diagnostic menu JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1336 of 2490

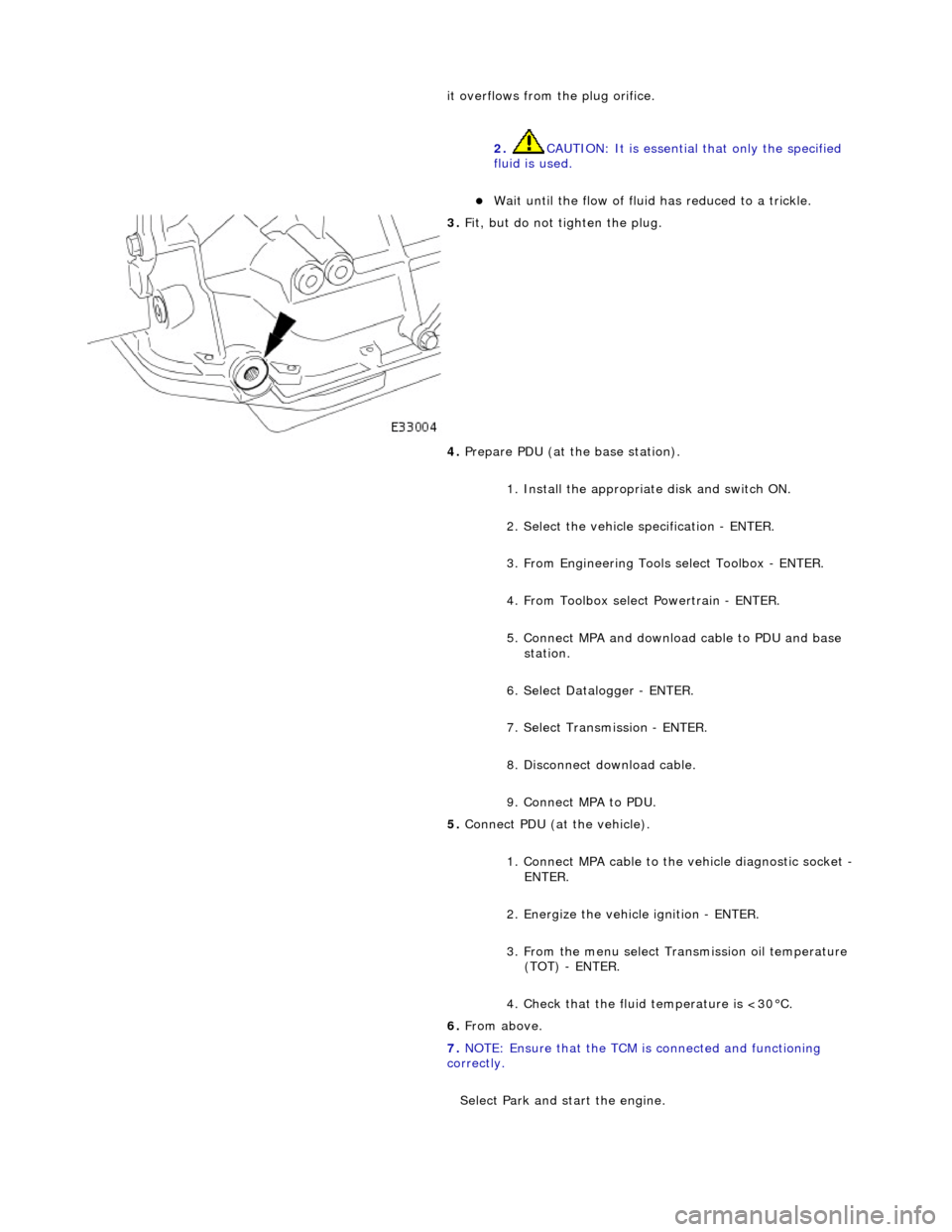

it overflows from the plug orifice. 2. CAUTION: It is essential that only the specified

fluid is used.

Wait until the flow of fluid has reduced to a trickle.

3. Fit, but do not tighten the plug.

4. Prepare PDU (at the base station).

1. Install the appropriat e disk and switch ON.

2. Select the vehicle specification - ENTER.

3. From Engineering Tools select Toolbox - ENTER.

4. From Toolbox select Powertrain - ENTER.

5. Connect MPA and download cable to PDU and base station.

6. Select Datalogger - ENTER.

7. Select Transmission - ENTER.

8. Disconnect download cable.

9. Connect MPA to PDU.

5. Connect PDU (at the vehicle).

1. Connect MPA cable to the vehicle diagnostic socket -

ENTER.

2. Energize the vehicle ignition - ENTER.

3. From the menu select Transmission oil temperature (TOT) - ENTER.

4. Check that the fluid temperature is <30°C.

6. From above.

7. NOTE: Ensure that the TCM is connected and functioning

correctly.

Select Park and start the engine.

Page 1743 of 2490

Accelerati

on Control - Accelerator Cable Adjustment

Gen

eral Procedures

1.

Load the Approved Jaguar Diagno stic System with power train

data logger.

2. Connect the Approved Jaguar Diag nostic System to the vehicle.

3. W

ith 'Disable Network Integrity Test - YES/ NO' displayed on

the screen select YES.

4. With new menu displayed on the screen, select ' Engine

Management'.

5. Turn the ignition to ON.

R

emove any previously selected data logger parameters.

6. On data logger select PPS11 an d PPS2 (Pedal demand sensors

1 and 2).

7. On Sedan models only, remove the bulkhead covers on both

sides and the engine compartment rear cover.

8. Cut, remove and discard the ra tchet strap which retains the

throttle cable to the abutment bracket.

9. Ensure there is no tension on the throttle cable by releasing

the throttle cable adjustment nut from the abutment bracket.

10. Record the voltages for both sensors, PPS11 and PPS2.

11. Partially insert the throttle cable adjustment nut into the

abutment bracket.

12. Recheck the voltages for both sensors, PPS11 and PPS2.

13. Where the voltages at step 12 are higher than the voltages

taken at step 10, contin ue to step 15 below.

14. Where the voltages at step 12 are the same as the voltages

taken at step 10, contin ue to step 16 below.

15. Rotate the adjustment nut clockwise (as viewed from the

front of the vehicle) until the same voltages are indicated as in

step 10. Continue to turn thro ugh a part revolution until the

sides of the nut are vertical. Tu rn through a further 90 degrees,

then fully insert the nut into the abutment bracket.

16. Rotate the adjustment nut anti-clockwise (as viewed from the

front of the vehicle) until the indicated voltage starts to

increase. Then rotate the nut clockwise through a part

revolution until the sides are ve rtical. Turn through a further 90

degrees, then fully insert the nut into the abutment bracket.

17. Fit a new ratchet strap to secure the throttle cable adjusting

nut to the abutment bracket.

18. Operate the throttle pedal through 20 full cycles to settle the

cable. Check the voltages now shown, remain the same as in

steps 15 and 16.

19. Check and where necessary adjust the kickdown switch. For

additional information, refer to Section 307

-05A Automatic Transmissi

on/Transaxle External Controls

Sectio

n

307

-05

B

Au

tomatic Transmission/Tra

nsaxle External Controls

.

20

.

On Sedan models only, refit the engine compartment rear

cover and the bulkhead co vers on both sides.

21. Switch the ignition OFF and disconnect the Approved Jaguar

Diagnostic System.