turn signal JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 25 of 2490

Rear Door Speaker (86.50.14)

Rear Door Tweeter Speaker (86.50.62)

Subwoofer

Speaker (86.51.05)

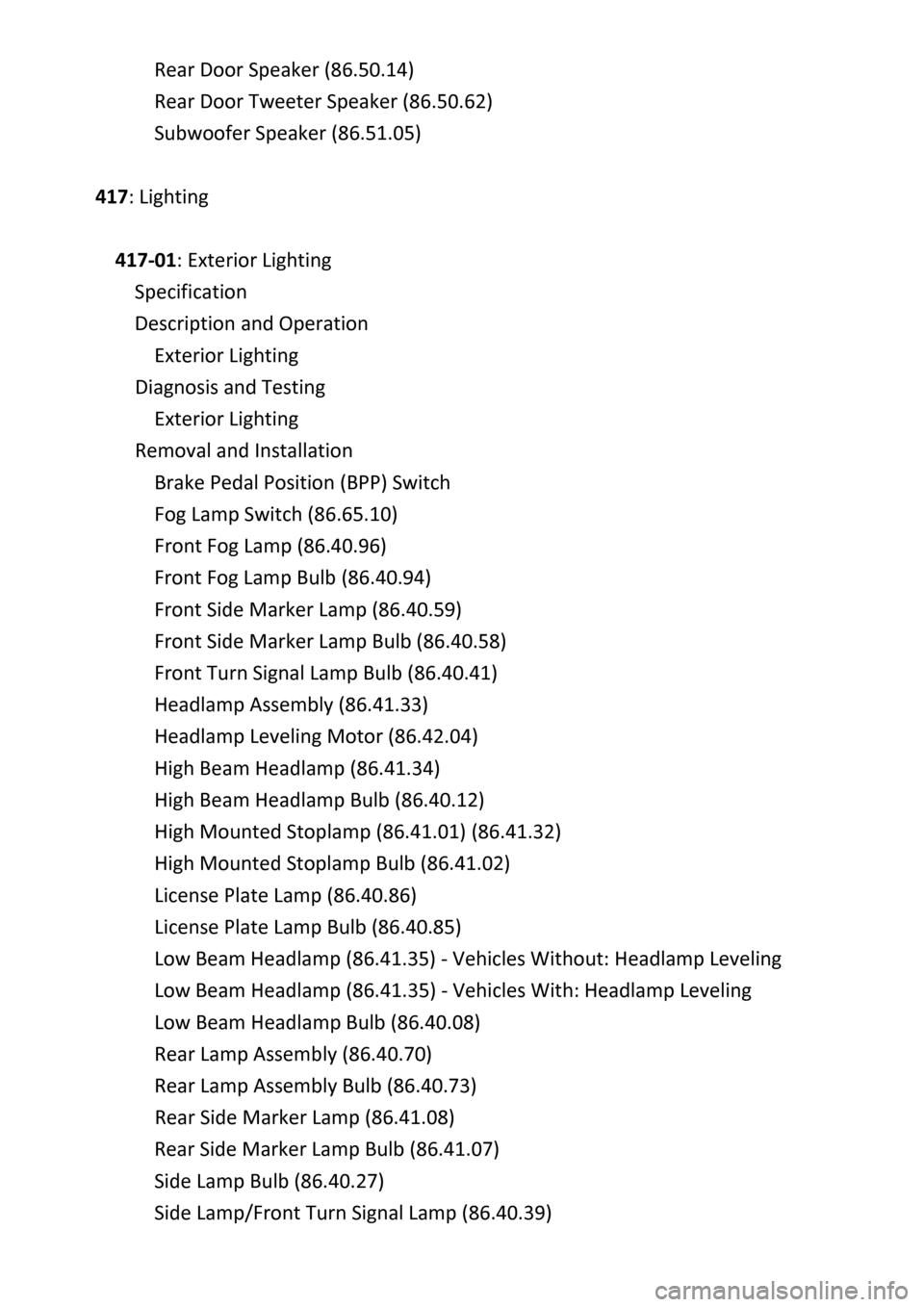

417: Lighting

417‐01: Exterior Lighting

Specification

Description and Operation

Exterior Lighting

Diagnosis and Testing

Exterior Lighting

Removal and Installation

Brake Pedal Position (BPP) Switch

Fog Lamp Switch (86.65.10)

Front Fog Lamp (86.

40.96)

Front Fog Lamp Bulb (86.40.94)

Front Side Marker Lamp (86.40.59)

Front Side Marker Lamp Bulb (86.40.58)

Front Turn Signal Lamp Bulb (86.40.41)

Headlamp Assembly (86.41.33)

Headlamp Leveling Motor (86.42.04)

High Beam Headlamp (86.41.34)

High Beam Headlamp Bulb (86.40.12)

High Mounted Stoplamp (86.41.01) (86.41.32)

High Mo

unted Stoplamp Bulb (86.41.02)

License Plate Lamp (86.40.86)

License Plate Lamp Bulb (86.40.85)

Low Beam Headlamp (86.41.35) ‐ Vehicles Without: Headlamp Leveling

Low Beam Headlamp (86.41.35) ‐ Vehicles With: Headlamp Leveling

Low Beam Headlamp Bulb (86.40.08)

Rear Lamp Assembly (86.40.70)

Rear Lamp Assembly Bulb (86.40.73)

Rear Side Marker La

mp (86.41.08)

Rear Side Marker Lamp Bulb (86.41.07)

Side Lamp Bulb (86.40.27)

Side Lamp/Front Turn Signal Lamp (86.40.39)

