SECURITY SYSTEM JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 185 of 3039

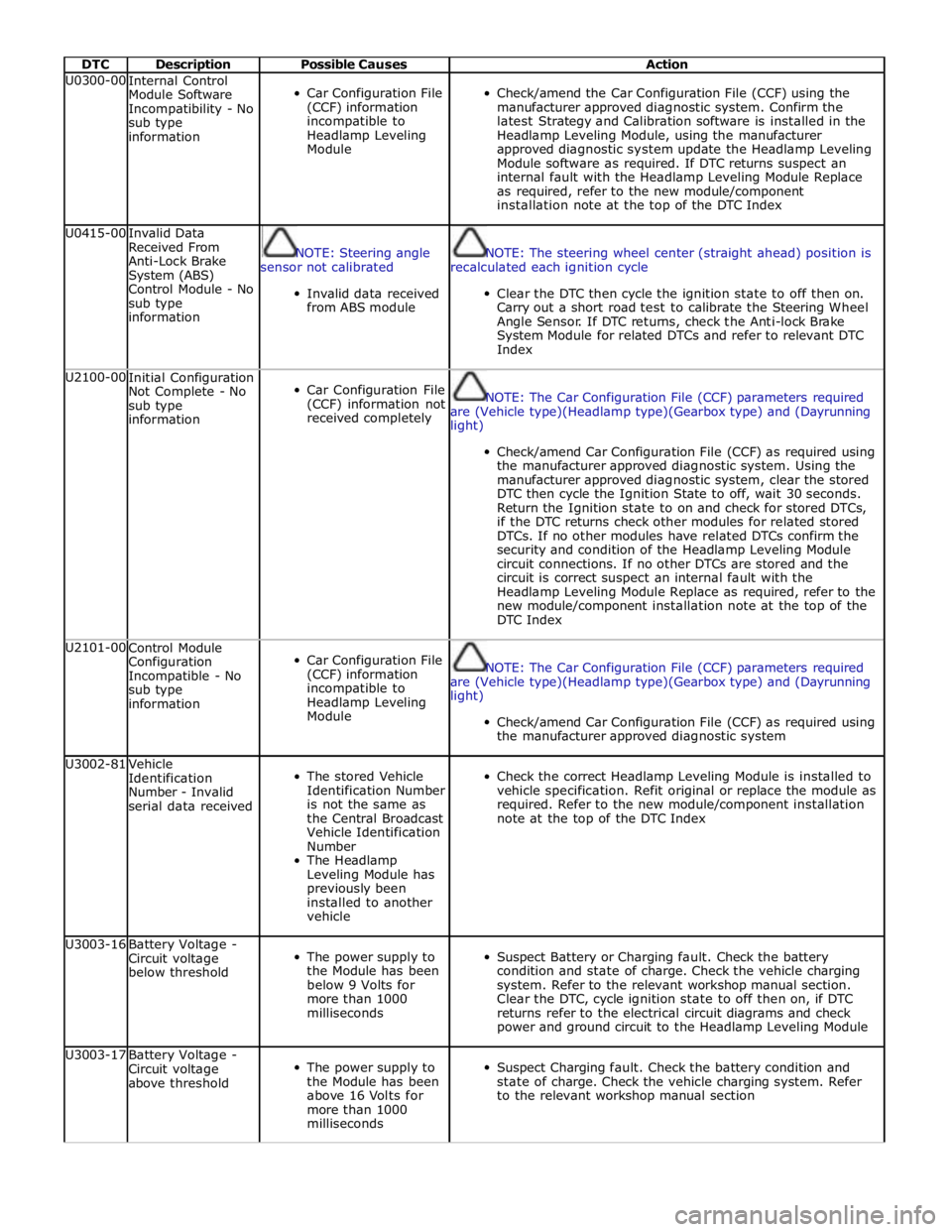

DTC Description Possible Causes Action U0300-00

Internal Control

Module Software

Incompatibility - No

sub type

information

Car Configuration File

(CCF) information

incompatible to

Headlamp Leveling

Module

Check/amend the Car Configuration File (CCF) using the

manufacturer approved diagnostic system. Confirm the

latest Strategy and Calibration software is installed in the

Headlamp Leveling Module, using the manufacturer

approved diagnostic system update the Headlamp Leveling

Module software as required. If DTC returns suspect an

internal fault with the Headlamp Leveling Module Replace

as required, refer to the new module/component

installation note at the top of the DTC Index U0415-00

Invalid Data

Received From

Anti-Lock Brake

System (ABS)

Control Module - No

sub type

information

NOTE: Steering angle

sensor not calibrated

Invalid data received

from ABS module

NOTE: The steering wheel center (straight ahead) position is

recalculated each ignition cycle

Clear the DTC then cycle the ignition state to off then on.

Carry out a short road test to calibrate the Steering Wheel

Angle Sensor. If DTC returns, check the Anti-lock Brake

System Module for related DTCs and refer to relevant DTC

Index U2100-00

Initial Configuration

Not Complete - No

sub type

information

Car Configuration File

(CCF) information not

received completely

NOTE: The Car Configuration File (CCF) parameters required

are (Vehicle type)(Headlamp type)(Gearbox type) and (Dayrunning

light)

Check/amend Car Configuration File (CCF) as required using

the manufacturer approved diagnostic system. Using the

manufacturer approved diagnostic system, clear the stored

DTC then cycle the Ignition State to off, wait 30 seconds.

