rear seat JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 3 of 2490

Rear Toe Adjustment (57.65. 08)

Whee

l

Bearing Circlip Inspection

Wheel Bearing Inspection

204‐01: Front Suspension

Specification

Description and Operation

Front Suspension

Removal and Installation

Ball Joint (60.15.02)

Rear Lower Arm (60.35.54)

Rear Lower Arm Bushing (60.35.56)

Front Shock Absorber (60.30.04)

Spring

Spring Seat (60.20.03)

Front Sta

bilizer Bar (60.10.01)

Front Stabilizer Bar Bushing (60.10.04)

Front Stabilizer Bar Link (60.10.02)

Upper Arm Bushing

Front Wheel Bearing (60.25.40)

Wheel Hub

Wheel Knuckle (60.25.23)

Wheel Knuckle and Wheel Hub Assembly (60.25.38.90)

Wheel Knuckle and Wheel Hub Assembly Conversion (60.25.43)

204‐02: Rear Suspension

Specif

ication

Description and Operation

Rear Suspension

Removal and Installation

Axle Bump Stop (64.30.15)

Rear Suspension and Axle Assembly (64.25.01)

Rear Shock Absorber (64.30.02)

Shock Absorber Lower Bushing (64.30.39)

Spring (64.20.01)

Rear Stabilizer Bar (64.35.08) ‐ 4.0L SC V8 ‐ AJ26

Rear Stabilizer Bar Bushing (64.35.18) ‐ 4.0L SC V8 ‐ AJ26

Page 27 of 2490

419:

Electronic Featu r

e

Group

419

‐10:

Multifunction Electronic Modules

Removal

and Installation

Driver

Seat Module (DSM) (86.75.28)

5: Body and Paint

501: Body and Paint

501‐00: Body System ‐ Gen

eral Information

Specification

Description and Operation

Body

501‐02: Front End Body Panels

Description and Operation

Front End Body Panels

Removal and Installation

Cowl Panel Grille (76.10.01) (76.43.39)

Driver Side Bulkhead Cover (76.11.34)

Passenger Side Bulkhead Cover (76.11.33)

Radiator Grille Opening Panel (76.10.06)

Radiator Grille Ope

ning Panel Reinforcement (76.11.24)

Radiator Splash Shield (76.22.90)

501‐03: Body Closures

Description and Operation

Body Closures

General Procedures

Hood Alignment (76.16.02)

Diagnosi

s

and Testing

(FDM)

Front

Door Module

(86.80.34)

Rear

(RDM)

Door

Module

Page 30 of 2490

501‐10: Seating

Specificatio

n

Description and Operation

Seats

Removal and Installation

Front Seat (76.70.01)

Front Seat Backrest (76.70.06)

Front Seat Backrest Cover (76.70.15)

Front Seat Backrest Heater Mat (86.75.14)

Front Seat Backrest Trim Panel (76.70.03)

Front Seat Cushion (76.70.11)

Front Seat Cushion Cover (76.70.33)

Front Sea

t Cushion Heater Mat (86.75.13)

Front Seat Head Restraint (76.70.14)

Front Seat Head Restraint Motor (86.75.17)

Front Seat Recliner Motor (86.75.04)

Front Seat Track (76.70.20)

Front Seat Track Motor (86.75.33)

Lumbar Motor (86.75.12)

Rear Seat Armrest (76.70.39)

Rear Seat Backrest (76.70.38)

Rear Seat Backrest Cover (76.70.48) (78.90.12)

Rear Seat Backrest Heater Mat (86.75.35)

Rear Seat Cushio

n (76.70.37)

Rear Seat Cushion Cover (76.70.47)

Rear Seat Cushion Heater Mat (86.75.37)

Rear Seat Head Restraint (76.70.56)

Rear Seat Track

Seat Control Switch (86.75.23)

501‐11: Glass, Frames and Mechanisms

Description and Operation

Glass, Fra

mes and Mechanisms

Removal and Installation

Door Window Control Switch Bulb (86.46.12)

Front Door Window Glass (76.31.01)

Front Door Window Glass Weatherstrip (76.40.28)

Page 70 of 2490

Upper

Wishbones

Each

upper wi

shbone assembly is a on

e-piece steel forging incorporating:

A pres

s-fit ball joint.