Page 26 of 2490

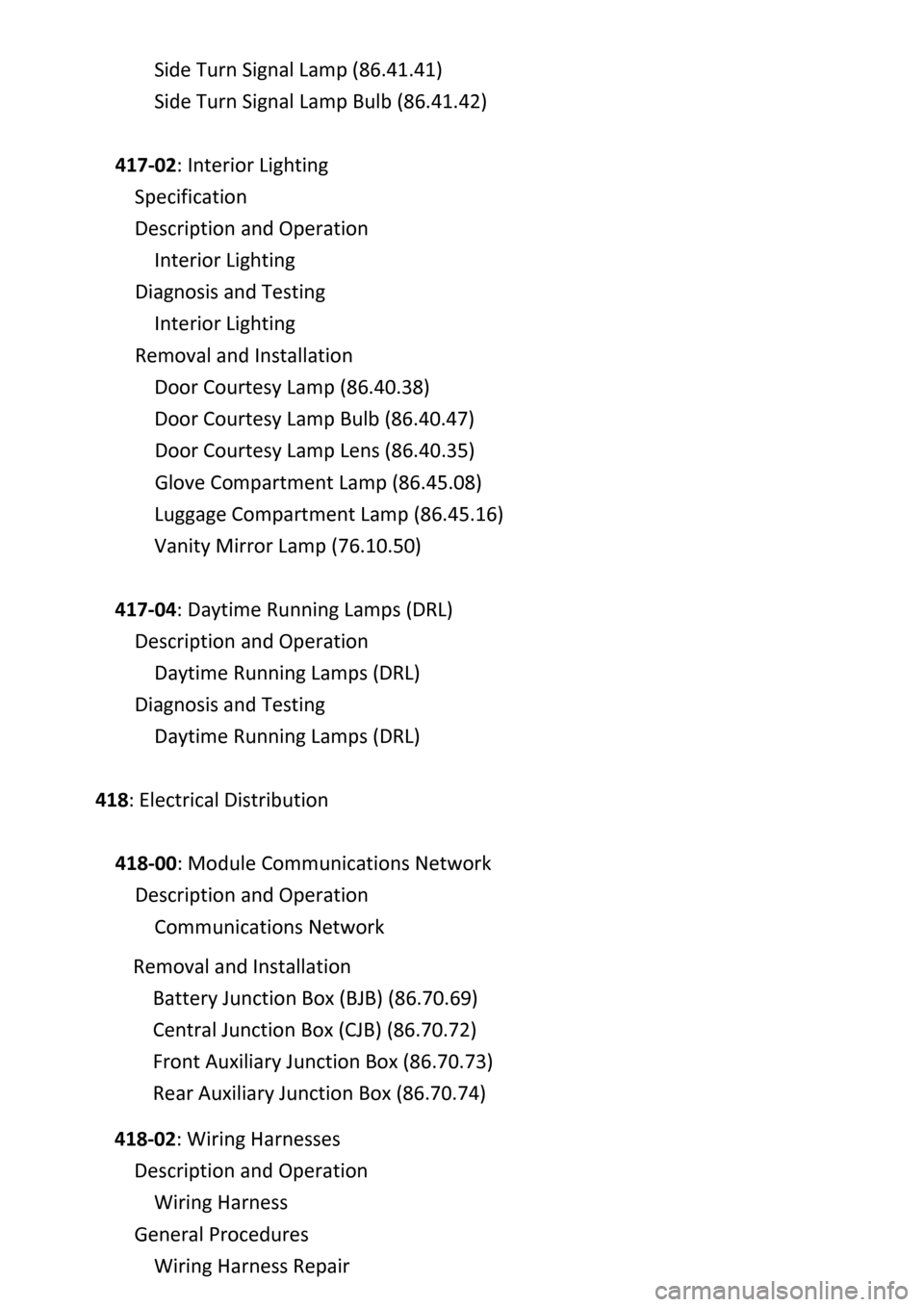

Side Turn Signal Lamp (86.41.41)

Side Turn Signal Lamp Bulb (86. 41.42)

417‐02

:

Interior Lighting

Specification

Description and Operation

Interior Lighting

Diagnosis and Testing

Interior Lighting

Removal and Installation

Door Courtesy Lamp (86.40.38)

Door Courtesy Lamp Bulb (86.40.47)

Door Courtesy Lamp Lens (86.40.35)

Glove Co

mpartment Lamp (86.45.08)

Luggage Compartment Lamp (86.45.16)

Vanity Mirror Lamp (76.10.50)

417‐04: Daytime Running Lamps (DRL)

Description and Operation

Daytime Running Lamps (DRL)

Diagnosis and Testing

Daytime Running Lamps (DRL)

418: Electrical Distribution

418‐00: Module Communications Network

Description and Operation

Communications Ne

twork

Removal

and Installation

Battery

Junction Box (BJB) (86.70.69)

Central

Junction Box (CJB) (86.70.72)

Front

Auxiliary Junction Box (86.70.73)

Rear

Auxiliary Junction Box (86.70.74)

