oil JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1521 of 3039

Transmission Cooling (Description and Operation), Transmission Cooling (Description and Operation).

Inspection and Verification

1. Verify the customer concern by operating the system.

2. Visually inspect for obvious signs of damage and system integrity.

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

Symptom Chart

Condition Possible Causes Action Over heating of the

automatic

transmission Obstruction in the automatic

transmission fluid cooler Flush out the automatic transmission fluid cooler with new

automatic transmission fluid. If the flushing is unsuccessful,

install a new transmission fluid cooler. Over heating of the

automatic

transmission Obstruction in the automatic

transmission fluid tubes Flush out the automatic transmission fluid cooler tubes with new

automatic transmission fluid. If the flushing is unsuccessful install

new automatic transmission fluid cooler tubes. Loss of automatic

transmission fluid Connections to the automatic

transmission and the automatic

transmission fluid cooler Check the integrity of the tubes, connections and seals. Check the

torque of the tube fixings. Loss of automatic

transmission fluid Leak at oil cooler

Check the integrity of tubes, connections and seals. Check the torque of the tube fixings. Mechanical

Feed and return tubes

Connections to the automatic transmission and the automatic transmission fluid cooler

Automatic transmission fluid level Visual Inspection

www.JagDocs.com

Page 1590 of 3039

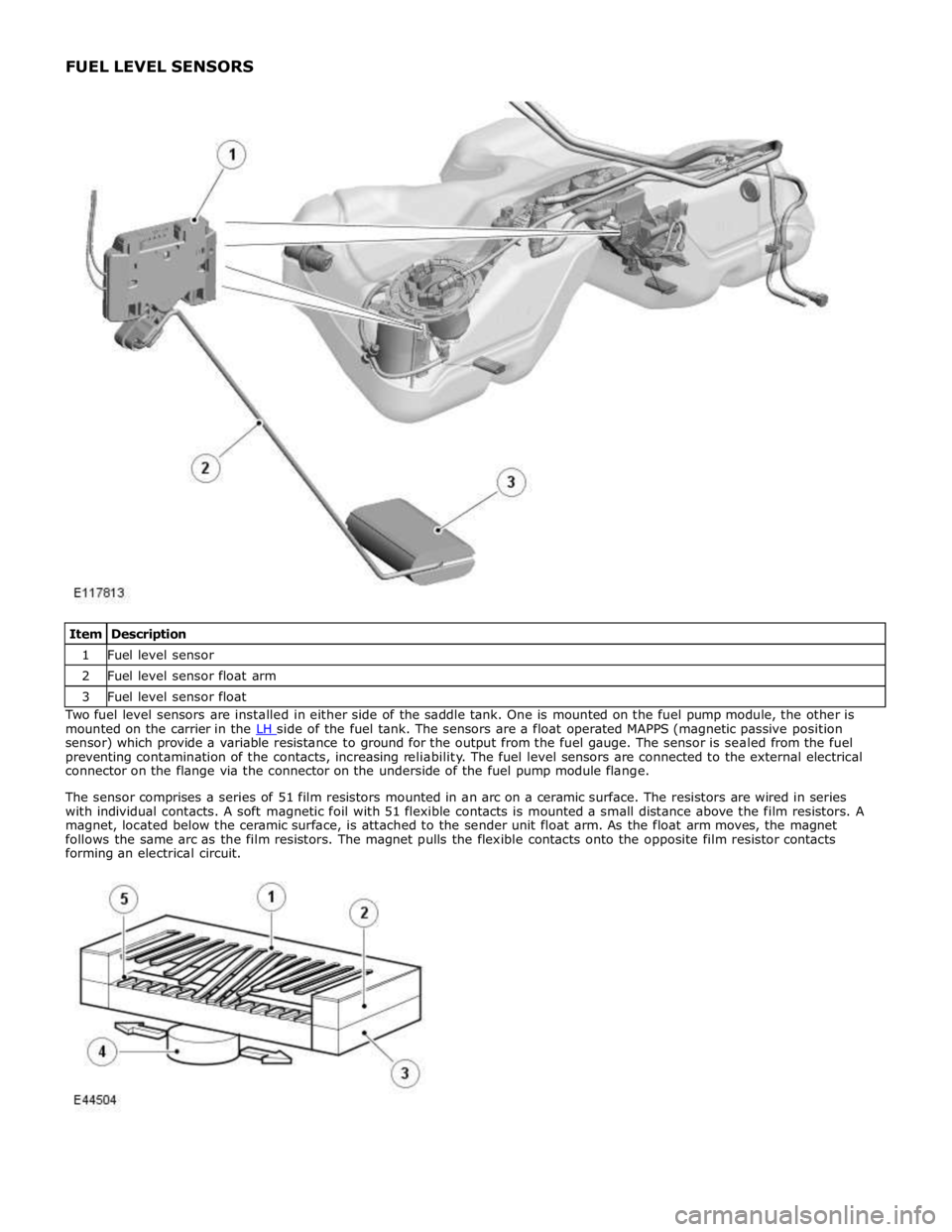

1 Fuel level sensor 2 Fuel level sensor float arm 3 Fuel level sensor float Two fuel level sensors are installed in either side of the saddle tank. One is mounted on the fuel pump module, the other is

mounted on the carrier in the LH side of the fuel tank. The sensors are a float operated MAPPS (magnetic passive position sensor) which provide a variable resistance to ground for the output from the fuel gauge. The sensor is sealed from the fuel

preventing contamination of the contacts, increasing reliability. The fuel level sensors are connected to the external electrical

connector on the flange via the connector on the underside of the fuel pump module flange.

