ignition coil JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 13 of 3039

Throttle Body303-05D: Accessory Drive - V8 S/C 5.0L PetrolSpecificationDescription and OperationComponent Location

OverviewRemoval and InstallationAccessory Drive Belt

Accessory Drive Belt Idler Pulley

Accessory Drive Belt Tensioner

Supercharger Belt Idler Pulley

Supercharger Belt Tensioner303-06C: Starting System - V8 5.0L Petrol/V8 S/C 5.0L PetrolSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingStarting System

Starting System - Vehicles With: Smart KeyRemoval and InstallationStarter Motor303-07B: Engine Ignition - V8 5.0L Petrol/V8 S/C 5.0L PetrolSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingEngine IgnitionRemoval and InstallationIgnition Coil-On-Plug - V8 S/C 5.0L Petrol303-08C: Engine Emission Control - V8 5.0L Petrol/V8 S/C 5.0L Petrol

Description and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingEngine Emission Control303-12D: Intake Air Distribution and Filtering - V8 S/C 5.0L PetrolSpecification

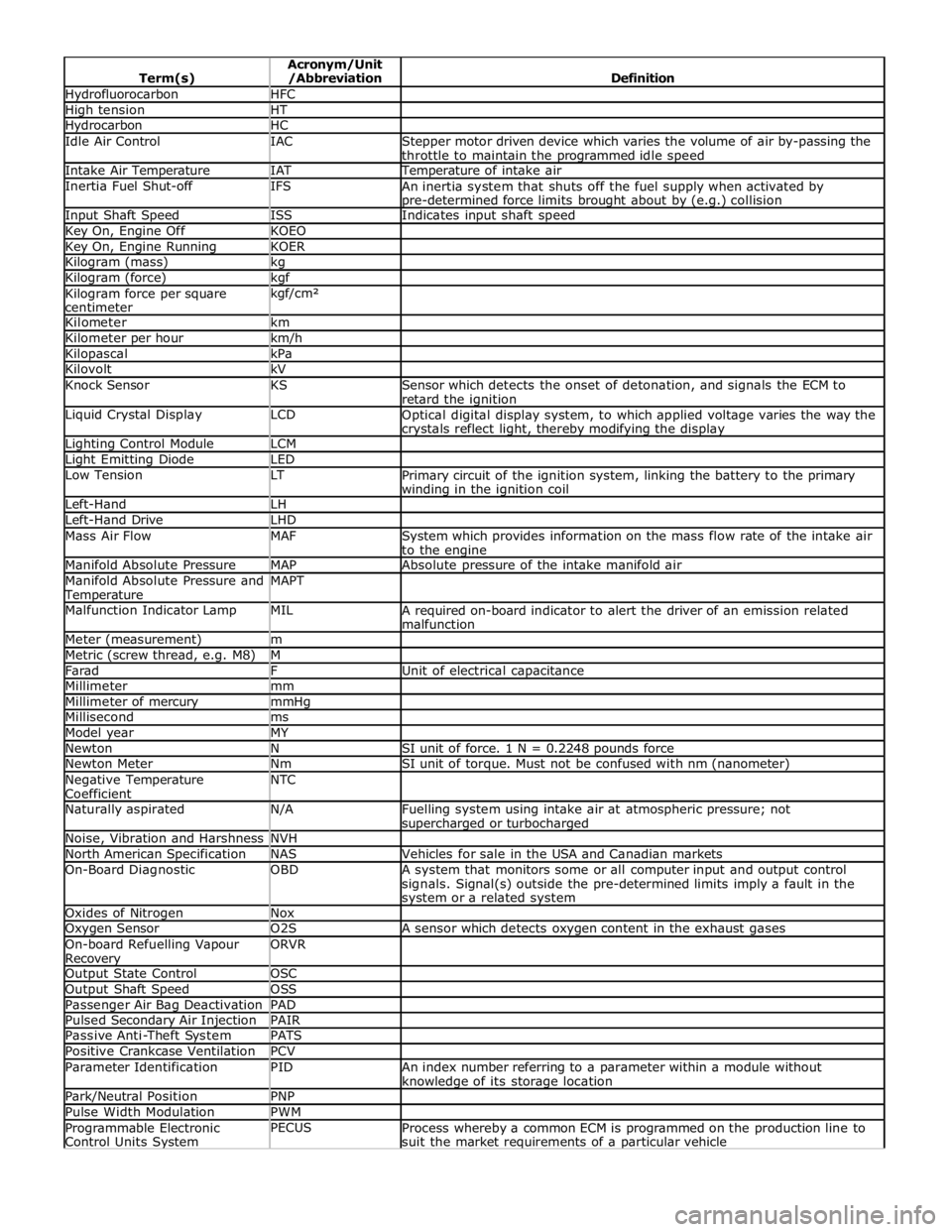

Page 54 of 3039

Hydrofluorocarbon HFC High tension HT Hydrocarbon HC Idle Air Control IAC

Stepper motor driven device which varies the volume of air by-passing the

throttle to maintain the programmed idle speed Intake Air Temperature IAT Temperature of intake air Inertia Fuel Shut-off IFS

An inertia system that shuts off the fuel supply when activated by pre-determined force limits brought about by (e.g.) collision Input Shaft Speed ISS Indicates input shaft speed Key On, Engine Off KOEO Key On, Engine Running KOER Kilogram (mass) kg Kilogram (force) kgf Kilogram force per square

centimeter kgf/cm²

Kilometer km Kilometer per hour km/h Kilopascal kPa Kilovolt kV Knock Sensor KS

Sensor which detects the onset of detonation, and signals the ECM to

retard the ignition Liquid Crystal Display LCD

Optical digital display system, to which applied voltage varies the way the crystals reflect light, thereby modifying the display Lighting Control Module LCM Light Emitting Diode LED Low Tension LT

