rear seat JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 394 of 2490

Parking Brake and Actuation - P

arking Brake Shoe

and Lining Adjustment

Gene

ral Procedures

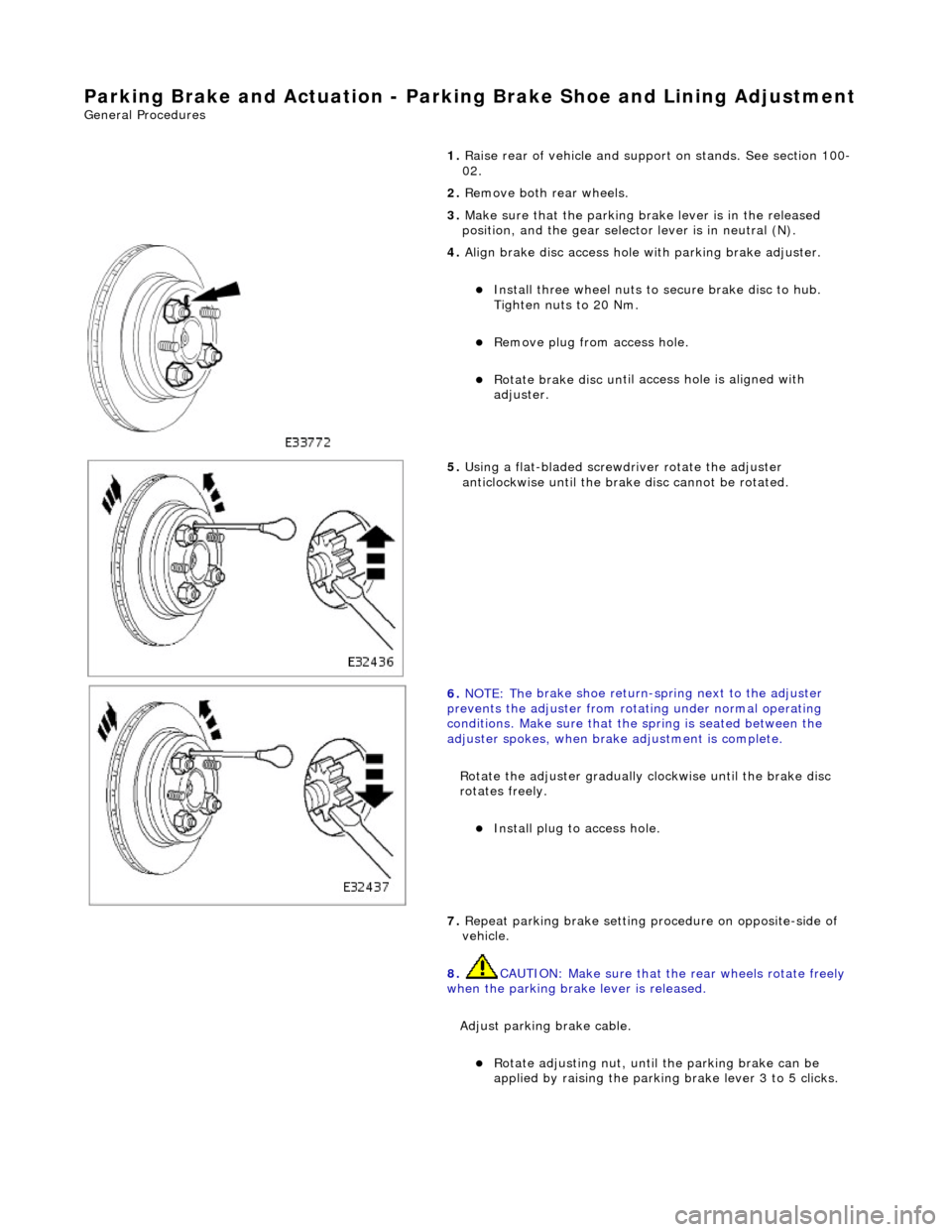

1. Raise rear of vehicle and support on stands. See section 100-

02.

2. Remove both rear wheels.

3. Make sure that the parking br ake lever is in the released

position, and the gear selector lever is in neutral (N).

4. Alig

n brake disc access hole

with parking brake adjuster.

