Coolant JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 12 of 3039

SpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingEngine Cooling - V8 5.0L Petrol/V8 S/C 5.0L PetrolGeneral ProceduresCooling System Draining and Vacuum Filling

Cooling System Partial Draining, Filling and Bleeding - V8 S/C 5.0L Petrol

Cooling System Draining, Filling and Bleeding - V8 S/C 5.0L PetrolRemoval and InstallationAuxiliary Radiator

Coolant Expansion Tank

Cooling Fan Motor and Shroud - Vehicles With: Supercharger

Cooling Module - Vehicles With: Supercharger

Coolant Pump - Vehicles With: Supercharger

Radiator (26.40.01) - Vehicles With: Supercharger

Thermostat Housing - Vehicles With: Supercharger303-03D: Supercharger Cooling - V8 S/C 5.0L Petrol

Description and OperationComponent Location

Overview

System Operation and Component DescriptionRemoval and InstallationRadiator303-04E: Fuel Charging and Controls - V8 S/C 5.0L PetrolSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingFuel Charging and ControlsGeneral ProceduresFuel Injection Component CleaningRemoval and InstallationFuel Injectors

Fuel Rail LH

Fuel Rail RH

Left-Hand Fuel Rail High-Pressure Fuel Pump

Right-Hand Fuel Rail High-Pressure Fuel Pump303-03C: Engine Cooling - V8 5.0L Petrol/V8 S/C 5.0L Petrol

Page 15 of 3039

Catalyst Monitor Sensor RH

Crankshaft Position (CKP) Sensor

Engine Control Module (ECM)

Engine Coolant Temperature (ECT) Sensor

Engine Oil Level Sensor

Front Knock Sensor (KS) LH

Front Knock Sensor (KS) RH

Fuel Rail Pressure (FRP) Sensor

Heated Oxygen Sensor (HO2S) LH

Heated Oxygen Sensor (HO2S) RH

Manifold Absolute Pressure (MAP) Sensor

Mass Air Flow (MAF) Sensor

Rear Knock Sensor (KS) LH

Rear Knock Sensor (KS) RH

Variable Valve Timing (VVT) Oil Control Solenoid LH

Variable Valve Timing (VVT) Oil Control Solenoid RH307: Automatic Transmission/Transaxle

307-01B: Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L

PetrolSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingDiagnosticsGeneral ProceduresTransmission Fluid Level Check

Transmission Fluid Drain and RefillRemoval and InstallationInput Shaft Seal

Extension Housing Seal

Transmission Control Module (TCM) and Main Control Valve Body

Transmission Fluid Pan, Gasket and Filter

Transmission Support Insulator - V8 5.0L Petrol/V8 S/C 5.0L Petrol

Transmission, Transmission Fluid Cooler and Transmission Fluid Cooler Tubes - V8 5.0L Petrol/V8

S/C 5.0L Petrol

Transmission and Transmission Fluid Cooler - V8 5.0L Petrol/V8 S/C 5.0L PetrolRemovalTransmission - V8 5.0L Petrol/V8 S/C 5.0L PetrolInstallationTransmission - V8 5.0L Petrol/V8 S/C 5.0L Petrol

Page 19 of 3039

Blower Motor Control Module

Center Registers

Climate Control Assembly

Climate Control Module

Defrost Vent/Register Blend Door Actuator

Driver Side Register

Evaporator

Floor Console Register

Footwell Vent/Duct Blend Door Actuator

Heater Core

Heater Core and Evaporator Core Housing

Instrument Panel Register Trim Panel

In-Vehicle Temperature Sensor

Passenger Side Register

Pollen Filter

Recirculation Blend Door Actuator

Sunload Sensor

Thermostatic Expansion Valve

Desiccant Bag - V6 3.0L Petrol/V8 5.0L Petrol/V8 S/C 5.0L Petrol412-02: Auxiliary Climate ControlSpecificationDescription and OperationComponent Location

System Operation and Component DescriptionRemoval and InstallationAuxiliary Coolant Flow Pump

Electric Booster Heater412-03: Air ConditioningSpecificationDiagnosis and TestingAir ConditioningRemoval and InstallationAir Conditioning (A/C) Compressor - V8 5.0L Petrol/V8 S/C 5.0L Petrol

Condenser Core - V8 S/C 5.0L Petrol

Pressure Cutoff Switch (82.10.32)413: Instrumentation and Warning Systems

413-01: Instrument ClusterSpecificationDescription and OperationComponent Location

