jacking points JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 39 of 2490

Before inspecting a component for wear or per

forming a dimensional check,

ensure that it is absolutely clean; a slight smear

of grease can conceal an incipient failure. When a component is to be checked dimensionally against figures quoted for it,

use the correct equipment (surface plates, micrometers, dial gauges etc.) in serviceable condition. The use of makeshift

equipment can be dangerous. Reject a component if its dimensio ns are outside the limits quoted, or if damage is apparent.

A part may be refitted if its critical di mension is exactly to the limit size and it is otherwise satisfactory. Use Plastigauge 12

Type PG-1 for checking bearing surface clearance, e.g. big end bearing shell to crank jour nal. Instructions for the use of

Plastigauge and a scale giving bearing clearances in steps of 0.0025 mm (0.0001 in) are supplied with the package.

Safety

Precautions

• WAR

NINGS:

WORKING ON THE FUEL SYSTEM RESULTS IN FUEL AND FUEL VAPOUR BEING PRESENT IN THE ATMOSPHERE. FUEL

VAPOUR IS EXTREMELY FLAMMABLE, HENCE GREAT CARE MUST BE TAKEN WHILST WORKING ON THE FUEL SYSTEM.

ADHERE STRICTLY TO THE FOLLOWING PRECAUTIONS:

DO

NOT SMOKE IN THE WORK AREA.

DISP

LAY 'NO SMOKING' SIGNS AROUND THE AREA.

DISCONNECT TH

E BATTERY BEFORE WORKING ON THE FUEL SYSTEM.

DO NOT CONNEC

T/DISCONNECT ELECTRICAL CIRCUITS

, USE ELECTRICAL EQUIPMENT OR OTHER TOOLS OR

ENGAGE IN WORKING PRACTICES WHICH IN ANY WAY MAY RESULT IN THE PRODUCTION OF SPARKS.

ENS

URE THAT A CO2 FIRE EXTINGUISHER IS CLOSE AT HAND.

ENS

URE THAT DRY SAND IS AVAILABLE TO SOAK UP ANY FUEL SPILLAGE.

EMP

TY FUEL USING SUITABLE FIRE PROOF EQUIPMENT IN

TO AN AUTHORIZED EXPLOSION PROOF CONTAINER.

DO NOT EMP

TY FUEL WHILE WORKING IN A WORKSHOP OR A PIT.

ENS

URE THAT WORKING AREA IS WELL VENTILATED.

ENS

URE THAT ANY WORK ON THE FUEL SYSTEM IS ON

LY CARRIED OUT BY EXPERIENCED AND WELL QUALIFIED

MAINTENANCE PERSONNEL.

ENS

URE THAT FUME EXTRACTION EQUIPMENT IS USED WHERE APPROPRIATE.

FUME EXTRACTION EQUIPMENT MUST BE IN OPERATION WHEN SOLVENTS ARE USED E.G. TRICHLOROETHANE,

WHITE SPIRIT, SBP3, METHYLENE CHLORIDE, PERCHLORETHY LENE. DO NOT SMOKE IN THE VICINITY OF VOLATILE

DEGREASING AGENTS.

General workshop practices:

Disc

onnect the grounded termin

al of the vehicle battery.

D

o not apply heat in an attempt to free seized nuts or fitt

ings; as well as causing damage to protective coatings,

there is a risk of damage from stray heat to electronic equipment and brake lines.

Keep oils and solven

ts away from naked flames and other sour

ces of ignition.

Adhere str

ictly to handling and safety inst

ructions given on containers and labels.

E

nsure that a suitab

le form of fire extinguisher is conveniently located.

Wh

en using electrical tools and equipment, inspect the power

lead for damage and check that it is properly earthed.

D

o not leave tools, equipment, spilt oil etc. around the work area.

Working beneath a vehicle:

Wh

enever possible, use a ramp or

pit in preference to jacking.

Posit

ion chocks at the wheels as we

ll as applying the parking brake.

N

ever rely on a jack alone to support a

vehicle; use axle stands, or blocks care fully placed at the jacking points, to

provide a rigid location.

Ch

eck that any lifting equipment used has adeq

uate capacity and is fully serviceable.

Working on air conditioning systems:

D

o not disconnect any pipes of the refrigeration system

unless you are trained and instructed to do so; a refrigerant

is used which can cause blindness if allowed to come into contact with the eyes.

Health Protection

P

rolonged and repeated contact with mineral oil will result in the removal of natural oils from the skin, leading to dryness,