Primary circuit of the ignition system, linking the battery to the primary winding in the ignition coil Left-Hand LH Left-Hand Drive LHD Mass Air Flow MAF

System which provides information on the mass flow rate of the intake air

to the engine Manifold Absolute Pressure MAP Absolute pressure of the intake manifold air Manifold Absolute Pressure and Temperature MAPT

Malfunction Indicator Lamp MIL

A required on-board indicator to alert the driver of an emission related

malfunction Meter (measurement) m Metric (screw thread, e.g. M8) M Farad F Unit of electrical capacitance Millimeter mm Millimeter of mercury mmHg Millisecond ms Model year MY Newton N SI unit of force. 1 N = 0.2248 pounds force Newton Meter Nm SI unit of torque. Must not be confused with nm (nanometer) Negative Temperature

Coefficient NTC

Naturally aspirated N/A

Fuelling system using intake air at atmospheric pressure; not supercharged or turbocharged Noise, Vibration and Harshness NVH North American Specification NAS Vehicles for sale in the USA and Canadian markets On-Board Diagnostic OBD

A system that monitors some or all computer input and output control

signals. Signal(s) outside the pre-determined limits imply a fault in the system or a related system Oxides of Nitrogen Nox Oxygen Sensor O2S A sensor which detects oxygen content in the exhaust gases On-board Refuelling Vapour Recovery ORVR

Output State Control OSC Output Shaft Speed OSS Passenger Air Bag Deactivation PAD Pulsed Secondary Air Injection PAIR Passive Anti-Theft System PATS Positive Crankcase Ventilation PCV Parameter Identification PID

An index number referring to a parameter within a module without knowledge of its storage location Park/Neutral Position PNP Pulse Width Modulation PWM Programmable Electronic

Control Units System PECUS

Process whereby a common ECM is programmed on the production line to

suit the market requirements of a particular vehicle

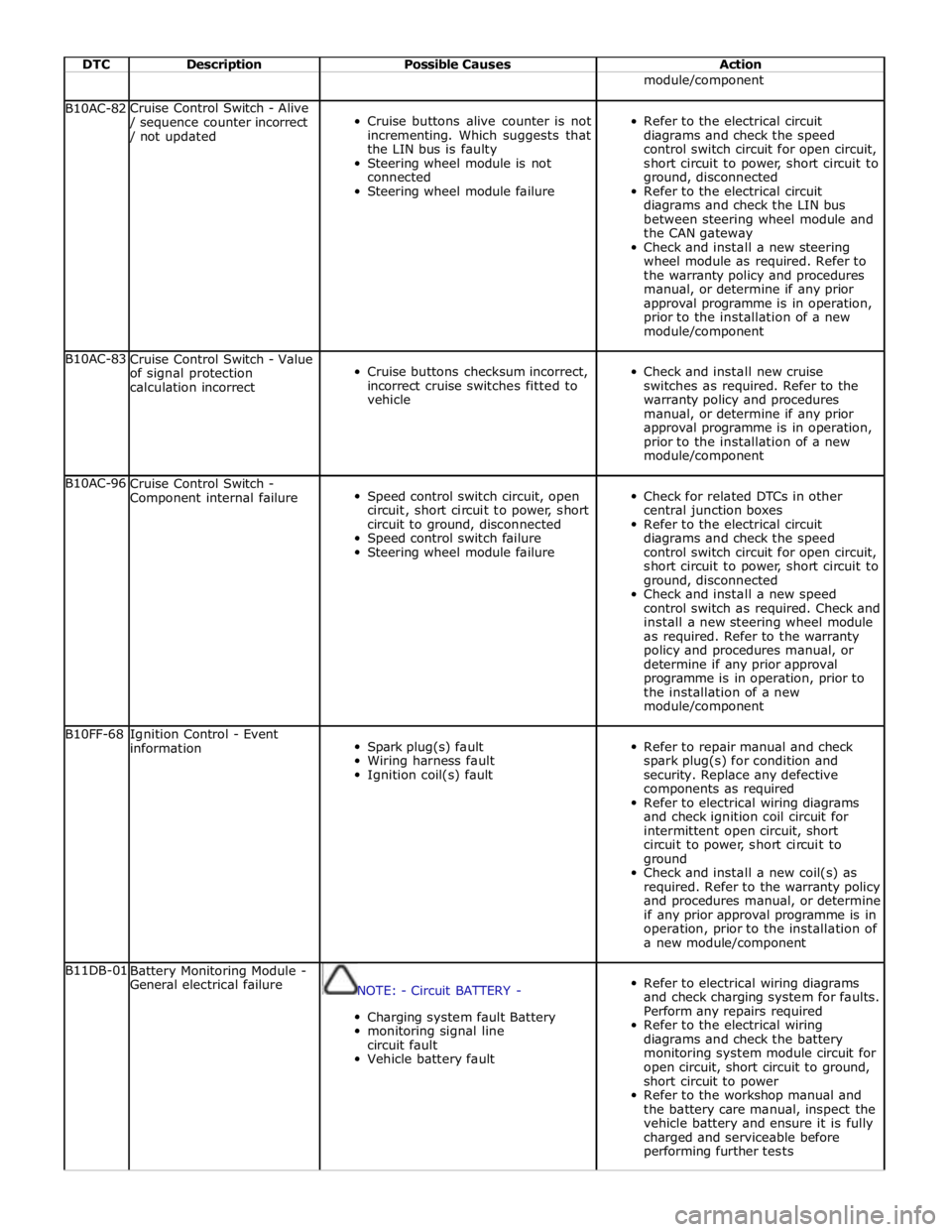

Page 165 of 3039

DTC Description Possible Causes Action module/component B10AC-82 Cruise Control Switch - Alive / sequence counter incorrect / not updated

