warning light JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 35 of 2490

General Infor

mation - Gene

ral Service Information

Description an

d Operation

Safety Notice

Appropri

ate service me

thods and proper repair procedures are essential for the safe, reliable operation of all motor vehicles,

as well as the safety of the person do ing the work. This manual provides genera l directions for accomplishing service and

repair work with tested, effect ive, techniques. Following them will help assure reliability.

There are numerous variations in procedures, techniques, tools, and parts for servicing vehicles, as well as in the skill of the

person doing the work. This manual cannot possibly anticipate all such variations and provide advice or cautions as to each.

Accordingly, anyone who depart s from the instructions provided in the manua l must first establish that neither personal

safety nor vehicle integrity is compromised from choices of methods, tools or parts.

Notes, Ca

utions and Warnings

Throughout

this manual, important inform

ation is highlighted by the use of notes, cautions and warnings. NOTES give

additional information on a topic or proc edure, CAUTIONS are given to prevent da mage to the vehicle, and WARNINGS are

given to prevent personal injury.

Worksh

op Manual Organization

This

manual incorporates descript

ive, diagnostic, and repair information to help trained Jaguar technicians complete service

and rectification procedures. The informat ion can be accessed by choosing the appropriate five digit section number. For

example, Section 412-03 covers air conditioning , which is part of the Climate Control System.

The manual is organized into groups covering generic aspects of the vehicle systems; the first digit of the section

number represents a group se lected from the following:

1. General Information.

2. Chassis.

3. Powertrain.

4. Electrical.

5. Body and Paint.

Each of the groups comprises sections re lating to specific areas of the vehicle.

The second and third digits of the section number indicate the vehicle system.

The last two digits of the se ction number define the system covered, more specifically.

Each section comprises one or more of the following sub-sections:

Specification

Page 88 of 2490

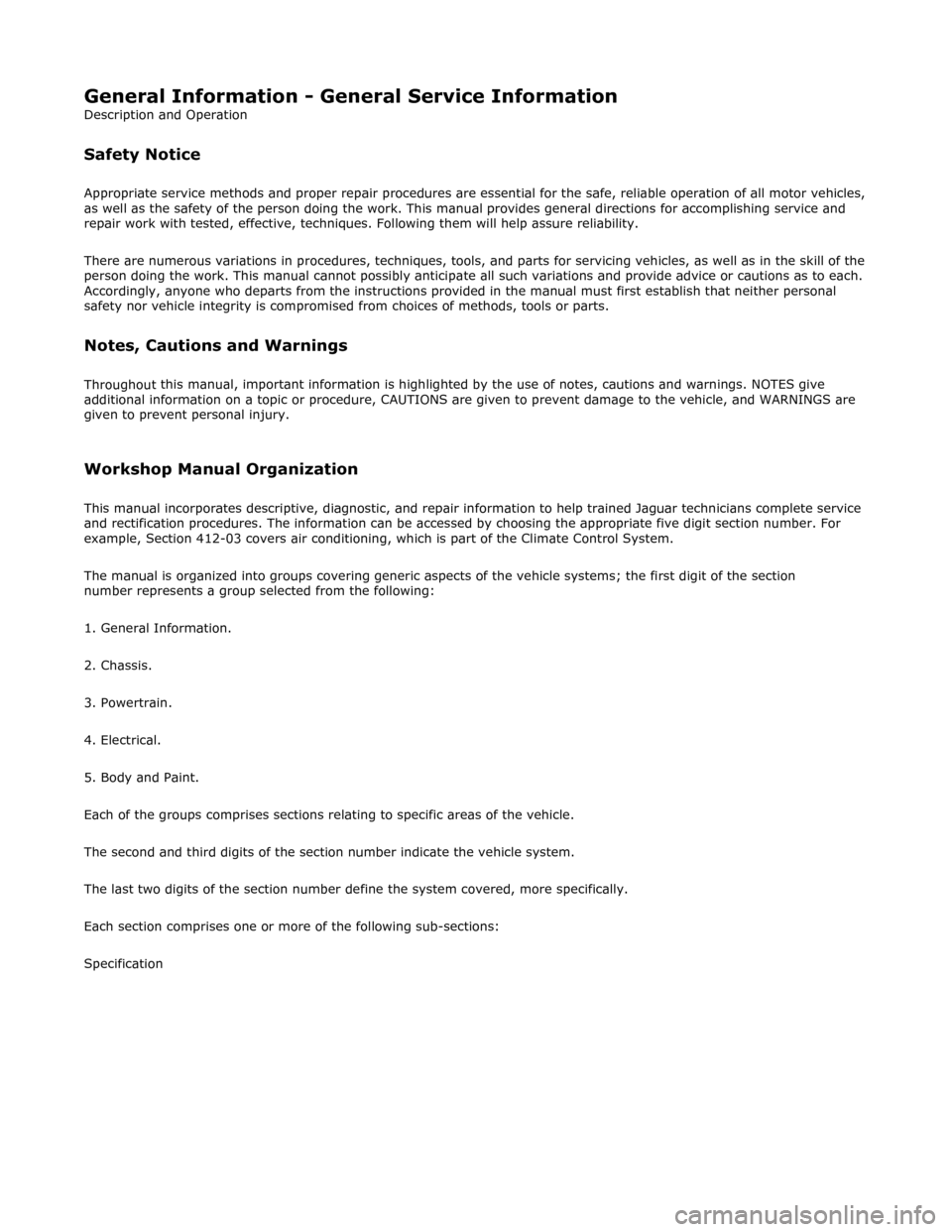

Ensure spring

upper se

at is correctly positioned in turret.

Engage tool dowel in turret slo

t.

R

o

tate adjuster of Special Tool 204-111 to lightly tension

spring.

17 . Ins

tall guide pins ( supplied with Special Tool 204-111) in

spring pan/wishbone bolt locations.

18 . WARNING: WHE

N ROTATING TOOL ADJUSTER, ENSURE

THAT TOOL STEM DOES NOT TU RN AND DISTURB POSITION OF

DOWEL IN SUSPENSION TURRET.

Install spring pan to wishbone securing bolts.

Ro t

ate tool adjuster to gradua

lly increase spring tension.

Pr

ogressively install but do no

t tighten spring pan securing

bolts.

Tigh ten spring pan

bolts to 70-90Nm.

Ensure spri

ng

lower seat is co

rrectly positioned in spring

pan.

19 . WARNING: WHE

N ROTATING TOOL ADJUSTER, ENSURE

THAT TOOL STEM DOES NOT TU RN AND DISTURB POSITION OF

DOWEL IN SUSPENSION TURRET.

Remove Special Tool 204-111 from suspension.

Rotat

e adjuster of Special Tool to release tension on

spring.

R otate

tool stem to release dowel from turret.

With

draw tool and adaptor

.assembly.

20

. Lower vehi

cle to working heig

ht and support on stands.

21. Install wheel speed sensor.

Positi

on wheel speed sensor on vertical link.