Press-fi

t bushes for location of the upper fulcrum bolt.

Lower Wishbones

Each l

o

wer wishbone comprising

forged steel front and rear arms bolted together, incorporates:

A p

ress-fit ball joint in the outer extremity of the rear arm.

Press-f

i

t bushes for location of the lower fulcrum bolts

Locati

on for the shock absor

b

er lower mounting plates.

Vertica l Links

The vertical

links are of forged steel

wi

th integral steering arms. Each is suppo rted between the upper and lower wishbones

by two ball joints and carries:

Front hub

Brake ca

liper and disc shield assembly

ABS se

nsor

.

Front Hub

s

Each f

o

rged steel front hub accommodates sealed for life cartridge

type wheel bearings, and carries:

The brake rotor assembl

y.

A

h

ub nut with toothed, integral ABS rotor.

Su

s

pension spring pi

n locking device.

Front Road

Springs

The road spri

ng

s are of coil type with their

rating dependent upon vehicle specification

Ea

ch spring is installed between the suspension crossbeam location and the lower wishbone spring pan.

Ru

bber seats ar

e installed betw

een the spring and the crossb eam and the spring pan.

Front Shock A

bsorbers

Th

e

shock absorbers are telescopic hydrau

lically operated units. Optional adaptive damping units incorporate a solenoid-

operated control valve at their upper extremity.

Each shoc

k absorber is installed between the lowe

r wishbone rear arm and a recess in the body.

The l

o

wer end of the shock absorber is se

cured to plates on the wishbone by a bolt that also serves as a pivot.

The u

pper en

d of each shock absorber is secured to the body location by a single nut.

Front Sta

b

ilizer Bar

A

front stabil

izer bar installed on all vehicles

is rated according to suspension specification.

Opera

tion

As each road wheel r

i

ses, move

ment is transmitted through the vertical link assembly to the lower wishbone. The resulting

rise of the wishbone compresses the road spring and partially telescopes the shock absorber. During this action, the spring

absorbs associated shocks and the shock absorber minimizes sprin

g os c

illation.

Du

ring cornering, vehicle weight

is transferred to the outer road wheel with a resulting tendency for the inner wheel to lift.

The stabilizer bar assists in minimizing this tendency by transf erring a proportion of potential lift of the inner wheel to the

outer wheel. This result s in enhanced body stability with improved corner ing capabilities.