Cruise buttons alive counter is not

incrementing. Which suggests that

the LIN bus is faulty

Steering wheel module is not

connected

Steering wheel module failure

Refer to the electrical circuit

diagrams and check the speed

control switch circuit for open circuit,

short circuit to power, short circuit to

ground, disconnected

Refer to the electrical circuit

diagrams and check the LIN bus

between steering wheel module and

the CAN gateway

Check and install a new steering

wheel module as required. Refer to

the warranty policy and procedures

manual, or determine if any prior

approval programme is in operation,

prior to the installation of a new

module/component B10AC-83

Cruise Control Switch - Value

of signal protection

calculation incorrect

Cruise buttons checksum incorrect,

incorrect cruise switches fitted to

vehicle

Check and install new cruise

switches as required. Refer to the

warranty policy and procedures

manual, or determine if any prior

approval programme is in operation,

prior to the installation of a new

module/component B10AC-96

Cruise Control Switch -

Component internal failure

Speed control switch circuit, open

circuit, short circuit to power, short

circuit to ground, disconnected

Speed control switch failure

Steering wheel module failure

Check for related DTCs in other

central junction boxes

Refer to the electrical circuit

diagrams and check the speed

control switch circuit for open circuit,

short circuit to power, short circuit to

ground, disconnected

Check and install a new speed

control switch as required. Check and

install a new steering wheel module

as required. Refer to the warranty

policy and procedures manual, or

determine if any prior approval

programme is in operation, prior to

the installation of a new

module/component B10FF-68

Ignition Control - Event

information

Spark plug(s) fault

Wiring harness fault

Ignition coil(s) fault

Refer to repair manual and check

spark plug(s) for condition and

security. Replace any defective

components as required

Refer to electrical wiring diagrams

and check ignition coil circuit for

intermittent open circuit, short

circuit to power, short circuit to

ground

Check and install a new coil(s) as

required. Refer to the warranty policy

and procedures manual, or determine

if any prior approval programme is in

operation, prior to the installation of

a new module/component B11DB-01

Battery Monitoring Module -

General electrical failure

NOTE: - Circuit BATTERY -

Charging system fault Battery

monitoring signal line

circuit fault

Vehicle battery fault

Refer to electrical wiring diagrams

and check charging system for faults.

