seat JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2335 of 3039

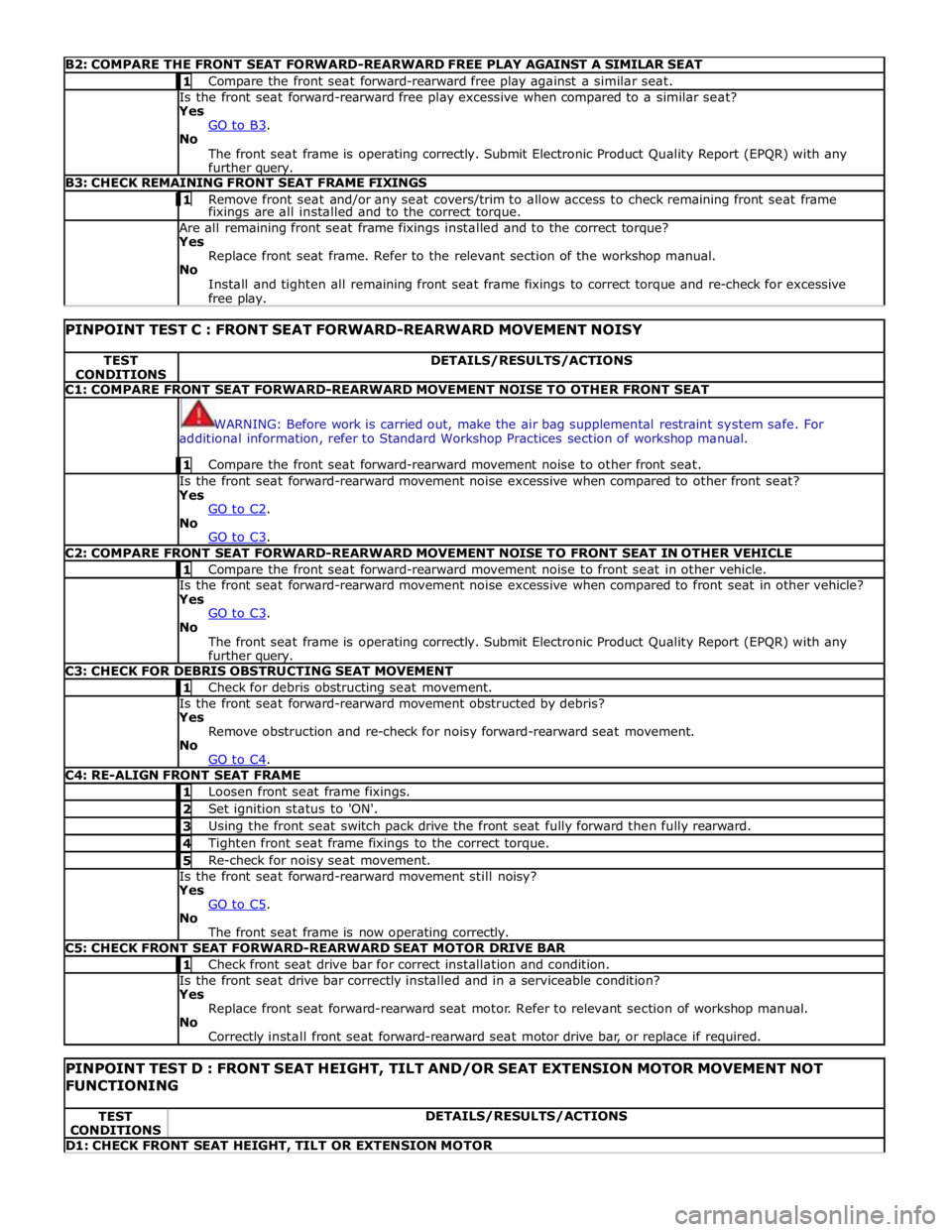

B2: COMPARE THE FRONT SEAT FORWARD-REARWARD FREE PLAY AGAINST A SIMILAR SEAT 1 Compare the front seat forward-rearward free play against a similar seat. Is the front seat forward-rearward free play excessive when compared to a similar seat?

Yes

GO to B3. No

The front seat frame is operating correctly. Submit Electronic Product Quality Report (EPQR) with any

further query. B3: CHECK REMAINING FRONT SEAT FRAME FIXINGS 1 Remove front seat and/or any seat covers/trim to allow access to check remaining front seat frame fixings are all installed and to the correct torque. Are all remaining front seat frame fixings installed and to the correct torque?

Yes

Replace front seat frame. Refer to the relevant section of the workshop manual.

No

Install and tighten all remaining front seat frame fixings to correct torque and re-check for excessive

free play.

PINPOINT TEST C : FRONT SEAT FORWARD-REARWARD MOVEMENT NOISY TEST

CONDITIONS DETAILS/RESULTS/ACTIONS C1: COMPARE FRONT SEAT FORWARD-REARWARD MOVEMENT NOISE TO OTHER FRONT SEAT

WARNING: Before work is carried out, make the air bag supplemental restraint system safe. For

additional information, refer to Standard Workshop Practices section of workshop manual. 1 Compare the front seat forward-rearward movement noise to other front seat. Is the front seat forward-rearward movement noise excessive when compared to other front seat?

Yes

GO to C2. No

GO to C3. C2: COMPARE FRONT SEAT FORWARD-REARWARD MOVEMENT NOISE TO FRONT SEAT IN OTHER VEHICLE 1 Compare the front seat forward-rearward movement noise to front seat in other vehicle. Is the front seat forward-rearward movement noise excessive when compared to front seat in other vehicle?

Yes

GO to C3. No

The front seat frame is operating correctly. Submit Electronic Product Quality Report (EPQR) with any

further query. C3: CHECK FOR DEBRIS OBSTRUCTING SEAT MOVEMENT 1 Check for debris obstructing seat movement. Is the front seat forward-rearward movement obstructed by debris?

Yes

Remove obstruction and re-check for noisy forward-rearward seat movement.

No

GO to C4. C4: RE-ALIGN FRONT SEAT FRAME 1 Loosen front seat frame fixings. 2 Set ignition status to 'ON'. 3 Using the front seat switch pack drive the front seat fully forward then fully rearward. 4 Tighten front seat frame fixings to the correct torque. 5 Re-check for noisy seat movement. Is the front seat forward-rearward movement still noisy?

