torque JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 888 of 3039

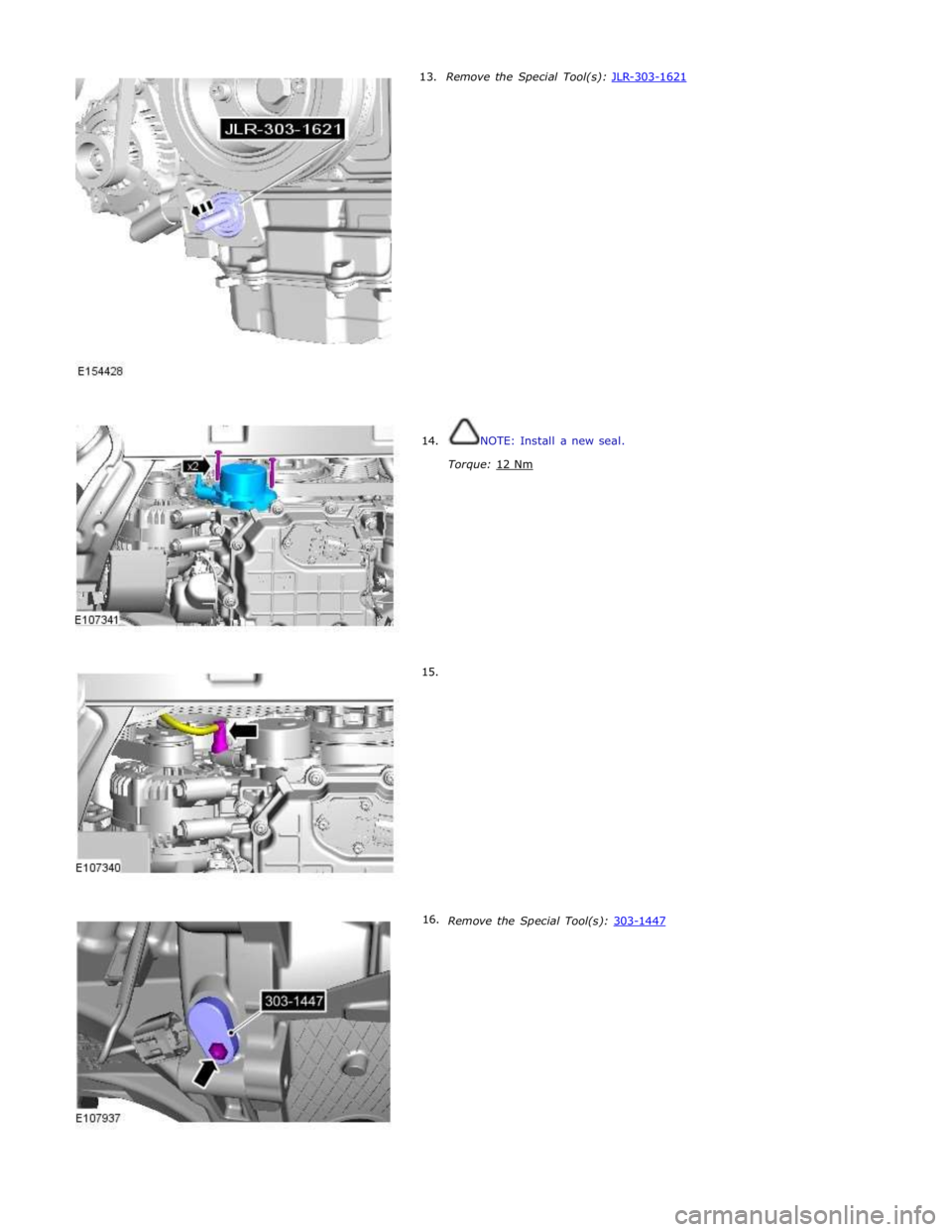

13.