Page 75 of 2490

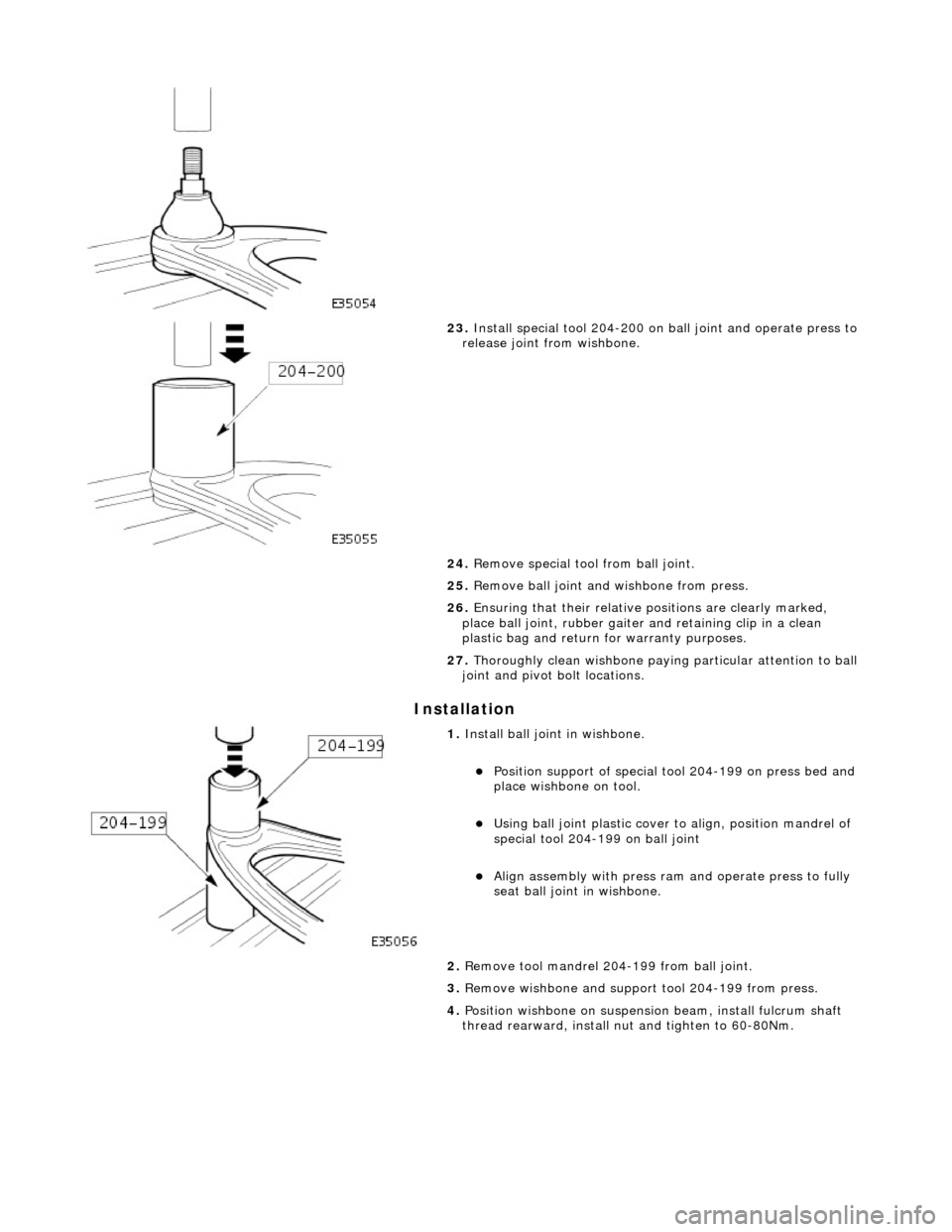

I

nstallation

23

.

Install special tool 204-200 on ball joint and operate press to

release joint from wishbone.

24. Remove special tool from ball joint.

25. Remove ball joint and wishbone from press.

26. Ensuring that their relative positions are clearly marked,

place ball joint, rubber gaiter and retaining clip in a clean

plastic bag and return for warranty purposes.

27. Thoroughly clean wishbone paying particular attention to ball

joint and pivot bolt locations.

1. Inst

all ball joint in wishbone.

Pos

ition support of special tool 204-199 on press bed and

place wishbone on tool.

U

sing ball joint plastic cover to align, position mandrel of

special tool 204-199 on ball joint

Ali

gn assembly with press ram and operate press to fully

seat ball joint in wishbone.

2. Remove tool mandrel 204-199 from ball joint.

3. Remove wishbone and support tool 204-199 from press.

4. Position wishbone on suspensi on beam, install fulcrum shaft

thread rearward, install nu t and tighten to 60-80Nm.

Page 132 of 2490

2. Apply a su

itable lubricant to exterior of each half-bush.

3. Install soft covers to vise jaws.

4. Install half-bush

/spacer tu

be assembly in wishbone.

1. Align half-bush/spacer tube assembly with wishbone bore.

2. Position wishbone and half bush/spacer tube assembly between vise jaws.

Cl

ose vise jaws until half-bush/tube assembly is fully

seated in wishbone.

5. Remove wishbone from vise.

6. Instal

l second half-bush in wishbone.

1. Align and engage second half-bush with installed

spacer tube.

2. Position wishbone and half bush assembly between vise jaws.

Close

vise jaws until second half-bush assembly is fully

seated.