Yes

GO to C5. No

The front seat frame is now operating correctly. C5: CHECK FRONT SEAT FORWARD-REARWARD SEAT MOTOR DRIVE BAR 1 Check front seat drive bar for correct installation and condition. Is the front seat drive bar correctly installed and in a serviceable condition?

Yes

Replace front seat forward-rearward seat motor. Refer to relevant section of workshop manual.

No

Correctly install front seat forward-rearward seat motor drive bar, or replace if required.

PINPOINT TEST D : FRONT SEAT HEIGHT, TILT AND/OR SEAT EXTENSION MOTOR MOVEMENT NOT FUNCTIONING TEST

CONDITIONS DETAILS/RESULTS/ACTIONS D1: CHECK FRONT SEAT HEIGHT, TILT OR EXTENSION MOTOR

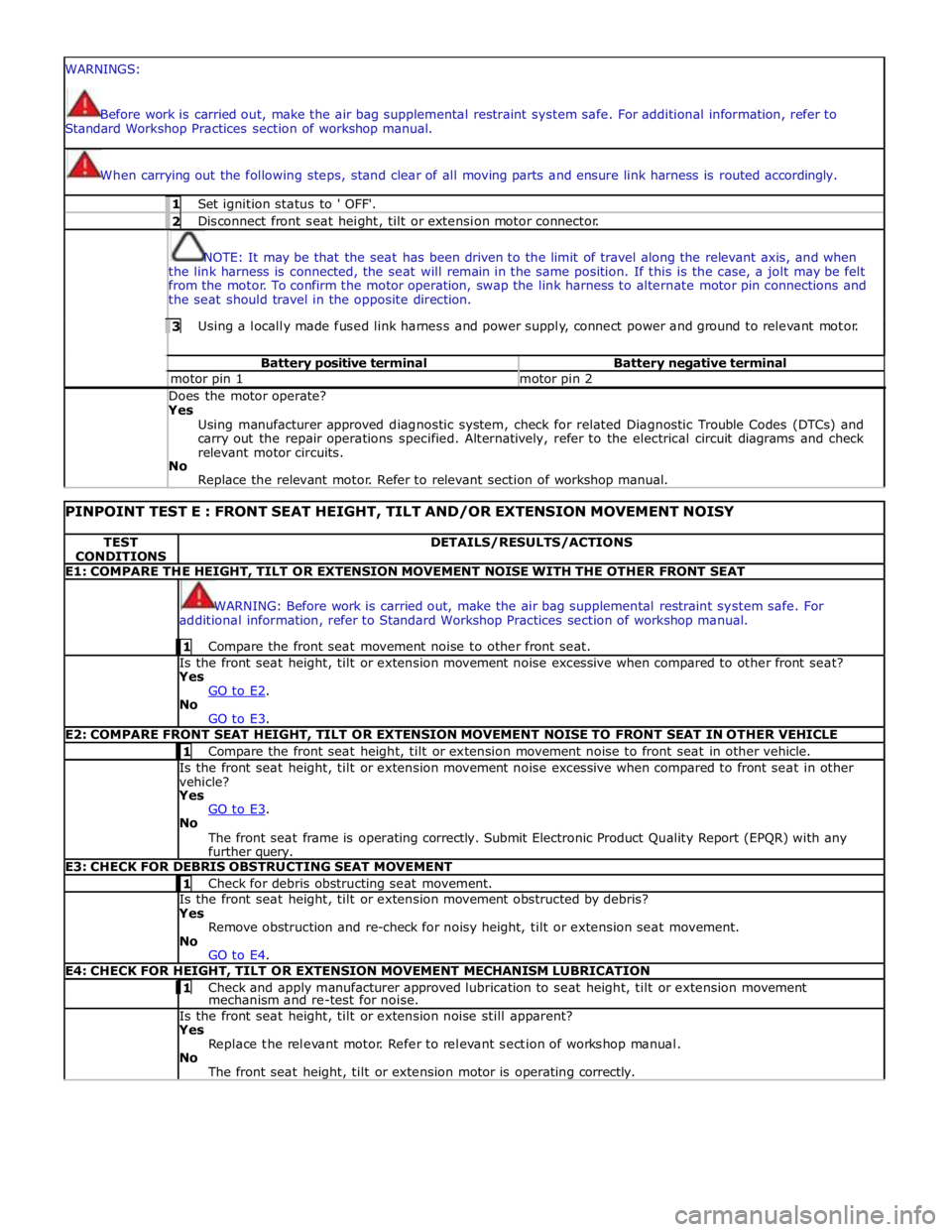

Page 2336 of 3039

WARNINGS:

Before work is carried out, make the air bag supplemental restraint system safe. For additional information, refer to

Standard Workshop Practices section of workshop manual.

When carrying out the following steps, stand clear of all moving parts and ensure link harness is routed accordingly. 1 Set ignition status to ' OFF'. 2 Disconnect front seat height, tilt or extension motor connector.

NOTE: It may be that the seat has been driven to the limit of travel along the relevant axis, and when

the link harness is connected, the seat will remain in the same position. If this is the case, a jolt may be felt

from the motor. To confirm the motor operation, swap the link harness to alternate motor pin connections and

the seat should travel in the opposite direction. 3 Using a locally made fused link harness and power supply, connect power and ground to relevant motor. Battery positive terminal Battery negative terminal motor pin 1 motor pin 2 Does the motor operate? Yes

Using manufacturer approved diagnostic system, check for related Diagnostic Trouble Codes (DTCs) and

carry out the repair operations specified. Alternatively, refer to the electrical circuit diagrams and check

relevant motor circuits.

No

Replace the relevant motor. Refer to relevant section of workshop manual.

PINPOINT TEST E : FRONT SEAT HEIGHT, TILT AND/OR EXTENSION MOVEMENT NOISY TEST

CONDITIONS DETAILS/RESULTS/ACTIONS E1: COMPARE THE HEIGHT, TILT OR EXTENSION MOVEMENT NOISE WITH THE OTHER FRONT SEAT

WARNING: Before work is carried out, make the air bag supplemental restraint system safe. For

additional information, refer to Standard Workshop Practices section of workshop manual. 1 Compare the front seat movement noise to other front seat. Is the front seat height, tilt or extension movement noise excessive when compared to other front seat?