Instal

l three wheel nuts to secure brake disc to hub.

Tighten nuts to 20 Nm.

R e

move plug from access hole.

Rotate

brake disc un

til ac

cess hole is aligned with

adjuster.

5. Using a flat-bladed screwdriv er rotate the adjuster

anti

clockwise until the brake disc cannot be rotated.

6. NOTE : Th

e brake shoe return-spring next to the adjuster

prevents the adjuster from rota ting under normal operating

conditions. Make sure that the spring is seated between the

adjuster spokes, when brake adjustment is complete.

Rotate the adjuster gradually clockwise until the brake disc

rotates freely.

Inst al

l plug to access hole.

7. Repeat parking brake setting pr ocedure on opposite-side of

vehicle.

8. CAUTION: Make sure that th e rear wheels rotate freely

when the parking brake lever is released.

Adjust parking brake cable.

Ro

tate adjusting nut, until the parking brake can be

applied by raising the parking brake lever 3 to 5 clicks.

Page 401 of 2490

I

nstallation

1

. Remove upper return spring.

2. Remove lower return spring.

9. Remove brake dust and clean components, see WARNING

above.

10. Repeat procedure to remove pa rking brake shoes on opposite

side of vehicle.

1. I

nstall brake shoes to vehicle.

Install brake shoes to parkin

g brake lever-me

chanism in

the arrangement shown.

2. N

OTE: Make sure retaining pin is seated correctly in backing

plate.

Install rear shoe retaining pin.

Align hu

b access hole.

Inst

all retaining pin.

3. Inst

all adjuster assembly.

Lubricate adjuster

mechanism

with appropriate grease.

Move

front shoe forwards.

Inst

all adjuster assembly.

4. NOTE: Make sure retaining pin is seated correctly in backing

Page 402 of 2490

plate.

Install front

shoe

retaining pin.

Align hu

b acc

ess hole.

Inst

al

l retaining pin.

5. Make sure brake shoes are seat ed correctly in adjuster and

lever mechanism.

6. Repeat procedure to install parking brake shoes on opposite

side of vehicle.

7. Install both rear br ake discs. Refer to operation 70.10.13.

8. Set parking brake. Refer to operation 70.35.37.

9. Fit rear wheels. See section 204-04.

10. Remove stands an d lower vehicle.

Page 409 of 2490

I

nstallation

10

.

Install plugs into master cylinder ports.

11. Clean components and mating surfaces.

1. Inst

all seals into master cylinder.

Re

move plugs.

Lubricate seals with

cl

ean brake fluid.

Inst

all seals.

2. Install

reservoir to master cylinder.

Re

move plugs.

Install

reservoir, making sure

reservoir is fully seated.

Inst

all locating pin.

3. Install pedal housing, brake booster and master cylinder

assembly. Refer to operation 70.35.39.

4. Install engine compartment rear cover. Refer to operation

76.11.35.

5. Reconnect battery ground cable (IMPORTANT, see operation

Page 413 of 2490

Lubricate seals with cl

ean brake fluid.

Inst

all seals.

2. Install

fluid reservoir to master cylinder.

R

emove plugs from reservoir

Install

reservoir, making sure

reservoir is fully seated.

Inst

all locating pin.

3. Inst

all master cylinder to brake booster.

Inst

all seal.

Inst

all master cylinder, make sure master cylinder rod

locates brake booster rod.

4. Inst

all and tighten nuts to 21-29 Nm.

5. Install pedal housing, brake booster and master cylinder

assembly. Refer to operation 70.35.39.

6. Install engine compartment rear cover. Refer to operation

76.11.35.

7. Connect battery ground cable (IMPORTANT, see operation

86.15.15 for further information).

8. Bleed brake system. Refer to operation 70.25.03.

9. Remove paint-work protection covers and close engine

com

partment.