418 ‐02: Wiring Harnesses

Description and Operati

on

Wiring Harness

General Procedures

Wiring Harness Repair

Page 44 of 2490

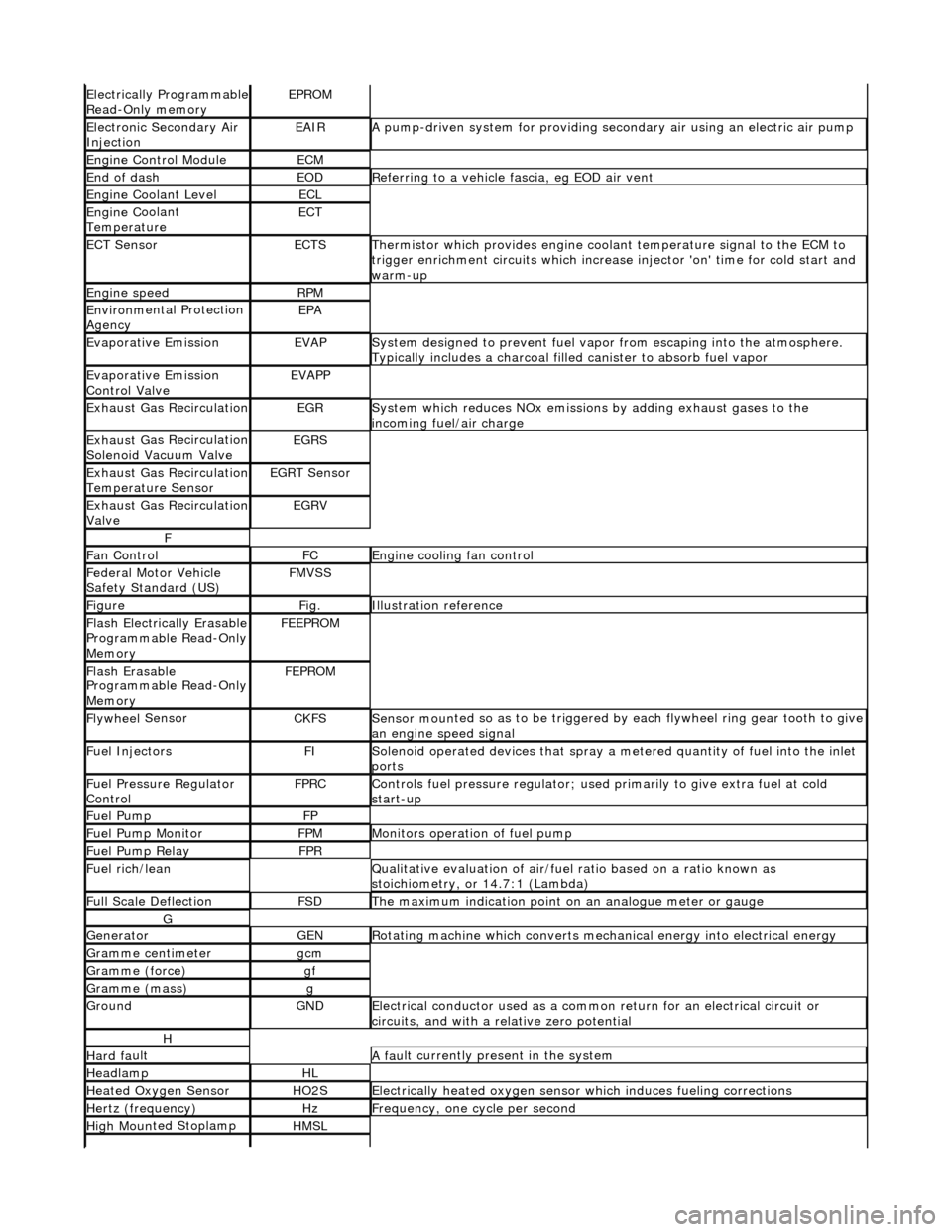

Electrically Programmable

R

ead-Only memory

EPROM

Ele

c

tronic Secondary Air

Injection

EAIRA p

ump-driven system for providing seco

ndary air using an electric air pump

Engine C

ontrol Module

ECM

End of dashEODR

e

ferring to a vehicle fascia, eg EOD air vent

Engine

C

oolant Level

ECL

Engine

C

oolant

Temperature

ECT

ECT Sen s

or

ECTSTherm

i

stor which provides engine coolant temperature signal to the ECM to

trigger enrichment circuits which increase injector 'on' time for cold start and

warm-up

Engine s

peed

RP

M

Environ m

ental Protection

Agency

EPA

Evaporative EmissionEVAPSy stem designed to prevent fu

el vapor from escaping into the atmosphere.

Typically includes a charcoal filled canister to absorb fuel vapor

Evaporative Emission

Control ValveEVAPP

Exhaust G

as Recirculation

EGRSys

t

em which reduces NOx emissions by adding exhaust gases to the

incoming fuel/air charge

Exhaus t G

as Recirculation

Solenoid Vacuum Valve

EGRS

Exhaus t G

as Recirculation

Temperature Sensor

EGRT Sen s

or

Exhaus

t G

as Recirculation

Valve

EGRV

F

F a

n Control

FCEngine

cooling fan control

F

e

deral Motor Vehicle

Safety Standard (US)

FMV S

S

Fi

gur

e

Fi

g.Illustrati

on reference

Flash

E

lectrically Erasable

Programmable Read-Only

Memory

FEE PR

OM

Flash

E

rasable

Programmable Read-Only

Memory

FEP R

OM

Flywhee

l

Sensor

CKFSSens

or moun

ted so as to be

triggered by each flywheel ring gear tooth to give

an engine speed signal

Fue l

Injectors

FISol

e

noid operated devices that spray a metered quantity of fuel into the inlet

ports

F u

el Pressure Regulator

Control

FP RCControls fuel pressure regu l

ator; used primarily to

give extra fuel at cold

start-up

Fue l

Pump

FP

Fue

l

Pump Monitor

FP

MMonitors operation of fuel pump

Fue l

Pump Relay

FP

R

Fu

el rich/lean

Q

u

alitative evaluation

of air/fuel ratio based on a ratio known as

stoichiometry, or 14.7:1 (Lambda)

F u

ll Scale Deflection

FSDTh

e

maximum indication point on

an analogue meter or gauge

G

Gene

rator

GENRot

a

ting machine which converts mechanical energy into electrical energy

G

r

amme centimeter

gcm

Gramm

e

(force)

gf

Gramm

e

(mass)