Return the Ignition state to on and check for stored DTCs,

if the DTC returns check other modules for related stored

DTCs. If no other modules have related DTCs confirm the

security and condition of the Headlamp Leveling Module

circuit connections. If no other DTCs are stored and the

circuit is correct suspect an internal fault with the

Headlamp Leveling Module Replace as required, refer to the

new module/component installation note at the top of the

DTC Index U2101-00

Control Module

Configuration

Incompatible - No

sub type

information

Car Configuration File

(CCF) information

incompatible to

Headlamp Leveling

Module

NOTE: The Car Configuration File (CCF) parameters required

are (Vehicle type)(Headlamp type)(Gearbox type) and (Dayrunning

light)

Check/amend Car Configuration File (CCF) as required using

the manufacturer approved diagnostic system U3002-81

Vehicle

Identification

Number - Invalid

serial data received

The stored Vehicle

Identification Number

is not the same as

the Central Broadcast

Vehicle Identification

Number

The Headlamp

Leveling Module has

previously been

installed to another

vehicle

Check the correct Headlamp Leveling Module is installed to

vehicle specification. Refit original or replace the module as

required. Refer to the new module/component installation

note at the top of the DTC Index U3003-16

Battery Voltage -

Circuit voltage

below threshold

The power supply to

the Module has been

below 9 Volts for

more than 1000

milliseconds

Suspect Battery or Charging fault. Check the battery

condition and state of charge. Check the vehicle charging

system. Refer to the relevant workshop manual section.