Page 425 of 2490

Power Brake Actuatio

n - Brake Boos

ter and Brake Master Cylinder

Re

moval and Installation

Remov

al

• C

AUTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

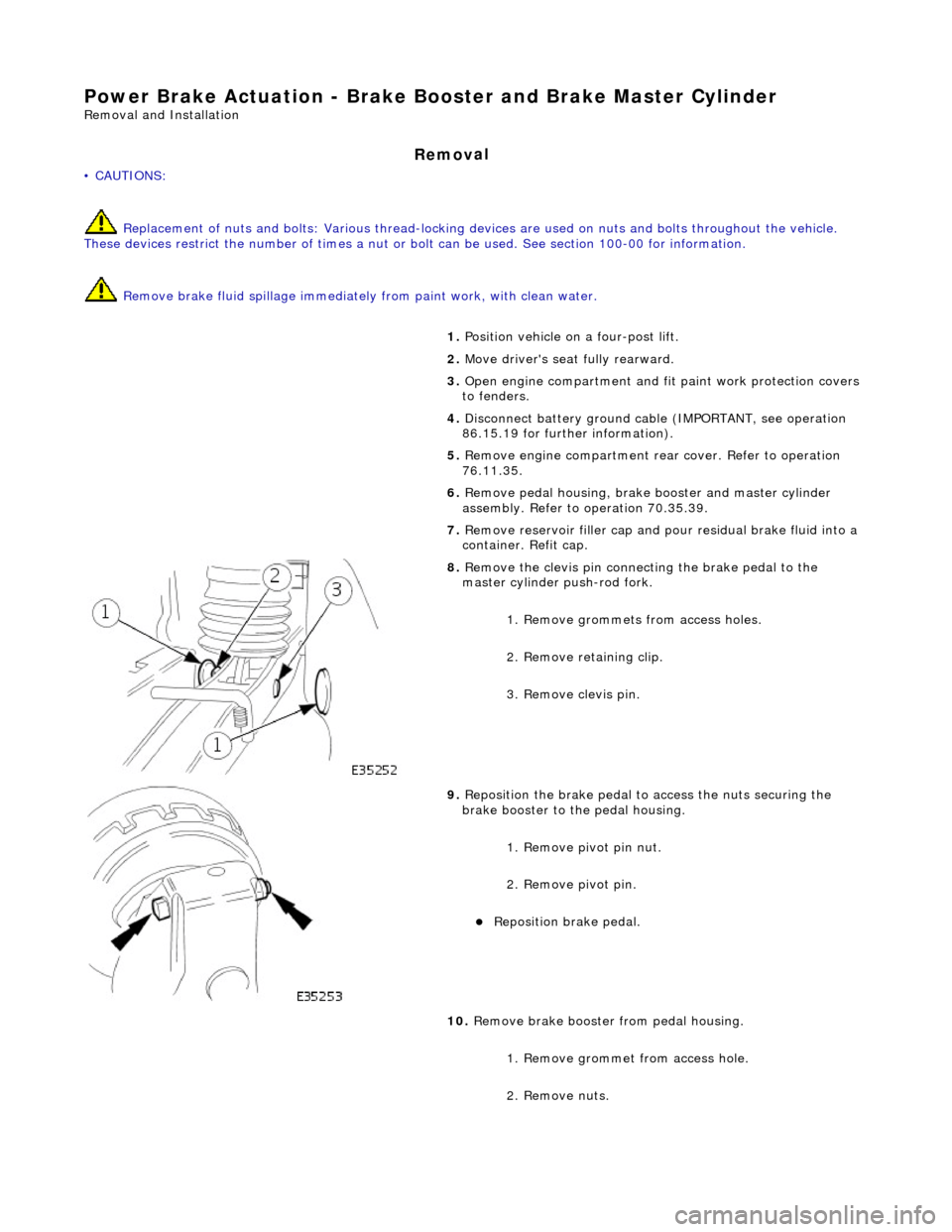

1. Position vehi

cle on a four-post lift.

2. Move driver's seat fully rearward.

3. Open engine compartment and fit paint work protection covers

to fenders.

4. Disconnect battery ground cable (IMPORTANT, see operation

86.15.19 for further information).

5. Remove engine compartment rear cover. Refer to operation

76.11.35.

6. Remove pedal housing, brake booster and master cylinder

assembly. Refer to operation 70.35.39.

7. Remove reservoir filler cap and po ur residual brake fluid into a

container. Refit cap.

8. R

emove the clevis pin connecting the brake pedal to the

master cylinder push-rod fork.