Perform any repairs required

Refer to the electrical wiring

diagrams and check the battery

monitoring system module circuit for

open circuit, short circuit to ground,

short circuit to power

Refer to the workshop manual and

the battery care manual, inspect the

vehicle battery and ensure it is fully

charged and serviceable before

performing further tests

Page 839 of 3039

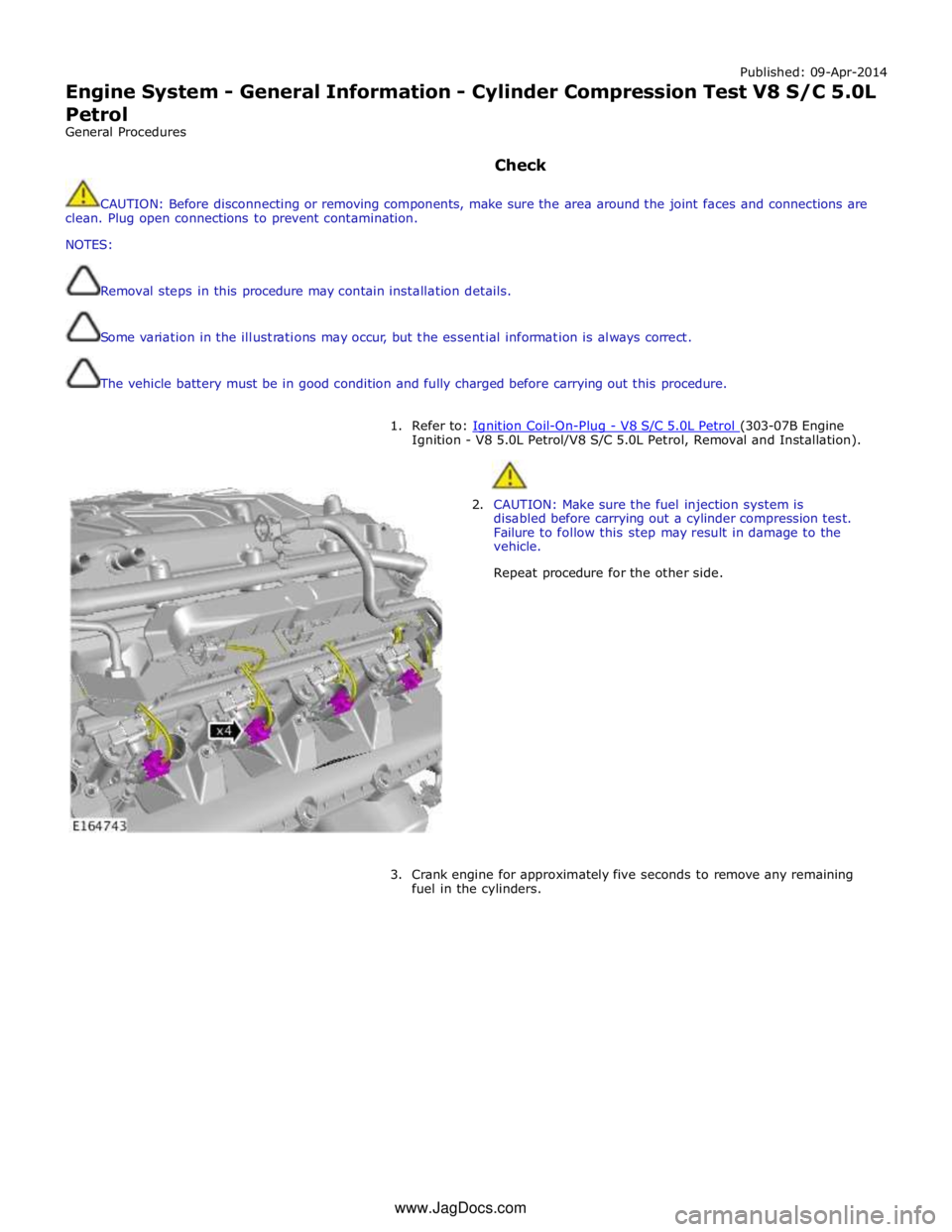

Published: 09-Apr-2014

Engine System - General Information - Cylinder Compression Test V8 S/C 5.0L

Petrol

General Procedures

Check

CAUTION: Before disconnecting or removing components, make sure the area around the joint faces and connections are

clean. Plug open connections to prevent contamination.

NOTES:

Removal steps in this procedure may contain installation details.

Some variation in the illustrations may occur, but the essential information is always correct.

The vehicle battery must be in good condition and fully charged before carrying out this procedure.

1. Refer to: Ignition Coil-On-Plug - V8 S/C 5.0L Petrol (303-07B Engine Ignition - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation).

2. CAUTION: Make sure the fuel injection system is

disabled before carrying out a cylinder compression test.

Failure to follow this step may result in damage to the

vehicle.

Repeat procedure for the other side.

3. Crank engine for approximately five seconds to remove any remaining

fuel in the cylinders. www.JagDocs.com

Page 845 of 3039

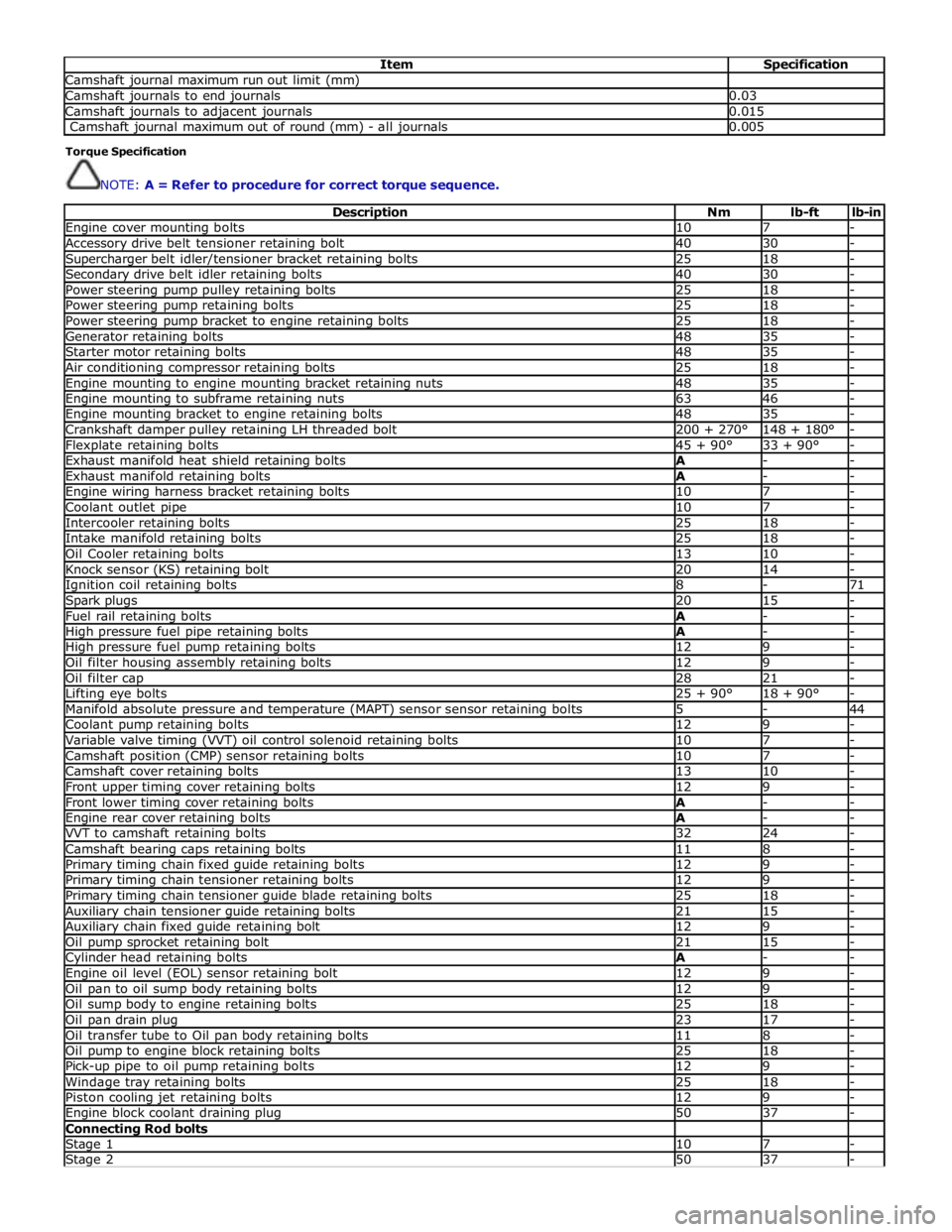

Item Specification Camshaft journal maximum run out limit (mm) Camshaft journals to end journals 0.03 Camshaft journals to adjacent journals 0.015 Camshaft journal maximum out of round (mm) - all journals 0.005 Torque Specification

NOTE: A = Refer to procedure for correct torque sequence.