Page 111 of 2490

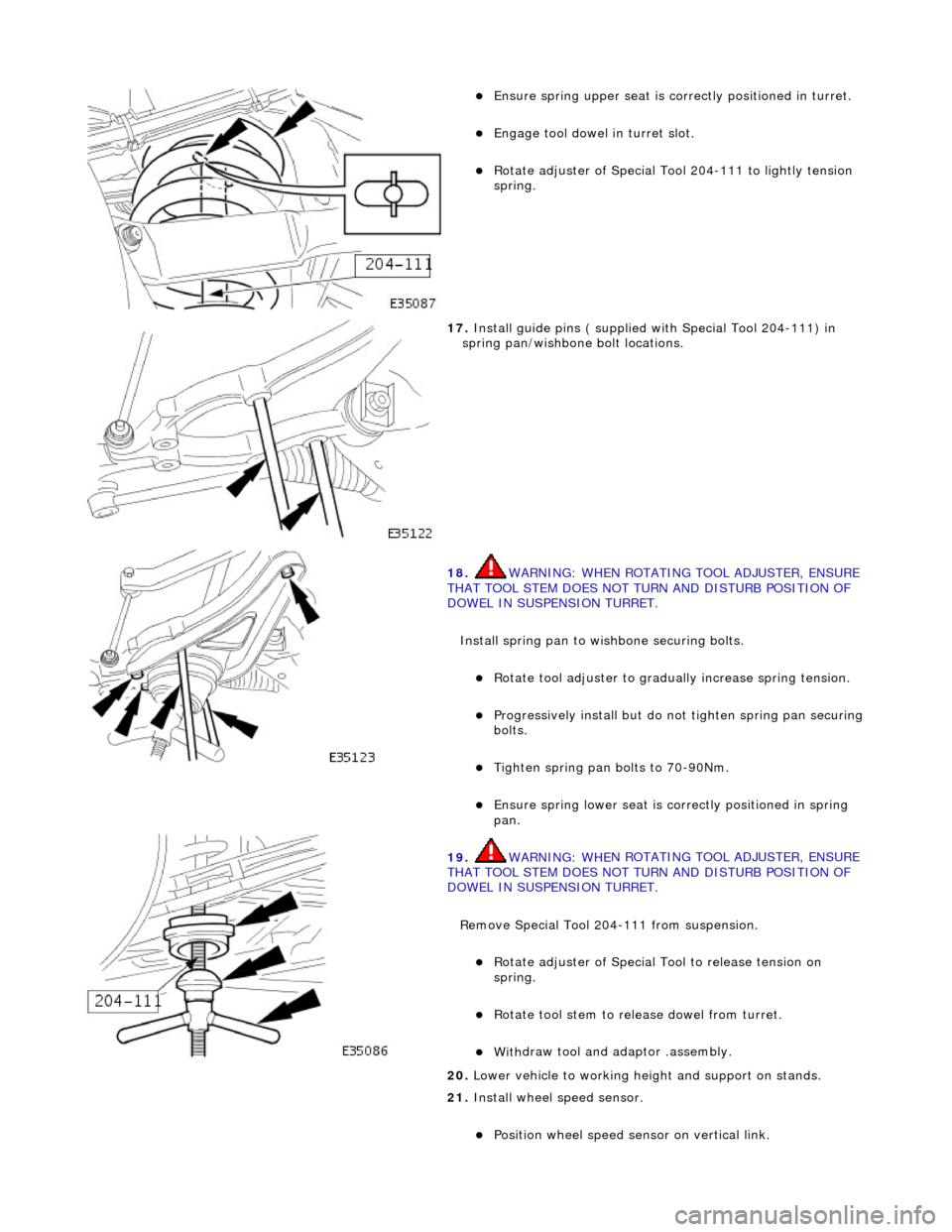

2. Ins

tall Special Tool 204-111 and spring assembly in suspension

turret.

P

osition spring assembly and Special Tool in suspension

turret.

Ensure spri

ng upper rubber se

at is correctly positioned

and fully seated.

Engage tool

dowel in turret slot.

3. Position spr

ing pan on lower wishbone.

Ro

tate adjuster of Special Tool to lightly tension spring.

Al

ign spring pan with lower wishbone bolt locations.

4. Inst

all suitable guide pins in

spring pan/wishbone bolt

locations.

5. WARNING: WHEN ROTATING TOOL ADJUSTER, ENSURE

THAT TOOL STEM DOES NOT TU RN AND DISTURB POSITION OF

DOWEL IN SUSPENSION TURRET.

Install spring pan to wishbone securing bolts.