g

GroundGNDEle

c

trical conductor used

as a common return for an electrical circuit or

circuits, and with a relative zero potential

H

Hard f a

ult

A

fau

lt currently present in the system

HeadlampHL

Heat

ed Oxygen

Sensor

HO2SElectrically

h

eated oxygen sensor which induces fueling corrections

Hertz (frequency)HzFrequ

e

ncy, one cycle per second

High

Moun

ted Stoplamp

HMSL

Page 47 of 2490

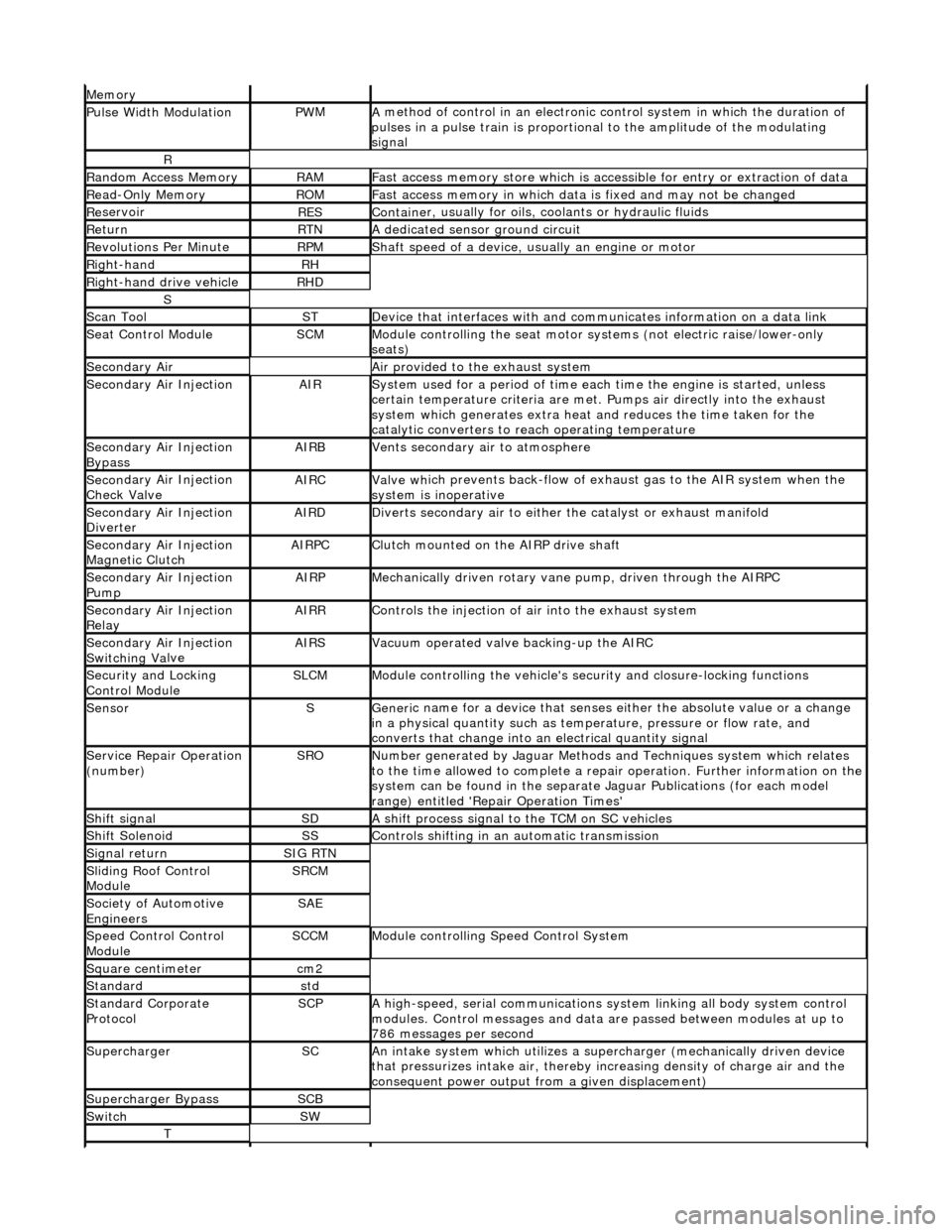

Mem

ory

Pulse Width ModulationPW

M

A

method of control in an electronic co

ntrol system in which the duration of

pulses in a pulse train is proportional to the amplitude of the modulating

signal

R

Ran

dom Access Memory

RAMF

ast access memory store which is accessible for entry or extraction of data

Re

ad-Only Memory

RO

M

F

ast access memory in which data

is fixed and may not be changed

Re

servoir

RESContaine

r, usually for oils,

coolants or hydraulic fluids

Re

turn

RTNA

dedicated sensor ground circuit

R

evolutions Per Minute

RP

M

Shaft speed o

f a device, us

ually an engine or motor

R

ight-hand

RH

Right-hand drive veh

icle

RHD

S

Scan T

ool

STDe

vice that interfaces with and comm

unicates information on a data link

Se

at Control Module

SCMModule

controlling the seat motor systems (not electric raise/lower-only

seats)

Secon

dary Air

Air pro

vided to the exhaust system

Secon

dary Air Injection

AIRSy

stem used for a period of time each

time the engine is started, unless

certain temperature criter ia are met. Pumps air directly into the exhaust

system which generates extra heat and reduces the time taken for the

catalytic converters to reach operating temperature

Secon

dary Air Injection

Bypass

AIRBVents secon

dary air to atmosphere

Secon

dary Air Injection

Check Valve

AIRCValve wh

ich prevents back-flow of exhaust gas to the AIR system when the

system is inoperative

Secon

dary Air Injection

Diverter

AIRDD

iverts secondary air to either

the catalyst or exhaust manifold

Secon

dary Air Injection

Magnetic Clutch

AIRP

C

Clu

tch mounted on the AIRP drive shaft

Secon

dary Air Injection

Pump

AIRPMe

chanically driven rotary vane

pump, driven through the AIRPC

Secon

dary Air Injection

Relay

AIRRCont

rols the injection of air into the exhaust system

Secon

dary Air Injection

Switchin

g Va

lve

AIRSV

acuum operated valve backing-up the AIRC

Secu

rity and Locking

Control Module

SLCMModul

e controlling the vehicle's security and closure-locking functions

SensorSGeneri

c name for a device

that senses either the absolute value or a change

in a physical quantity su ch as temperature, pressure or flow rate, and

converts that change into an electrical quantity signal

Servic

e Repair Operation

(number)

SRONu

mber generated by Jaguar Methods

and Techniques system which relates

to the time allowed to complete a repair operation. Further information on the

system can be found in the separate Jaguar Publications (for each model

range) entitled 'Repair Operation Times'