Clear the DTC, cycle ignition state to off then on, if DTC

returns refer to the electrical circuit diagrams and check

power and ground circuit to the Headlamp Leveling Module U3003-17

Battery Voltage -

Circuit voltage

above threshold

The power supply to

the Module has been

above 16 Volts for

more than 1000

milliseconds

Suspect Charging fault. Check the battery condition and

state of charge. Check the vehicle charging system. Refer

to the relevant workshop manual section

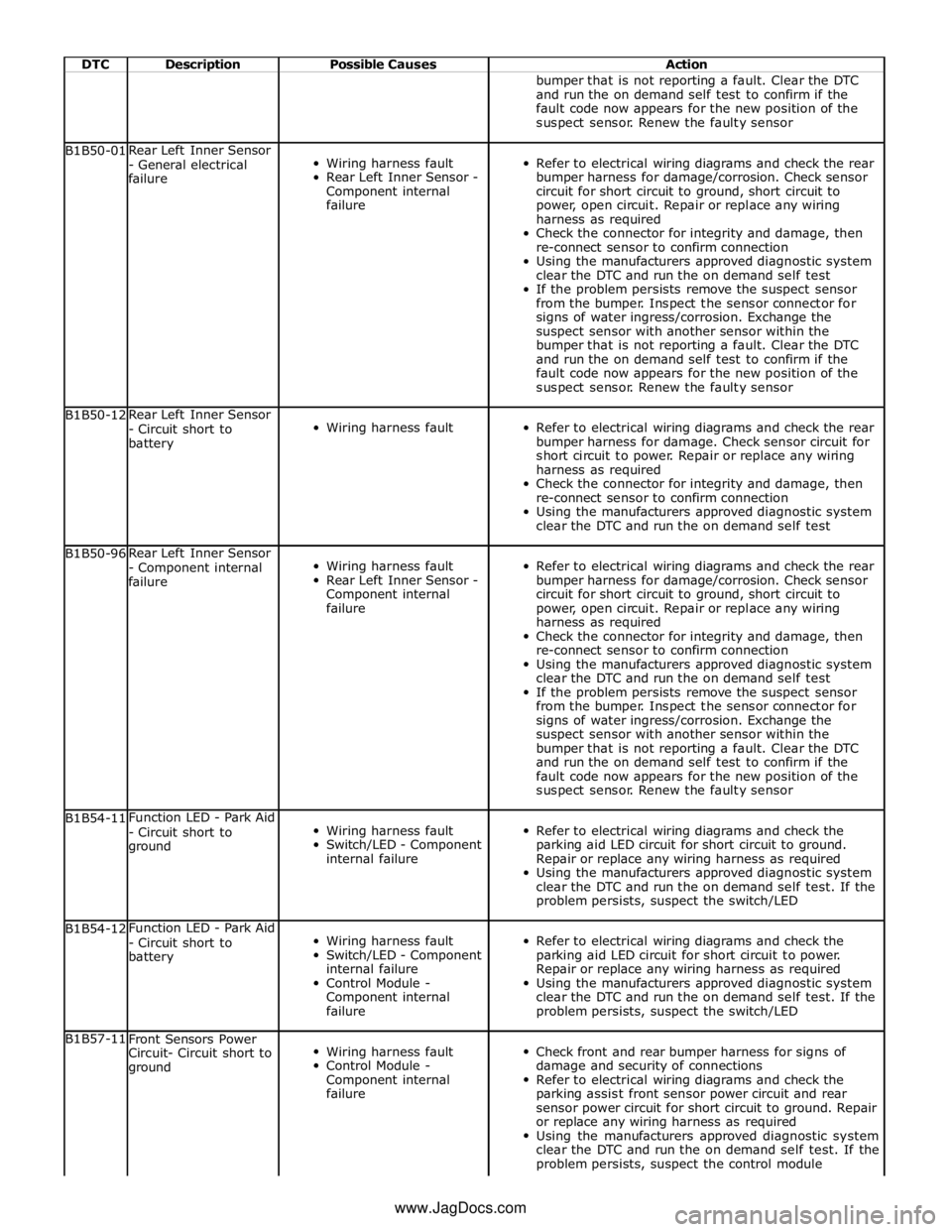

Page 211 of 3039

DTC Description Possible Causes Action bumper that is not reporting a fault. Clear the DTC

and run the on demand self test to confirm if the

fault code now appears for the new position of the

suspect sensor. Renew the faulty sensor B1B50-01 Rear Left Inner Sensor

- General electrical

failure

Wiring harness fault

Rear Left Inner Sensor -

Component internal

failure

Refer to electrical wiring diagrams and check the rear

bumper harness for damage/corrosion. Check sensor

circuit for short circuit to ground, short circuit to

power, open circuit. Repair or replace any wiring

harness as required

Check the connector for integrity and damage, then

re-connect sensor to confirm connection

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test

If the problem persists remove the suspect sensor

from the bumper. Inspect the sensor connector for

signs of water ingress/corrosion. Exchange the

suspect sensor with another sensor within the

bumper that is not reporting a fault. Clear the DTC

and run the on demand self test to confirm if the

fault code now appears for the new position of the

suspect sensor. Renew the faulty sensor B1B50-12 Rear Left Inner Sensor

- Circuit short to

battery

Wiring harness fault

Refer to electrical wiring diagrams and check the rear

bumper harness for damage. Check sensor circuit for

short circuit to power. Repair or replace any wiring

harness as required

Check the connector for integrity and damage, then

re-connect sensor to confirm connection

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test B1B50-96 Rear Left Inner Sensor

- Component internal

failure

Wiring harness fault

Rear Left Inner Sensor -

Component internal

failure

Refer to electrical wiring diagrams and check the rear

bumper harness for damage/corrosion. Check sensor

circuit for short circuit to ground, short circuit to

power, open circuit. Repair or replace any wiring

harness as required

Check the connector for integrity and damage, then

re-connect sensor to confirm connection

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test

If the problem persists remove the suspect sensor

from the bumper. Inspect the sensor connector for

signs of water ingress/corrosion. Exchange the

suspect sensor with another sensor within the

bumper that is not reporting a fault. Clear the DTC

and run the on demand self test to confirm if the

fault code now appears for the new position of the

suspect sensor. Renew the faulty sensor B1B54-11 Function LED - Park Aid

- Circuit short to

ground

Wiring harness fault

Switch/LED - Component

internal failure

Refer to electrical wiring diagrams and check the

parking aid LED circuit for short circuit to ground.

Repair or replace any wiring harness as required

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test. If the

problem persists, suspect the switch/LED B1B54-12 Function LED - Park Aid

- Circuit short to

battery

Wiring harness fault

Switch/LED - Component

internal failure

Control Module -

Component internal

failure

Refer to electrical wiring diagrams and check the

parking aid LED circuit for short circuit to power.