Page 115 of 2490

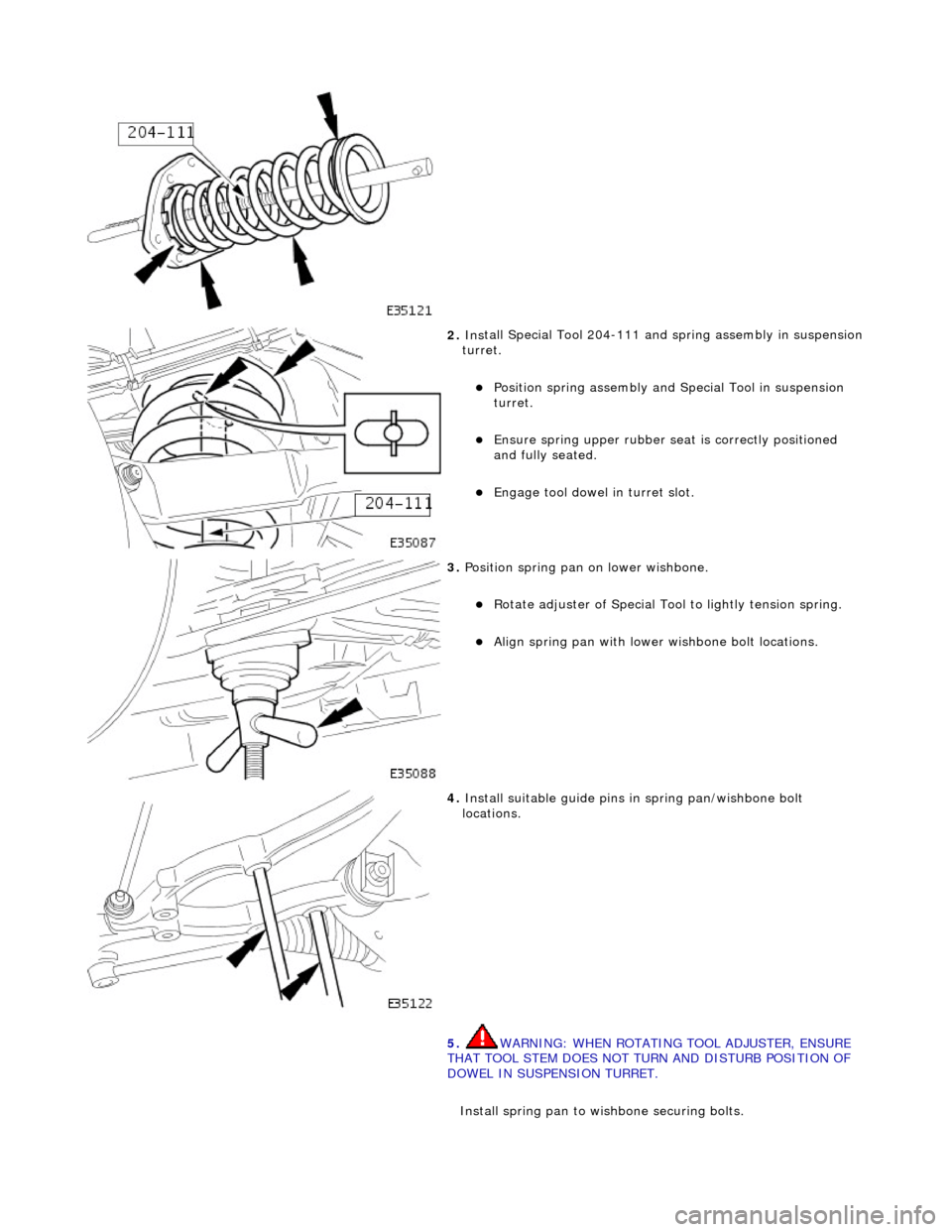

2. Ins

tall Special Tool 204-111 and spring assembly in suspension

turret.

P

osition spring assembly and Special Tool in suspension

turret.

Ensure spri

ng upper rubber se

at is correctly positioned

and fully seated.

Engage tool

dowel in turret slot.

3. Position spr

ing pan on lower wishbone.

R

otate adjuster of Special Tool 204-111 to lightly tension

spring.

4. Install guide pins ( su

pplied wi

th Special Tool 204-111) in

spring pan/wishbone bolt locations.

5. WARNING: WHEN ROTATING TOOL ADJUSTER, ENSURE

THAT TOOL STEM DOES NOT TU RN AND DISTURB POSITION OF

DOWEL IN SUSPENSION TURRET.

Install spring pan to wishbone securing bolts.

Page 318 of 2490

Comp

onent Tests

Bra

k

e Booster

1.

1. Chec k all

hoses and connections. All unused vacuum connectors should be capped. Hoses and their connections

should be correctly secured and in good condition with no holes and no collapsed areas. Inspect the valve on the

brake booster for damage.

2. 2. Check the hydraulic brake system for leaks or low fluid.

3. 3. With the transmission in PARK, stop the engine and apply the parking brake. Pump the brake pedal several times

to exhaust all vacuum in the system.