Overview

System Operation and Component Description

Page 53 of 3039

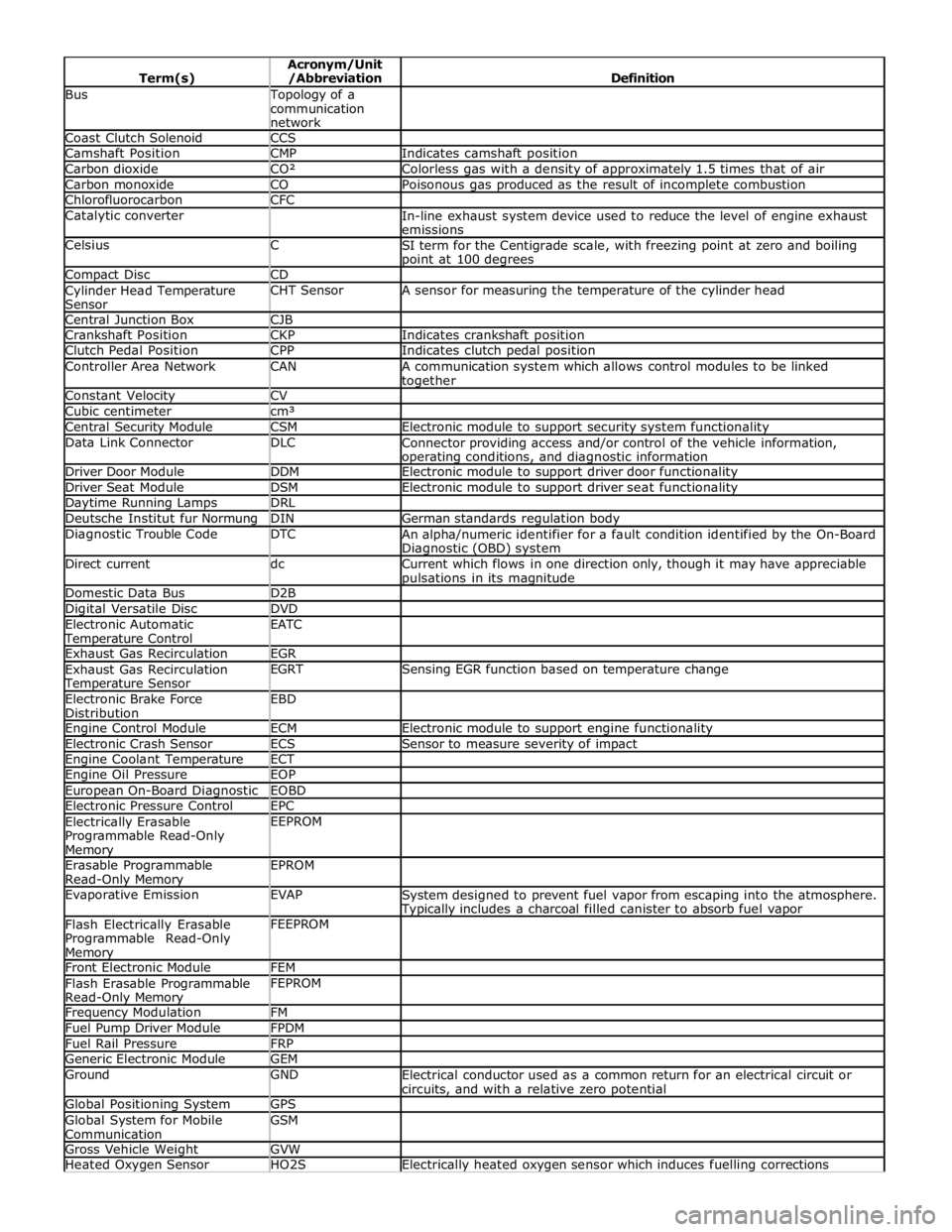

Bus Topology of a

communication

network Coast Clutch Solenoid CCS Camshaft Position CMP Indicates camshaft position Carbon dioxide CO² Colorless gas with a density of approximately 1.5 times that of air Carbon monoxide CO Poisonous gas produced as the result of incomplete combustion Chlorofluorocarbon CFC Catalytic converter

In-line exhaust system device used to reduce the level of engine exhaust

emissions Celsius C

SI term for the Centigrade scale, with freezing point at zero and boiling point at 100 degrees Compact Disc CD Cylinder Head Temperature

Sensor CHT Sensor A sensor for measuring the temperature of the cylinder head Central Junction Box CJB Crankshaft Position CKP Indicates crankshaft position Clutch Pedal Position CPP Indicates clutch pedal position Controller Area Network CAN

A communication system which allows control modules to be linked together Constant Velocity CV Cubic centimeter cm³ Central Security Module CSM Electronic module to support security system functionality Data Link Connector DLC

Connector providing access and/or control of the vehicle information, operating conditions, and diagnostic information Driver Door Module DDM Electronic module to support driver door functionality Driver Seat Module DSM Electronic module to support driver seat functionality Daytime Running Lamps DRL Deutsche Institut fur Normung DIN German standards regulation body Diagnostic Trouble Code DTC