Yes

GO to E2. No

GO to E3. E2: COMPARE FRONT SEAT HEIGHT, TILT OR EXTENSION MOVEMENT NOISE TO FRONT SEAT IN OTHER VEHICLE 1 Compare the front seat height, tilt or extension movement noise to front seat in other vehicle. Is the front seat height, tilt or extension movement noise excessive when compared to front seat in other

vehicle?

Yes

GO to E3. No

The front seat frame is operating correctly. Submit Electronic Product Quality Report (EPQR) with any

further query. E3: CHECK FOR DEBRIS OBSTRUCTING SEAT MOVEMENT 1 Check for debris obstructing seat movement. Is the front seat height, tilt or extension movement obstructed by debris?

Yes

Remove obstruction and re-check for noisy height, tilt or extension seat movement.

No

GO to E4. E4: CHECK FOR HEIGHT, TILT OR EXTENSION MOVEMENT MECHANISM LUBRICATION 1 Check and apply manufacturer approved lubrication to seat height, tilt or extension movement mechanism and re-test for noise. Is the front seat height, tilt or extension noise still apparent?

Yes

Replace the relevant motor. Refer to relevant section of workshop manual.

No

The front seat height, tilt or extension motor is operating correctly.

Page 2337 of 3039

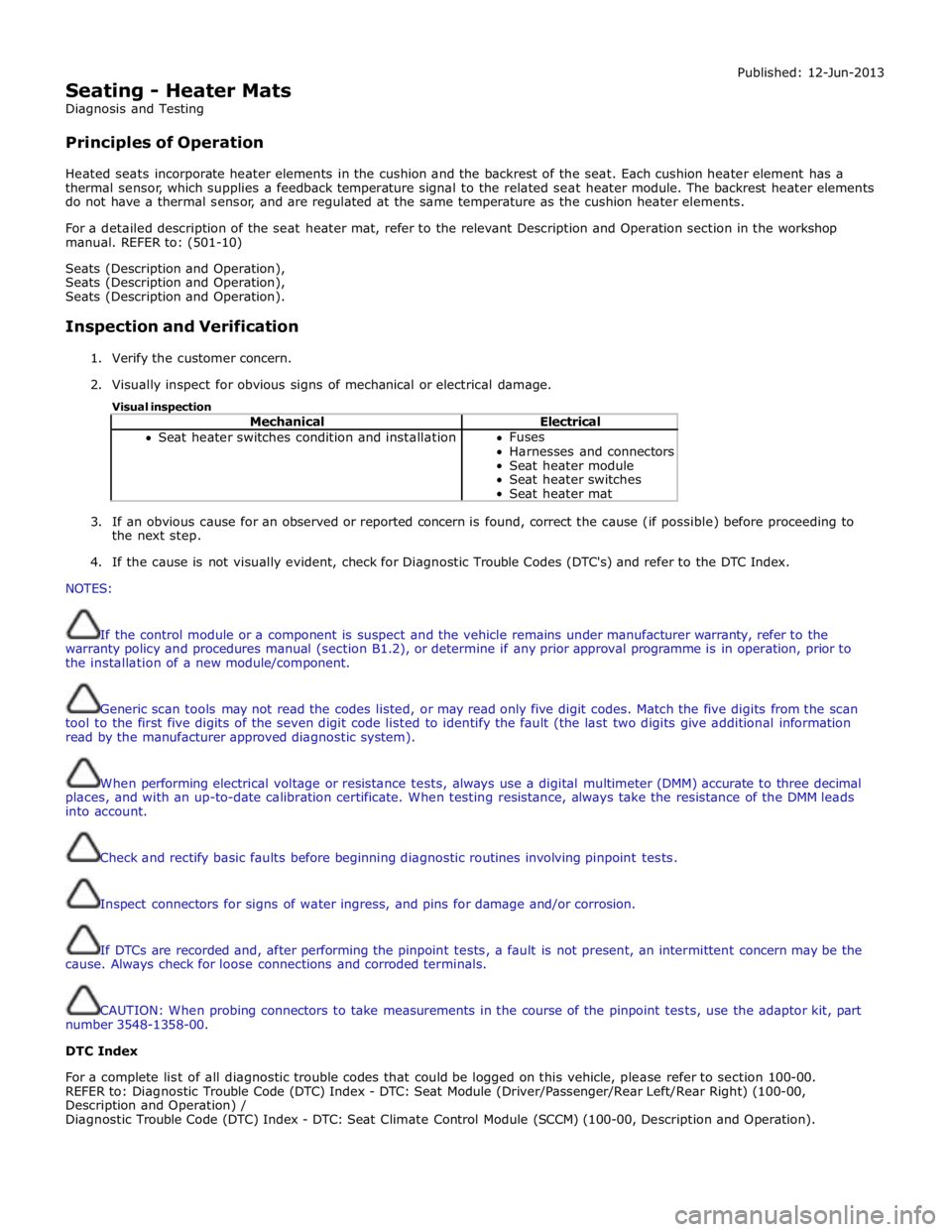

Seating - Heater Mats

Diagnosis and Testing

Principles of Operation Published: 12-Jun-2013

Heated seats incorporate heater elements in the cushion and the backrest of the seat. Each cushion heater element has a

thermal sensor, which supplies a feedback temperature signal to the related seat heater module. The backrest heater elements

do not have a thermal sensor, and are regulated at the same temperature as the cushion heater elements.

For a detailed description of the seat heater mat, refer to the relevant Description and Operation section in the workshop

manual. REFER to: (501-10)

Seats (Description and Operation),

Seats (Description and Operation),

Seats (Description and Operation).

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual inspection

Mechanical Electrical Seat heater switches condition and installation Fuses

Harnesses and connectors

Seat heater module

Seat heater switches

Seat heater mat

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTC's) and refer to the DTC Index.

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer approved diagnostic system).

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal

places, and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads

into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00.

DTC Index

For a complete list of all diagnostic trouble codes that could be logged on this vehicle, please refer to section 100-00.

REFER to: Diagnostic Trouble Code (DTC) Index - DTC: Seat Module (Driver/Passenger/Rear Left/Rear Right) (100-00,

Description and Operation) /

Diagnostic Trouble Code (DTC) Index - DTC: Seat Climate Control Module (SCCM) (100-00, Description and Operation).