In

spection

Page 51 of 2490

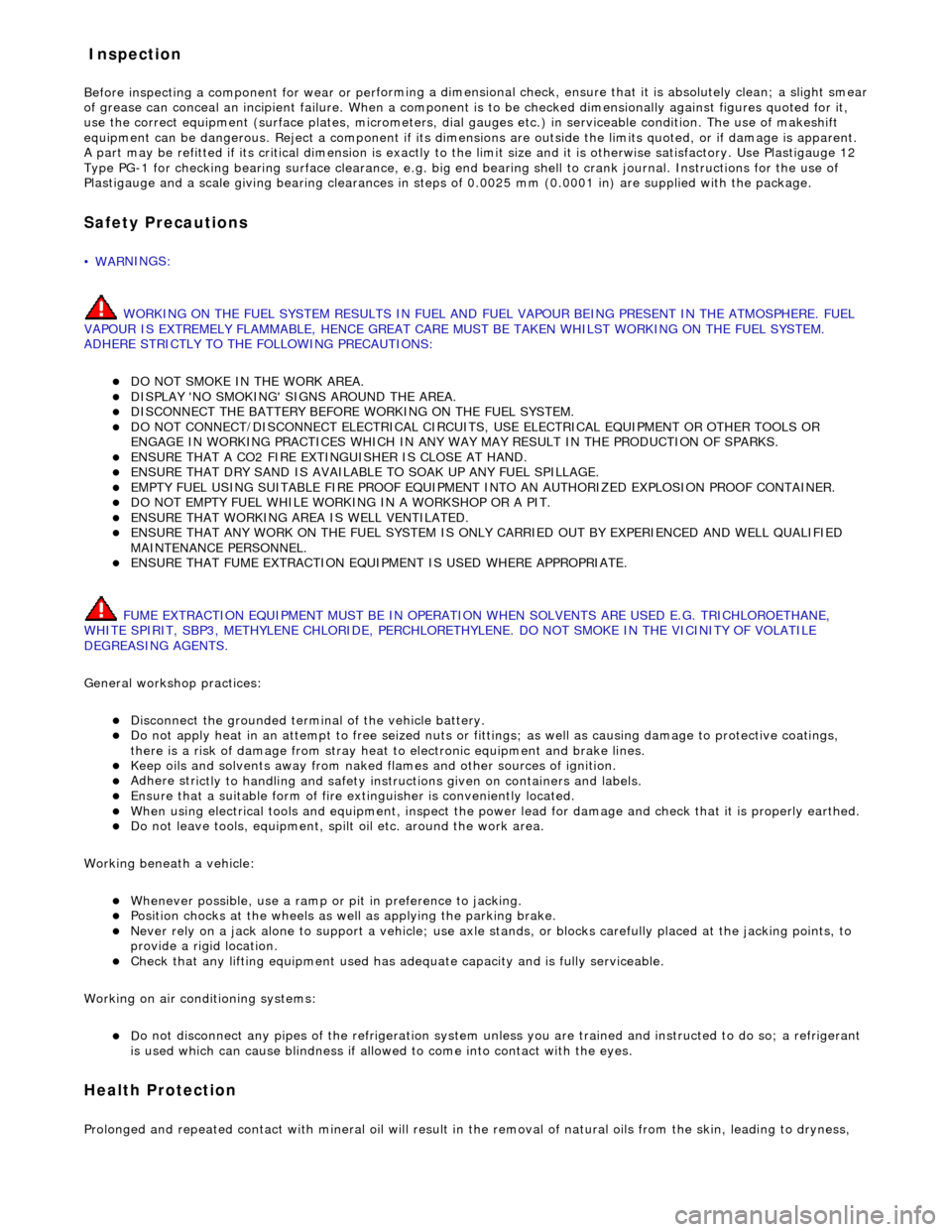

Jacking and Lifting - Jacking

Description an

d Operation

The vehicle jack and wheel chock are stored in the trunk as part of the vehicle toolkit.

Use of the vehicle jack and workshop jacks is desc ribed in the general procedures in this section.

Jacking Points

The four vehicle jacking points:

Are situ

ated below the body side members.

Are l

ocated behind each front wheel

and in front of each rear wheel.

Consist

of a square-section socket, pr

otected by a rubber cover, to provide positive engagement with the vehicle

jack.

Provi

de the support points for the four

lifting pads of a wheel-free lift.