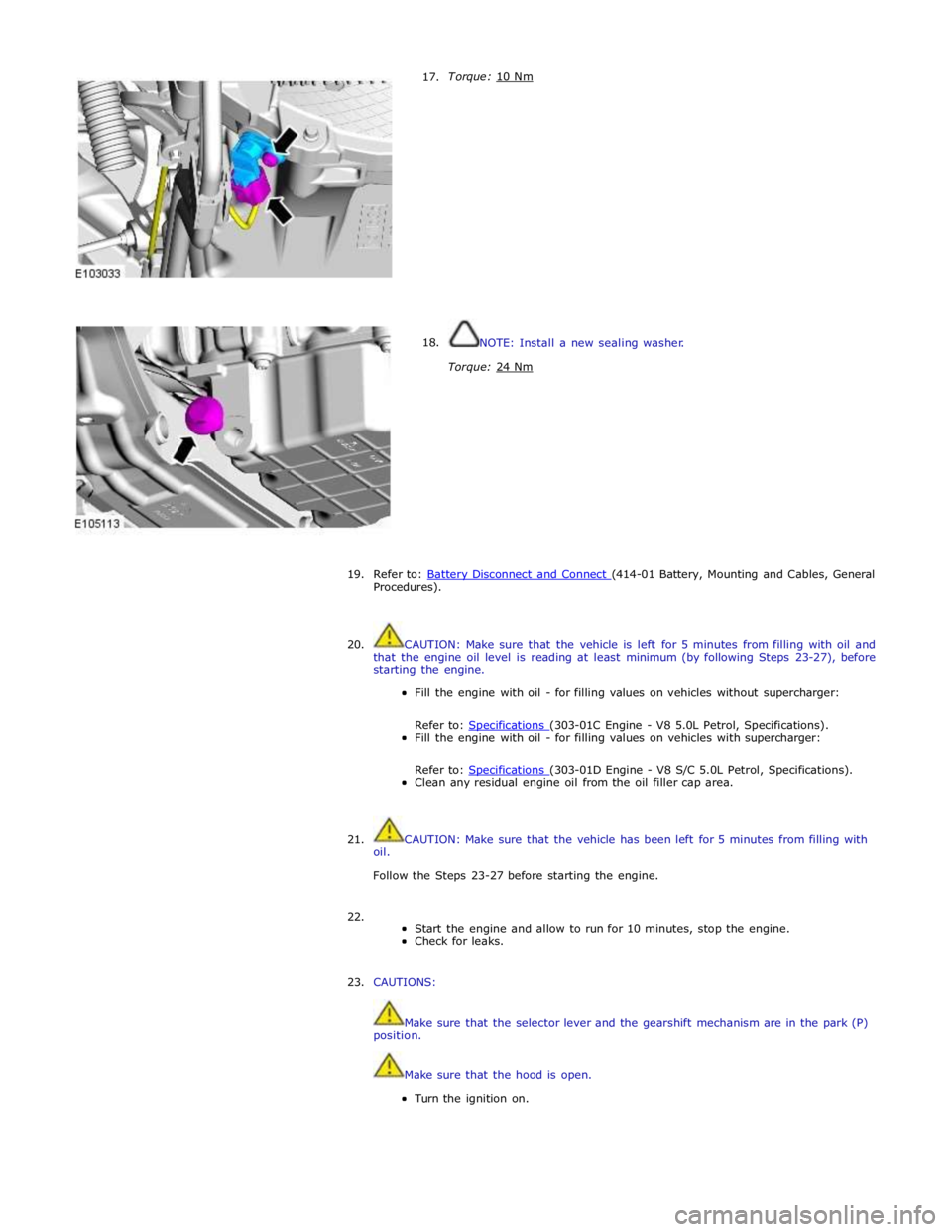

14.

15.

16. Remove the Special Tool(s): JLR-303-1621

NOTE: Install a new seal.

Torque: 12 Nm

Remove the Special Tool(s): 303-1447

Page 889 of 3039

17.

18. Torque: 10 Nm

NOTE: Install a new sealing washer.

Torque: 24 Nm

19.

20. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

CAUTION: Make sure that the vehicle is left for 5 minutes from filling with oil and

that the engine oil level is reading at least minimum (by following Steps 23-27), before

starting the engine.

Fill the engine with oil - for filling values on vehicles without supercharger:

Refer to: Specifications (303-01C Engine - V8 5.0L Petrol, Specifications). Fill the engine with oil - for filling values on vehicles with supercharger:

Refer to: Specifications (303-01D Engine - V8 S/C 5.0L Petrol, Specifications). Clean any residual engine oil from the oil filler cap area.

21.

oil. CAUTION: Make sure that the vehicle has been left for 5 minutes from filling with

Follow the Steps 23-27 before starting the engine.

22.

Start the engine and allow to run for 10 minutes, stop the engine.

Check for leaks.

23. CAUTIONS:

Make sure that the selector lever and the gearshift mechanism are in the park (P)

position.

Make sure that the hood is open.

Turn the ignition on.