4. 4. With the engine switched off and all vacuum in the system exhausted, appl y the brake pedal and hold it down.

Start the engine. If the vacuum system is operating, the brake pedal will tend to move downward under constant

foot pressure. If no motion is felt, the vacuum booster system is not functioning.

5. 5. Remove the vacuum hose from the brake booster. Manifold vacuum should be available at the brake booster end

of the hose with the engine at idle speed and the transm ission in PARK or NEUTRAL. Make sure that all unused

vacuum outlets are correctly capped, hose connectors are correctly secured and vacuum hoses are in good

condition. When it is established that manifold vacuum is available to the brake booster, connect the vacuum hose

to the brake booster and repeat Step 3. If no downward movement of the brake pedal is felt, install a new brake

booster.

6. 6. Operate the engine for a minimum of 10 seconds at a fast idle. Stop the engine and allow the vehicle to stand for

10 minutes. Then, apply th e brake pedal with approximately 89 N ( 20lb) of force. The pedal feel (brake

application) should be the same as that noted with the engine running. If the brake pedal feels hard (no power

assist), install a new valve and then re peat the test. If the brake pedal still feels hard, in stall a new brake booster.

If the brake pedal movement feels spongy, bleed the brak e system. For additional information, refer to General

Procedures in this section.

Bra k

e Master Cylinder

Usual

l

y, the first and strongest

indicator of anything wrong in the brake syst em is a feeling through the brake pedal. In

diagnosing the condition of the brake master cylinder, check pedal feel as evidence of a brake concern. Check for brake

warning lamp illumination and the brake fluid le vel in the brake master cylinder reservoir.

Normal Conditio

ns

The fo

llowing conditions are considered norm

al and are not indications that the brake master cylinder is in need of repair.

New bra

ke systems are designed to produc

e a pedal effort that is not as hard as in the past. Complaints of light

pedal efforts should be compared to the pedal effort s of another vehicle of the same model and year.

The fl

uid level will fall with brake pad wear.

Abnormal Conditions

•

NOTE: Prior to carrying out any diag

nosis, make sure the brake system warning indicator is functional.

Changes in the brake pedal feel or brake pedal travel are in dicators that something could be wrong in the brake system. The

diagnostic procedure and techniques use brake pedal feel, warning indicator illu mination and low brake fluid level as

indicators to diagnosing brake system co ncerns. The following conditions are cons idered abnormal and indicate that the

brake master cylinder is in need of repair:

Brake ped a

l goes down fast. Th

is could be caused by an ex ternal or internal leak.

Brake pedal goes down slowly

. This could be

caused by an internal or external leak.

Brak

e pedal is low or feels spongy. This condition may be ca

used by no fluid in the brake master cylinder, reservoir

Page 319 of 2490

cap ven

t holes clogged or air in the hydraulic system.

Brake ped

al effort is excessive. This ma

y be caused by a bind or obstruction in the pedal/linkage, a faulty non return

valve, booster or insuffi cient booster vacuum.

R

ear brakes lock up during light pedal force. This may

be caused by damaged brake pads, an incorrectly adjusted

parking brake, a partially applied parking brake, a damaged ABS sensor or bearing failure.

Brake ped

al effort erratic. This condition could be caused by the brake booste

r or incorrectly installed brake pads.

Brake warning indicator i

s on. This may be caused

by low fluid level or float assembly damaged.

No

n Pressure Leaks

Any reduced fluid v

olume in the brake ma

ster cylinder reservoir condition may be caused by two types of none pressure

external leaks.

Type 1: An external leak may be occur at the master cylinder reservoir cap because of incorre ct positioning of gasket and

cap. Reposition cap and gasket.

Type 2: An external leak may occur at th e reservoir mounting seals. Repair such a leak by installing new seals and make

sure that the reservoir retainin g bolt is correctly installed.

Page 396 of 2490

Parking Brake and Actuation - P

arking Brake Control

Re

mo

val and Installation

Remov

a

l

W

A

RNING: BRAKE DUST, IF INHALED CAN DAMAGE YOUR

HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST INTO THE ATMOSPHERE.