An alpha/numeric identifier for a fault condition identified by the On-Board Diagnostic (OBD) system Direct current dc

Current which flows in one direction only, though it may have appreciable pulsations in its magnitude Domestic Data Bus D2B Digital Versatile Disc DVD Electronic Automatic Temperature Control EATC

Exhaust Gas Recirculation EGR Exhaust Gas Recirculation Temperature Sensor EGRT Sensing EGR function based on temperature change Electronic Brake Force

Distribution EBD

Engine Control Module ECM Electronic module to support engine functionality Electronic Crash Sensor ECS Sensor to measure severity of impact Engine Coolant Temperature ECT Engine Oil Pressure EOP European On-Board Diagnostic EOBD Electronic Pressure Control EPC Electrically Erasable

Programmable Read-Only Memory EEPROM

Erasable Programmable

Read-Only Memory EPROM

Evaporative Emission EVAP

System designed to prevent fuel vapor from escaping into the atmosphere. Typically includes a charcoal filled canister to absorb fuel vapor Flash Electrically Erasable

Programmable Read-Only Memory FEEPROM

Front Electronic Module FEM Flash Erasable Programmable

Read-Only Memory FEPROM

Frequency Modulation FM Fuel Pump Driver Module FPDM Fuel Rail Pressure FRP Generic Electronic Module GEM Ground GND

Electrical conductor used as a common return for an electrical circuit or

circuits, and with a relative zero potential Global Positioning System GPS Global System for Mobile

Communication GSM

Gross Vehicle Weight GVW Heated Oxygen Sensor HO2S Electrically heated oxygen sensor which induces fuelling corrections

Page 103 of 3039

General Information - Road/Roller Testing

Description and Operation Published: 11-May-2011

Road or roller testing may be carried out for various reasons and a procedure detailing pre-test checks, through engine starting

and stopping, pre-driving checks, on-test checks to final checks on completion of the test is given in this section.

Unless complete vehicle performance is being checked, the full road test procedure need not be carried out. Instead, those

items particularly relevant to the system/s being checked can be extracted.

Pre - Test Checks

WARNING: If the brake system hydraulic fluid level is low, pedal travel is excessive or a hydraulic leak is found, do not

attempt to road test the vehicle until the reason for the low fluid level, excessive pedal travel or hydraulic leak is found and

rectified.

It is suggested that pre-test checks, and functional tests of those systems/circuits which affect the safe and legal operations

of the vehicle, such as brakes, lights and steering, should always be carried out before the road or roller test.

Engine oil level

Engine coolant level

Tires, for correct pressure, compatible types and tread patterns, and wear within limits

There is sufficient fuel in the tank to complete the test

All around the engine, transmission and under the vehicle for oil, coolant, hydraulic and fuel leaks. Make a note of any

apparent leaks and wipe off the surrounding areas to make it easier to identify the extent of the leak on completion of

the test

Starting the Engine

CAUTION: On initial drive away from cold and within the first 1.5 km (1 mile), do not depress accelerator pedal beyond

half travel until the vehicle has attained a minimum speed of 25 km/h (15 miles/h). Never operate at high engine speed or

with the accelerator pedal at full travel whilst the engine is cold.

With the ignition switched off, check:

The parking brake is applied

The transmission selector lever is in Park

All instrument gauges (except fuel gauge) read zero

With the ignition switched on, check:

Ignition controlled warning lamps come on

Engine coolant temperature gauge registers a reading compatible with the engine coolant temperature

Fuel gauge registers a reading appropriate to the fuel level in the tank

The operation of the parking brake and brake fluid level warning lamps

On Road or Roller Test Check:

CAUTION: If road testing, check the brake operation while still travelling at low speed before continuing with the test. If

the brakes pull to one side, or appear to be otherwise faulty, do not continue with the road test until the fault has been found

and rectified.

Initial gear engagement is smooth

Parking brake control operates smoothly and the parking brake releases quickly and completely

Transmission takes up the drive smoothly, without judder

The engine power output is satisfactory, full power is achieved, acceleration is smooth and pedal operation not stiff or

heavy, and engine speed returns to idle correctly

There is no excessive or abnormally colored smoke from the engine under normal driving, heavy load or overrun

conditions

Steering operation, including power steering, is smooth, accurate, not excessively heavy or with excessive free play or

vibration. Does not pull to one side and self centres smoothly after cornering

Speedometer, oil pressure warning lamp, coolant temperature gauge and tachometer register the correct readings or

operate correctly

Switches and controls operate smoothly and positively, warning lamps operate correctly and the direction indicator

control self cancels when the steering is returned to the straight ahead position

Heating and ventilation systems work correctly and effectively

Brake operation and efficiency

Brake Testing

WARNING: When brake testing, avoid breathing the smoke or fumes from hot brakes, this may contain asbestos dust

which is hazardous to health, see Health and Safety Precautions.