Repair or replace any wiring harness as required

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test. If the

problem persists, suspect the switch/LED B1B57-11

Front Sensors Power

Circuit- Circuit short to

ground

Wiring harness fault

Control Module -

Component internal

failure

Check front and rear bumper harness for signs of

damage and security of connections

Refer to electrical wiring diagrams and check the

parking assist front sensor power circuit and rear

sensor power circuit for short circuit to ground. Repair

or replace any wiring harness as required

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test. If the

problem persists, suspect the control module www.JagDocs.com

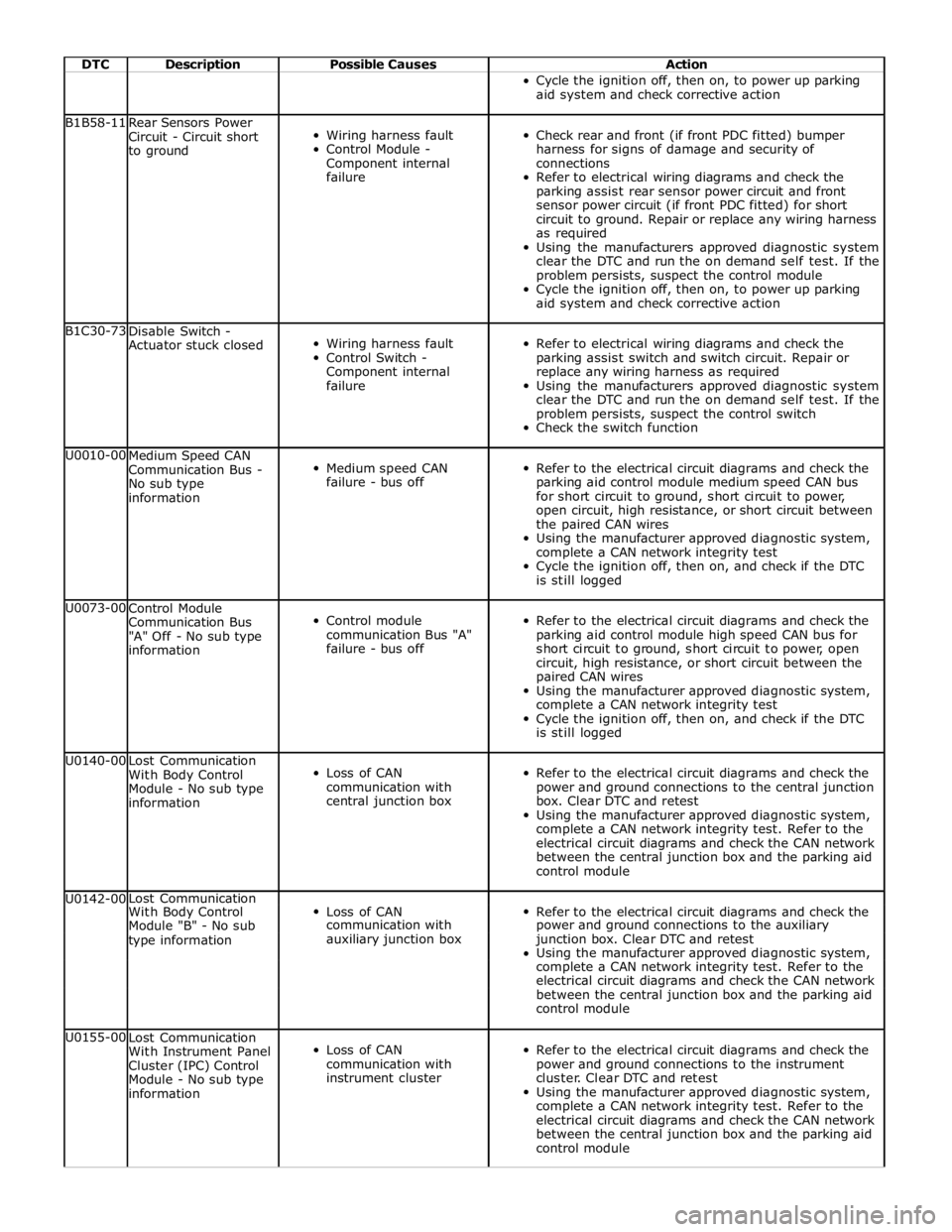

Page 212 of 3039

DTC Description Possible Causes Action Cycle the ignition off, then on, to power up parking

aid system and check corrective action B1B58-11

Rear Sensors Power

Circuit - Circuit short

to ground

Wiring harness fault

Control Module -

Component internal

failure

Check rear and front (if front PDC fitted) bumper

harness for signs of damage and security of

connections

Refer to electrical wiring diagrams and check the

parking assist rear sensor power circuit and front

sensor power circuit (if front PDC fitted) for short

circuit to ground. Repair or replace any wiring harness

as required

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test. If the

problem persists, suspect the control module

Cycle the ignition off, then on, to power up parking

aid system and check corrective action B1C30-73

Disable Switch -

Actuator stuck closed

Wiring harness fault

Control Switch -

Component internal

failure

Refer to electrical wiring diagrams and check the

parking assist switch and switch circuit. Repair or

replace any wiring harness as required

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test. If the

problem persists, suspect the control switch

Check the switch function U0010-00

Medium Speed CAN

Communication Bus -

No sub type

information

Medium speed CAN

failure - bus off

Refer to the electrical circuit diagrams and check the

parking aid control module medium speed CAN bus

for short circuit to ground, short circuit to power,

open circuit, high resistance, or short circuit between

the paired CAN wires

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test

Cycle the ignition off, then on, and check if the DTC

is still logged U0073-00

Control Module

Communication Bus

"A" Off - No sub type

information

Control module

communication Bus "A"

failure - bus off

Refer to the electrical circuit diagrams and check the

parking aid control module high speed CAN bus for

short circuit to ground, short circuit to power, open

circuit, high resistance, or short circuit between the

paired CAN wires

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test

Cycle the ignition off, then on, and check if the DTC

is still logged U0140-00

Lost Communication

With Body Control

Module - No sub type

information

Loss of CAN

communication with

central junction box

Refer to the electrical circuit diagrams and check the

power and ground connections to the central junction

box. Clear DTC and retest

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the central junction box and the parking aid

control module U0142-00 Lost Communication

Loss of CAN

Refer to the electrical circuit diagrams and check the With Body Control Module "B" - No sub communication with power and ground connections to the auxiliary type information auxiliary junction box junction box. Clear DTC and retest Using the manufacturer approved diagnostic system, complete a CAN network integrity test. Refer to the electrical circuit diagrams and check the CAN network between the central junction box and the parking aid control module U0155-00