7. Remove wishbone from vise.

8. Following steps 1 to 7, install final bush assembly to wishbone.

9. Inst al

l wishbone on crossbeam.

Posi

ti

on wishbone on crossbeam.

Install

fulcrum shaft with threaded end rearward.

Install nut an

d tighten to 60-80Nm.

10. Remove wire temporarily securing vertical link to road spring.

Page 168 of 2490

Each r

oad spring and is located between the wishbone in

tegral spring seat and the body suspension turret.

Each shoc

k absorber unit is installed

co-axially within the road spring.

The lo

wer end of each shock absorber is secured to the

wishbone by a bolt which also functions as a pivot.

Adaptive damping is av

ailable as an option.

A

rear stabi

lizer bar is installed on

Supercharged and Sport Suspension models . Mounted at the rear of the wishbone

tie assembly, the stabilizer bar is connected to the wishbone by short links.

Op era

tion

As each road wheel r

i

ses, move

ment is transmitted through th e hub carrier assembly to the wishbone and axle shaft. The

corresponding rise of the wishbone compre sses the road spring and partially telescopes the shock absorber. During this

action, the spring absorbs result ing shocks and the shock absorber minimizes spring oscillation.

During cornering, vehicle weight is transferred to the outer road wheel with a resulting tendency for the inner wheel to lift.

On Supercharged and Sport Suspension vehicl es, a rear stabilizer bar assists in minimizing this tendency by transferring a

proportion of potential lift of the inner wheel to the outer wheel. This results in enhanced body stability with improved

cornering capabilities.