Page 53 of 2490

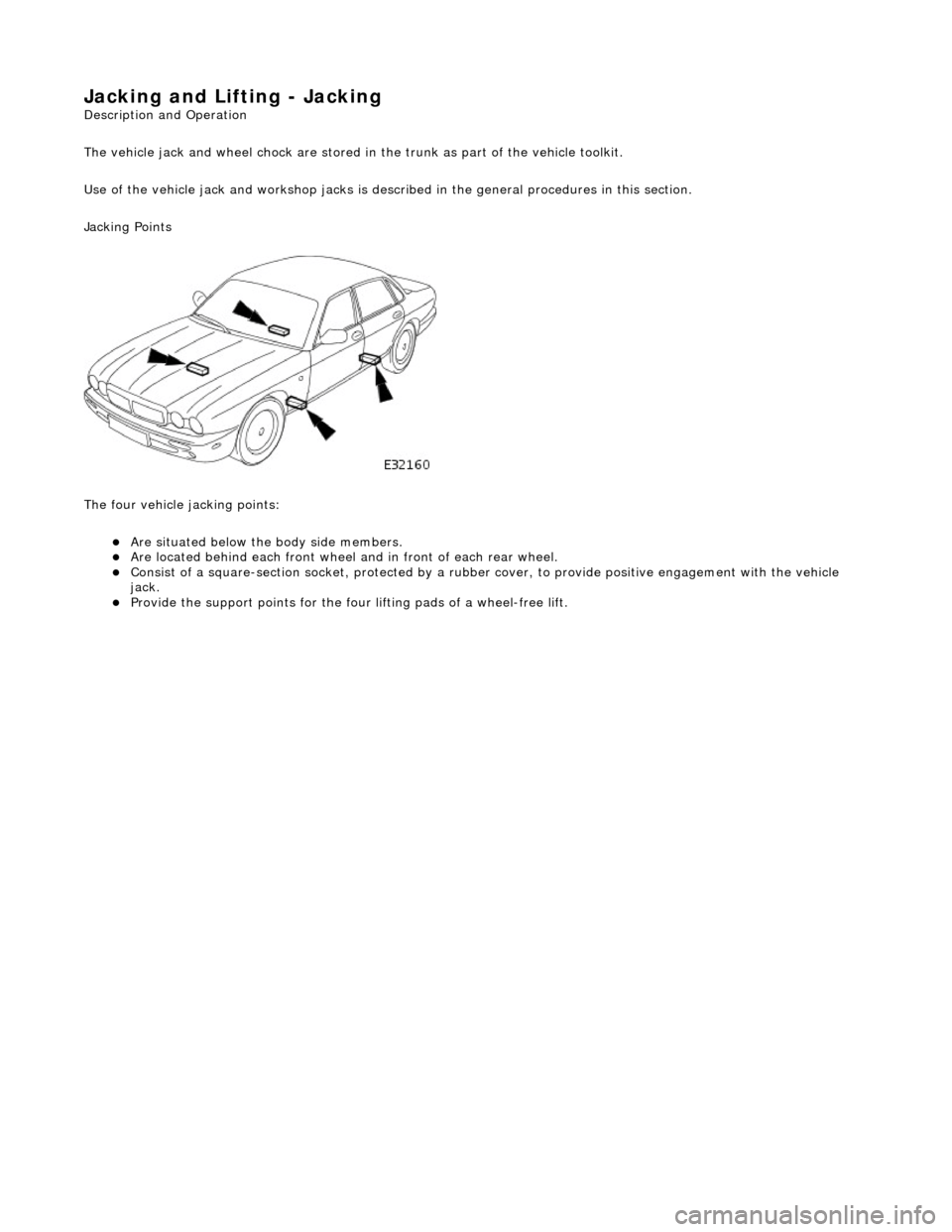

Jacking and Lifting - Vehicle Recovery

Description an

d Operation

• NOTE: Prior to recovery, ensure that the vehicle keys are available and the security system disarmed.

Vehicle recovery methods are:

By fl

at-bed transporter.

By rear suspended tow.

By emergency to

wing for

very short distances.

Gears

hift Interlock

The

gear selector lever can only be moved

from the Park position by turning the igni tion key to position II and depressing

the brake pedal.

To remove the key from the ignition switch, the gear select or lever must be moved to the Park position. With the key

removed, the gear selector is locked in the Park position.

The selector lever can be manually unlocked from the Park position in the event of electrical failure or when moving the

vehicle without power. Refer to the general procedure in this section.

Transporter or Trailer Recovery

When the vehicle is being recove red by transporter or trailer:

The parking brake must be

be applied and the wheels chocked.

The

gear selector lever must be in Ne

utral. Do not select Park as the park ing lock mechanism may be damaged by

the forward and backward rocking motion of the vehicle.

The ve

hicle must be securely tied down to the transporter or

trailer. There are four tie-down brackets on the vehicle

underbody. Do not use the vehicle towing points or crossbeam tie bar.

Page 57 of 2490

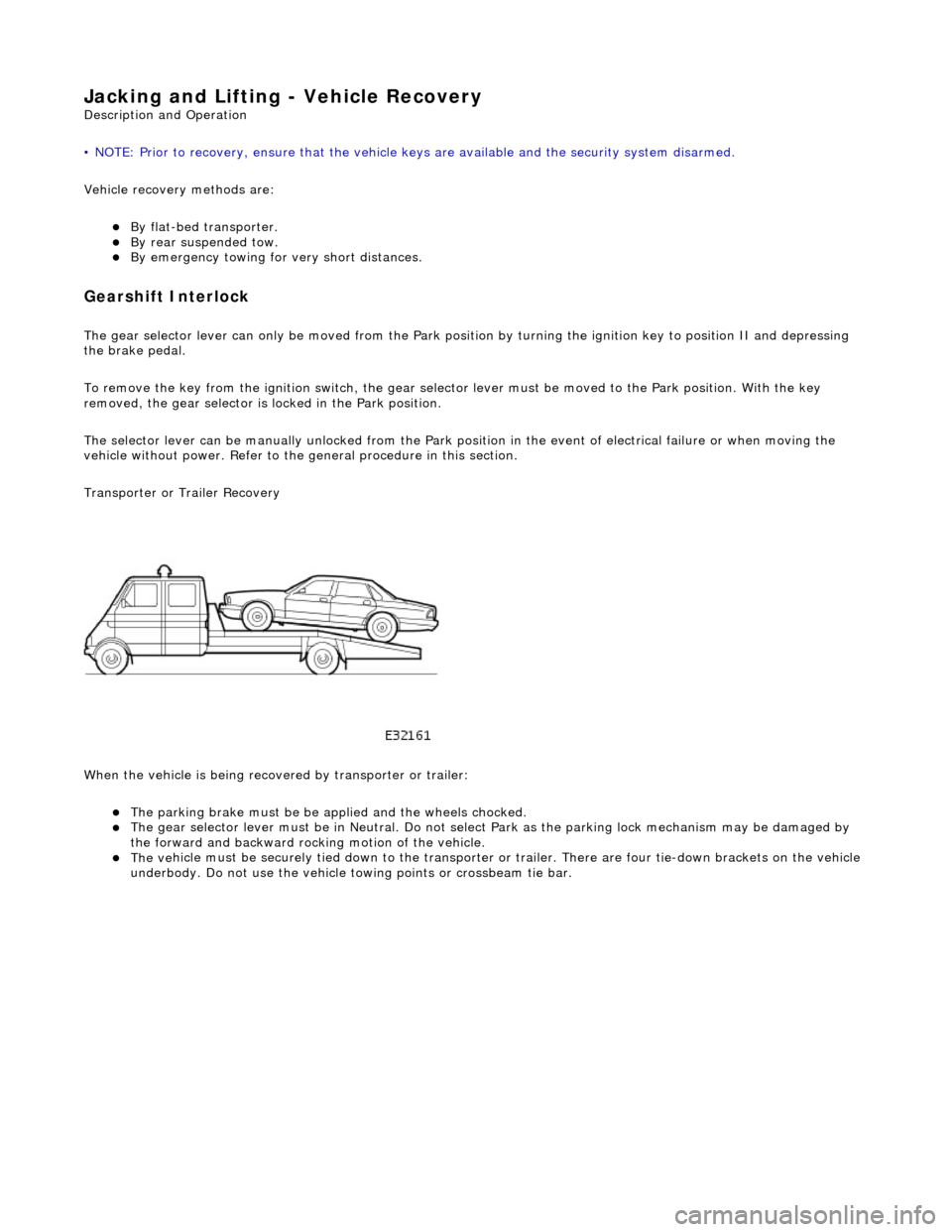

Jacking and Lifting - Using the Workshop Jack

Gen

eral Procedures

1.