1. Remove grommets from access holes.

2. Remove retaining clip.

3. Remove clevis pin.

9. Re

position the brake pedal to access the nuts securing the

brake booster to the pedal housing.

1. Remove pivot pin nut.

2. Remove pivot pin.

Reposition brake pedal.

10

.

Remove brake booster from pedal housing.

1. Remove grommet from access hole.

2. Remove nuts.

Page 440 of 2490

Anti-Lock Control - Anti-Lock Brake System (ABS) Module

Remo

val and Installation

Remov

a

l

• C

A

UTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

Sp

ecial Tool(s)

Brake Pedal

H

old Tool

JDS 9013

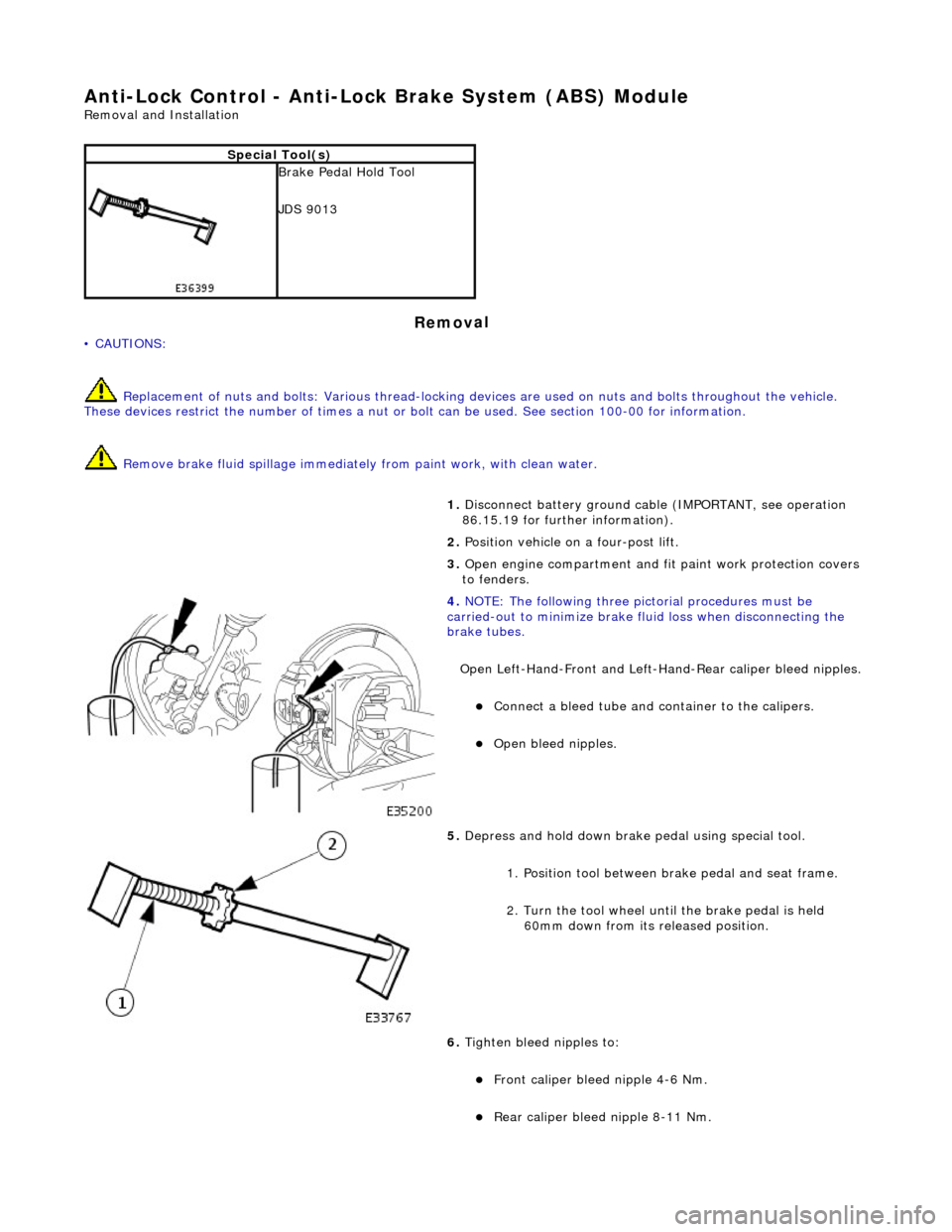

1. Disc onne

ct battery ground cable (IMPORTANT, see operation

86.15.19 for further information).