Page 272 of 2490

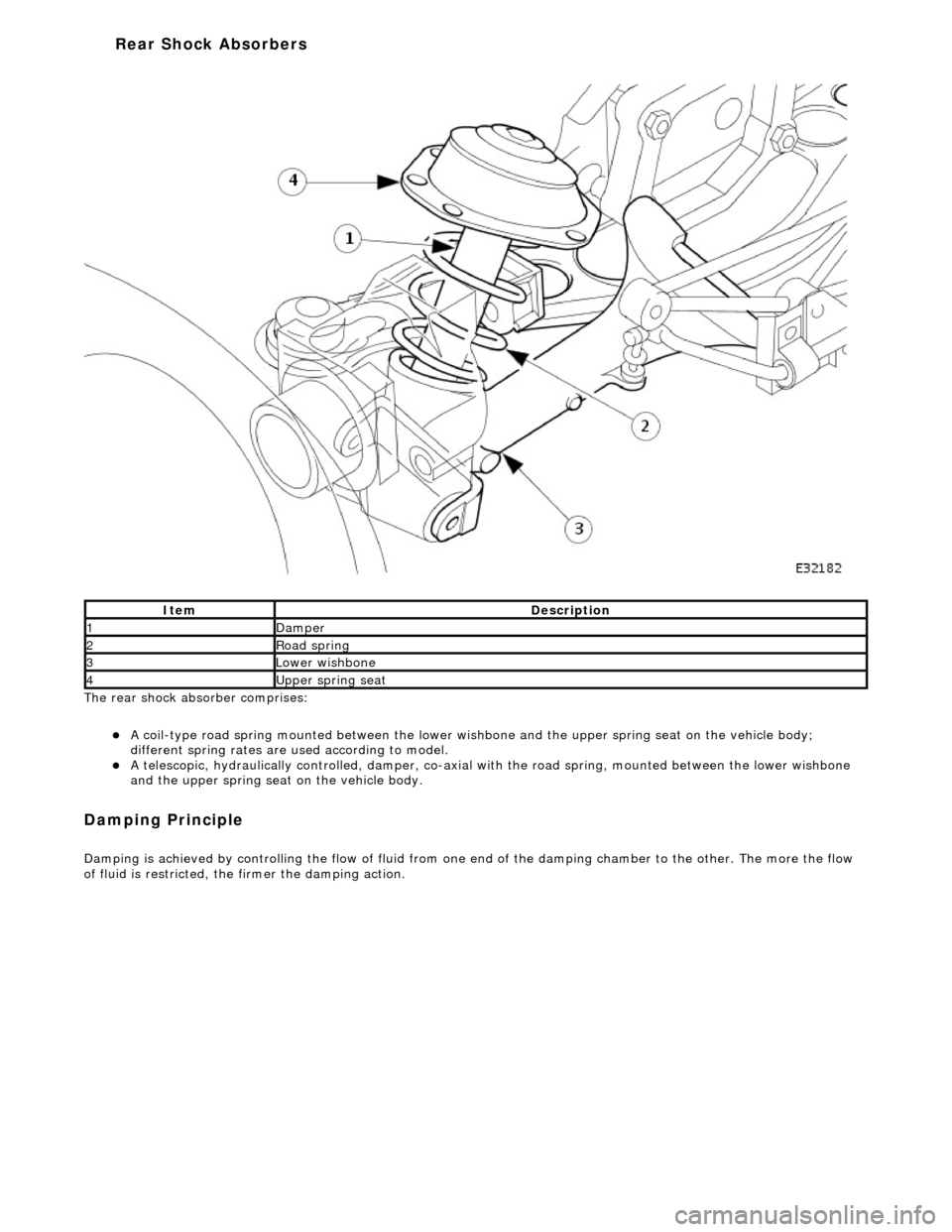

The rear shock ab

sorber comprises:

A

c

oil-type road spring mounted between the lower wish

bone and the upper spring seat on the vehicle body;

different spring rates are used according to model.

A te

lescopic, hydraulically controlled, damper, co-axial wi

th the road spring, mounted between the lower wishbone

and the upper spring seat on the vehicle body.

Damp

ing Principle

D

a

mping is achieved by controlling the flow of fluid from one

end of the damping chamber to the other. The more the flow

of fluid is restricted, the firmer the damping action.