Lost Communication

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

Loss of CAN

communication with

instrument cluster

Refer to the electrical circuit diagrams and check the

power and ground connections to the instrument

cluster. Clear DTC and retest

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the central junction box and the parking aid

control module

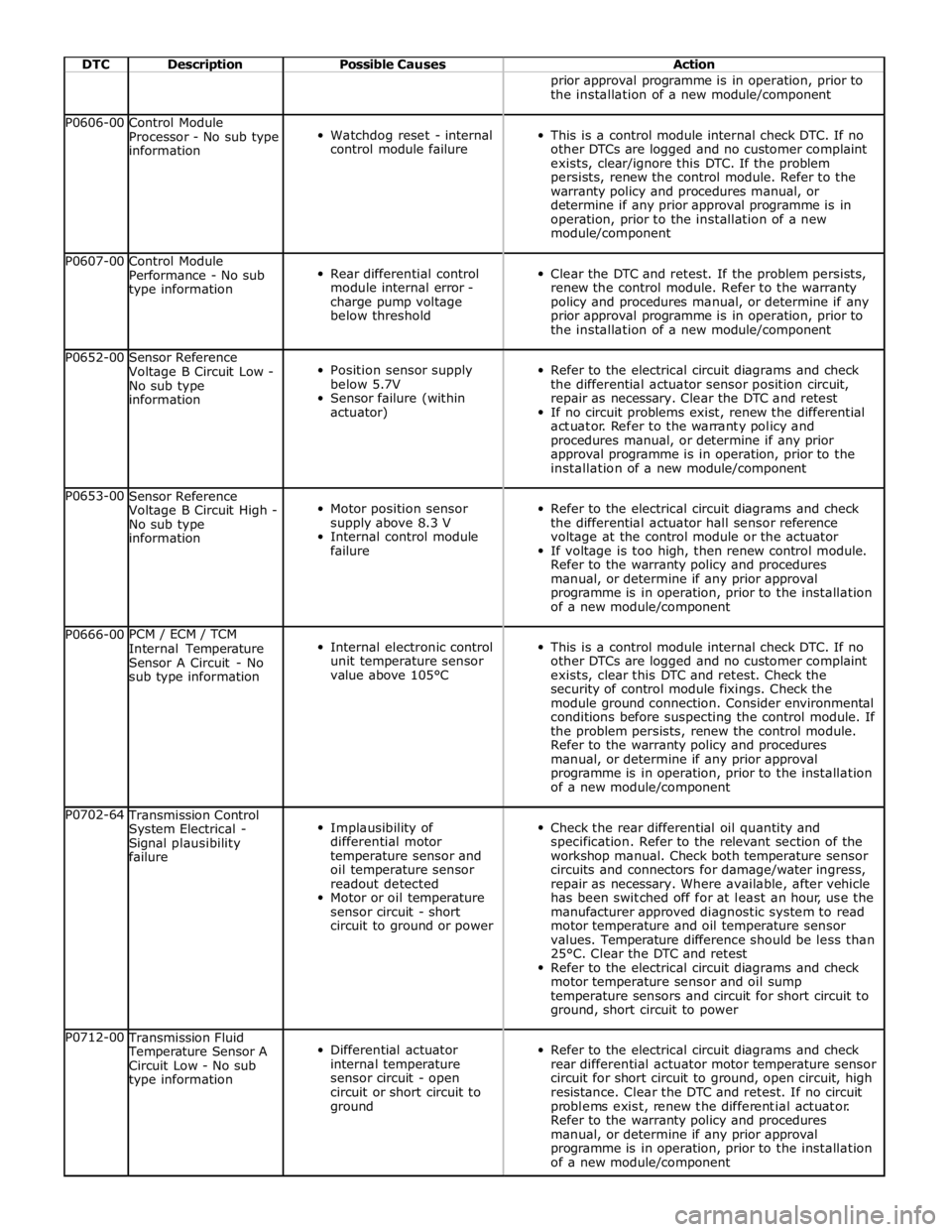

Page 217 of 3039

DTC Description Possible Causes Action prior approval programme is in operation, prior to

the installation of a new module/component P0606-00

Control Module

Processor - No sub type

information

Watchdog reset - internal

control module failure

This is a control module internal check DTC. If no

other DTCs are logged and no customer complaint

exists, clear/ignore this DTC. If the problem

persists, renew the control module. Refer to the

warranty policy and procedures manual, or

determine if any prior approval programme is in

operation, prior to the installation of a new

module/component P0607-00

Control Module

Performance - No sub

type information

Rear differential control

module internal error -

charge pump voltage

below threshold

Clear the DTC and retest. If the problem persists,

renew the control module. Refer to the warranty

policy and procedures manual, or determine if any

prior approval programme is in operation, prior to

the installation of a new module/component P0652-00

Sensor Reference

Voltage B Circuit Low -

No sub type

information

Position sensor supply

below 5.7V

Sensor failure (within

actuator)

Refer to the electrical circuit diagrams and check

the differential actuator sensor position circuit,

repair as necessary. Clear the DTC and retest

If no circuit problems exist, renew the differential

actuator. Refer to the warranty policy and

procedures manual, or determine if any prior

approval programme is in operation, prior to the

installation of a new module/component P0653-00

Sensor Reference

Voltage B Circuit High -

No sub type

information

Motor position sensor

supply above 8.3 V

Internal control module

failure

Refer to the electrical circuit diagrams and check

the differential actuator hall sensor reference

voltage at the control module or the actuator

If voltage is too high, then renew control module.