To raise

both

front wheels:

P

osition the jack centrally

under the front suspension

crossbeam.

Pla

ce a block of wood between the jack head and the

crossbeam.

R

aise the vehicle.

P

lace suitable vehicle stands

in position at the front

vehicle jacking points.

Lo

wer the vehicle onto the vehicle stands.

2. To raise

both rear wheels:

P

osition the jack centrally

under the rear suspension

subframe.

Pla

ce a block of wood between the jack head and the

subframe.

R

aise the vehicle.

P

lace suitable vehicle stands in

position at the rear vehicle

jacking points.

Lo

wer the vehicle onto the vehicle stands.

Page 1672 of 2490

Exhaust System - Intermediate Muffler LH4.0L NA V8 - AJ27/3.2L NA V8 -

AJ26

Re mo

val and Installation

Remova

l

1.

Ra

ise the vehicle on a four-post ramp.

2. Raise the rear of the vehicle bo dy and support on two stands,

located under the re ar jacking points.

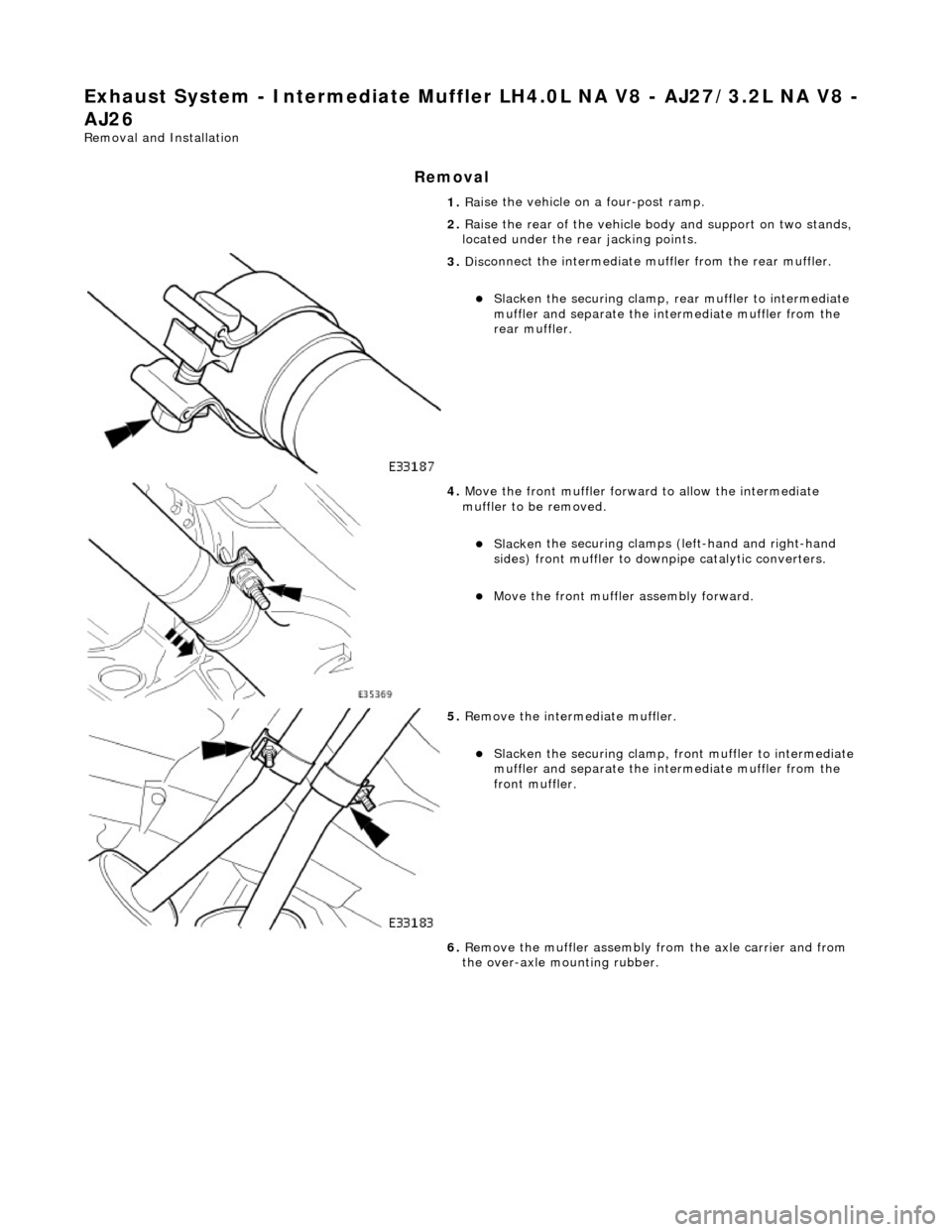

3. Disc

onnect the intermediate

muffler from the rear muffler.

Slacken the securi

ng clamp, re

ar muffler to intermediate

muffler and separate the in termediate muffler from the

rear muffler.

4. Move the front muf f

ler forwar

d to allow the intermediate

muffler to be removed.

Sl acke

n the securing clamps (left-hand and right-hand

sides) front muffler to downpipe catalytic converters.