Page 104 of 3039

Avoid brake testing on busy roads where it can cause inconvenience or danger to other road users.

CAUTION: Brake testing which includes heavy brake applications should not be carried out with new brake pads/discs or

linings/drums until the components have bedded-in. New brake friction components will not reach full efficiency until the

bedding-in process is complete.

Test the brakes at several speeds within the normal operating range using both light and heavy pedal pressure. Note any

tendency to snatch, pull or drag, and any undue delay in application or release.

Allow the vehicle to coast and note any tendency to pull to one side, or evidence that the brakes are binding.

After stopping the vehicle (not immediately after a period of heavy braking), carefully check the brake temperature. A disc

which feels hot, or appreciably hotter than the others, indicates that the brake is binding.

After completion of the test, check for:

Oil, coolant, hydraulic, air and fuel leaks

Abnormal temperature of any moving components or assemblies, e.g. wheel hubs, transmission, axle etc., which might

indicate over tightness or lack of lubrication

Page 142 of 3039

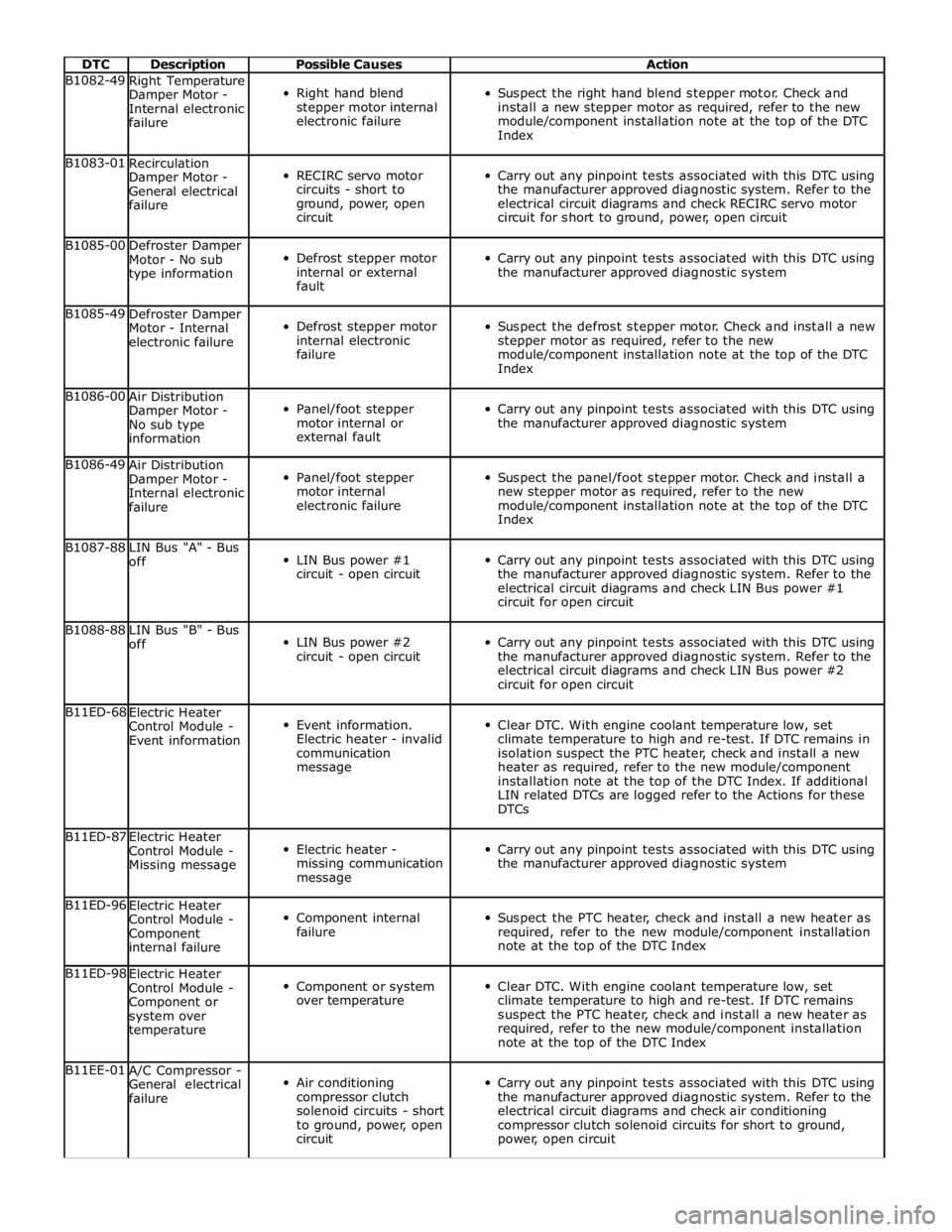

DTC Description Possible Causes Action B1082-49

Right Temperature

Damper Motor -

Internal electronic

failure

Right hand blend

stepper motor internal

electronic failure

Suspect the right hand blend stepper motor. Check and

install a new stepper motor as required, refer to the new

module/component installation note at the top of the DTC

Index B1083-01

Recirculation

Damper Motor -

General electrical

failure

RECIRC servo motor

circuits - short to

ground, power, open

circuit

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check RECIRC servo motor

circuit for short to ground, power, open circuit B1085-00

Defroster Damper

Motor - No sub

type information

Defrost stepper motor

internal or external

fault

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B1085-49

Defroster Damper

Motor - Internal

electronic failure

Defrost stepper motor

internal electronic

failure

Suspect the defrost stepper motor. Check and install a new

stepper motor as required, refer to the new

module/component installation note at the top of the DTC

Index B1086-00

Air Distribution

Damper Motor -

No sub type

information

Panel/foot stepper

motor internal or

external fault

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B1086-49

Air Distribution

Damper Motor -

Internal electronic

failure

Panel/foot stepper

motor internal

electronic failure

Suspect the panel/foot stepper motor. Check and install a

new stepper motor as required, refer to the new

module/component installation note at the top of the DTC

Index B1087-88

LIN Bus "A" - Bus

off

LIN Bus power #1

circuit - open circuit

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check LIN Bus power #1

circuit for open circuit B1088-88

LIN Bus "B" - Bus

off

LIN Bus power #2

circuit - open circuit

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check LIN Bus power #2

circuit for open circuit B11ED-68

Electric Heater

Control Module -

Event information

Event information.