Page 894 of 3039

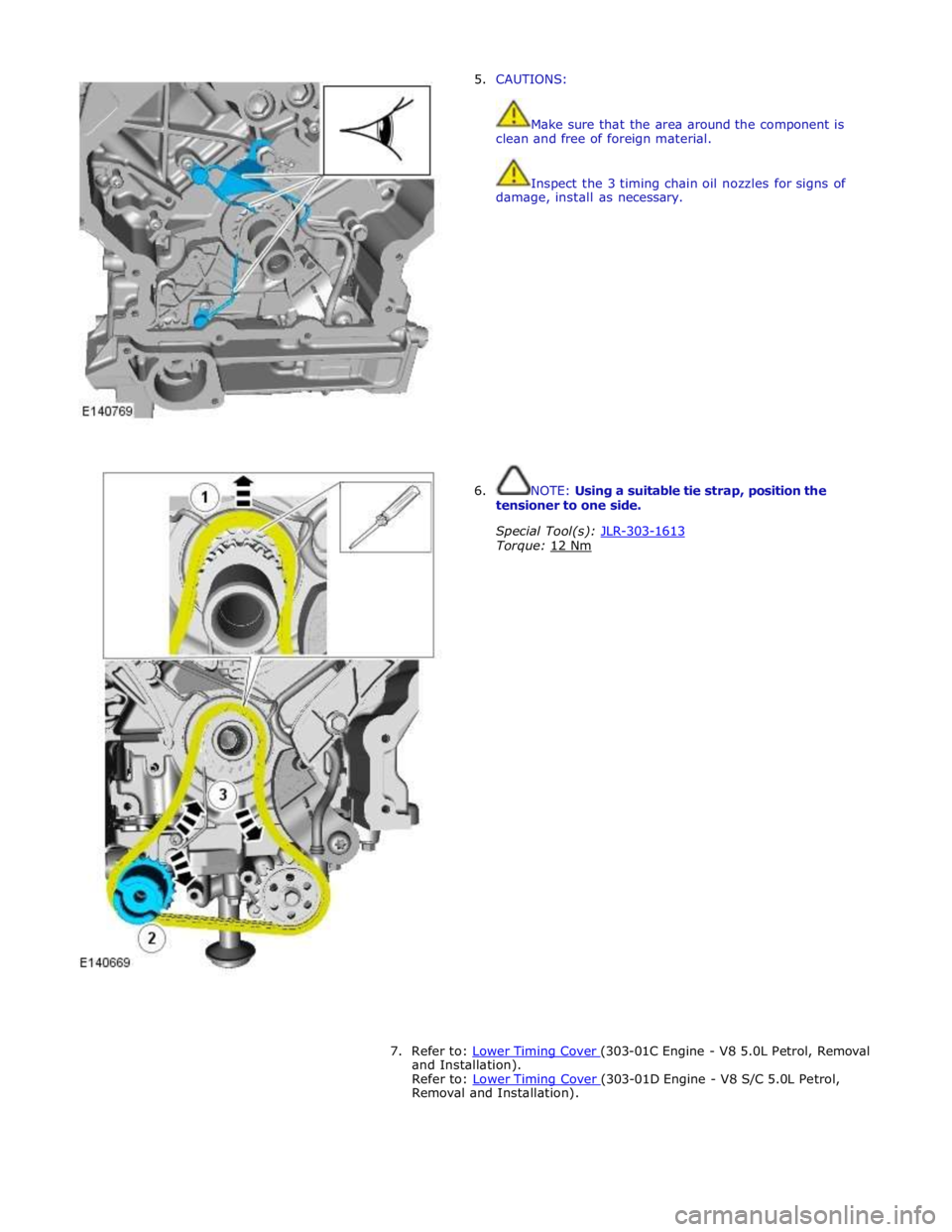

5. CAUTIONS:

Make sure that the area around the component is

clean and free of foreign material.

Inspect the 3 timing chain oil nozzles for signs of

damage, install as necessary.

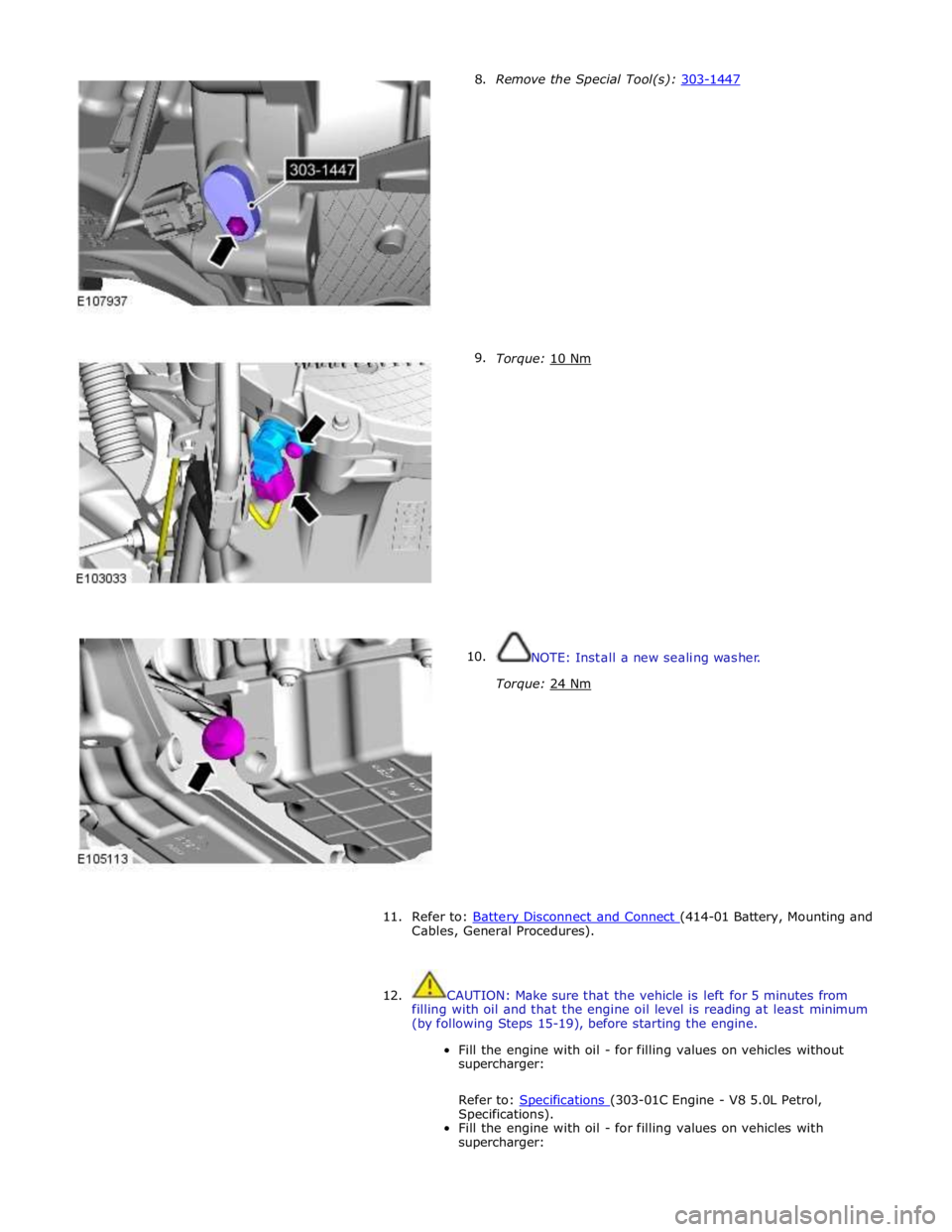

6. NOTE: Using a suitable tie strap, position the

tensioner to one side.