CAUTION: Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

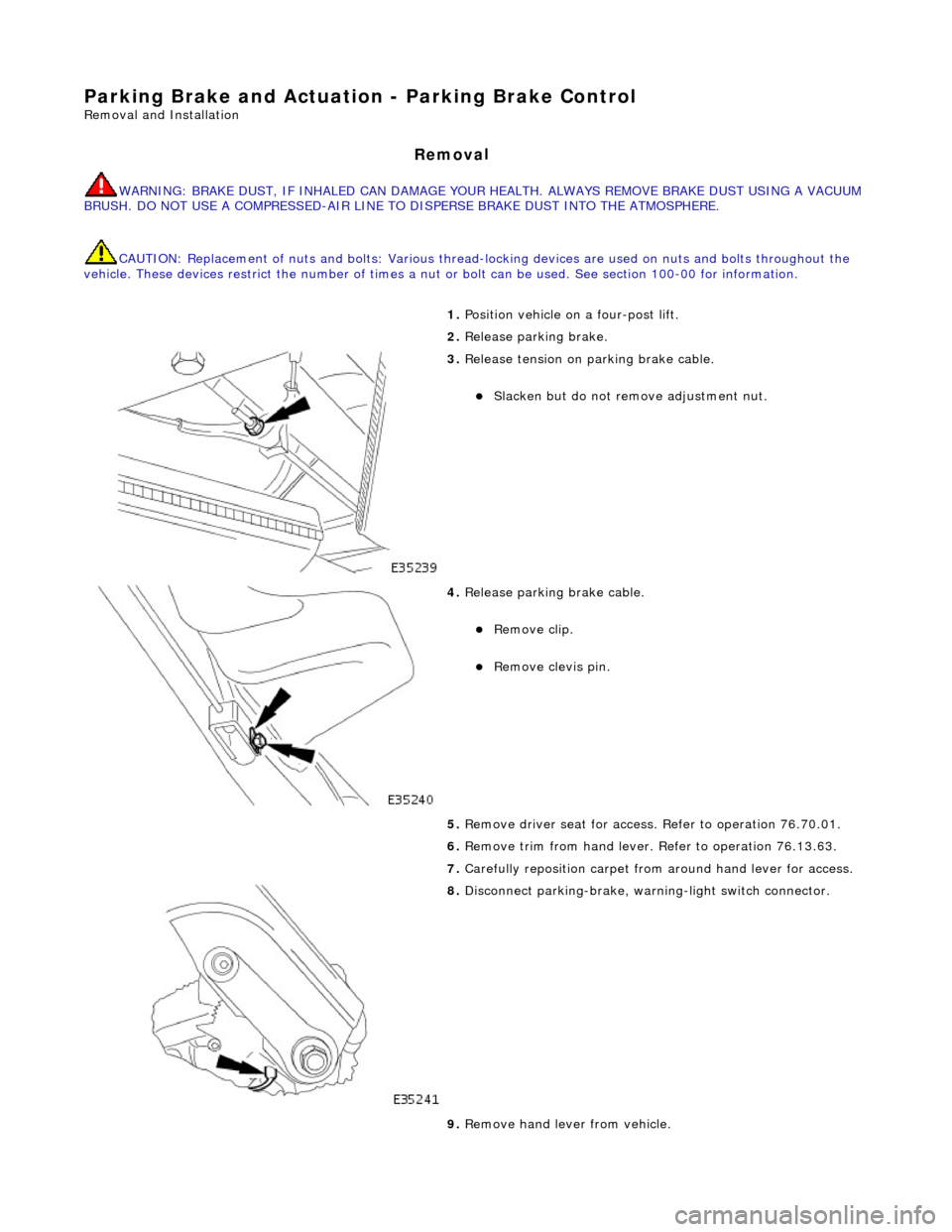

1. Position vehi cl

e on a four-post lift.

2. Release parking brake.

3. Releas

e tension on parking brake cable.

Slacken bu

t do not remove adjustment nut.

4. Releas

e parking brake cable.

Remo

ve clip.

Re

mo

ve clevis pin.

5. Remove driver seat for access . Refer to operation 76.70.01.

6. Remove trim from hand lever. Refer to operation 76.13.63.

7. Carefully reposition carpet from around hand lever for access.

8. Disconnect park ing-br

ake, warning-light switch connector.