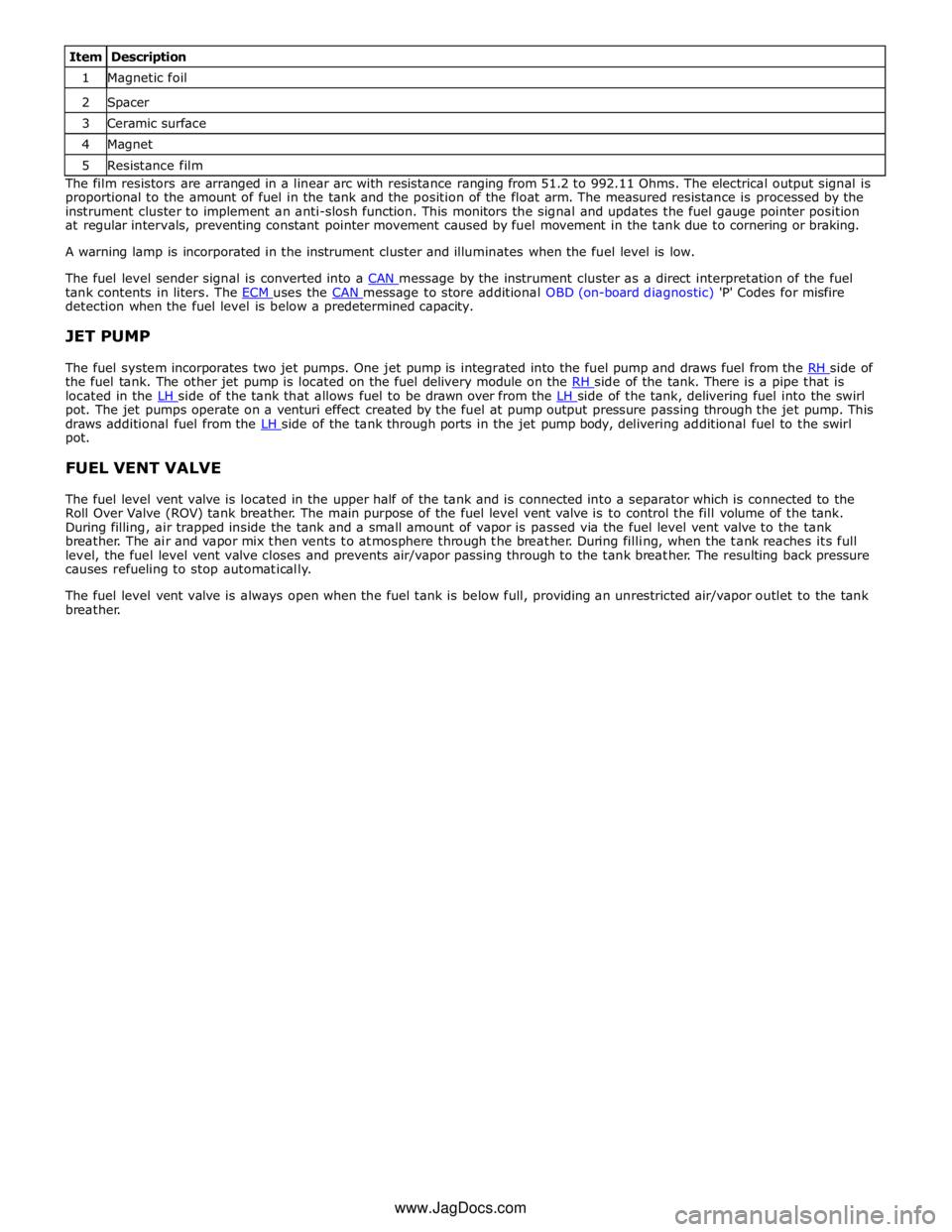

The sensor comprises a series of 51 film resistors mounted in an arc on a ceramic surface. The resistors are wired in series

with individual contacts. A soft magnetic foil with 51 flexible contacts is mounted a small distance above the film resistors. A

magnet, located below the ceramic surface, is attached to the sender unit float arm. As the float arm moves, the magnet

follows the same arc as the film resistors. The magnet pulls the flexible contacts onto the opposite film resistor contacts

forming an electrical circuit.

Page 1591 of 3039

1 Magnetic foil 2 Spacer 3 Ceramic surface 4 Magnet 5 Resistance film The film resistors are arranged in a linear arc with resistance ranging from 51.2 to 992.11 Ohms. The electrical output signal is

proportional to the amount of fuel in the tank and the position of the float arm. The measured resistance is processed by the

instrument cluster to implement an anti-slosh function. This monitors the signal and updates the fuel gauge pointer position

at regular intervals, preventing constant pointer movement caused by fuel movement in the tank due to cornering or braking.

A warning lamp is incorporated in the instrument cluster and illuminates when the fuel level is low.

The fuel level sender signal is converted into a CAN message by the instrument cluster as a direct interpretation of the fuel tank contents in liters. The ECM uses the CAN message to store additional OBD (on-board diagnostic) 'P' Codes for misfire detection when the fuel level is below a predetermined capacity.

JET PUMP

The fuel system incorporates two jet pumps. One jet pump is integrated into the fuel pump and draws fuel from the RH side of the fuel tank. The other jet pump is located on the fuel delivery module on the RH side of the tank. There is a pipe that is located in the LH side of the tank that allows fuel to be drawn over from the LH side of the tank, delivering fuel into the swirl pot. The jet pumps operate on a venturi effect created by the fuel at pump output pressure passing through the jet pump. This

draws additional fuel from the LH side of the tank through ports in the jet pump body, delivering additional fuel to the swirl pot.

FUEL VENT VALVE

The fuel level vent valve is located in the upper half of the tank and is connected into a separator which is connected to the

Roll Over Valve (ROV) tank breather. The main purpose of the fuel level vent valve is to control the fill volume of the tank.

During filling, air trapped inside the tank and a small amount of vapor is passed via the fuel level vent valve to the tank

breather. The air and vapor mix then vents to atmosphere through the breather. During filling, when the tank reaches its full

level, the fuel level vent valve closes and prevents air/vapor passing through to the tank breather. The resulting back pressure

causes refueling to stop automatically.