Shif

t signal

SDA

shift process signal to the TCM on SC vehicles

Shif

t Solenoid

SSControls shi

fting in an automatic transmission

Si

gnal return

SIG RTN

Slidin

g Roof Control

Module

SRCM

Society of Automotive

Engineers

SAE

Speed

Control Control

Module

SCCMModule con

trolling Speed Control System

Square c

entimeter

cm

2

Stan

dard

std

Stan

dard Corporate

Protocol

SCPA

high-speed, serial communications system linking all body system control

modules. Control messages and data ar e passed between modules at up to

786 messages per second

SuperchargerSCAn in

take system which utilizes a supercharger (mechanically driven device

that pressurizes intake air, thereby in creasing density of charge air and the

consequent power output from a given displacement)

Supercharger

Bypass

SCB

SwitchSW

T

Page 431 of 2490

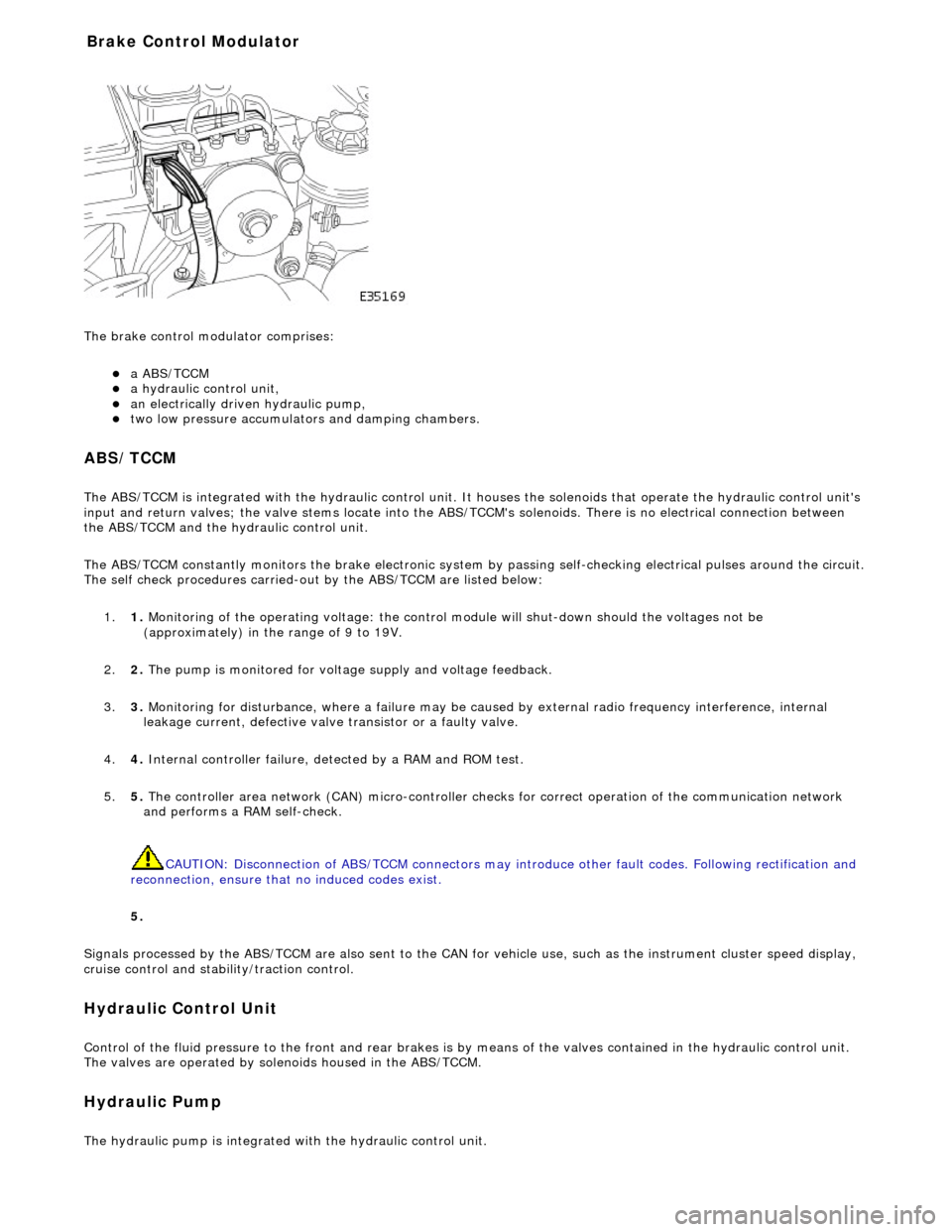

The brake

control modulator comprises:

a A

BS/TCCM

a h

ydraulic control unit,

an electrically driven hydrau

lic pump,

two low pressure accumulato

rs and damping chambers.

ABS/TCCM

The AB

S/TCCM is integrated with the hydrau

lic control unit. It houses the solenoids that operate the hydraulic control unit's

input and return valves; the valve stems locate into the ABS/TCCM's solenoids. There is no electrical connection between

the ABS/TCCM and the hydraulic control unit.

The ABS/TCCM constantly monitors the brake electronic system by passing self-checking electrical pulses around the circuit.

The self check procedures carried-out by the ABS/TCCM are listed below:

1. 1. Monitoring of the operating voltage: the control mo dule will shut-down should the voltages not be

(approximately) in the range of 9 to 19V.

2. 2. The pump is monitored for volt age supply and voltage feedback.

3. 3. Monitoring for disturbance, where a failure may be caus ed by external radio frequency interference, internal

leakage current, defective valve transistor or a faulty valve.

4. 4. Internal controller failure, de tected by a RAM and ROM test.

5. 5. The controller area network (CAN) micr o-controller checks for correct operation of the communication network

and performs a RAM self-check.

CAUTION: Disconnection of ABS/TCCM connectors may introduce other fault codes. Following rectification and

reconnection, ensure that no induced codes exist.

5.

Signals processed by the ABS/TCCM are also sent to the CAN for vehicle use, such as the instrument cluster speed display,

cruise control and stability/traction control.

Hydraulic Control Unit

Control of

the fluid pressure to

the front and rear brakes is by means of the valves contained in the hydraulic control unit.

The valves are operated by solenoids housed in the ABS/TCCM.

Hydraulic Pump

The

hydraulic pump is integrated

with the hydraulic control unit.