Page 2338 of 3039

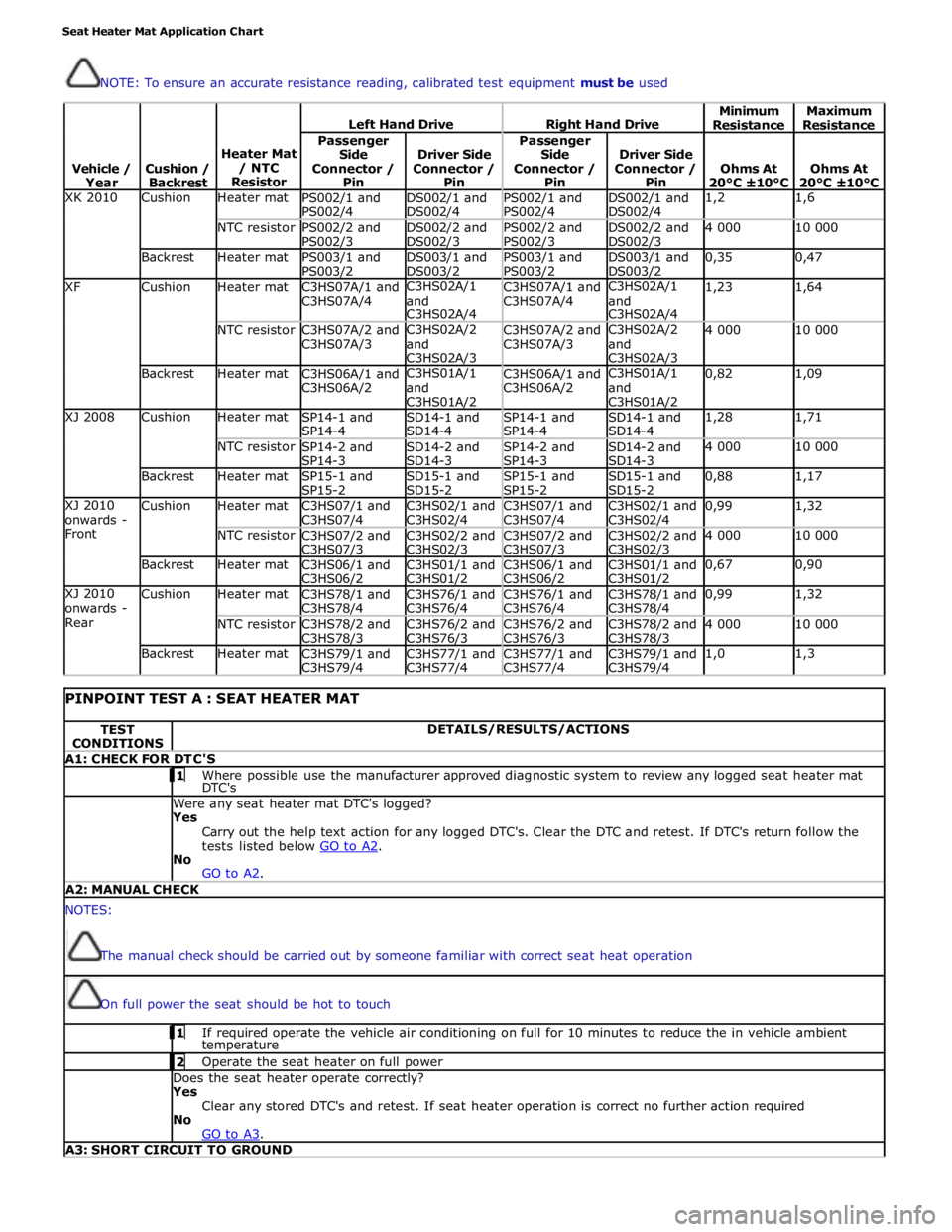

Seat Heater Mat Application Chart

NOTE: To ensure an accurate resistance reading, calibrated test equipment must be used