Special Tool(s): JLR-303-1613 Torque: 12 Nm

7. Refer to: Lower Timing Cover (303-01C Engine - V8 5.0L Petrol, Removal and Installation).

Refer to: Lower Timing Cover (303-01D Engine - V8 S/C 5.0L Petrol, Removal and Installation).

Page 895 of 3039

8.

9.

10. Remove the Special Tool(s): 303-1447

Torque: 10 Nm

NOTE: Install a new sealing washer.

Torque: 24 Nm

11. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

12. CAUTION: Make sure that the vehicle is left for 5 minutes from

filling with oil and that the engine oil level is reading at least minimum

(by following Steps 15-19), before starting the engine.

Fill the engine with oil - for filling values on vehicles without

supercharger:

Refer to: Specifications (303-01C Engine - V8 5.0L Petrol, Specifications).

Fill the engine with oil - for filling values on vehicles with

supercharger:

Page 903 of 3039

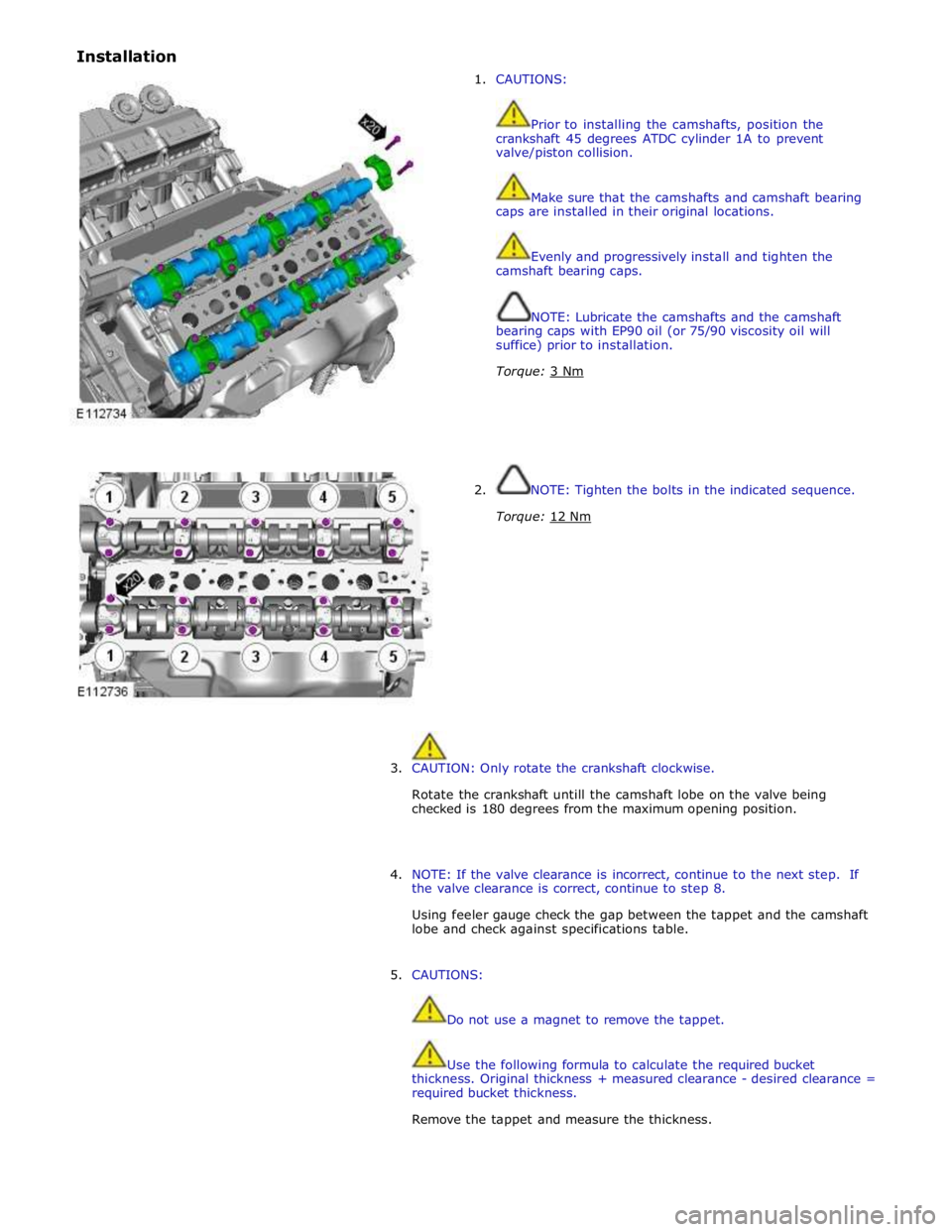

Installation

1. CAUTIONS:

Prior to installing the camshafts, position the

crankshaft 45 degrees ATDC cylinder 1A to prevent

valve/piston collision.

Make sure that the camshafts and camshaft bearing

caps are installed in their original locations.

Evenly and progressively install and tighten the

camshaft bearing caps.

NOTE: Lubricate the camshafts and the camshaft

bearing caps with EP90 oil (or 75/90 viscosity oil will

suffice) prior to installation.