Bra

ke Control Modulator

Page 432 of 2490

It is a reciprocating two

-circuit pu

mp in which one brake circuit is as signed to each pump circuit.

It supplies th

e fluid pressure and vo

lume to supply the brake circuits under ABS and Traction control.

The pump is driven by an electri

c motor, with the pump

housing incorporating two lo w pressure accumulators and

damping chambers for each brake circuit.

The ac cu

mulator stores the pressure and smooths out the output pu

lses from the pump.

ABS Warning Lamp

The sys

tem will be set in a fail-safe mode if a problem is de

tected; a warning lamp on the instrument panel will notify the

driver there is a problem.

Anti-Lock Braking Sy

stem (ABS)

The AB

S components are combined with

an hydraulic booster and a tandem master cylinder to provide a two circuit braking

system. The system comprises, four wheel speed sensor s, a brake control modulator and an ABS warning lamp.

Should a wheel start to lock-up during braking a signal tr ansmitted from the wheel speed sensor to the brake control

modulator will start the hydraulic pump. The brake control modula tor will close the input valve of the line connected to the

locked-wheel to stop any increase in fluid pressure to the br ake caliper. If this fails to prevent the wheel locking, the

pressure in the caliper will be decreased by opening the return valve until th e wheel starts accelerating again. The fluid

pressure from the return va lve is directed into the low pressure accumulator, housed in the pump.

From the low pressure accumulator, fl uid is pumped through the damping cham ber to the brake master cylinder. The

pressure to the brake caliper will then be increased in small steps to maintain maximum adhesion between the tire and road

surface. This is achieved by closing the return valve, and opening the input valve and using the hydraulic pump to increase

the pressure.

Although the system senses all four wheels independently, the rear wheels are regulated as a pair. If a sensor on a rear

wheel detects a wheel decelerating rapidly, then the fluid pressure to both wheels is reduced. The fluid pressure is then

dictated by the wheel having the lowe st adhesion with the road surface.

The ABS system will be set in a fail-safe mode if a problem is detected; a warn ing lamp on the instrument panel will notify

the driver there is a problem. The brake system will still operate conventionally and with the same standard of performance

as a vehicle not equipped with ABS.

Automa tic Stability Control (ASC)

Th

e ASC utilizes the ABS sensing arrangement to provide the maximum traction force to propel the vehicle.

The ASC is switched on when the engine is started. The system can be switched off by pressing the 'ASC OFF' (the switched

is marked 'TRAC OFF' on vehicles fitted with traction control). The switch, which is situated in the center console switchpack,

lights up to warn that the system is sw itched off. An 'ASC' amber warning light flashes on the instrument panel when the

system detects a spinning wheel.

The ASC system uses engine intervention to reduce the torque delivered to the drive wheels to prevent them spinning.

Engine torque is re duced in three ways:

The

throttle is moved towards the closed position.

The ignition is retarded. F

u

el is cut-off at the cylinder injectors.

Wheel spin is detected by the wheel sp eed sensors and communicated to the AB S/TCCM. The ABS/TCCM uses information

from the controller area network (CAN) to calculate the torque that the engine should produce to stop the wheel spinning.

Torque reductions are then requested from the engine control module (ECM ) through the CAN. The throttle is then

positioned to provide the target torque, which has been calculated to prevent wheel spin. During the transient phase of

torque reduction the fuel is cut-off and th e ignition retarded Both the fuel cut-off an d ignition retard will be restored to

normal when the throttle is set to its new position.

The ASC uses a brake control modulator with six solenoid va lves: three normally open inlet valves and three normally

Page 437 of 2490

Make sure the ignition is turned off. 1

Meas

ure the resistances between LF27,

pins 08 and 24 (B) and ground.

2

Are

the resistances less than 5 ohms?

Yes The power and ground supplies to the module are ok . Recheck the DTCs for codes indicating a fault

elsewhere.

No Repair the high resistance circui t. Refer to the electrical guides. Clear the DTC, check for normal

operation.

PINPOINT TE

ST B : CHECK THE RIGHT-HAND FRONT WSS AND CIRCUITS

•

NOTE: Check connectors and pins for damage/corrosion

(see visual inspection).

•

NOTE: Check the WSS ring condition, whee

l bearing etc. Before beginning pinpoint test s refer to the visual inspection.

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

B1: CHECK

THE WSS OUTPUT

Disc

onnect the ABS sensor connector, FR01.

1

Connec

t a multimeter set

to read alternating curr ent volts (AC volts) between pins 1 and 2 of the

sensor.

2

Spin

the wheel by hand and check the meter display.

3

Doe

s the sensor generate a voltage?

Yes GO to B2

.

No

If the WSS ring is in good condition, install a new WSS.

REFER to: Front Wheel Speed Sensor

(20

6-09 Anti-Lock Control, Removal and Installation).

B2:

CHECK THE WSS SIGNAL CIRCUIT CONTINUITY

Make sure the ignition is off. 1

Di

sconnect the ABS module connector, LF27.

2

Meas

ure the resistance between LF27

, pin 03 (Y) and FR01, pin 02 (Y).

3

I

s the resistance less than 5 ohms?

Yes GO to B3

.

No

Repair the high resistance circui t. This circuit includes intermediate connector, LF02. Refer to the

electrical guides. Clear the DTC, check for normal operation.

B3:

CHECK THE WSS RETURN CIRCUIT CONTINUITY

Meas

ure the resistance between LF27

, pin 04 (G) and FR01, pin 01 (G).

1

I

s the resistance less than 5 ohms?

Yes The WSS and circuits are OK. Check for DTCs indicating a possible module failure.

No Repair the high resistance circui t. This circuit includes intermediate connector, LF02. Refer to the

electrical guides. Clear the DTC, check for normal operation.

P

INPOINT TEST C : CHECK THE LEFT-HAND FRONT WSS AND CIRCUITS

•

NOTE: Check connectors and pins for damage/corrosion

(see visual inspection).

•

NOTE: Check the WSS ring condition, whee

l bearing etc. Before beginning pinpoint test s refer to the visual inspection.