Move the front muf f

ler

assembly forward.

5. Re

move the intermediate muffler.

Sl

acken the securi

ng clamp, front muffler to intermediate

muffler and separate the in termediate muffler from the

front muffler.

6. Remove the muffler assembly from the axle carrier and from

the over-axle mounting rubber.

Page 1674 of 2490

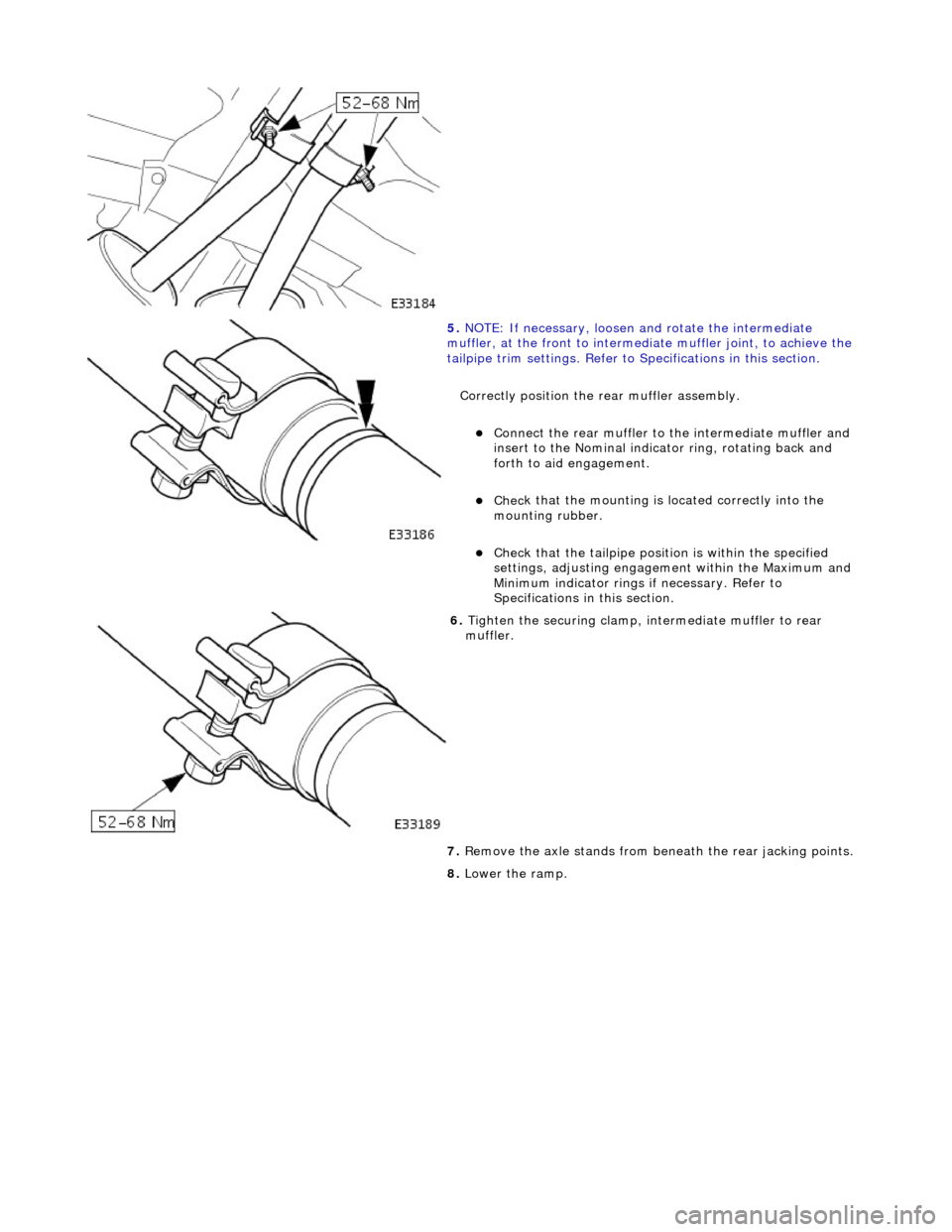

5.

NO TE

: If necessary, loosen and rotate the intermediate

muffler, at the front to intermediate muffler joint, to achieve the

tailpipe trim settings. Refer to Specifications in this section.

Correctly position the rear muffler assembly.

Connect the rear muffl

er to the intermediate muffler and

insert to the Nominal indicator ring, rotating back and

forth to aid engagement.

Chec k

that the mounting is located correctly into the

mounting rubber.

Chec k

that the tailpi

pe position is wi thin the specified

settings, adjusting engageme nt within the Maximum and

Minimum indicator rings if necessary. Refer to

Specifications in this section.

6. Tigh te

n the securing clamp, in

termediate muffler to rear

muffler.