Torque: 3 Nm

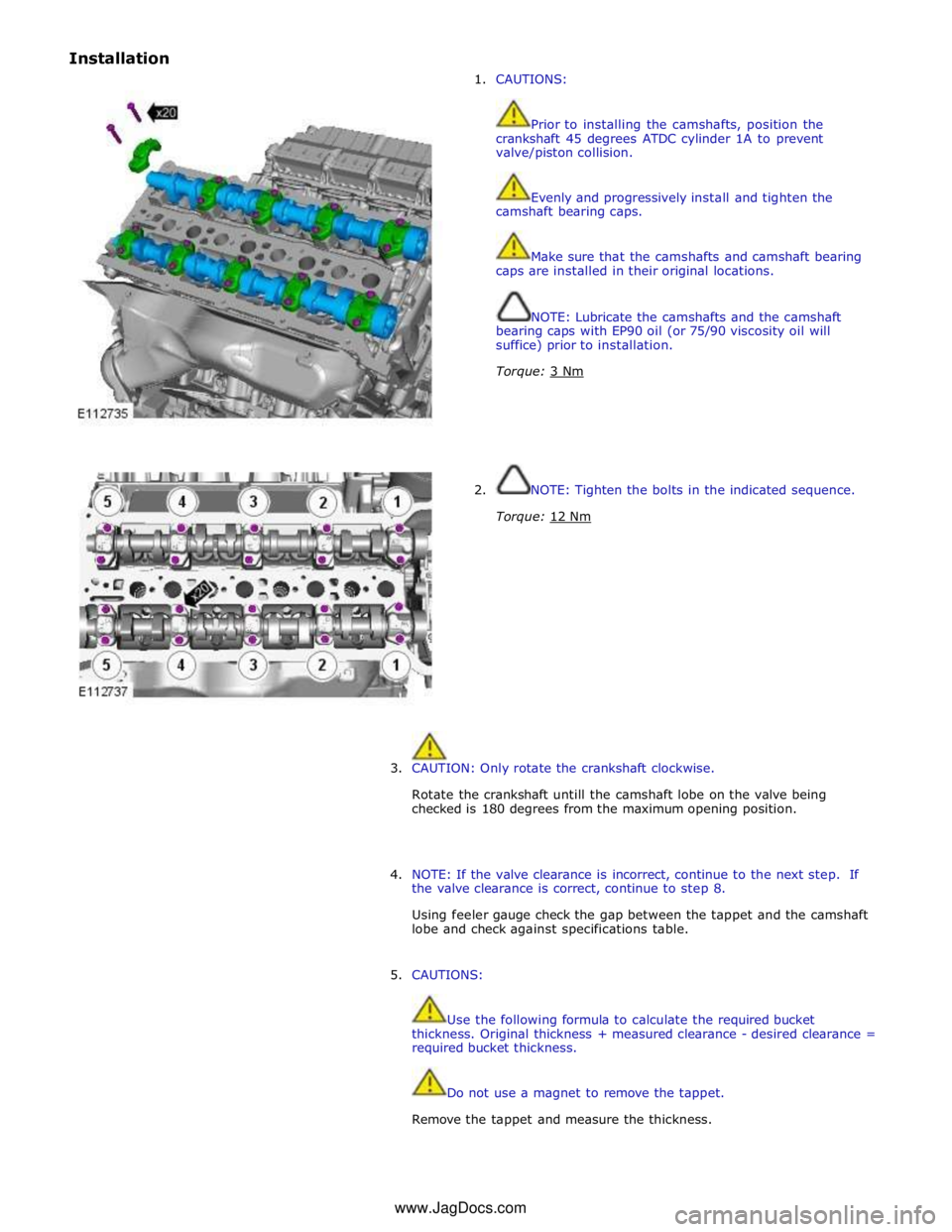

2. NOTE: Tighten the bolts in the indicated sequence.

Torque: 12 Nm

3. CAUTION: Only rotate the crankshaft clockwise.

Rotate the crankshaft untill the camshaft lobe on the valve being

checked is 180 degrees from the maximum opening position.

4. NOTE: If the valve clearance is incorrect, continue to the next step. If

the valve clearance is correct, continue to step 8.

Using feeler gauge check the gap between the tappet and the camshaft

lobe and check against specifications table.

5. CAUTIONS:

Do not use a magnet to remove the tappet.

Use the following formula to calculate the required bucket

thickness. Original thickness + measured clearance - desired clearance =

required bucket thickness.

Remove the tappet and measure the thickness.

Page 906 of 3039

Installation

1. CAUTIONS:

Prior to installing the camshafts, position the

crankshaft 45 degrees ATDC cylinder 1A to prevent

valve/piston collision.

Evenly and progressively install and tighten the

camshaft bearing caps.

Make sure that the camshafts and camshaft bearing

caps are installed in their original locations.

NOTE: Lubricate the camshafts and the camshaft

bearing caps with EP90 oil (or 75/90 viscosity oil will

suffice) prior to installation.

Torque: 3 Nm

2. NOTE: Tighten the bolts in the indicated sequence.

Torque: 12 Nm

3. CAUTION: Only rotate the crankshaft clockwise.

Rotate the crankshaft untill the camshaft lobe on the valve being

checked is 180 degrees from the maximum opening position.

4. NOTE: If the valve clearance is incorrect, continue to the next step. If

the valve clearance is correct, continue to step 8.