The fuel level vent valve is always open when the fuel tank is below full, providing an unrestricted air/vapor outlet to the tank

breather.

www.JagDocs.com

Page 1663 of 3039

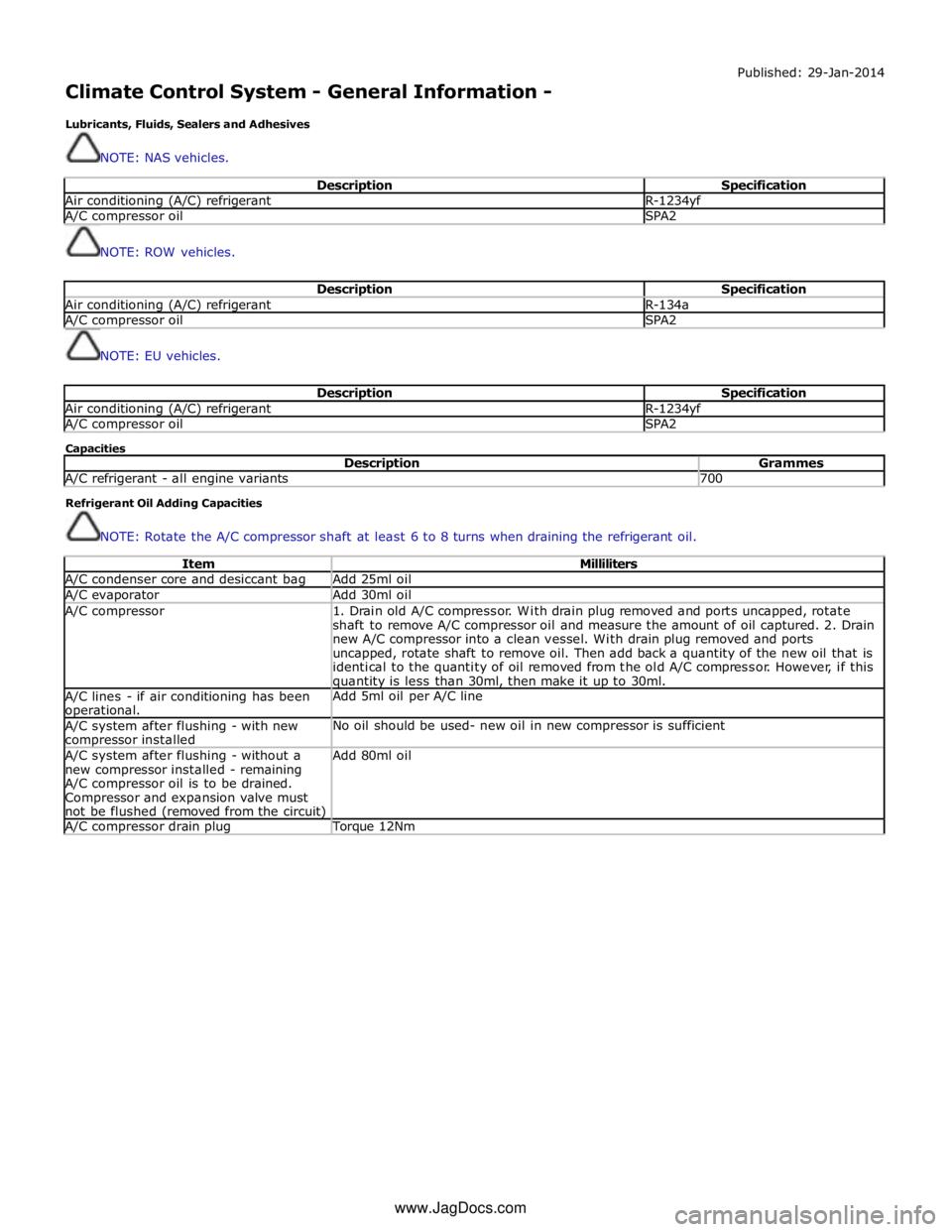

Climate Control System - General Information -

Lubricants, Fluids, Sealers and Adhesives

NOTE: NAS vehicles. Published: 29-Jan-2014

Description Specification Air conditioning (A/C) refrigerant R-1234yf A/C compressor oil SPA2

NOTE: ROW vehicles.

Description Specification Air conditioning (A/C) refrigerant R-134a A/C compressor oil SPA2

NOTE: EU vehicles.

Description Specification Air conditioning (A/C) refrigerant R-1234yf A/C compressor oil SPA2 Capacities

Description Grammes A/C refrigerant - all engine variants 700 Refrigerant Oil Adding Capacities

NOTE: Rotate the A/C compressor shaft at least 6 to 8 turns when draining the refrigerant oil.