7. Remove the axle stands from be neath the rear jacking points.

8. Lower the ramp.

Page 1675 of 2490

Exhaust System - Intermediate Muffler LH4

.0L SC V8 - AJ26

Re

moval and Installation

Remov

al

Installation

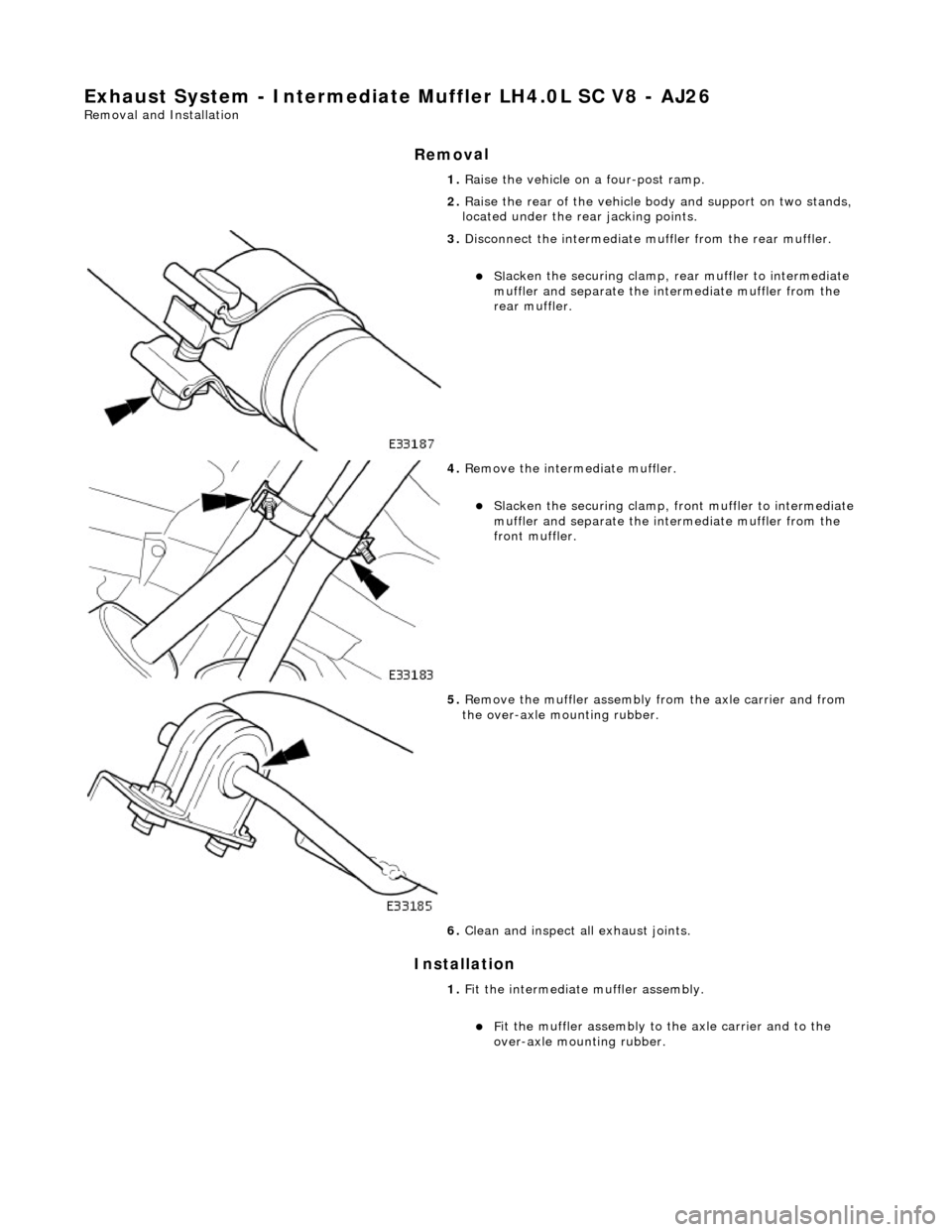

1. R

aise the vehicle on a four-post ramp.

2. Raise the rear of the vehicle bo dy and support on two stands,

located under the re ar jacking points.

3. Di

sconnect the intermediate

muffler from the rear muffler.

Sl

acken the securing clamp, re

ar muffler to intermediate

muffler and separate the in termediate muffler from the

rear muffler.

4. R

emove the intermediate muffler.

Sl

acken the securing clamp, front muffler to intermediate

muffler and separate the in termediate muffler from the

front muffler.

5. R

emove the muffler assembly

from the axle carrier and from

the over-axle mounting rubber.

6. Clean and inspect al l exhaust joints.

1. Fit the intermediate muffler assembly.

F

it the muffler assembly to the axle carrier and to the

over-axle mounting rubber.