Description Nm lb-ft lb-in Engine cover mounting bolts 10 7 - Accessory drive belt tensioner retaining bolt 40 30 - Supercharger belt idler/tensioner bracket retaining bolts 25 18 - Secondary drive belt idler retaining bolts 40 30 - Power steering pump pulley retaining bolts 25 18 - Power steering pump retaining bolts 25 18 - Power steering pump bracket to engine retaining bolts 25 18 - Generator retaining bolts 48 35 - Starter motor retaining bolts 48 35 - Air conditioning compressor retaining bolts 25 18 - Engine mounting to engine mounting bracket retaining nuts 48 35 - Engine mounting to subframe retaining nuts 63 46 - Engine mounting bracket to engine retaining bolts 48 35 - Crankshaft damper pulley retaining LH threaded bolt 200 + 270° 148 + 180° - Flexplate retaining bolts 45 + 90° 33 + 90° - Exhaust manifold heat shield retaining bolts A - - Exhaust manifold retaining bolts A - - Engine wiring harness bracket retaining bolts 10 7 - Coolant outlet pipe 10 7 - Intercooler retaining bolts 25 18 - Intake manifold retaining bolts 25 18 - Oil Cooler retaining bolts 13 10 - Knock sensor (KS) retaining bolt 20 14 - Ignition coil retaining bolts 8 - 71 Spark plugs 20 15 - Fuel rail retaining bolts A - - High pressure fuel pipe retaining bolts A - - High pressure fuel pump retaining bolts 12 9 - Oil filter housing assembly retaining bolts 12 9 - Oil filter cap 28 21 - Lifting eye bolts 25 + 90° 18 + 90° - Manifold absolute pressure and temperature (MAPT) sensor sensor retaining bolts 5 - 44 Coolant pump retaining bolts 12 9 - Variable valve timing (VVT) oil control solenoid retaining bolts 10 7 - Camshaft position (CMP) sensor retaining bolts 10 7 - Camshaft cover retaining bolts 13 10 - Front upper timing cover retaining bolts 12 9 - Front lower timing cover retaining bolts A - - Engine rear cover retaining bolts A - - VVT to camshaft retaining bolts 32 24 - Camshaft bearing caps retaining bolts 11 8 - Primary timing chain fixed guide retaining bolts 12 9 - Primary timing chain tensioner retaining bolts 12 9 - Primary timing chain tensioner guide blade retaining bolts 25 18 - Auxiliary chain tensioner guide retaining bolts 21 15 - Auxiliary chain fixed guide retaining bolt 12 9 - Oil pump sprocket retaining bolt 21 15 - Cylinder head retaining bolts A - - Engine oil level (EOL) sensor retaining bolt 12 9 - Oil pan to oil sump body retaining bolts 12 9 - Oil sump body to engine retaining bolts 25 18 - Oil pan drain plug 23 17 - Oil transfer tube to Oil pan body retaining bolts 11 8 - Oil pump to engine block retaining bolts 25 18 - Pick-up pipe to oil pump retaining bolts 12 9 - Windage tray retaining bolts 25 18 - Piston cooling jet retaining bolts 12 9 - Engine block coolant draining plug 50 37 - Connecting Rod bolts Stage 1 10 7 - Stage 2 50 37 -