Item Milliliters A/C condenser core and desiccant bag Add 25ml oil A/C evaporator Add 30ml oil A/C compressor

1. Drain old A/C compressor. With drain plug removed and ports uncapped, rotate

shaft to remove A/C compressor oil and measure the amount of oil captured. 2. Drain

new A/C compressor into a clean vessel. With drain plug removed and ports

uncapped, rotate shaft to remove oil. Then add back a quantity of the new oil that is

identical to the quantity of oil removed from the old A/C compressor. However, if this quantity is less than 30ml, then make it up to 30ml. A/C lines - if air conditioning has been operational. Add 5ml oil per A/C line A/C system after flushing - with new compressor installed No oil should be used- new oil in new compressor is sufficient A/C system after flushing - without a

new compressor installed - remaining

A/C compressor oil is to be drained.

Compressor and expansion valve must

not be flushed (removed from the circuit) Add 80ml oil A/C compressor drain plug Torque 12Nm www.JagDocs.com

Page 1669 of 3039

8. WARNING: Refrigerant must always be recycled before re-use to ensure

that the purity of the refrigerantis high enough for safe use in the air

conditioning system. Recycling should always be carried out with

equipment which is design certified by Underwriter Laboratory Inc. for

compliance with SEA J1991. Other equipment may not recycle refrigerant

to the required level of purity. R143a Refrigerant Recover Recycling

Recharging station must not be used with any other type of

refrigerant.Refrigerant R134a from domestic and comercial sources must

not be used in motor vehicles air conditioning systems.

Allow the system to recover the refrigerant from the system.

9. Close the valves on the refrigerant station.

10. Turn the main switch 'OFF'.

11. Close the valves on the connections.

12. Disconnect the high and low pressure connections.

13. Install the dust covers to the connectors.

14. Open the tap at the rear of the station to drain the refrigerant oil.

15. Measure and record the quantity of refrigerant oil recovered from the

system.

16. Close the tap at the rear of the station.

17. Evacuation.

18. Remove the dust covers from the high and low pressure connections.

19. Connect the high and low pressure lines to the appropriate connections.

20. Open the valves on the connections.

21. Turn the valves on the station to the correct positions.

22. Turn the process switch to the correct position.

23. Turn the main switch to 'ON'.

24. Allow the station to evacuate the A/C system.

25. CAUTION: The system must be evacuated immediatley before

recharging commences. Delay between evacuation and recharging is not

permitted

Recharging

26. Close the valves on the refrigerant station.

Page 1670 of 3039

27. Close the valve on the oil charger.

28. Disconnect the yellow line from the refrigerant station.

29. Remove the cover from the oil charger.

30. Pour the correct quantity of refrigerant oil into the oil charger.

31. Install the cover to the oil charger.

32. Connect the yellow line to the refrigerant station.

33. Open the valve on the oil charger.

34. Move the pointer on the refrigerant gauge to mark the position of the

refrigerant drop.

35. Slowly open the correct valve on the refrigerant to allow the vacuum to

pull the refrigerant into the system.

36. Close the valve on the refrigerant station when the correct amount of

refrigerant has been drawn into the air conditioning system.

37. Turn the main switch 'OFF'.

38. Close the valves on the connections.

39. Disconnect the high and low pressure connections.

Page 1671 of 3039

Published: 11-May-2011

Climate Control System - General Information - Air Conditioning (A/C) System

Flushing

General Procedures

1. WARNINGS:

Use extreme care and observe all safety precautions related to the

use of refrigerants. Due to refrigerant hazards, always wear safety

goggles and non-penetrable gloves when working on or flushing air

conditioning (A/C) systems. Failure to follow this instruction may result

in personal injury.

When flushing the A/C system, refer to the manufacturers

equipment instructions for additional information. Failure to do so may

result in system damage or personal injury.