9. Remove hand lever from vehicle.

Page 397 of 2490

I

nstallation

Re

move bolts.

R

emove lever.

10

.

Remove gasket.

11

.

Remove warning-light switch from lever.

R

emove screws.

Re

move switch.

1. Inst

all warning-light switch to hand lever.

Install and tigh

ten

screws to 3 Nm.

2. Install gasket to handbrake lever.

Page 415 of 2490

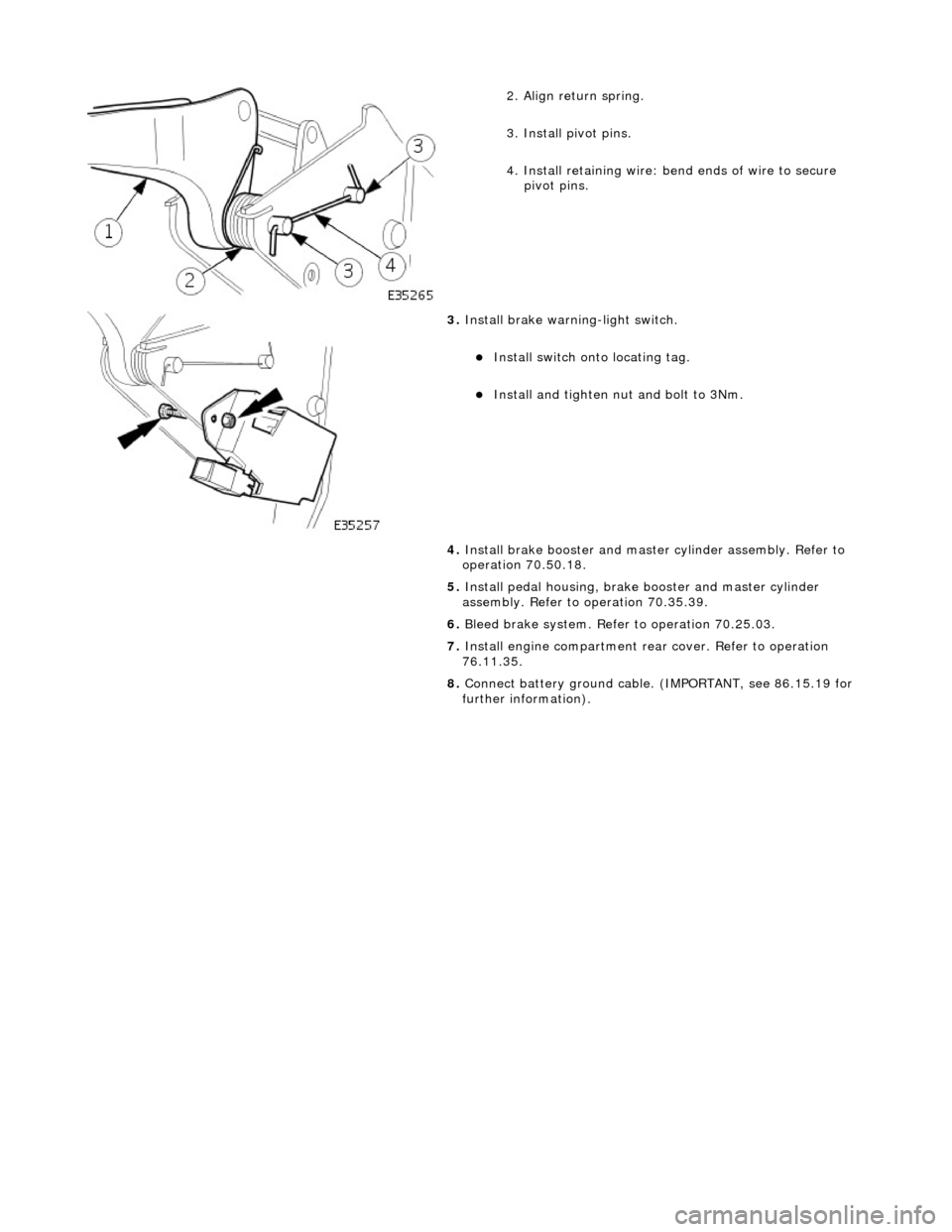

2

. Align return spring.