Vehicle /

Year

Cushion /

Backrest

Heater Mat

/ NTC

Resistor

Left Hand Drive

Right Hand Drive Minimum

Resistance Maximum

Resistance Passenger

Side

Connector /

Pin

Driver Side

Connector /

Pin Passenger

Side

Connector /

Pin

Driver Side

Connector /

Pin

Ohms At

20°C ±10°C

Ohms At

20°C ±10°C XK 2010 Cushion Heater mat

PS002/1 and

PS002/4 DS002/1 and

DS002/4 PS002/1 and

PS002/4 DS002/1 and

DS002/4 1,2 1,6 NTC resistor

PS002/2 and

PS002/3 DS002/2 and

DS002/3 PS002/2 and

PS002/3 DS002/2 and

DS002/3 4 000 10 000 Backrest Heater mat

PS003/1 and

PS003/2 DS003/1 and

DS003/2 PS003/1 and

PS003/2 DS003/1 and

DS003/2 0,35 0,47 XF Cushion Heater mat

C3HS07A/1 and

C3HS07A/4 C3HS02A/1

and

C3HS02A/4 C3HS07A/1 and

C3HS07A/4 C3HS02A/1

and

C3HS02A/4 1,23 1,64 NTC resistor

C3HS07A/2 and

C3HS07A/3 C3HS02A/2

and

C3HS02A/3 C3HS07A/2 and

C3HS07A/3 C3HS02A/2

and

C3HS02A/3 4 000 10 000 Backrest Heater mat

C3HS06A/1 and

C3HS06A/2 C3HS01A/1

and

C3HS01A/2 C3HS06A/1 and

C3HS06A/2 C3HS01A/1

and

C3HS01A/2 0,82 1,09 XJ 2008 Cushion Heater mat

SP14-1 and

SP14-4 SD14-1 and

SD14-4 SP14-1 and

SP14-4 SD14-1 and

SD14-4 1,28 1,71 NTC resistor

SP14-2 and

SP14-3 SD14-2 and

SD14-3 SP14-2 and

SP14-3 SD14-2 and

SD14-3 4 000 10 000 Backrest Heater mat

SP15-1 and

SP15-2 SD15-1 and

SD15-2 SP15-1 and

SP15-2 SD15-1 and

SD15-2 0,88 1,17 XJ 2010

onwards -

Front Cushion Heater mat

C3HS07/1 and

C3HS07/4 C3HS02/1 and

C3HS02/4 C3HS07/1 and

C3HS07/4 C3HS02/1 and

C3HS02/4 0,99 1,32 NTC resistor

C3HS07/2 and

C3HS07/3 C3HS02/2 and

C3HS02/3 C3HS07/2 and

C3HS07/3 C3HS02/2 and

C3HS02/3 4 000 10 000 Backrest Heater mat

C3HS06/1 and

C3HS06/2 C3HS01/1 and

C3HS01/2 C3HS06/1 and

C3HS06/2 C3HS01/1 and

C3HS01/2 0,67 0,90 XJ 2010

onwards -

Rear Cushion Heater mat

C3HS78/1 and

C3HS78/4 C3HS76/1 and

C3HS76/4 C3HS76/1 and

C3HS76/4 C3HS78/1 and

C3HS78/4 0,99 1,32 NTC resistor

C3HS78/2 and

C3HS78/3 C3HS76/2 and

C3HS76/3 C3HS76/2 and

C3HS76/3 C3HS78/2 and

C3HS78/3 4 000 10 000 Backrest Heater mat

C3HS79/1 and

C3HS79/4 C3HS77/1 and

C3HS77/4 C3HS77/1 and

C3HS77/4 C3HS79/1 and

C3HS79/4 1,0 1,3

PINPOINT TEST A : SEAT HEATER MAT TEST

CONDITIONS DETAILS/RESULTS/ACTIONS A1: CHECK FOR DTC'S 1 Where possible use the manufacturer approved diagnostic system to review any logged seat heater mat DTC's Were any seat heater mat DTC's logged?

Yes

Carry out the help text action for any logged DTC's. Clear the DTC and retest. If DTC's return follow the

tests listed below GO to A2. No

GO to A2. A2: MANUAL CHECK NOTES:

The manual check should be carried out by someone familiar with correct seat heat operation

On full power the seat should be hot to touch 1 If required operate the vehicle air conditioning on full for 10 minutes to reduce the in vehicle ambient temperature 2 Operate the seat heater on full power Does the seat heater operate correctly?

Yes

Clear any stored DTC's and retest. If seat heater operation is correct no further action required

No

GO to A3. A3: SHORT CIRCUIT TO GROUND

Page 2339 of 3039

1 Refer to the electrical circuit diagrams and the seat heater mat application chart (see above) to identify the connector 2 Disconnect the connector 3 Refer to the electrical circuit diagrams and check the seat heater mat heater circuit and the NTC resistor circuit for short circuit to ground Are either of the circuits short circuit to ground?

Yes

Repair the circuit or replace the seat heater mat as required. Refer to the warranty policy and procedures

manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component. Clear any stored DTC's and retest

No

GO to A4. A4: CIRCUIT CONTINUITY TEST 1 Refer to the electrical circuit diagrams and check the seat heater mat ( heater circuit ) for circuit continuity Does the seat heater mat heater circuit pass the continuity test?

Yes

GO to A5. No

Repair the circuit or replace the seat heater mat as required. Refer to the warranty policy and procedures

manual, or determine if any prior approval programme is in operation, prior to the installation of a new module/component. Clear any stored DTC's and retest A5: POWER CONSUMPTION

NOTE: The seat heater power supply cycles on and off dependant on the seat and cabin temperature and may only

switch on for 5 seconds in 30 seconds 1 Reconnect the connector 2 Operate the vehicle air conditioning on full for 10 minutes to reduce the in vehicle ambient temperature 3 Refer to the electrical circuit diagrams and check the seat heater mat ( heater circuit ) using a current clamp 4 Operate the seat heater on full power 5 Use the chart above to calculate typical value (V/R=I) (Volts divided by Resistance equals Current in Amps) 6 Examples (12 volts / 0.5 ohms =24 amps) (12 volts / 1 ohms = 12 amps) (12 volts / 2 ohms = 6 amps) Does the seat heater mat consume the correct level of current?

Yes

Clear any stored DTC's and retest. If operation correct, no further action required

No

GO to A6. A6: RESISTANCE CHECK NOTES:

Ensure the multimeter used is calibrated and a resistance reading of 0 ohms is shown when the test leads are connected

together, alternately subtract any resistance shown from the result

The seat heater mat circuits should be checked at the seat heater module connector

Refer to the electrical circuit diagrams and to confirm the total resistance of the circuit the cushion and backrest are

connected in series 1 Refer to the electrical circuit diagrams and the seat heater mat application chart (see above) to identify the terminals 2 Disconnect the connector 3 Using a multimeter, carry out a resistance check of the seat heater mat heater circuit and the NTC resistor circuit. Record the results 4 Compare the results to the chart (see above) Are the results within specification at the given ambient temperature? (tolerance +/- 0.5 Ohms)

Yes

Reconnect the connector. Clear any stored DTC's and retest. If customer concern or DTC's return refer to

electrical circuit diagrams and investigate the power and ground supply circuits

No

Replace the seat heater mat as required. Refer to the warranty policy and procedures manual, or

determine if any prior approval programme is in operation, prior to the installation of a new module/component. Clear any stored DTC's and retest www.JagDocs.com

Page 2340 of 3039

Seating - Seats Vehicles With: Climate Controlled Seats

Diagnosis and Testing

Principle of Operation Published: 16-Apr-2014

For a detailed description of the seating systems and operation, refer to the relevant description and operation section of the

workshop manual. REFER to: (501-10 Seating)

Seats (Description and Operation), Seats (Description and Operation), Seats (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals

The DTC index containing an actions list is for guidance only any reference to “check and install new blower unit” should

only be carried out following failure confirmation using the pin out diagnostics and/or the over temperature and fluid/air leak

diagnostics contained below. The recording of a DTC does NOT signify a permanently failed unit

The climate system functions in a manner that means any detected error state either intermittent or permanent will shut

down the complete seat climate system until the next ignition cycle, this does not mean that both climate units within the one

seat have failed. This shut down is design intent to protect the system to ensure that the fault detected does not damage the

units, it is possible that both units are functioning correctly and that the fault lies elsewhere within the system. The following

process can be carried out without removing either the seats or the climate units from the vehicle and should correctly identify

any failed units, this should ensure that only failed units are changed under warranty. Any units exhibiting the correct reading

as per process below, should NOT be changed under warranty. If all units have a correct reading then re-confirm customer

symptom, if customer symptom is still present then carry out further system checks