2. Position vehicle on a four-post lift.

3. Open engine compartment and fit paint work protection covers

to fenders.

4. NOTE : Th

e following three pictorial procedures must be

carried-out to minimize brake fl uid loss when disconnecting the

brake tubes.

Open Left-Hand-Front and Left-H and-Rear caliper bleed nipples.

Connect a

bleed tube and co

ntainer to the calipers.

Op

en bleed nipples.

5. Depress and hold down brake pedal u s

ing special tool.

1. Position tool between brake pedal and seat frame.

2. Turn the tool wheel unti l the brake pedal is held

60mm down from its released position.

6. Tighten bleed nipples to:

Front caliper blee d nipple 4-6 Nm.

Rear

caliper bleed nip

ple 8-11 Nm.

Page 445 of 2490

Anti-Lock Control - Hydraulic Contro

l Unit (HCU)

Re

moval and Installation

Remov

al

• C

AUTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

S

pecial Tool(s)

Brake Pedal

Hold Tool

JDS 9013

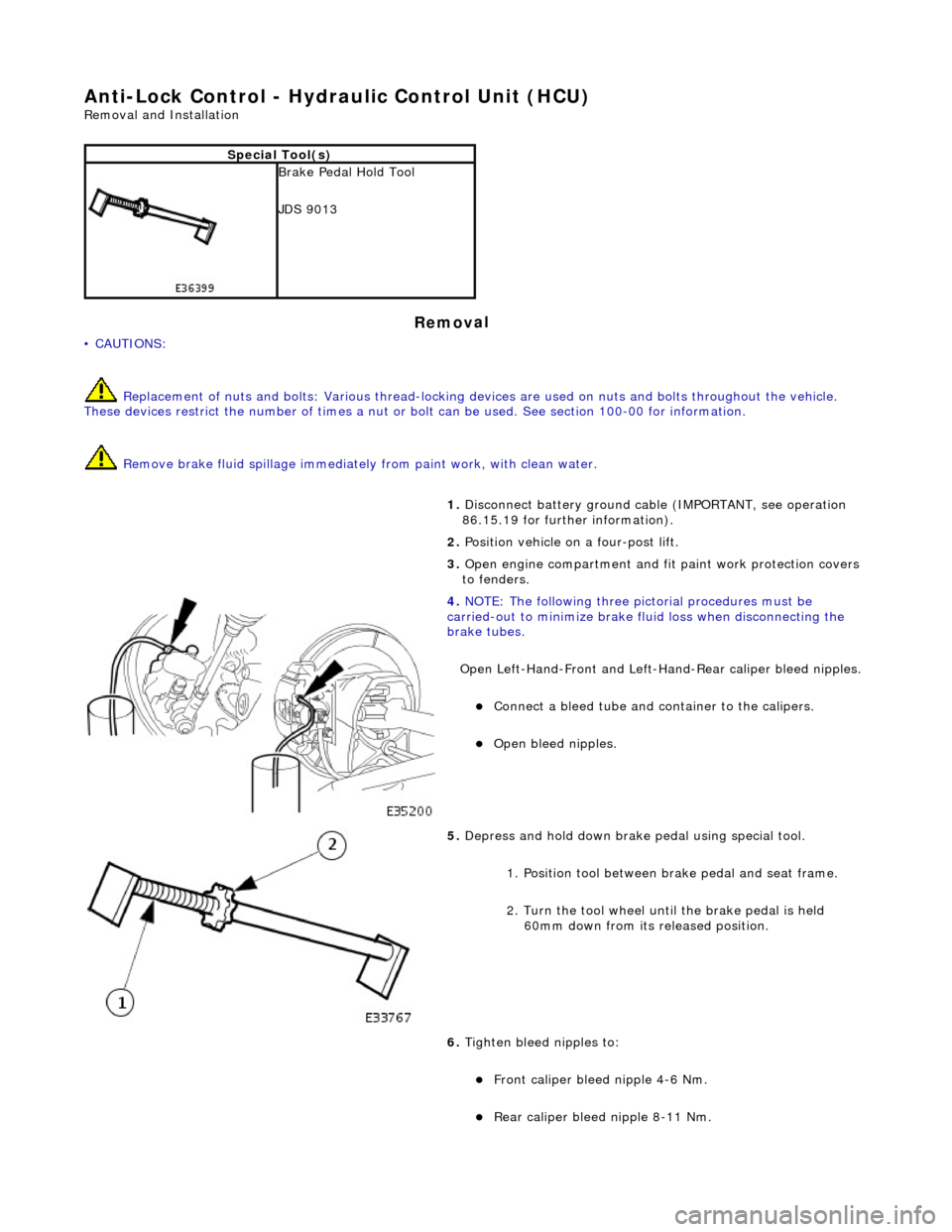

1. Disc

onnect battery ground cable (IMPORTANT, see operation

86.15.19 for further information).

2. Position vehicle on a four-post lift.

3. Open engine compartment and fit paint work protection covers

to fenders.

4. NOTE

: The following three pictorial procedures must be

carried-out to minimize brake fl uid loss when disconnecting the

brake tubes.

Open Left-Hand-Front and Left-H and-Rear caliper bleed nipples.

Connect

a bleed tube and co

ntainer to the calipers.

O

pen bleed nipples.

5. Depress and hold down brake pedal u

sing special tool.

1. Position tool between brake pedal and seat frame.

2. Turn the tool wheel unti l the brake pedal is held

60mm down from its released position.

6. Tighten bleed nipples to:

Front caliper blee d nipple 4-6

Nm.

Rear

caliper bleed nipple 8-11 Nm.

Page 623 of 2490

Re

position the sprocket (and the VVT unit) for the most advantageous

position for use of the tool.

R

emove the tool.

25

.

Install the primary timing chain.

R

eposition the VVT unit forwards on the cam journal (do not rotate it)

to allow the chain to cl ear the head casting. Disconnect the primary

chain from the Ty-strap.

1. Install the primary chain to position over the crankshaft sprocket and the VVT unit sprocket. There mu st be no slack on the drive