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

C1

: CHECK THE WSS OUTPUT

Disc

onnect the ABS sensor connector, FL01.

1

Connec

t a multimeter set

to read alternating curr ent volts (AC volts) between pins 1 and 2 of the

sensor.

2

Spin

the wheel by hand and check the meter display.

3

Doe

s the sensor generate a voltage?

Yes GO to C2

.

No

If the WSS ring is in good condition, install a new WSS.

REFER to: Front Wheel Speed Sensor

(20

6-09 Anti-Lock Control, Removal and Installation).

C2

: CHECK THE WSS SIGNAL CIRCUIT CONTINUITY

Page 438 of 2490

Make sure the ignition is off. 1

Disc

onnect the ABS module connector, LF27.

2

M

e

asure the resistance between LF27, pin 17 (W) and FL01, pin 02 (W).

3

I

s

the resistance less than 5 ohms?

Yes GO to C3

.

No

Re

pair the high resistance circui

t. This circuit includes intermed iate connector, LF02. Refer to the

electrical guides. Clear the DTC, check for normal operation.

C3: CH

ECK THE WSS RETURN CIRCUIT CONTINUITY

Measure

the resistance between LF27, pin 18 (R) and FL01, pin 01 (R).

1

Is

the resistance less than 5 ohms?

Yes The WSS and circuits are OK. Check for DTCs indicating a possible module failure.

No Repair the high resistance circui t. This circuit includes intermediate connector, LF01. Refer to the

electrical guides. Clear the DTC, check for normal operation.

PI

NPOINT TEST D : CHECK THE RIGH

T-HAND REAR WSS AND CIRCUITS

•

NOTE: Check connectors and pins for damage/corrosion

(see visual inspection).

• NO

TE: Check the WSS ring condition, whee

l bearing etc. Before beginning pinpoint test s refer to the visual inspection.

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

D1: CHECK

THE WSS OUTPUT

Disc

onne

ct the ABS sensor connector, RA02.

1

Connec

t

a multimeter set

to read alternating curr ent volts (AC volts) between pins 1 and 2 of the

sensor.

2

Spin

the wheel by hand and check the meter display.

3

Doe

s

the sensor generate a voltage?

Yes GO to D2

.

No

If

the WSS ring is in good condition, install a new WSS.

REFER to: Rear Wheel Speed Sensor

(206-0

9 Anti-Lock Control, Removal and Installation).

D

2

: CHECK THE WSS SIGNAL CIRCUIT CONTINUITY

Make sure the ignition is off. 1

Disc

onnect the ABS module connector, LF27.

2

Measure t

he resistance between LF27

, pin 07 (O) and RA02, pin 01 (O).

3

Is

the resistance less than 5 ohms?

Yes GO to D3

.

No Re

pair the high resistance circui

t. This circuit includes intermed iate connector, LA02. Refer to the

electrical guides. Clear the DTC, check for normal operation.

D3:

CHECK THE WSS RETURN CIRCUIT CONTINUITY

Meas

ure t

he resistance between LF27

, pin 06 (Y) and RA02, pin 02 (Y).

1

Is

the resistance less than 5 ohms?

Yes The WSS and circuits are OK. Check for DTCs indicating a possible module failure.

No Repair the high resistance circui t. This circuit includes intermediate connector, CA09. Refer to the

electrical guides. Clear the DTC, check for normal operation.

PI

NPOINT TEST E : CHECK THE LEFT-HAND REAR WSS AND CIRCUITS

•

NOTE: Check connectors and pins for damage/corrosion

(see visual inspection).

• NO

TE: Check the WSS ring condition, whee

l bearing etc. Before beginning pinpoint test s refer to the visual inspection.