Electric heater - invalid

communication

message

Clear DTC. With engine coolant temperature low, set

climate temperature to high and re-test. If DTC remains in

isolation suspect the PTC heater, check and install a new

heater as required, refer to the new module/component

installation note at the top of the DTC Index. If additional

LIN related DTCs are logged refer to the Actions for these

DTCs B11ED-87

Electric Heater

Control Module -

Missing message

Electric heater -

missing communication

message

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B11ED-96

Electric Heater

Control Module -

Component

internal failure

Component internal

failure

Suspect the PTC heater, check and install a new heater as

required, refer to the new module/component installation

note at the top of the DTC Index B11ED-98

Electric Heater

Control Module -

Component or

system over

temperature

Component or system

over temperature

Clear DTC. With engine coolant temperature low, set

climate temperature to high and re-test. If DTC remains

suspect the PTC heater, check and install a new heater as

required, refer to the new module/component installation

note at the top of the DTC Index B11EE-01

A/C Compressor -

General electrical

failure

Air conditioning

compressor clutch

solenoid circuits - short

to ground, power, open

circuit

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check air conditioning

compressor clutch solenoid circuits for short to ground,

power, open circuit

Page 173 of 3039

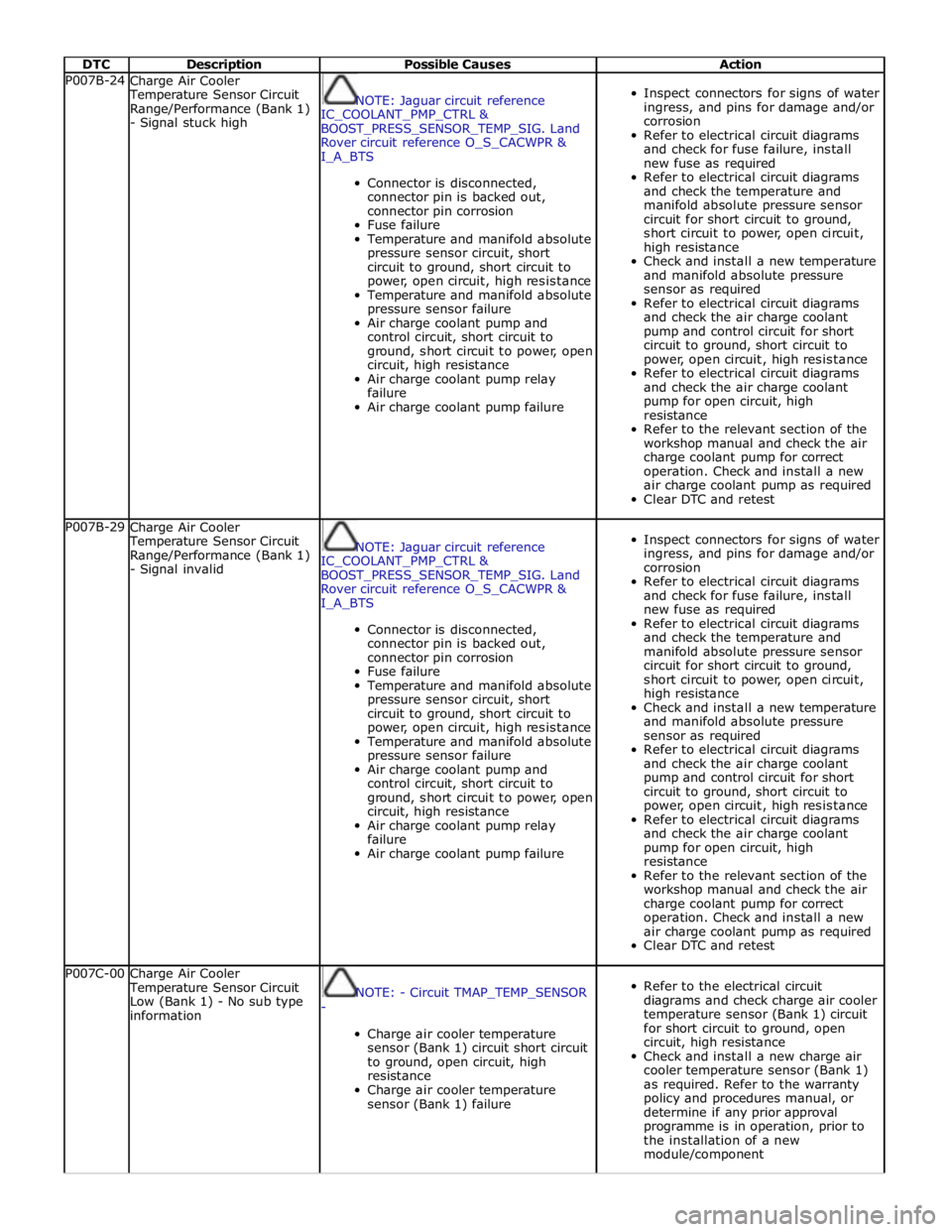

DTC Description Possible Causes Action P007B-24

Charge Air Cooler

Temperature Sensor Circuit

Range/Performance (Bank 1)