Page 1177 of 3039

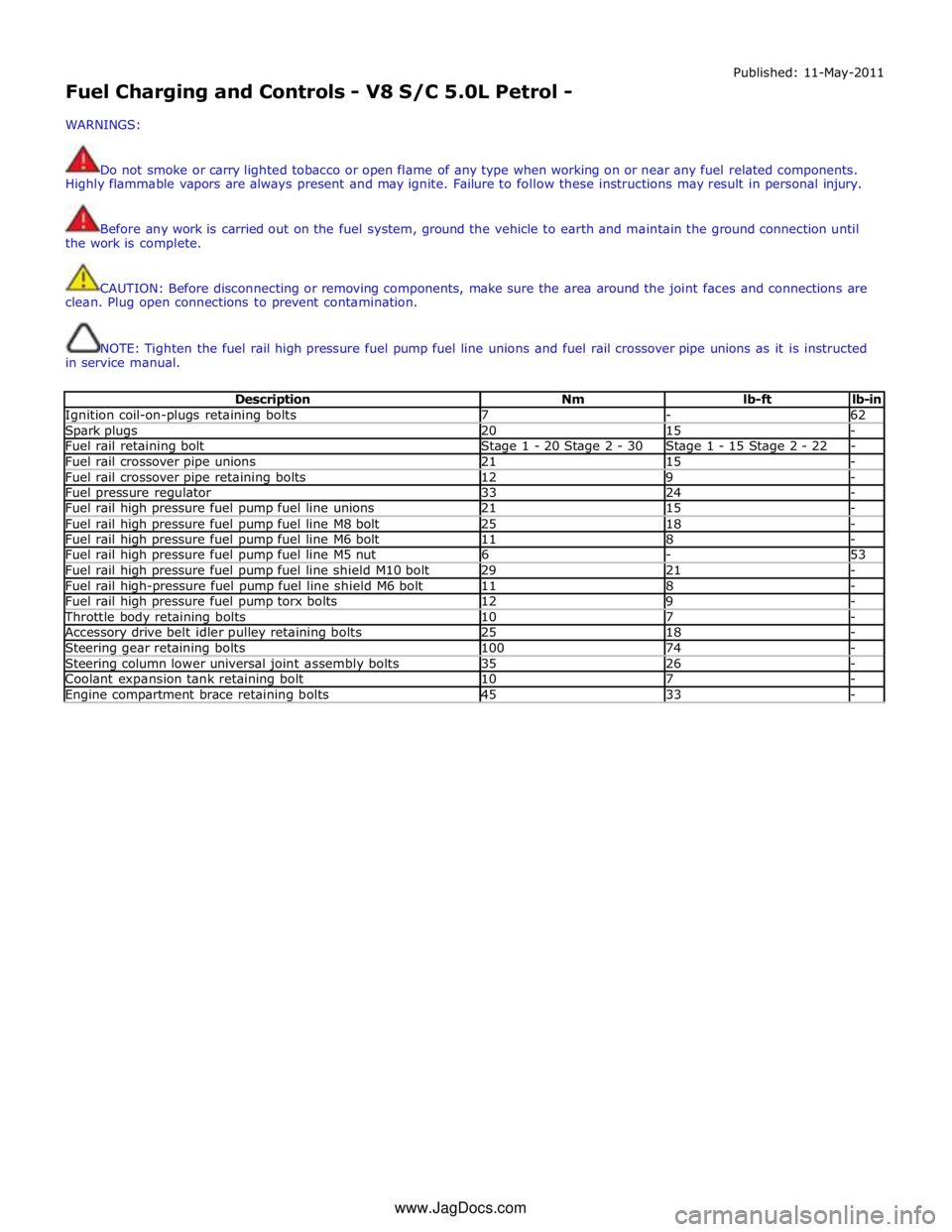

Fuel Charging and Controls - V8 S/C 5.0L Petrol -

WARNINGS: Published: 11-May-2011

Do not smoke or carry lighted tobacco or open flame of any type when working on or near any fuel related components.

Highly flammable vapors are always present and may ignite. Failure to follow these instructions may result in personal injury.

Before any work is carried out on the fuel system, ground the vehicle to earth and maintain the ground connection until

the work is complete.

CAUTION: Before disconnecting or removing components, make sure the area around the joint faces and connections are

clean. Plug open connections to prevent contamination.

NOTE: Tighten the fuel rail high pressure fuel pump fuel line unions and fuel rail crossover pipe unions as it is instructed

in service manual.

Description Nm lb-ft lb-in Ignition coil-on-plugs retaining bolts 7 - 62 Spark plugs 20 15 - Fuel rail retaining bolt Stage 1 - 20 Stage 2 - 30 Stage 1 - 15 Stage 2 - 22 - Fuel rail crossover pipe unions 21 15 - Fuel rail crossover pipe retaining bolts 12 9 - Fuel pressure regulator 33 24 - Fuel rail high pressure fuel pump fuel line unions 21 15 - Fuel rail high pressure fuel pump fuel line M8 bolt 25 18 - Fuel rail high pressure fuel pump fuel line M6 bolt 11 8 - Fuel rail high pressure fuel pump fuel line M5 nut 6 - 53 Fuel rail high pressure fuel pump fuel line shield M10 bolt 29 21 - Fuel rail high-pressure fuel pump fuel line shield M6 bolt 11 8 - Fuel rail high pressure fuel pump torx bolts 12 9 - Throttle body retaining bolts 10 7 - Accessory drive belt idler pulley retaining bolts 25 18 - Steering gear retaining bolts 100 74 - Steering column lower universal joint assembly bolts 35 26 - Coolant expansion tank retaining bolt 10 7 - Engine compartment brace retaining bolts 45 33 - www.JagDocs.com

Page 1181 of 3039

to deliver the correct mass of fuel to the combustion chambers.