Refer to the warranty policy and procedures

manual, or determine if any prior approval

programme is in operation, prior to the installation

of a new module/component P0666-00 PCM / ECM / TCM

Internal Temperature

Sensor A Circuit - No

sub type information

Internal electronic control

unit temperature sensor

value above 105°C

This is a control module internal check DTC. If no

other DTCs are logged and no customer complaint

exists, clear this DTC and retest. Check the

security of control module fixings. Check the

module ground connection. Consider environmental

conditions before suspecting the control module. If

the problem persists, renew the control module.

Refer to the warranty policy and procedures

manual, or determine if any prior approval

programme is in operation, prior to the installation

of a new module/component P0702-64 Transmission Control

System Electrical -

Signal plausibility

failure

Implausibility of

differential motor

temperature sensor and

oil temperature sensor

readout detected

Motor or oil temperature

sensor circuit - short

circuit to ground or power

Check the rear differential oil quantity and

specification. Refer to the relevant section of the

workshop manual. Check both temperature sensor

circuits and connectors for damage/water ingress,

repair as necessary. Where available, after vehicle

has been switched off for at least an hour, use the

manufacturer approved diagnostic system to read

motor temperature and oil temperature sensor

values. Temperature difference should be less than

25°C. Clear the DTC and retest

Refer to the electrical circuit diagrams and check

motor temperature sensor and oil sump

temperature sensors and circuit for short circuit to

ground, short circuit to power P0712-00 Transmission Fluid Temperature Sensor A

Circuit Low - No sub

type information

Differential actuator

internal temperature

sensor circuit - open

circuit or short circuit to

ground

Refer to the electrical circuit diagrams and check

rear differential actuator motor temperature sensor

circuit for short circuit to ground, open circuit, high

resistance. Clear the DTC and retest. If no circuit

problems exist, renew the differential actuator.