The A/C refrigerant analyzer must be used before the recovery of

any vehicle's A/C refrigerant. Failure to do so puts shop bulk refrigerant

at risk of contamination. If the vehicle A/C refrigerant is contaminated,

refer the customer to return to the repair facility that performed the last

A/C repair. If the customer wishes to pay the additional cost, use the

A/C recovery equipment that is designated for recovering contaminated

A/C refrigerant. All contaminated A/C refrigerant must be disposed of as

hazardous waste. For additional information, refer to the manufacturers

equipment instructions. Failure to follow this instruction may result in

personal injury.

Prior to using the A/C flushing equipment for the first time, follow

the operating instructions. Failure to follow this instruction may result in

personal injury.

CAUTION: Prior to flushing, remove and discard the desiccant sack.

Depending on the equipment used, other A/C components may have to

be removed prior to flushing. For additional information, refer to the

manufacturers equipment instructions before flushing the A/C system.

Recover the refrigerant.

For additional information, refer to Air conditioning (A/C) System Recovery, Evacuation and Charging in this section.

2. Remove the desiccant sack.

For additional information, refer to Section 412-03 Air Conditioning.

3. Flush the system. For additional information, refer to the manufacturers

equipment instructions.

4. Install new refrigerant lines if blocked with debris.

5. Install a new desiccant sack.

For additional information, refer to Section 412-03 Air Conditioning.

6. Add the required amount of oil to the A/C system depending on the

repair procedure.

For additional information, refer to Refrigerant Oil Adding in this section.

7. Evacuate and charge the A/C system.

For additional information, refer to Air conditioning (A/C) System Recovery, Evacuation and Charging in this section.

8. Carry out fluorescent dye leak detection test.

Page 1675 of 3039

Published: 11-May-2011

Climate Control System - General Information - Fluorescent Dye Leak Detection

General Procedures

1. WARNING: Eye protection glasses supplied with the ultraviolet (UV)

lamp should be used to protect eyesight from harm.

NOTE: The air conditioning (A/C) system has an R-134a leak trace

dye wafer incorporated into the desiccant bag. The exact location of

leaks can be pinpointed by the bright yellow/green glow of the tracer

dye. Since more than one leak may exist, always inspect each

component. If it is necessary to add dye (due to a severe leakage for

example) use proprietary tracer dye injection equipment.

Check for leaks using ultraviolet (UV) lamp.

2. Check all components, fittings and lines of the A/C system.

3. Carry out the repair. For additional information, refer to Section 412-03 Air Conditioning.

4. After the leak is repaired, remove any traces of leak trace dye with a

general purpose oil solvent.

5. Check the A/C system for correct operation.

6. Verify the repair by operating the system for a short time and inspecting

with the (UV) lamp.

Page 1676 of 3039

Published: 11-May-2011

Climate Control System - General Information - Inspection and Assembly Requirements

General Procedures

1. Check for leaks using ultraviolet (UV) Lamp.

For additional information, refer to Flourescent Dye Leak Detection in this section.

2. NOTES:

Any time a hose or component connection leak is observed, the

component and fitting must be separated, cleaned and a new O-ring

fitted and lubricated with air conditioning compressor oil.

For additional information, refer to Specifications in this section.

When separating A/C joints, cap the open connections

immediately. Do not leave open to atmosphere.

O-ring seal surfaces must be free of dirt, lint, burrs and scratches. The

O-ring and connector should be lubricated with air conditioning

compressor oil.

For additional information, refer to Specifications in this section.

Page 1678 of 3039

Published: 11-May-2011

Climate Control System - General Information - Refrigerant Oil Adding TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol

General Procedures

CAUTIONS:

Collect the refrigerant oil in a clean measuring cylinder. Check

Make sure that all openings are sealed. Use new blanking caps.

Be prepared to collect escaping fluids.

NOTE: Removal steps in this procedure may contain installation details.