Page 1677 of 2490

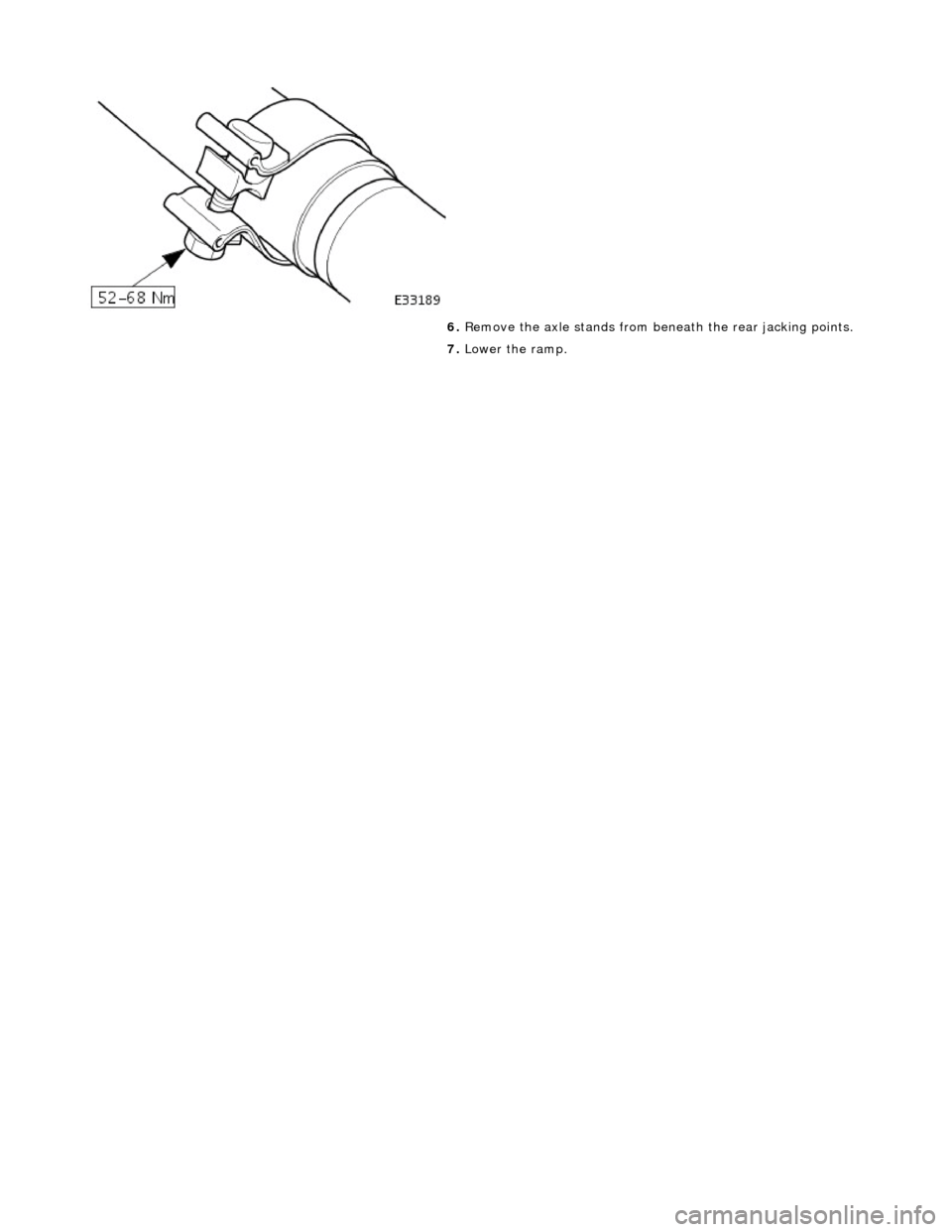

6.

R

emove the axle stands from be

neath the rear jacking points.

7. Lower the ramp.

Page 1678 of 2490

Exhaust System - Intermediate Muffler RH4.0L NA V8 - AJ27/3.2L NA V8 -

AJ26

Re mo

val and Installation

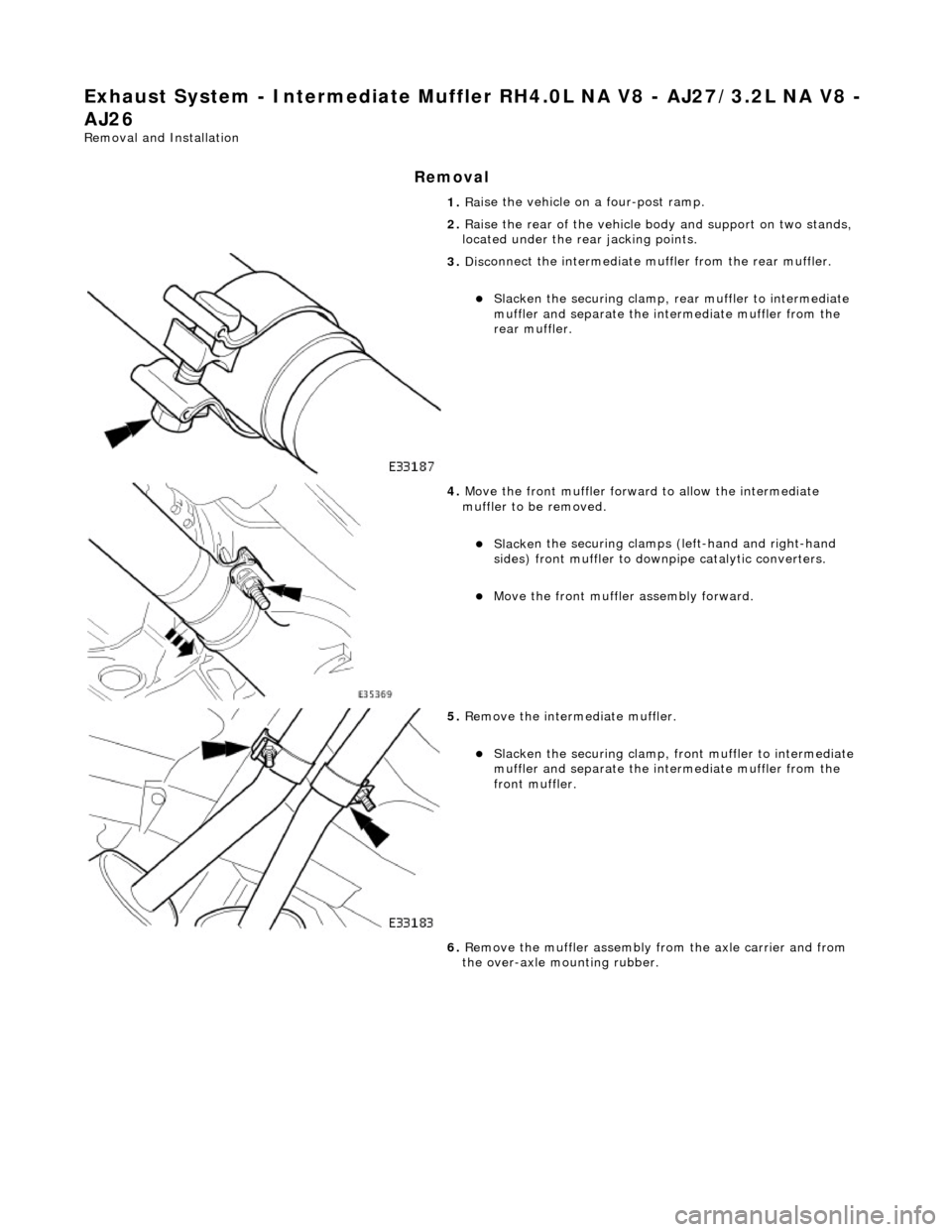

Remova

l

1.