Refer to the warranty policy and procedures

manual, or determine if any prior approval

programme is in operation, prior to the installation

of a new module/component

Page 296 of 3039

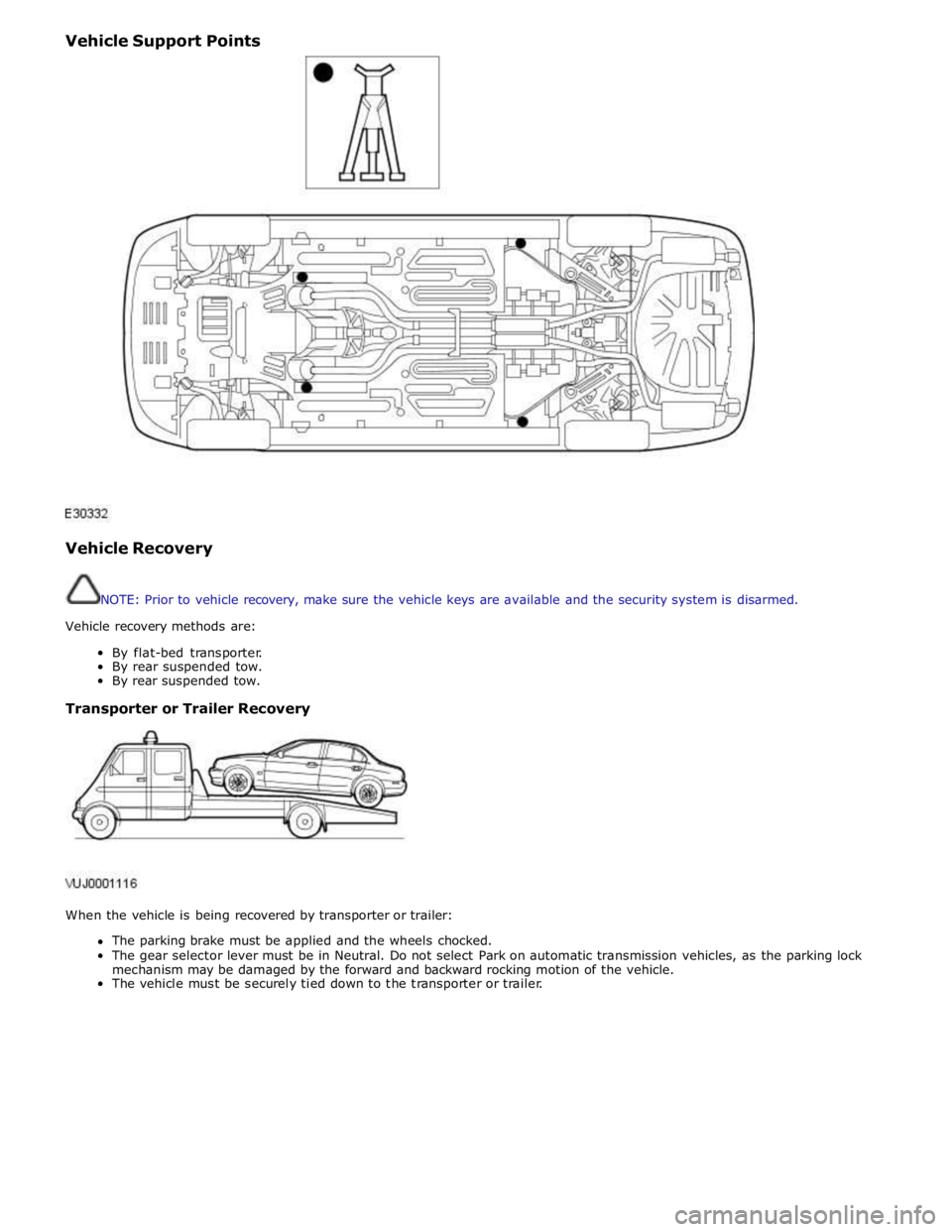

Vehicle Support Points

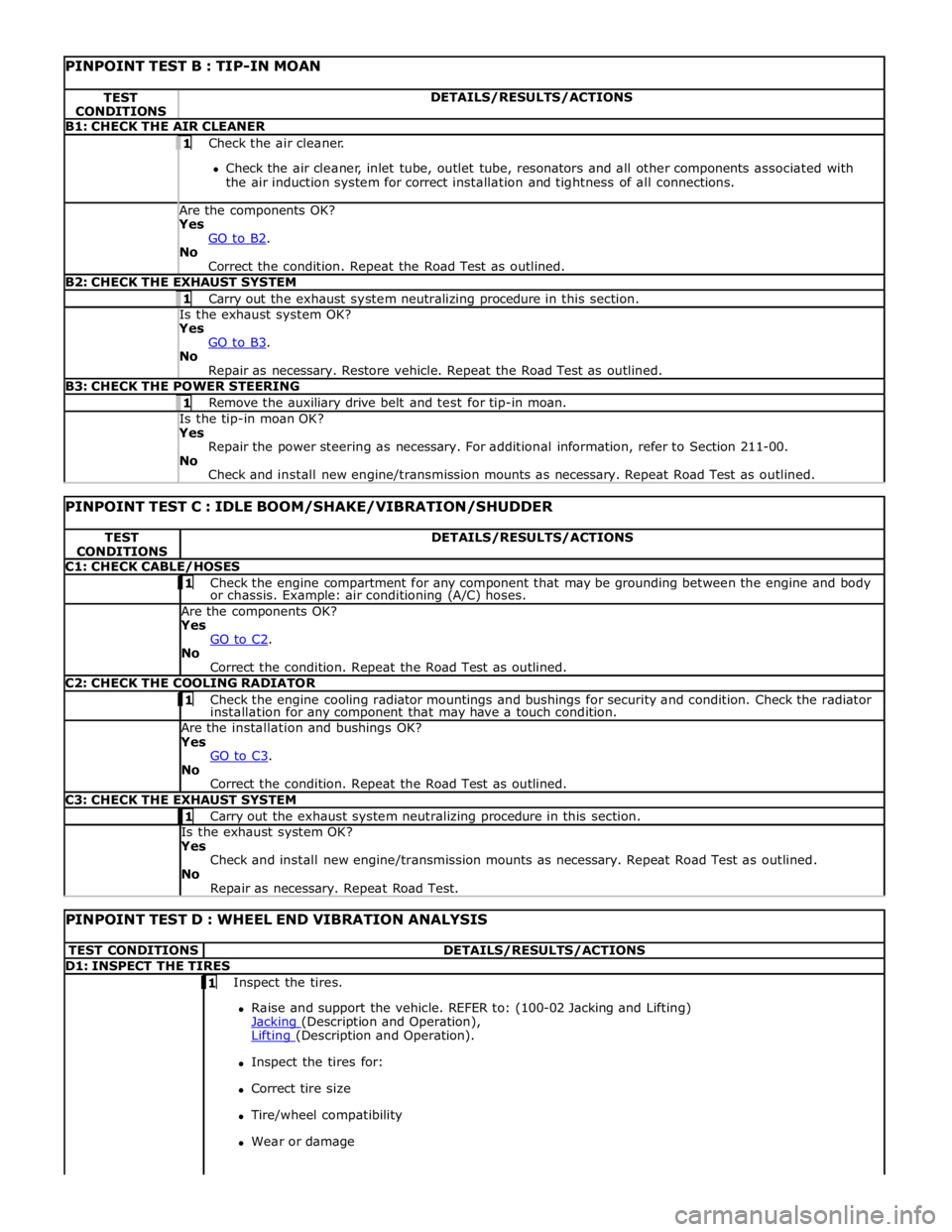

Vehicle Recovery

NOTE: Prior to vehicle recovery, make sure the vehicle keys are available and the security system is disarmed.

Vehicle recovery methods are:

By flat-bed transporter.

By rear suspended tow.

By rear suspended tow.

