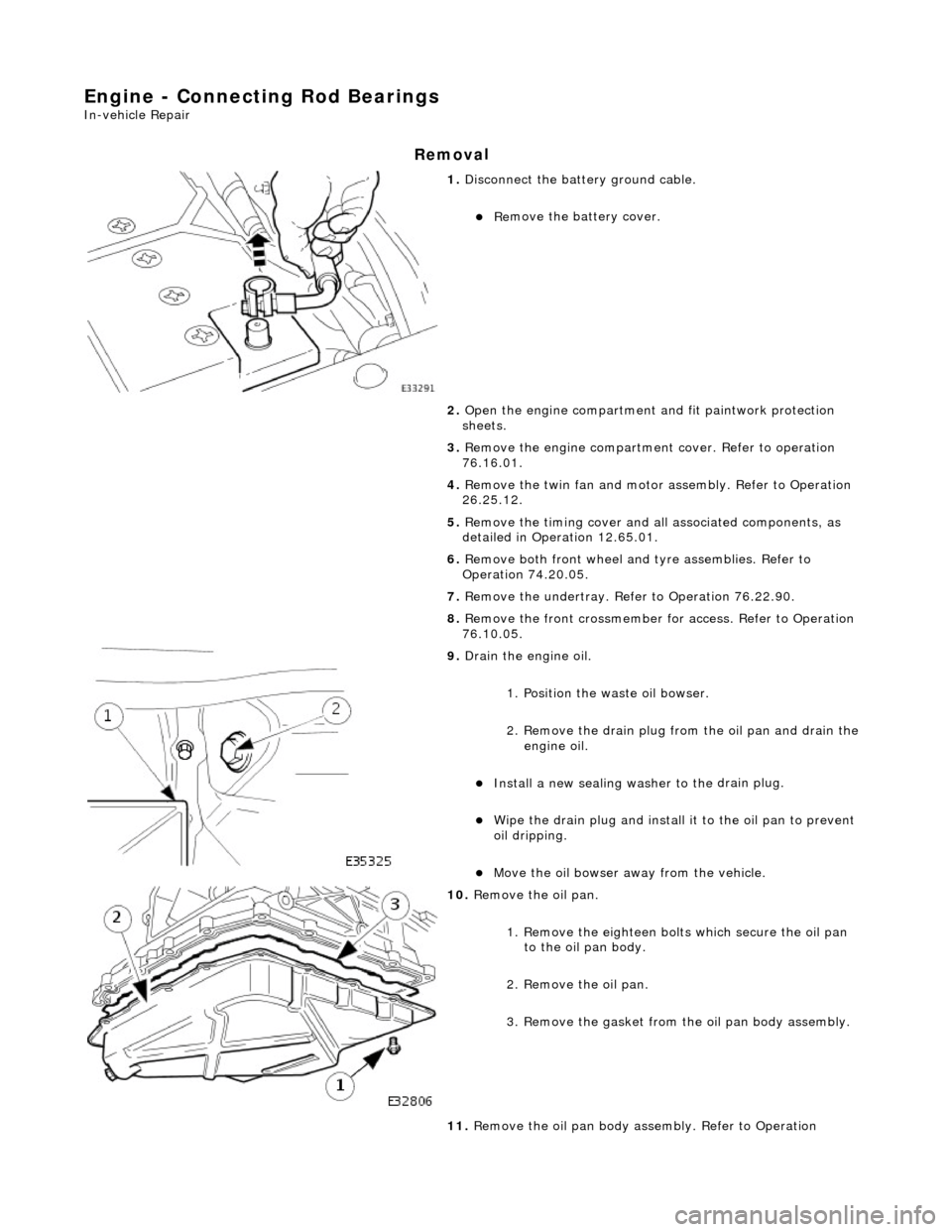

Engine - Connecting Rod Bearings

In-vehic

le Repair

Remov

a

l

1.

Disc

onnect the batt

ery ground cable.

Re

move the battery cover.

2. Open the engine compartment and fit paintwork protection

sheets.

3. Remove the engine compartmen t cover. Refer to operation

76.16.01.

4. Remove the twin fan and motor assembly. Refer to Operation

26.25.12.

5. Remove the timing cover and al l associated components, as

detailed in Operation 12.65.01.

6. Remove both front wheel and tyre assemblies. Refer to

Operation 74.20.05.

7. Remove the undertray. Re fer to Operation 76.22.90.

8. Remove the front crossmember fo r access. Refer to Operation

76.10.05.

9. Drai

n the engine oil.

1. Position the waste oil bowser.

2. Remove the drain plug from the oil pan and drain the engine oil.

Install a new sealing wash er to the

drain plug.

Wipe the drain plug an

d

install

it to the oil pan to prevent

oil dripping.

Move the oil bowser away f

rom the vehicle.

10 . Re

move the oil pan.

1. Remove the eighteen bolt s which secure the oil pan

to the oil pan body.

2. Remove the oil pan.

3. Remove the gasket from the oil pan body assembly.

11. Remove the oil pan body a ssembly. Refer to Operation