- Signal stuck high

NOTE: Jaguar circuit reference

IC_COOLANT_PMP_CTRL &

BOOST_PRESS_SENSOR_TEMP_SIG. Land

Rover circuit reference O_S_CACWPR &

I_A_BTS

Connector is disconnected,

connector pin is backed out,

connector pin corrosion

Fuse failure

Temperature and manifold absolute

pressure sensor circuit, short

circuit to ground, short circuit to

power, open circuit, high resistance

Temperature and manifold absolute

pressure sensor failure

Air charge coolant pump and

control circuit, short circuit to

ground, short circuit to power, open

circuit, high resistance

Air charge coolant pump relay

failure

Air charge coolant pump failure

Inspect connectors for signs of water

ingress, and pins for damage and/or

corrosion

Refer to electrical circuit diagrams

and check for fuse failure, install

new fuse as required

Refer to electrical circuit diagrams

and check the temperature and

manifold absolute pressure sensor

circuit for short circuit to ground,

short circuit to power, open circuit,

high resistance

Check and install a new temperature

and manifold absolute pressure

sensor as required

Refer to electrical circuit diagrams

and check the air charge coolant

pump and control circuit for short

circuit to ground, short circuit to

power, open circuit, high resistance

Refer to electrical circuit diagrams

and check the air charge coolant

pump for open circuit, high

resistance

Refer to the relevant section of the

workshop manual and check the air

charge coolant pump for correct

operation. Check and install a new

air charge coolant pump as required

Clear DTC and retest P007B-29

Charge Air Cooler

Temperature Sensor Circuit

Range/Performance (Bank 1)