1. Verify the customer concern

2. Visually inspect for obvious signs of mechanical or electrical damage

Visual Inspection

Mechanical Electrical

Seat heater switch condition and installation

Battery condition and state of charge

Fuses

Harnesses and connectors

Seat heater switch(es)

Seat heater elements

Seat module(s)

Ignition switch

Battery junction box

Central junction box

LIN circuit

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident, carry out normal dealer warranty process, perform on-demand self test, check for

DTCs and refer to the relevant DTC index

5. Allow 30 mins since the last seat/cooled operation prior to carrying out pin testing detailed below in the section

"Connector and Pin Information"

Page 2341 of 3039

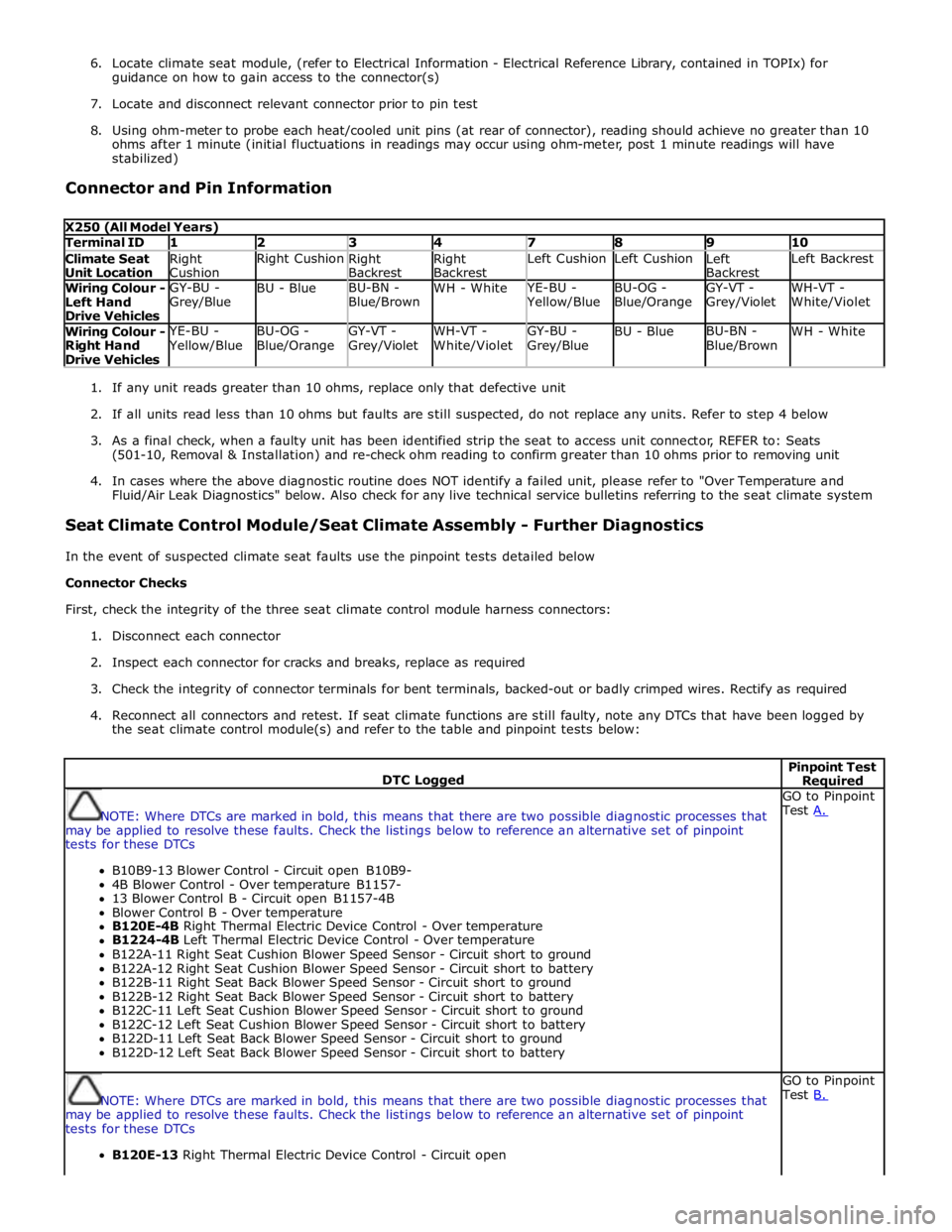

6. Locate climate seat module, (refer to Electrical Information - Electrical Reference Library, contained in TOPIx) for

guidance on how to gain access to the connector(s)

7. Locate and disconnect relevant connector prior to pin test

8. Using ohm-meter to probe each heat/cooled unit pins (at rear of connector), reading should achieve no greater than 10

ohms after 1 minute (initial fluctuations in readings may occur using ohm-meter, post 1 minute readings will have

stabilized)

Connector and Pin Information

X250 (All Model Years) Terminal ID 1 2 3 4 7 8 9 10 Climate Seat

Unit Location Right

Cushion Right Cushion

Right

Backrest Right

Backrest Left Cushion Left Cushion

Left

Backrest Left Backrest Wiring Colour -

Left Hand

Drive Vehicles GY-BU -

Grey/Blue BU - Blue BU-BN -

Blue/Brown WH - White YE-BU - Yellow/Blue BU-OG -

Blue/Orange GY-VT -

Grey/Violet WH-VT -

White/Violet Wiring Colour -

Right Hand

Drive Vehicles YE-BU - Yellow/Blue BU-OG -

Blue/Orange GY-VT -

Grey/Violet WH-VT -

White/Violet GY-BU -

Grey/Blue BU - Blue BU-BN -

Blue/Brown WH - White

1. If any unit reads greater than 10 ohms, replace only that defective unit

2. If all units read less than 10 ohms but faults are still suspected, do not replace any units. Refer to step 4 below

3. As a final check, when a faulty unit has been identified strip the seat to access unit connector, REFER to: Seats

(501-10, Removal & Installation) and re-check ohm reading to confirm greater than 10 ohms prior to removing unit

4. In cases where the above diagnostic routine does NOT identify a failed unit, please refer to "Over Temperature and

Fluid/Air Leak Diagnostics" below. Also check for any live technical service bulletins referring to the seat climate system

Seat Climate Control Module/Seat Climate Assembly - Further Diagnostics

In the event of suspected climate seat faults use the pinpoint tests detailed below

Connector Checks

First, check the integrity of the three seat climate control module harness connectors:

1. Disconnect each connector

2. Inspect each connector for cracks and breaks, replace as required

3. Check the integrity of connector terminals for bent terminals, backed-out or badly crimped wires. Rectify as required

4. Reconnect all connectors and retest. If seat climate functions are still faulty, note any DTCs that have been logged by

the seat climate control module(s) and refer to the table and pinpoint tests below:

DTC Logged Pinpoint Test Required

NOTE: Where DTCs are marked in bold, this means that there are two possible diagnostic processes that

may be applied to resolve these faults. Check the listings below to reference an alternative set of pinpoint

tests for these DTCs

B10B9-13 Blower Control - Circuit open B10B9-

4B Blower Control - Over temperature B1157-

13 Blower Control B - Circuit open B1157-4B

Blower Control B - Over temperature

B120E-4B Right Thermal Electric Device Control - Over temperature

B1224-4B Left Thermal Electric Device Control - Over temperature

B122A-11 Right Seat Cushion Blower Speed Sensor - Circuit short to ground

B122A-12 Right Seat Cushion Blower Speed Sensor - Circuit short to battery

B122B-11 Right Seat Back Blower Speed Sensor - Circuit short to ground

B122B-12 Right Seat Back Blower Speed Sensor - Circuit short to battery

B122C-11 Left Seat Cushion Blower Speed Sensor - Circuit short to ground

B122C-12 Left Seat Cushion Blower Speed Sensor - Circuit short to battery

B122D-11 Left Seat Back Blower Speed Sensor - Circuit short to ground

B122D-12 Left Seat Back Blower Speed Sensor - Circuit short to battery GO to Pinpoint

Test A.

NOTE: Where DTCs are marked in bold, this means that there are two possible diagnostic processes that

may be applied to resolve these faults. Check the listings below to reference an alternative set of pinpoint

tests for these DTCs

B120E-13 Right Thermal Electric Device Control - Circuit open GO to Pinpoint

Test B.

Page 2342 of 3039

DTC Logged Pinpoint Test Required B120E-19 Right Thermal Electric Device Control - Circuit current above threshold

B1223-13 Right Seat Cushion Temperature Sensor - Circuit open

B1224-13 Left Thermal Electric Device Control - Circuit open

B1224-19 Left Thermal Electric Device Control - Circuit current above threshold

B1225-13 Right Seat Back Temperature Sensor - Circuit open

B1229-13 Left Seat Back Temperature Sensor - Circuit open

B1235-13 Left Seat Cushion Temperature Sensor - Circuit open

B120F-98 Left Seat Cushion - Component or system over temperature

B122E-98 Right Seat Cushion - Component or system over temperature

B122F-98 Right Seat Back - Component or system over temperature

B1230-98 Left Seat Back - Component or system over temperature

B1231-7A Right Seat - Fluid leak or seal failure

B1232-7A Left Seat - Fluid leak or seal failure GO to Pinpoint

Test C.

NOTE: Where DTCs are marked in bold, this means that there are two possible diagnostic processes that

may be applied to resolve these faults. Check the listings above to reference an alternative set of pinpoint

tests for these DTCs

B120E-4B Right Thermal Electric Device Control - Over temperature

B120E-13 Right Thermal Electric Device Control - Circuit open

B120E-19 Right Thermal Electric Device Control - Circuit current above threshold

B1223-13 Right Seat Cushion Temperature Sensor - Circuit open

B1224-4B Left Thermal Electric Device Control - Over temperature

B1224-13 Left Thermal Electric Device Control - Circuit open

B1224-19 Left Thermal Electric Device Control - Circuit current above threshold

B1225-13 Right Seat Back Temperature Sensor - Circuit open

B1229-13 Left Seat Back Temperature Sensor - Circuit open

B1235-13 Left Seat Cushion Temperature Sensor - Circuit open GO to Pinpoint

Test D.

PINPOINT TEST A : CLIMATE SEATS ASSEMBLY - BLOWER DIAGNOSTICS TEST

CONDITIONS DETAILS/RESULTS/ACTIONS A1: CLIMATE SEATS ASSEMBLY - BLOWER SPEED CONTROL CIRCUIT RESISTANCE CHECKS AT SEAT TO VEHICLE

CONNECTOR 1 Uncouple connector C3HS03C from the seat climate control module 2 Check the resistance of the climate seats blower speed control circuits at connector C3HS03C For right-side seat cushion blower, check resistance at pins 3 and 7

For right-side seat backrest blower, check resistance at pins 4 and 7

For left-side seat cushion blower, check resistance at pins 11 and 15

For left-side seat backrest blower, check resistance at pins 12 and 15 Is the resistance between 290 and 420 kilo-ohms? Yes

No circuit faults present. No further action

No

GO to A2. A2: CLIMATE SEATS ASSEMBLY - BLOWER POWER CIRCUIT RESISTANCE CHECKS AT SEAT CLIMATE ASSEMBLY

CONNECTOR 1 Locate the appropriate seat backrest/seat cushion climate assembly connector 2 Disconnect connector 3 Check the integrity of connector terminals for bent terminals, backed-out or badly crimped wires. Rectify as required 4 Check the resistance of the climate seats blower power circuits at the climate assembly connector, pins 2 and 4 Is the resistance between 290 and 420 kilo-ohms? Yes

GO to A3. No

Replace the seat climate assembly A3: CLIMATE SEATS ASSEMBLY - BLOWER SPEED CONTROL CIRCUIT RESISTANCE CHECKS AT SEAT CLIMATE

ASSEMBLY CONNECTOR 1 Check the resistance of the climate seats blower control circuits at the climate assembly connector, pins 4 and 7

Page 2343 of 3039

PINPOINT TEST B : CLIMATE SEATS ASSEMBLY - THERMAL ELECTRIC DEVICE (TED) DIAGNOSTICS TEST

CONDITIONS DETAILS/RESULTS/ACTIONS B1: CLIMATE SEATS ASSEMBLY - TED SENSOR CIRCUIT RESISTANCE CHECKS AT SEAT TO VEHICLE CONNECTOR 1 Uncouple connector C3HS03B from the seat climate control module 2 Check the resistance of the climate seats TED sensor circuits at connector C3HS03B For right-side seat cushion TED sensor circuits, check resistance at pins 2 and 3

For right-side seat backrest TED sensor circuits, check resistance at pins 4 and 5