3. Install pivot pins.

4. Install retaining wire: bend ends of wire to secure

pivot pins.

3. Inst

all brake warning-light switch.

Inst

all switch onto locating tag.

Install and tigh

ten nut and bolt to 3Nm.

4. Install brake booster and master cylinder assembly. Refer to

operation 70.50.18.

5. Install pedal housing, brake booster and master cylinder

assembly. Refer to operation 70.35.39.

6. Bleed brake system. Refer to operation 70.25.03.

7. Install engine compartment rear cover. Refer to operation

76.11.35.

8. Connect battery ground cable. (IMPORTANT, see 86.15.19 for

further information).

Page 432 of 2490

It is a reciprocating two

-circuit pu

mp in which one brake circuit is as signed to each pump circuit.

It supplies th

e fluid pressure and vo

lume to supply the brake circuits under ABS and Traction control.

The pump is driven by an electri

c motor, with the pump

housing incorporating two lo w pressure accumulators and

damping chambers for each brake circuit.

The ac cu

mulator stores the pressure and smooths out the output pu

lses from the pump.

ABS Warning Lamp

The sys

tem will be set in a fail-safe mode if a problem is de

tected; a warning lamp on the instrument panel will notify the

driver there is a problem.

Anti-Lock Braking Sy

stem (ABS)

The AB

S components are combined with

an hydraulic booster and a tandem master cylinder to provide a two circuit braking

system. The system comprises, four wheel speed sensor s, a brake control modulator and an ABS warning lamp.

Should a wheel start to lock-up during braking a signal tr ansmitted from the wheel speed sensor to the brake control

modulator will start the hydraulic pump. The brake control modula tor will close the input valve of the line connected to the

locked-wheel to stop any increase in fluid pressure to the br ake caliper. If this fails to prevent the wheel locking, the

pressure in the caliper will be decreased by opening the return valve until th e wheel starts accelerating again. The fluid

pressure from the return va lve is directed into the low pressure accumulator, housed in the pump.

From the low pressure accumulator, fl uid is pumped through the damping cham ber to the brake master cylinder. The

pressure to the brake caliper will then be increased in small steps to maintain maximum adhesion between the tire and road

surface. This is achieved by closing the return valve, and opening the input valve and using the hydraulic pump to increase

the pressure.

Although the system senses all four wheels independently, the rear wheels are regulated as a pair. If a sensor on a rear

wheel detects a wheel decelerating rapidly, then the fluid pressure to both wheels is reduced. The fluid pressure is then

dictated by the wheel having the lowe st adhesion with the road surface.

The ABS system will be set in a fail-safe mode if a problem is detected; a warn ing lamp on the instrument panel will notify

the driver there is a problem. The brake system will still operate conventionally and with the same standard of performance

as a vehicle not equipped with ABS.

Automa tic Stability Control (ASC)

Th

e ASC utilizes the ABS sensing arrangement to provide the maximum traction force to propel the vehicle.

The ASC is switched on when the engine is started. The system can be switched off by pressing the 'ASC OFF' (the switched

is marked 'TRAC OFF' on vehicles fitted with traction control). The switch, which is situated in the center console switchpack,

lights up to warn that the system is sw itched off. An 'ASC' amber warning light flashes on the instrument panel when the

system detects a spinning wheel.

The ASC system uses engine intervention to reduce the torque delivered to the drive wheels to prevent them spinning.

Engine torque is re duced in three ways:

The

throttle is moved towards the closed position.

The ignition is retarded. F

u

el is cut-off at the cylinder injectors.

Wheel spin is detected by the wheel sp eed sensors and communicated to the AB S/TCCM. The ABS/TCCM uses information

from the controller area network (CAN) to calculate the torque that the engine should produce to stop the wheel spinning.

Torque reductions are then requested from the engine control module (ECM ) through the CAN. The throttle is then

positioned to provide the target torque, which has been calculated to prevent wheel spin. During the transient phase of

torque reduction the fuel is cut-off and th e ignition retarded Both the fuel cut-off an d ignition retard will be restored to

normal when the throttle is set to its new position.

The ASC uses a brake control modulator with six solenoid va lves: three normally open inlet valves and three normally