- Signal invalid

NOTE: Jaguar circuit reference

IC_COOLANT_PMP_CTRL &

BOOST_PRESS_SENSOR_TEMP_SIG. Land

Rover circuit reference O_S_CACWPR &

I_A_BTS

Connector is disconnected,

connector pin is backed out,

connector pin corrosion

Fuse failure

Temperature and manifold absolute

pressure sensor circuit, short

circuit to ground, short circuit to

power, open circuit, high resistance

Temperature and manifold absolute

pressure sensor failure

Air charge coolant pump and

control circuit, short circuit to

ground, short circuit to power, open

circuit, high resistance

Air charge coolant pump relay

failure

Air charge coolant pump failure

Inspect connectors for signs of water

ingress, and pins for damage and/or

corrosion

Refer to electrical circuit diagrams

and check for fuse failure, install

new fuse as required

Refer to electrical circuit diagrams

and check the temperature and

manifold absolute pressure sensor

circuit for short circuit to ground,

short circuit to power, open circuit,

high resistance

Check and install a new temperature

and manifold absolute pressure

sensor as required

Refer to electrical circuit diagrams

and check the air charge coolant

pump and control circuit for short

circuit to ground, short circuit to

power, open circuit, high resistance

Refer to electrical circuit diagrams

and check the air charge coolant

pump for open circuit, high

resistance

Refer to the relevant section of the

workshop manual and check the air

charge coolant pump for correct

operation. Check and install a new

air charge coolant pump as required

Clear DTC and retest P007C-00

Charge Air Cooler

Temperature Sensor Circuit

Low (Bank 1) - No sub type

information

NOTE: - Circuit TMAP_TEMP_SENSOR

-

Charge air cooler temperature

sensor (Bank 1) circuit short circuit

to ground, open circuit, high

resistance

Charge air cooler temperature

sensor (Bank 1) failure

Refer to the electrical circuit

diagrams and check charge air cooler

temperature sensor (Bank 1) circuit

for short circuit to ground, open

circuit, high resistance

Check and install a new charge air

cooler temperature sensor (Bank 1)

as required. Refer to the warranty

policy and procedures manual, or

determine if any prior approval

programme is in operation, prior to

the installation of a new

module/component

Page 340 of 3039

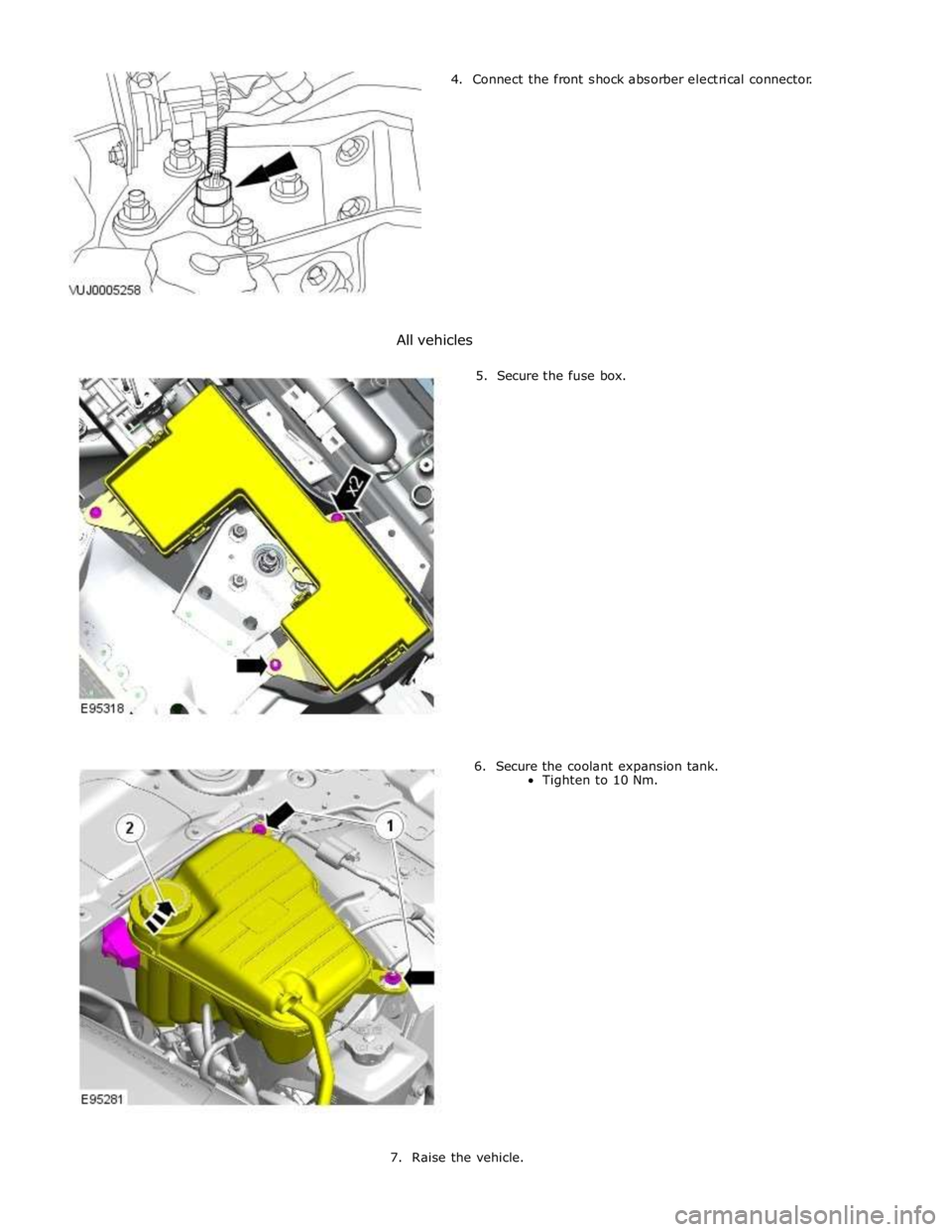

4. Connect the front shock absorber electrical connector.

All vehicles

5. Secure the fuse box.

6. Secure the coolant expansion tank.

Tighten to 10 Nm.