Ite

m

De

scr

iption

1Dam

p

er

2Ro

ad s

pring

3Lower wishbon

e

4Upper sprin

g seat

Rear Shock A

b

sorbers

Page 343 of 2490

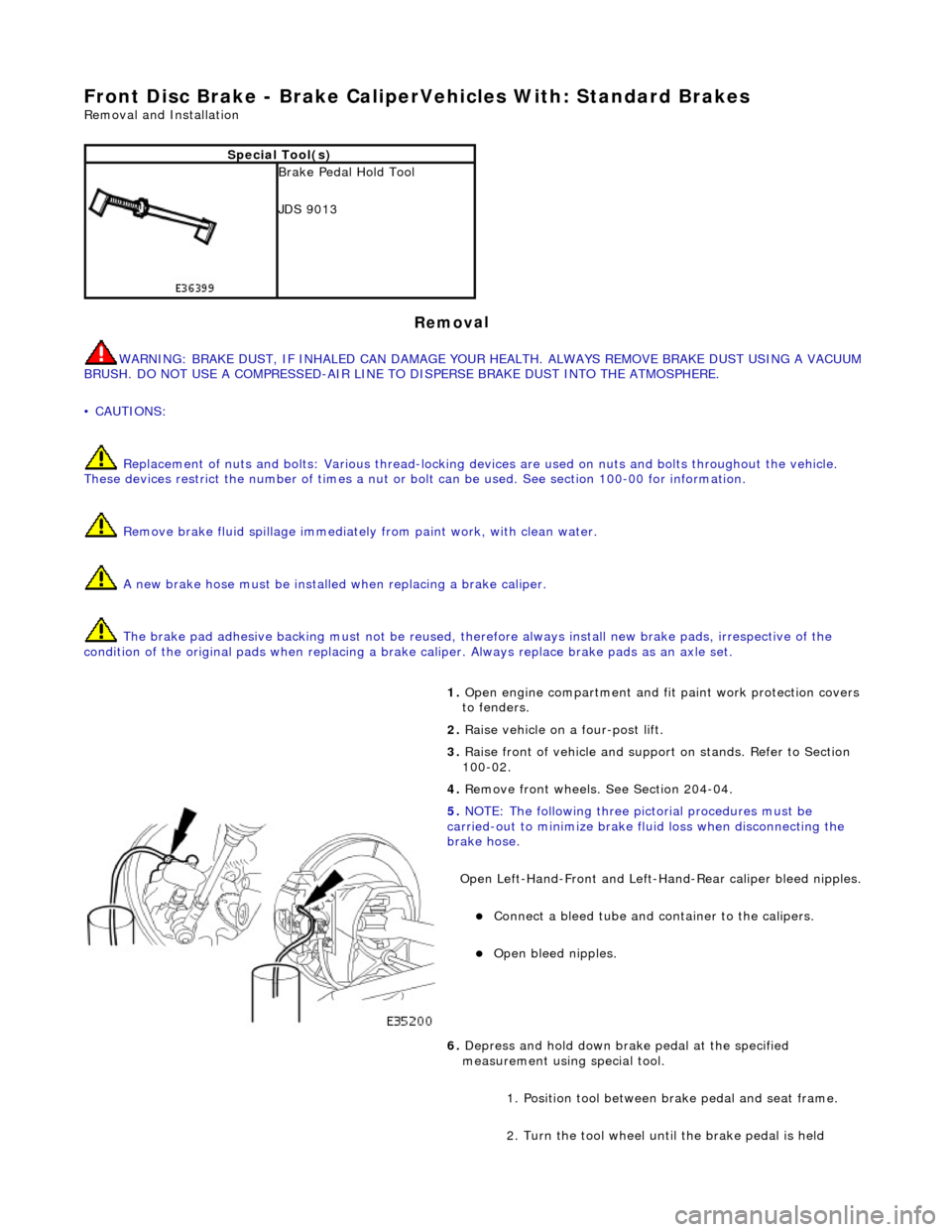

Front Disc Brake - Brake CaliperVehicles

With: Standard Brakes

Re

moval and Installation

Remov

al

W

ARNING: BRAKE DUST, IF INHALED CAN DAMAGE YOUR

HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

A new brake hose must be installe d when replacing a brake caliper.

The brake pad adhesive backing must not be reused, therefore always install new brake pads, irrespective of the

condition of the original pads when replacing a brake caliper. Always replace brake pads as an axle set.

S

pecial Tool(s)

Brake Pedal

Hold Tool

JDS 9013

1. O

pen engine compartment and fit

paint work protection covers

to fenders.

2. Raise vehicle on a four-post lift.

3. Raise front of vehicle and support on stands. Refer to Section

100-02.

4. Remove front wheels. See Section 204-04.

5. NOTE

: The following three pictorial procedures must be

carried-out to minimize brake fl uid loss when disconnecting the

brake hose.

Open Left-Hand-Front and Left-H and-Rear caliper bleed nipples.

Connect

a bleed tube and co

ntainer to the calipers.

O

pen bleed nipples.

6. Depress and hold down brak e pedal at the specified

measurement using special tool.

1. Position tool between brake pedal and seat frame.

2. Turn the tool wheel unti l the brake pedal is held

Page 368 of 2490

Rear Disc Brake - Brake CaliperVehicles W

ith: Standard Brakes

Re

mo

val and Installation

Remov

a

l

WA

RNING: BRAKE DUST, IF INHALED CAN DAMAGE YOUR

HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

The brake pad adhesive backing must not be reused, therefore always install new brake pads, irrespective of the

condition of the original pads when replacing a brake caliper. Always replace brake pads as an axle set.

Sp

ecial Tool(s)

Brake Pedal

H

old Tool

JDS 9013

1. Op

en luggage compartment lid and fit suitable paintwork

protection equipment.

2. Raise vehicle on a four-post lift.

3. Raise rear of vehicl e and support on stan ds. See Section 100-

02.