Using feeler gauge check the gap between the tappet and the camshaft

lobe and check against specifications table.

5. CAUTIONS:

Use the following formula to calculate the required bucket

thickness. Original thickness + measured clearance - desired clearance =

required bucket thickness.

Do not use a magnet to remove the tappet.

Remove the tappet and measure the thickness. www.JagDocs.com

Page 914 of 3039

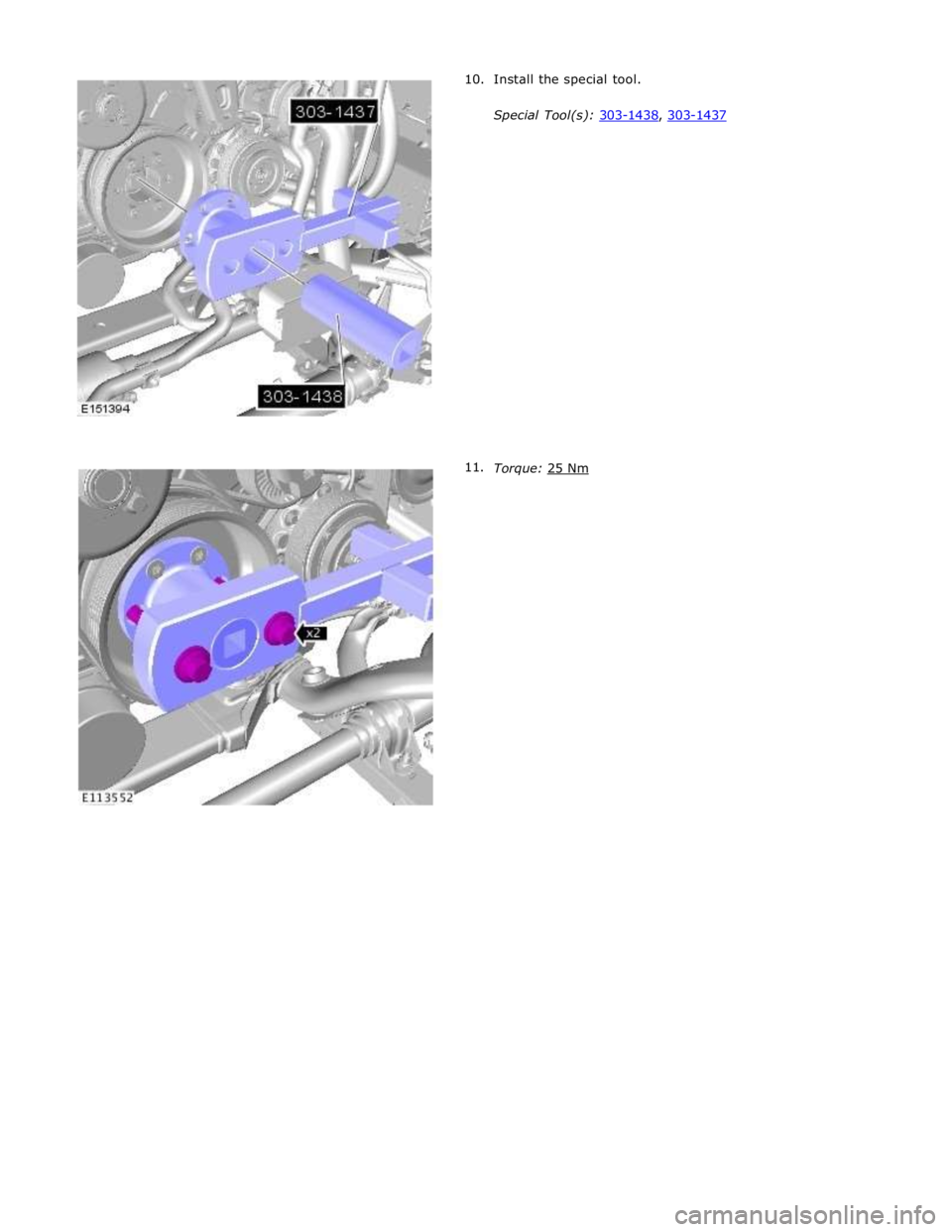

Torque: 25 Nm

Page 925 of 3039

10.

11.