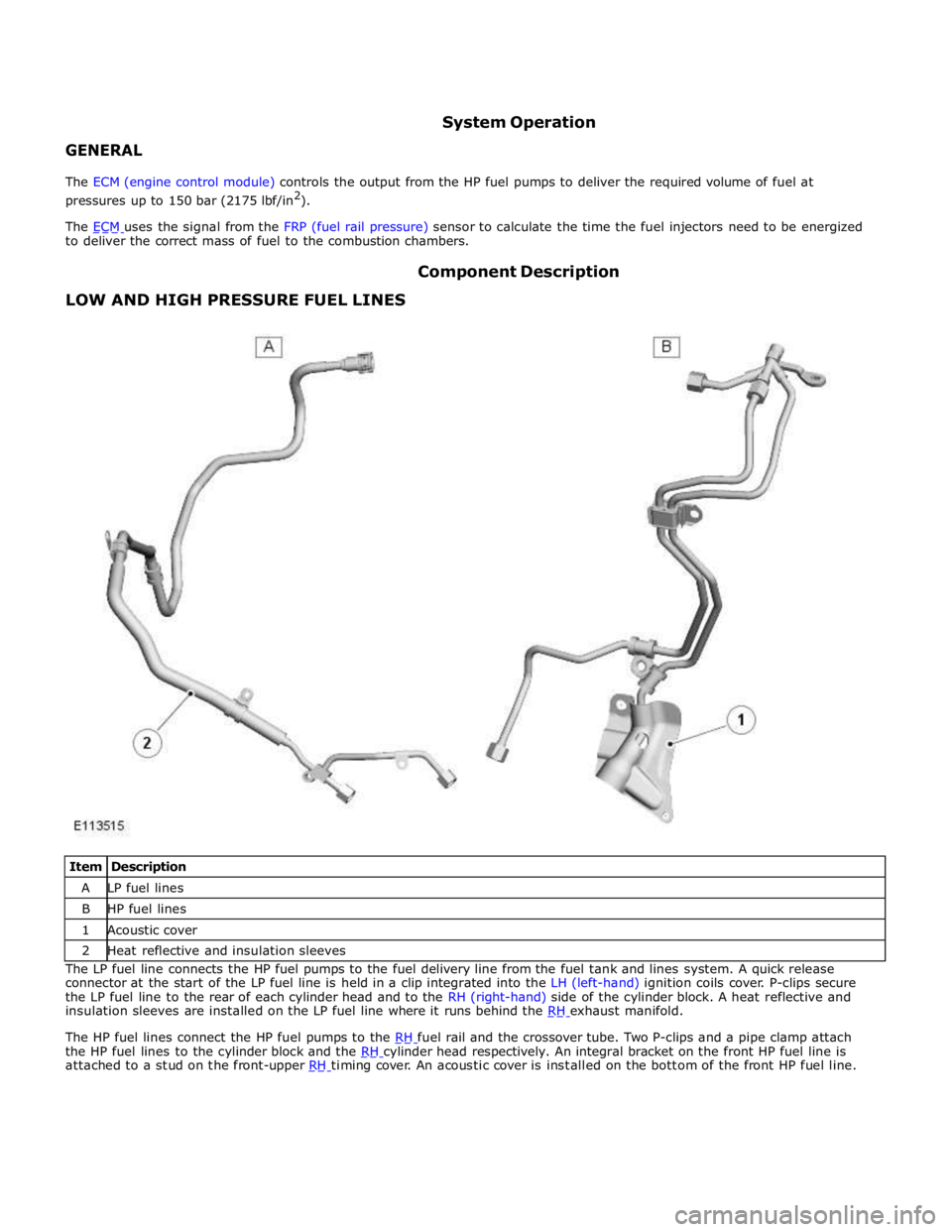

LOW AND HIGH PRESSURE FUEL LINES Component Description

Item Description A LP fuel lines B HP fuel lines 1 Acoustic cover 2 Heat reflective and insulation sleeves The LP fuel line connects the HP fuel pumps to the fuel delivery line from the fuel tank and lines system. A quick release

connector at the start of the LP fuel line is held in a clip integrated into the LH (left-hand) ignition coils cover. P-clips secure

the LP fuel line to the rear of each cylinder head and to the RH (right-hand) side of the cylinder block. A heat reflective and

insulation sleeves are installed on the LP fuel line where it runs behind the RH exhaust manifold.

The HP fuel lines connect the HP fuel pumps to the RH fuel rail and the crossover tube. Two P-clips and a pipe clamp attach the HP fuel lines to the cylinder block and the RH cylinder head respectively. An integral bracket on the front HP fuel line is attached to a stud on the front-upper RH timing cover. An acoustic cover is installed on the bottom of the front HP fuel line.