4. Remove rear wheel. See Section 204-04.

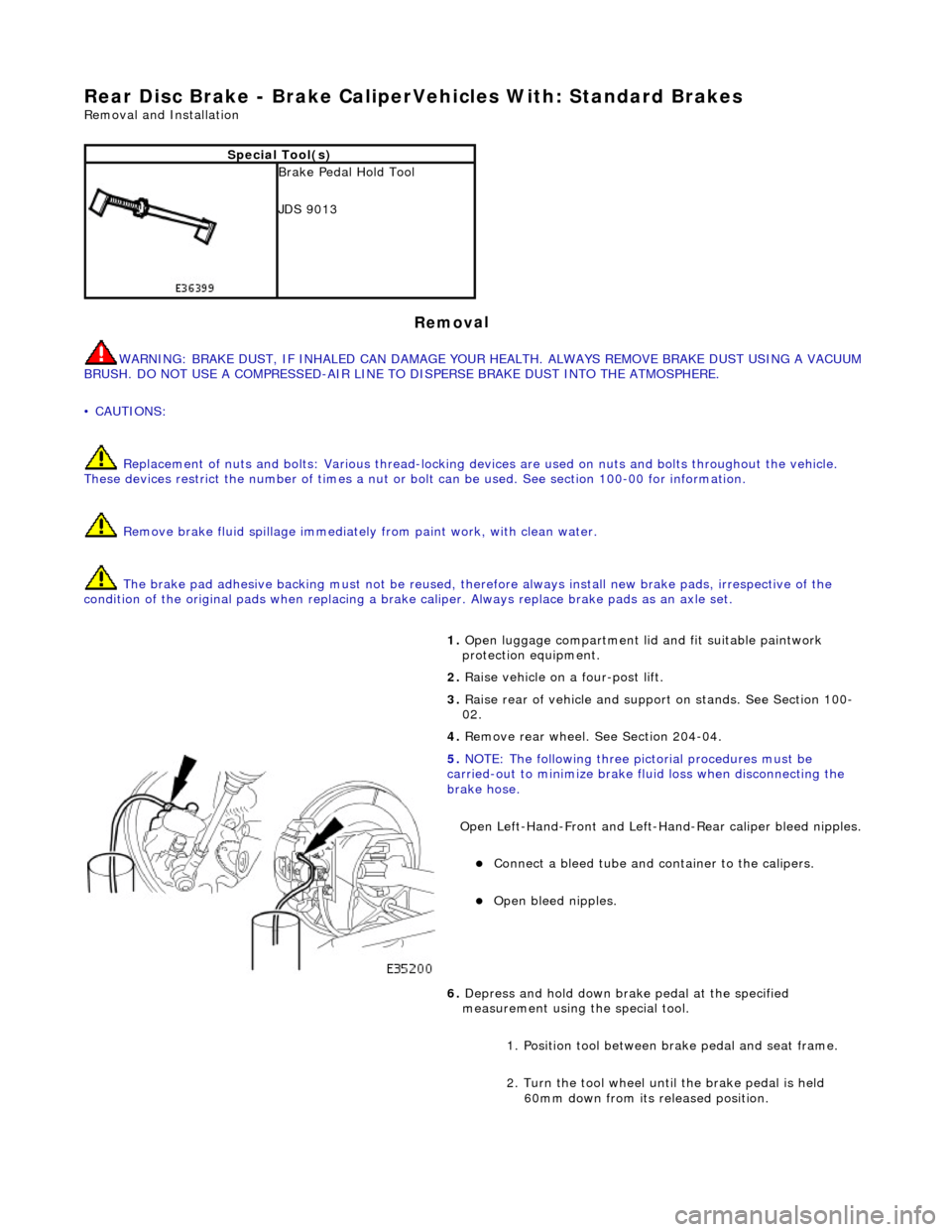

5. NOTE

: Th

e following three pictorial procedures must be

carried-out to minimize brake fl uid loss when disconnecting the

brake hose.

Open Left-Hand-Front and Left-H and-Rear caliper bleed nipples.

Connect a

bleed tube and co

ntainer to the calipers.

Op

en bleed nipples.

6. Depress and hold down brak e pedal at the specified

measurement using the special tool.

1. Position tool between brake pedal and seat frame.

2. Turn the tool wheel unti l the brake pedal is held

60mm down from its released position.