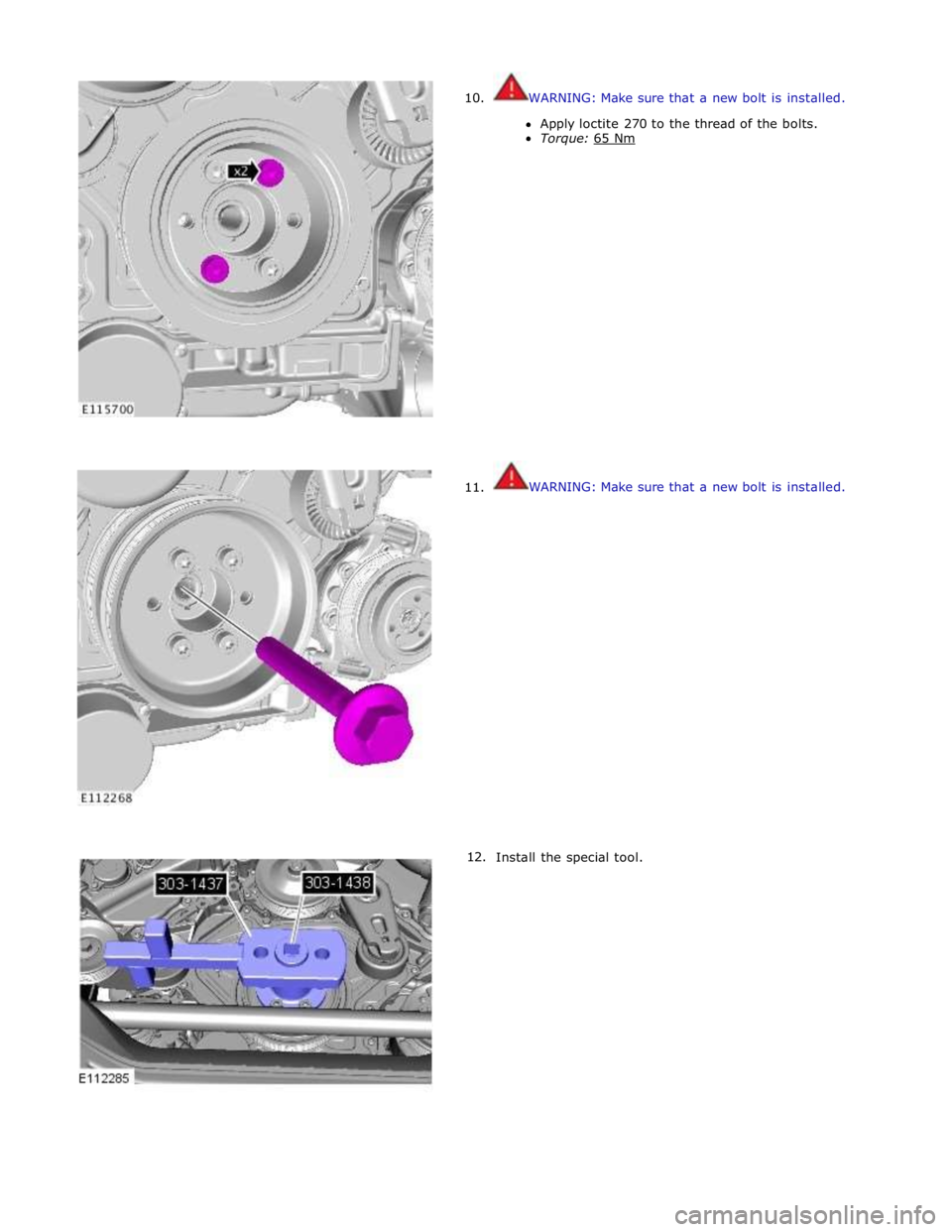

12. WARNING: Make sure that a new bolt is installed.

Apply loctite 270 to the thread of the bolts.

Torque: 65 Nm

WARNING: Make sure that a new bolt is installed.

Install the special tool.