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

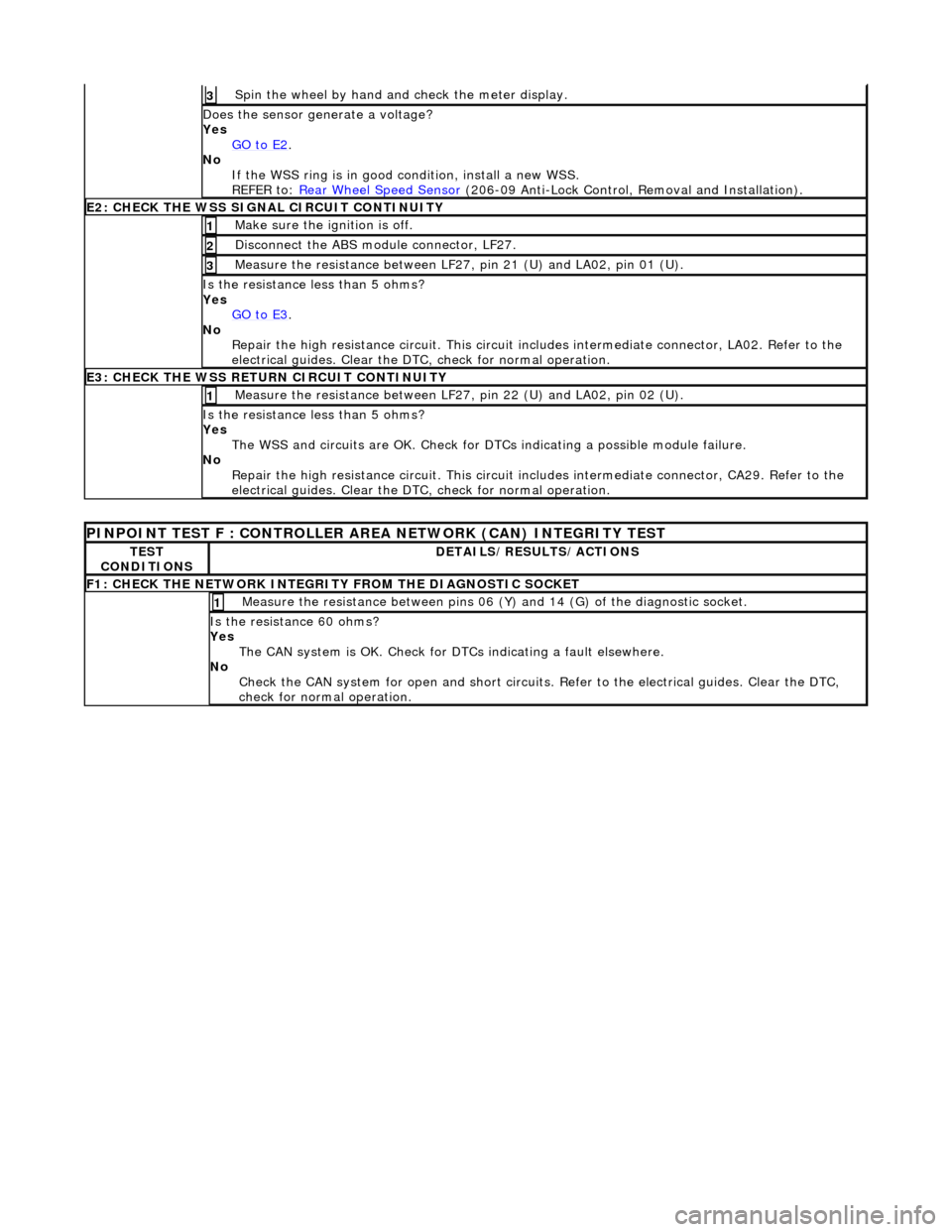

E1

: CHECK THE W

SS OUTPUT

Disc

onne

ct the ABS sensor connector, LA02.

1

Connec

t

a multimeter set

to read alternating curr ent volts (AC volts) between pins 1 and 2 of the

sensor.

2

Page 439 of 2490

Spin

the wheel by hand and check the meter display.

3

Doe

s the sensor generate a voltage?

Yes GO to E2

.

No

If the WSS ring is in good condition, install a new WSS.

REFER to: Rear Wheel Speed Sensor

(20

6-09 Anti-Lock Control, Removal and Installation).

E2

: CHECK THE WSS SIGNAL CIRCUIT CONTINUITY

Make sure the ignition is off. 1

Di

sconnect the ABS module connector, LF27.

2

Meas

ure the resistance between LF27

, pin 21 (U) and LA02, pin 01 (U).

3

I

s the resistance less than 5 ohms?

Yes GO to E3

.

No

Repair the high resistance circui t. This circuit includes intermediate connector, LA02. Refer to the

electrical guides. Clear the DTC, check for normal operation.

E3

: CHECK THE WSS RETURN CIRCUIT CONTINUITY

Meas

ure the resistance between LF27

, pin 22 (U) and LA02, pin 02 (U).

1

I

s the resistance less than 5 ohms?

Yes The WSS and circuits are OK. Check for DTCs indicating a possible module failure.

No Repair the high resistance circui t. This circuit includes intermediate connector, CA29. Refer to the

electrical guides. Clear the DTC, check for normal operation.

P

INPOINT TEST F : CONT

ROLLER AREA NETWORK (CAN) INTEGRITY TEST

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

F

1: CHECK THE NETWORK INTEGRITY

FROM THE DIAGNOSTIC SOCKET

M

easure the resistance between pins 06 (Y) and 14 (G) of the diagnostic socket.

1

I

s the resistance 60 ohms?

Yes The CAN system is OK. Check for DTCs indicating a fault elsewhere.

No Check the CAN system for open an d short circuits. Refer to the electrical guides. Clear the DTC,

check for normal operation.

Page 522 of 2490

diverter val

ve (if fitted) and oil filter.

Main

bearings

which are grooved in the upper positions and plain in

the lower positions. They are manufactured from

aluminium / tin material.

A c

rankshaft with under

cuts and rolled fillets for extra strength.

Fracture

-split connecting rods in sintered-forged steel.

Brackets

bolted to the front of

the cylinder

block are used to mo unt all accessories.

A sin

gle, seven ribbed vee belt

drives the accessories.

An au

tomatic belt tensioner for the front accessory drive,

incorporating a wear indicator.

An advanced en

gine management system inco

rporating electronic throttle control.

The un

it meets the requirements of the CARB OBDII USA legislation.

Ancillary Systems

The an

ci

llary systems, driven by the engine, each have a

detailed Description and Operation along with Diagnostic

Procedures, and Removal and Installation instructions ; refer to the following sections of this manual:

Power Steeri

ng Pump - Section 211-02

Ai

r Conditioning Compressor - Sectio

n 412-03

Engine

C

ooling Pump - Section 303-03

Generator

- Sectio

n 414-02

The drive belt, idler pulley and automatic tensioner are described in Section 303-05.

The engine starting system is described in Section 303-06.

En

gine Management and Emission Control System

Engine Control Modu

le (ECM)

Engine

management and exhaust emissions are controlled by the ECM, which has the

following main functions:

Fu

el injection

Idle

s

peed

Ignition Ev

aporative loss system

Engine

cooling fans Clim

ate control compressor clutch demand

The microprocessor within the ECM receiv es signals from various sensors and other modules and uses a pre-determined

program to compute engine management functions.

Adaptive functions are incorporated in the ECM to cater for co ntinuous adjustments to its computations to suit prevailing

conditions. Because the system also controls emissions to suit all modes, neither CO levels nor idle speed require service

attention or adjustment, except if an error should occur.

On Board Diagnostics are controlled by the ECM with the continuous monitoring of incoming signals and the subsequent

verification against what the module expects to 'see'. Should a si gnal be incorrect or missing, the ECM will substitute a fixed

value to provide the 'limp home mode' and alert the driver of the problem. Fixed values may be adopted for:

Transmission oil

temperature

Mechanica

l

guar

d position

Throttle blade angle Camshaft position

Inta

k

e air temperature

Diagnostic trouble codes (DTC), including OBD II codes, are stored in the ECM memo ry and can be read by an appropriate

retrieval tool.

Should either the ECM or TCM fa il, ensure that the control housing cooling fan is operating correctly. Failure of the cooling

fan MUST be rectified before renewing a control module and details of a fa n failure should accompany a returned control

module.