7. Raise the vehicle.

Page 682 of 3039

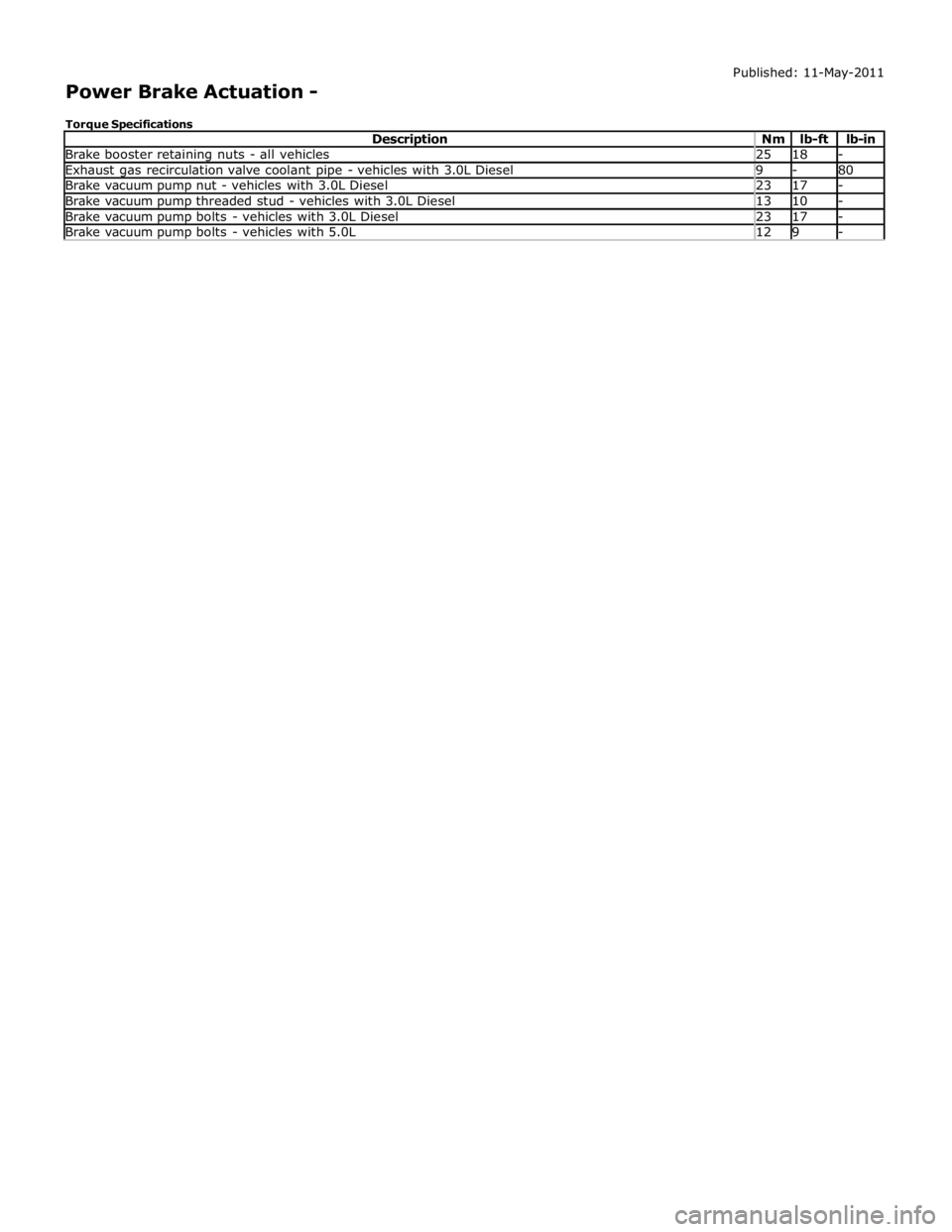

Brake booster retaining nuts - all vehicles 25 18 - Exhaust gas recirculation valve coolant pipe - vehicles with 3.0L Diesel 9 - 80 Brake vacuum pump nut - vehicles with 3.0L Diesel 23 17 - Brake vacuum pump threaded stud - vehicles with 3.0L Diesel 13 10 - Brake vacuum pump bolts - vehicles with 3.0L Diesel 23 17 - Brake vacuum pump bolts - vehicles with 5.0L 12 9 -