Ra

ise the vehicle on a four-post ramp.

2. Raise the rear of the vehicle bo dy and support on two stands,

located under the re ar jacking points.

3. Disc

onnect the intermediate

muffler from the rear muffler.

Slacken the securi

ng clamp, re

ar muffler to intermediate

muffler and separate the in termediate muffler from the

rear muffler.

4. Move the front muf f

ler forwar

d to allow the intermediate

muffler to be removed.

Sl acke

n the securing clamps (left-hand and right-hand

sides) front muffler to downpipe catalytic converters.

Move the front muf f

ler

assembly forward.

5. Re

move the intermediate muffler.

Sl

acken the securi

ng clamp, front muffler to intermediate

muffler and separate the in termediate muffler from the

front muffler.

6. Remove the muffler assembly from the axle carrier and from

the over-axle mounting rubber.

Page 1680 of 2490

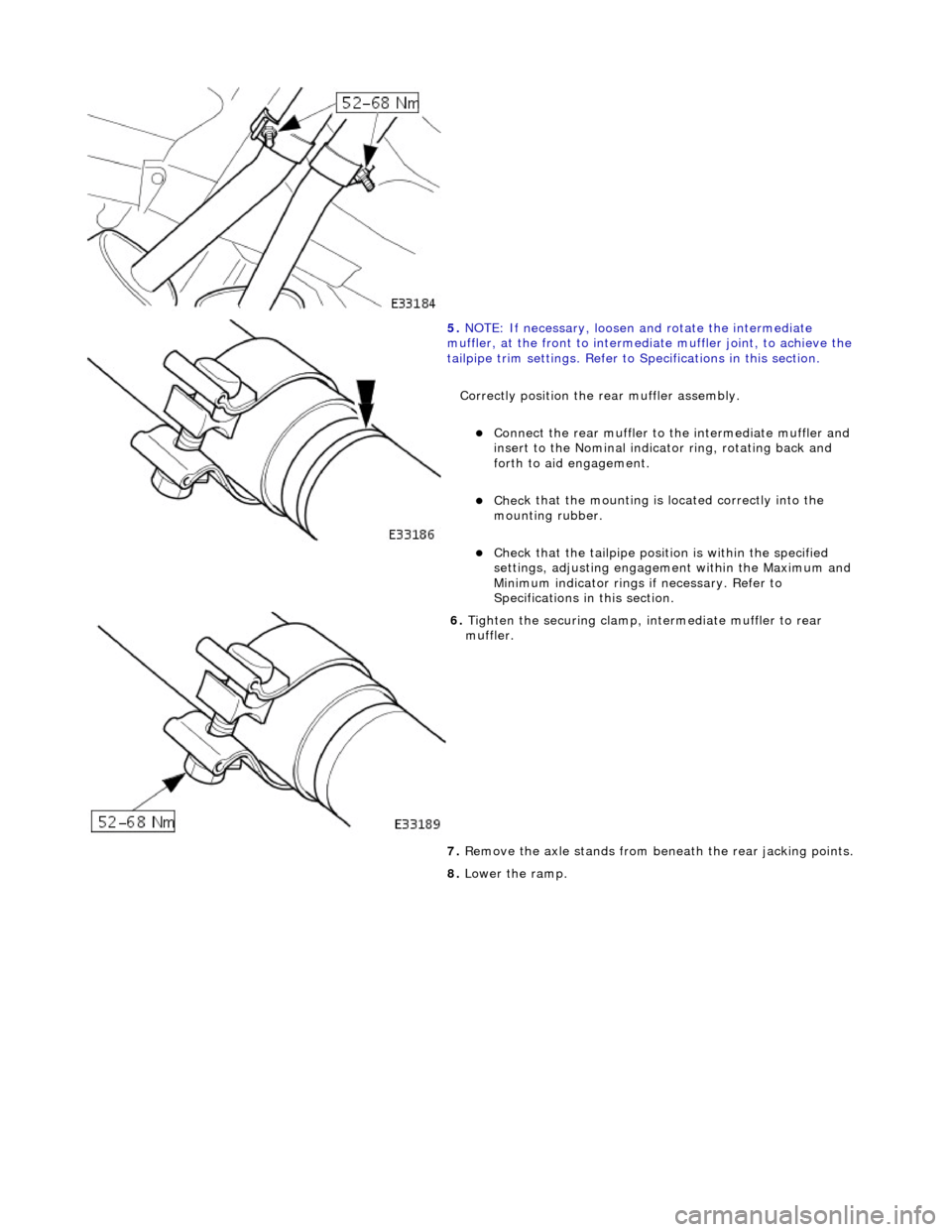

5.

NO TE

: If necessary, loosen and rotate the intermediate

muffler, at the front to intermediate muffler joint, to achieve the

tailpipe trim settings. Refer to Specifications in this section.

Correctly position the rear muffler assembly.

Connect the rear muffl

er to the intermediate muffler and

insert to the Nominal indicator ring, rotating back and

forth to aid engagement.

Chec k

that the mounting is located correctly into the

mounting rubber.

Chec k

that the tailpi

pe position is wi thin the specified

settings, adjusting engageme nt within the Maximum and

Minimum indicator rings if necessary. Refer to

Specifications in this section.

6. Tigh te

n the securing clamp, in

termediate muffler to rear

muffler.

7. Remove the axle stands from be neath the rear jacking points.

8. Lower the ramp.