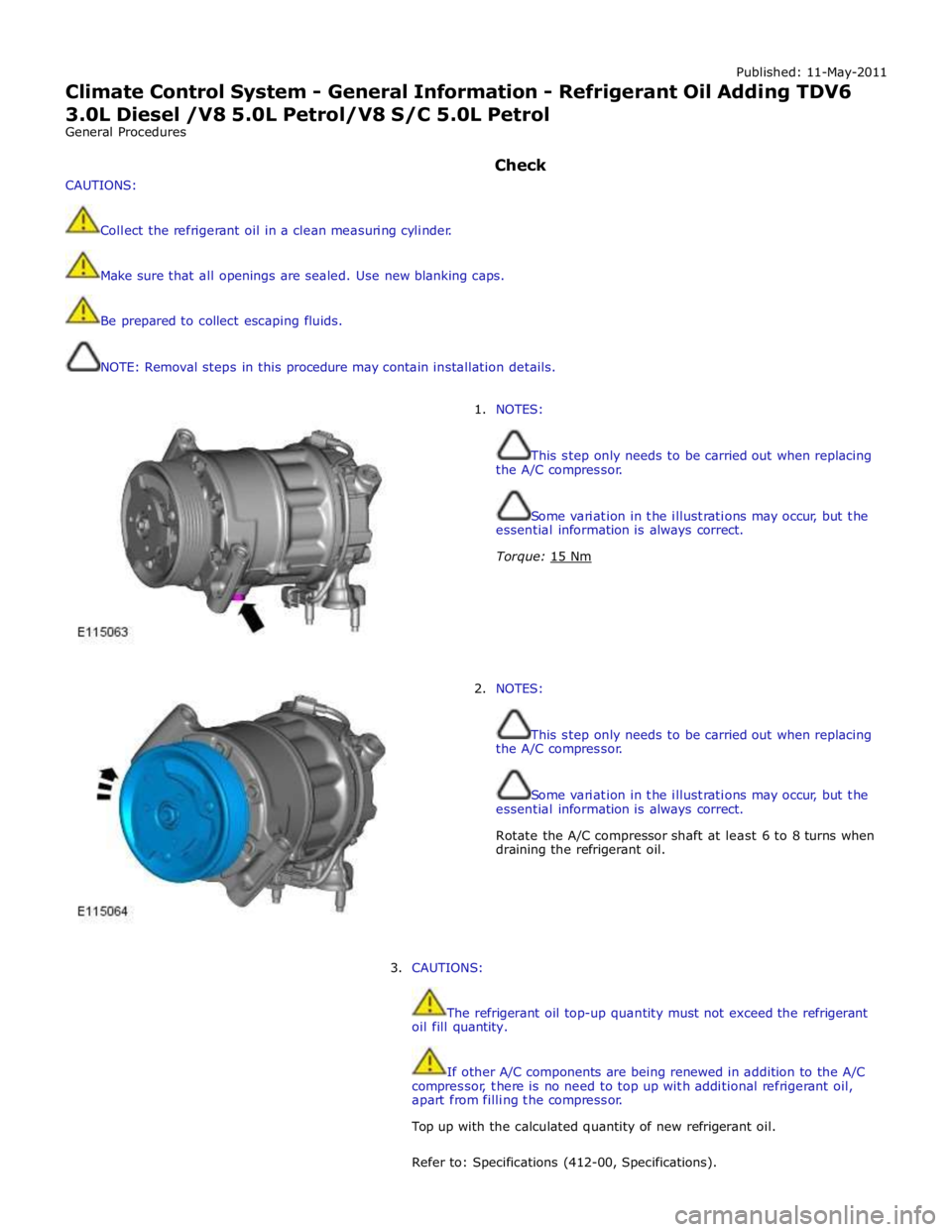

1. NOTES:

This step only needs to be carried out when replacing

the A/C compressor.

Some variation in the illustrations may occur, but the

essential information is always correct.

Torque: 15 Nm

2. NOTES:

This step only needs to be carried out when replacing

the A/C compressor.

Some variation in the illustrations may occur, but the

essential information is always correct.

Rotate the A/C compressor shaft at least 6 to 8 turns when

draining the refrigerant oil.

3. CAUTIONS:

The refrigerant oil top-up quantity must not exceed the refrigerant

oil fill quantity.

If other A/C components are being renewed in addition to the A/C

compressor, there is no need to top up with additional refrigerant oil,

apart from filling the compressor.

Top up with the calculated quantity of new refrigerant oil.

Refer to: Specifications (412-00, Specifications).