Page 926 of 3039

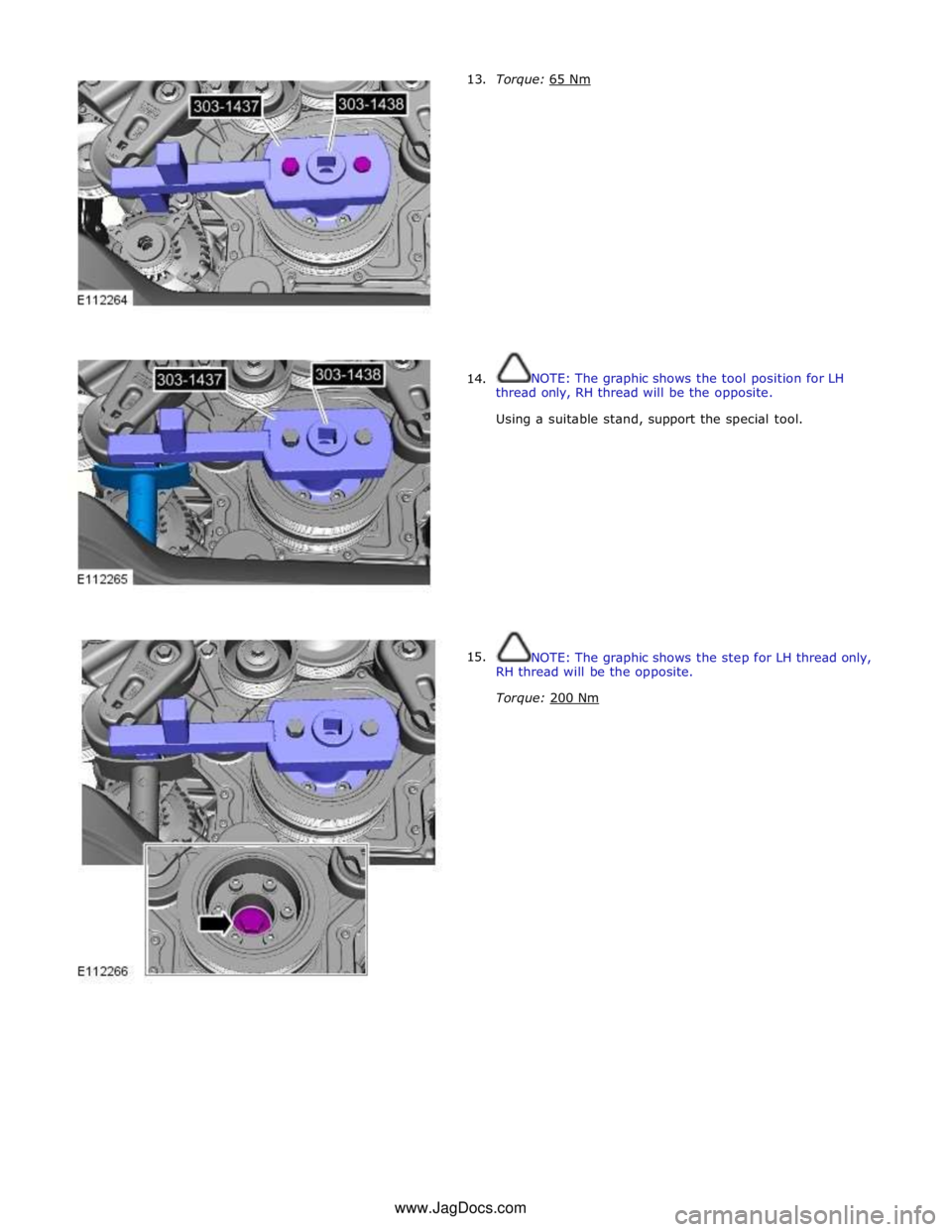

13.

14.

15. Torque: 65 Nm

NOTE: The graphic shows the tool position for LH

thread only, RH thread will be the opposite.

Using a suitable stand, support the special tool.

NOTE: The graphic shows the step for LH thread only,

RH thread will be the opposite.

Torque: 200 Nm www.JagDocs.com

Page 927 of 3039

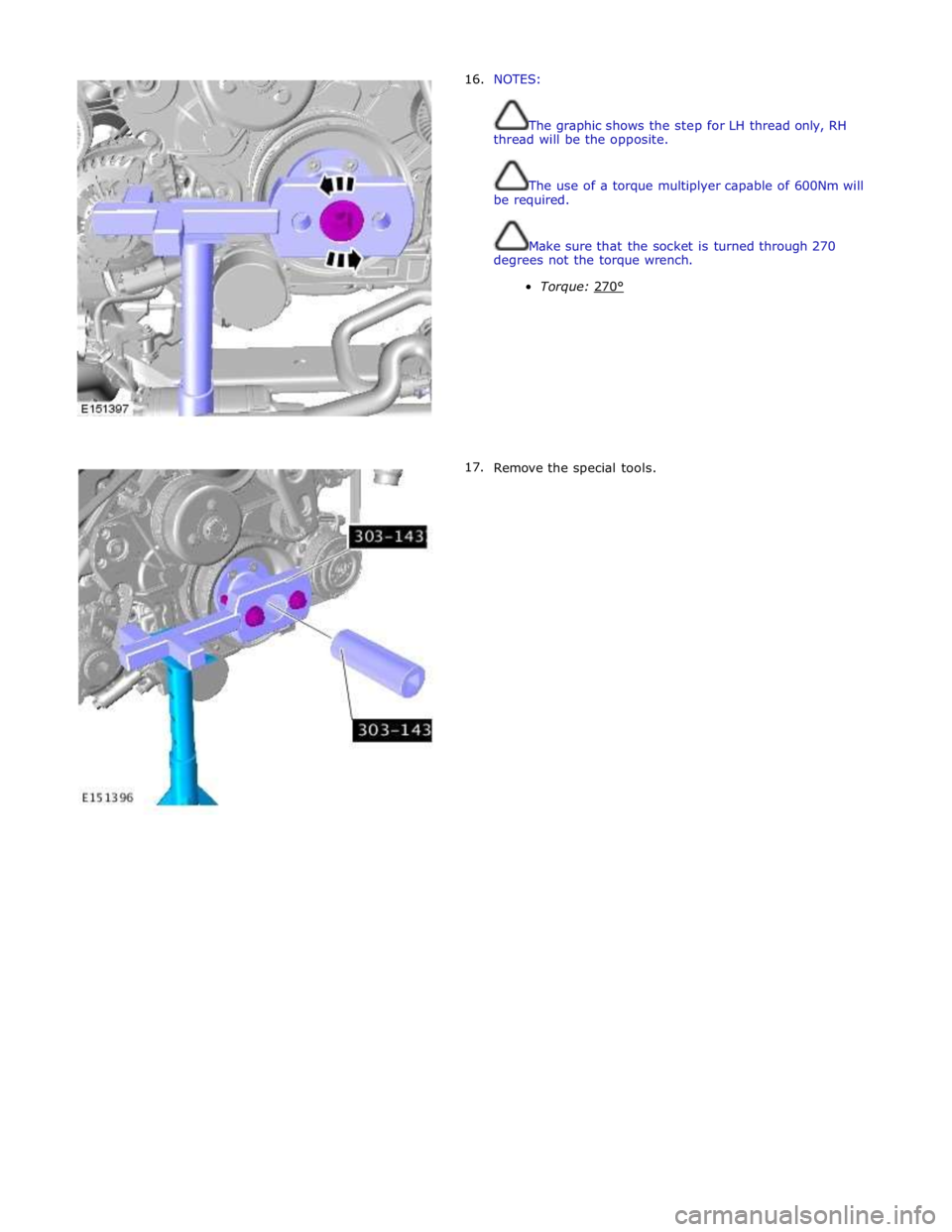

16.

17. NOTES:

The graphic shows the step for LH thread only, RH

thread will be the opposite.

The use of a torque multiplyer capable of 600Nm will

be required.

Make sure that the socket is turned through 270

degrees not the torque wrench.

Torque: 270°

Remove the special tools.