Page 1270 of 3039

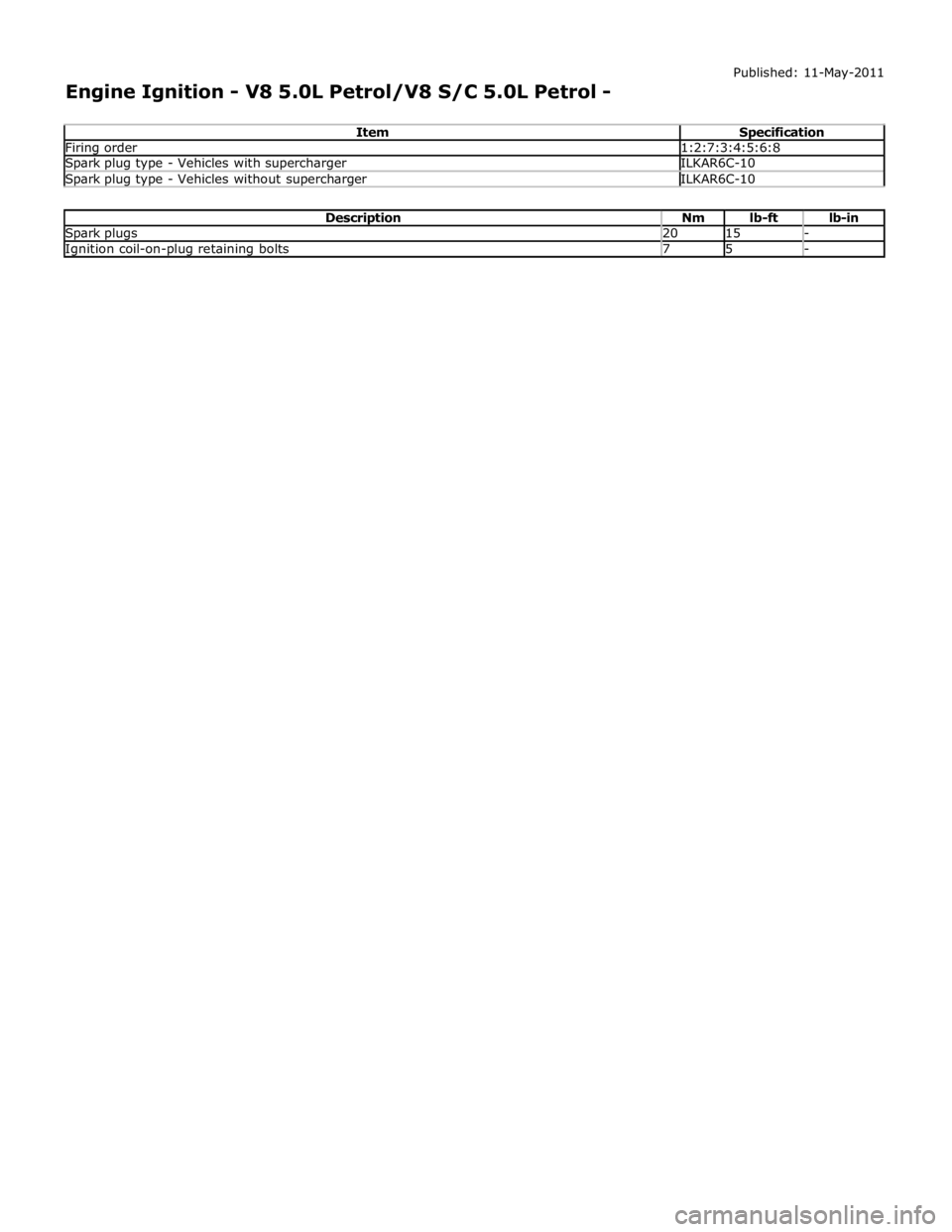

Firing order 1:2:7:3:4:5:6:8 Spark plug type - Vehicles with supercharger ILKAR6C-10 Spark plug type - Vehicles without supercharger ILKAR6C-10

Description Nm lb-ft lb-in Spark plugs 20 15 - Ignition coil-on-plug retaining bolts 7 5 -

Page 1271 of 3039

Published: 11-May-2011

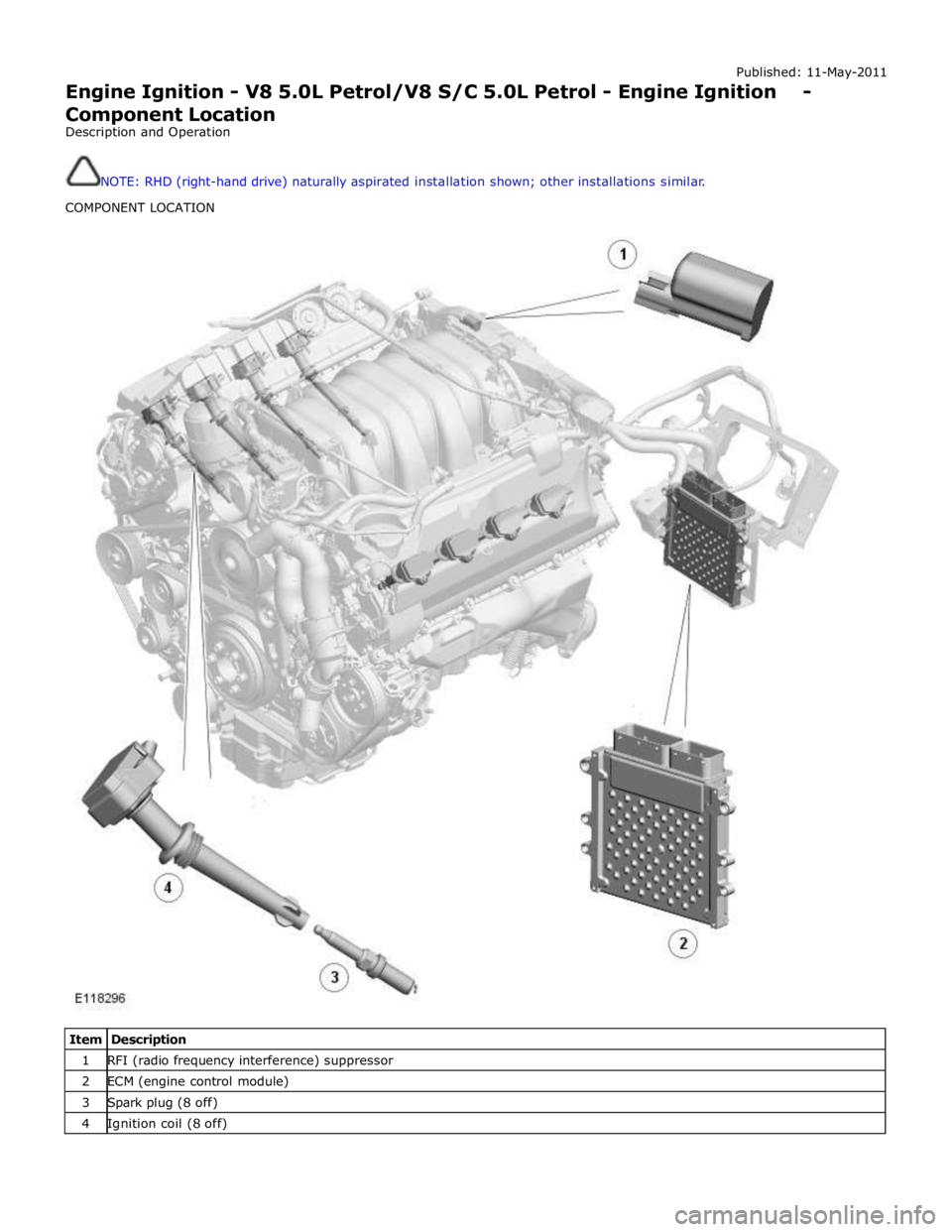

Engine Ignition - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Engine Ignition - Component Location

Description and Operation

NOTE: RHD (right-hand drive) naturally aspirated installation shown; other installations similar.

COMPONENT LOCATION

Item Description 1 RFI (radio frequency interference) suppressor 2 ECM (engine control module) 3 Spark plug (8 off) 4 Ignition coil (8 off)

Page 1272 of 3039

Published: 11-May-2011

Engine Ignition - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Engine Ignition - Overview

Description and Operation

OVERVIEW

The engine ignition system is a coil-on-plug, single spark system controlled by the ECM (engine control module). An iridium

tipped spark plug is installed in each combustion chamber, between the inlet and exhaust valves, and an ignition coil is

installed on each spark plug. A RFI (radio frequency interference) suppressor is connected to the power feed to the ignition

coils.