side of the primary chain and the VVT unit must not be rotated on

the camshaft.

26

.

Install the primary chain tensioner blade.

1. Position the tensioner blade to the cylinder block.

2. Install the retaining / pivot bolt and tighten it to 14 Nm.

27

.

Push the primary chain tensioner piston into the body to provide clearance

for installing.

1. Insert a thin rigid wire through the hole in the end of the tensioner

piston to displace the ball from the non-return valve seat.

2. With the wire in position, press the piston fully into the tensioner body.

Re

move the wire.

28

.

Assemble the tensioner.

1. Install the two mounting bolts to the tensioner.

2. Locate the tensioner back-plate to the two bolts.

29. Install the tensioner to the cylinder block.

1. Position and align the tensioner to the cylinder block and to the mating slot on the rear face of the tensioner blade.

2. Install and tighten the two bolts to 12 Nm.

Page 674 of 2490

Installation

12. Remove the bolt which secures the sprocket to the exhaust

camshaft.

Move the sprocket forward from the camshaft boss.

13. Remove the secondary chain tensioner. The tensioner piston

cannot be pushed into the body with the assembly in position.

1. Remove the two bolts which secure the tensioner.

Lift the tensioner, sprocket (release it fully from the

camshaft) and ch ain assembly.

2. Remove the tensioner rearward from between the chain.

14. Remove the sprocket and leav e the chain resting on the

cylinder head.

15. Clean and inspect all relevant components.

1. Install the sprocket to the secondary chain.

1. With the sprocket installe d to the chain, temporarily

position (do not install the securing bolt) the sprocket

onto the camshaft.

2. Adjust the position of the sprocket within the chain to

allow the chain tensioning tool 303-532 to be

approximately vertical, as shown.

Remove the chain tensioni ng tool; during future

operations, do not move the sprocket within the chain.

2. Push the tensioner piston into the body to provide clearance

for installing.

1. Insert a thin rigid wire th rough the hole in the end of

the tensioner piston to displace the ball from the non-

return valve seat.