For left-side seat cushion TED sensor circuits, check resistance at pins 7 and 8

For left-side seat backrest TED sensor circuits, check resistance at pins 9 and 10 Is the resistance between 0.9 and 1.1 kilo-ohms? (Note: these values are based on an ambient temperature

of 22°C/72°F) Yes

No circuit faults present. No further action

No

GO to B2. B2: CLIMATE SEATS ASSEMBLY - TED SENSOR CIRCUIT RESISTANCE CHECKS AT SEAT CLIMATE ASSEMBLY

CONNECTOR 1 Locate the appropriate seat backrest/seat cushion climate assembly connector 2 Disconnect connector 3 Check the integrity of connector terminals for bent terminals, backed-out or badly crimped wires. Rectify as required 4 Check the resistance of the climate seats TED sensor circuits at the climate assembly connector, pins 5 and 8 (Green and Green wires) Is the resistance between 0.9 and 1.1 kilo-ohms? (Note: these values are based on an ambient temperature

of 22°C/72°F) Yes

GO to B3. No

Replace the seat climate assembly B3: CLIMATE SEATS ASSEMBLY - TED SUPPLY CIRCUIT OPEN CIRCUIT CHECKS AT SEAT CLIMATE ASSEMBLY

CONNECTOR 1 Check the TED supply circuits at the climate assembly connector, pins 1 and 3 (Blue and Yellow wires) for open circuit faults Is an open-circuit fault present? Yes

Replace the seat climate assembly

No

No internal circuit faults present. Check for circuit faults in wiring harness between seat climate control

module and climate seat assembly and replace as required

PINPOINT TEST C : CLIMATE SEATS ASSEMBLY - BLOWER AND DUCTING DIAGNOSTICS TEST

CONDITIONS DETAILS/RESULTS/ACTIONS C1: CLIMATE SEATS ASSEMBLY - BLOWER SPEED CONTROL CIRCUIT RESISTANCE CHECKS AT SEAT TO VEHICLE

CONNECTOR 1 Uncouple connector C3HS03C from the seat climate control module 2 Check the resistance of the climate seats blower speed control circuits at connector C3HS03C For right-side seat cushion blower, check resistance at pins 3 and 7

For right-side seat backrest blower, check resistance at pins 4 and 7

For left-side seat cushion blower, check resistance at pins 11 and 15

For left-side seat backrest blower, check resistance at pins 12 and 15 Is the resistance between 290 and 420 kilo-ohms?

Yes

No circuit faults present. No further action

No

GO to C2. C2: CLIMATE SEATS ASSEMBLY - BLOWER CIRCUIT RESISTANCE CHECKS AT SEAT CLIMATE ASSEMBLY CONNECTOR Is the resistance between 290 and 420 kilo-ohms?

Yes

No internal circuit faults present. Check for circuit faults in wiring harness between seat climate control

module and climate seat assembly and replace as required

No

Replace the seat climate assembly

Page 2344 of 3039

1 Locate the appropriate seat backrest/seat cushion climate assembly connector 2 Disconnect connector 3 Check the integrity of connector terminals for bent terminals, backed-out or badly crimped wires. Rectify as required 4 Check the resistance of the climate seats blower circuits at the climate assembly connector, pins 2 and 4 (Violet and Black wires) Is the resistance between 290 and 420 kilo-ohms?

Yes

GO to C3. No

Replace the seat climate assembly C3: CLIMATE SEATS ASSEMBLY - BLOWER CONTROL CIRCUIT RESISTANCE CHECKS AT SEAT CLIMATE ASSEMBLY

CONNECTOR 1 Check the resistance of the climate seats blower control circuits at the climate assembly connector, pins 4 and 7 (Black and Purple wires) Is the resistance between 290 and 420 kilo-ohms?

Yes

No internal circuit faults present. Check for circuit faults in wiring harness between seat climate control

module and climate seat assembly and replace as required. If no harness faults are found, GO to C4. No

Replace the seat climate assembly C4: CLIMATE SEATS ASSEMBLY - BLOWER DUCTING INSPECTION 1 Check that the ducting is securely attached to the blower and thermal electric device 2 Check the ducting for holes, cuts or tears Is the ducting undamaged and securely attached to the blower and thermal electric device?

Yes

GO to C5. No

Replace the seat climate assembly C5: CLIMATE SEATS ASSEMBLY - EXHAUST AIRFLOW CHECKS 1 Check for blockages or restrictions at the thermal electric device exhaust vent Are blockages or restrictions present?

Yes

Rectify as required

No

GO to C6. C6: CLIMATE SEATS ASSEMBLY - BLOWER AIRFLOW CHECKS 1 Check for blockages or restrictions at the blower air intake 2 Check that the blower fan movement is not restricted Are there any air intake blockages or restrictions to the blower fan movement?

Yes

Rectify as required

No

No further action

PINPOINT TEST D : CLIMATE SEATS ASSEMBLY - THERMAL ELECTRIC DEVICE (TED) AND DUCTING

DIAGNOSTICS TEST

CONDITIONS DETAILS/RESULTS/ACTIONS D1: CLIMATE SEATS ASSEMBLY - TED SENSOR CIRCUIT RESISTANCE CHECKS AT SEAT TO VEHICLE CONNECTOR 1 Uncouple connector C3HS03B from the seat climate control module 2 Check the resistance of the climate seats TED sensor circuits at connector C3HS03B For right-side seat cushion TED sensor circuits, check resistance at pins 2 and 3

For right-side seat backrest TED sensor circuits, check resistance at pins 4 and 5

For left-side seat cushion TED sensor circuits, check resistance at pins 7 and 8

For left-side seat backrest TED sensor circuits, check resistance at pins 9 and 10 Is the resistance between 0.9 and 1.1 kilo-ohms? (Note: these values are based on an ambient temperature

of 22°C/72°F)

Yes

No circuit faults present. No further action

No

GO to D2. D2: CLIMATE SEATS ASSEMBLY - TED SENSOR CIRCUIT RESISTANCE CHECKS AT SEAT CLIMATE ASSEMBLY

CONNECTOR 1 Locate the appropriate seat backrest/seat cushion climate assembly connector 2 Disconnect connector 3 Check the integrity of connector terminals for bent terminals, backed-out or badly crimped wires. Rectify as required www.JagDocs.com