Transporter or Trailer Recovery

When the vehicle is being recovered by transporter or trailer:

The parking brake must be applied and the wheels chocked.

The gear selector lever must be in Neutral. Do not select Park on automatic transmission vehicles, as the parking lock

mechanism may be damaged by the forward and backward rocking motion of the vehicle.

The vehicle must be securely tied down to the transporter or trailer.

Page 303 of 3039

PINPOINT TEST B : TIP-IN MOAN TEST

CONDITIONS DETAILS/RESULTS/ACTIONS B1: CHECK THE AIR CLEANER 1 Check the air cleaner.

Check the air cleaner, inlet tube, outlet tube, resonators and all other components associated with

the air induction system for correct installation and tightness of all connections. Are the components OK? Yes

GO to B2. No

Correct the condition. Repeat the Road Test as outlined. B2: CHECK THE EXHAUST SYSTEM 1 Carry out the exhaust system neutralizing procedure in this section. Is the exhaust system OK? Yes

GO to B3. No

Repair as necessary. Restore vehicle. Repeat the Road Test as outlined. B3: CHECK THE POWER STEERING 1 Remove the auxiliary drive belt and test for tip-in moan. Is the tip-in moan OK? Yes

Repair the power steering as necessary. For additional information, refer to Section 211-00.

No

Check and install new engine/transmission mounts as necessary. Repeat Road Test as outlined.

PINPOINT TEST C : IDLE BOOM/SHAKE/VIBRATION/SHUDDER TEST

CONDITIONS DETAILS/RESULTS/ACTIONS C1: CHECK CABLE/HOSES 1 Check the engine compartment for any component that may be grounding between the engine and body or chassis. Example: air conditioning (A/C) hoses. Are the components OK? Yes

GO to C2. No

Correct the condition. Repeat the Road Test as outlined. C2: CHECK THE COOLING RADIATOR 1 Check the engine cooling radiator mountings and bushings for security and condition. Check the radiator installation for any component that may have a touch condition. Are the installation and bushings OK? Yes

GO to C3. No

Correct the condition. Repeat the Road Test as outlined. C3: CHECK THE EXHAUST SYSTEM 1 Carry out the exhaust system neutralizing procedure in this section. Is the exhaust system OK? Yes

Check and install new engine/transmission mounts as necessary. Repeat Road Test as outlined.

No

Repair as necessary. Repeat Road Test.

PINPOINT TEST D : WHEEL END VIBRATION ANALYSIS TEST CONDITIONS DETAILS/RESULTS/ACTIONS D1: INSPECT THE TIRES 1 Inspect the tires.

Raise and support the vehicle. REFER to: (100-02 Jacking and Lifting)

Jacking (Description and Operation), Lifting (Description and Operation).

Inspect the tires for:

Correct tire size

Tire/wheel compatibility

Wear or damage

Page 718 of 3039

Steering System - General Information - Steering System

Diagnosis and Testing

Principle of Operation Published: 11-May-2011

For a detailed description of the steering system operation, refer to the relevant Description and Operation sections of the

workshop manual. REFER to:

Power Steering (211-02 Power Steering, Description and Operation), Power Steering (211-02 Power Steering, Description and Operation), Power Steering (211-02 Power Steering, Description and Operation), Steering Linkage (211-03 Steering Linkage, Description and Operation), Steering Linkage (211-03 Steering Linkage, Description and Operation), Steering Linkage (211-03 Steering Linkage, Description and Operation), Steering Column (211-04 Steering Column, Description and Operation), Steering Column (211-04 Steering Column, Description and Operation), Steering Column (211-04 Steering Column, Description and Operation), Steering Column Switches (211-05 Steering Column Switches, Description and Operation), Steering Column Switches (211-05 Steering Column Switches, Description and Operation), Steering Column Switches (211-05 Steering Column Switches, Description and Operation).

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Tire condition/pressure

Fluid level

Leaks

Security, condition and correct installation of suspension components

Security, condition and correct installation of steering system components

Fuses

Harnesses for damage/corrosion

Electrical connector(s)

Damaged/corroded pins

CAUTION: If a steering gear assembly is returned under warranty with leaking output shaft seals, but there is also

damage to the steering gear boot/boots the steering gear warranty will be invalid. This is due to the steering gear output

shaft seals being damaged due to foreign materials entering the steering gear boot and damaging the steering gear output

shaft seals thereafter.

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the concern is not visually evident, verify the symptom and refer to the symptom chart.

Symptom Charts

WARNING: It is not possible to CHECK the torque of a patchlock bolt, if the torque is suspected to be low, the bolt must

be REMOVED/DISCARDED and a new bolt MUST be INSTALLED and torque to the correct value.

NOTE: If the module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

Fluid Leakage

NOTE: Confirm the location of the fluid leak. CLEAN the area of the leak, inspect the area and confirm the exact position.

Ensure the fluid is not from another system on the vehicle.

Symptom Possible Causes Action

Power steering

fluid leakage

Overfilled system

Correct the fluid level as required

Steering gear

Check and install new steering gear as required, refer to the new

module/component installation note at the top of the Symptom

Charts

Page 803 of 3039

automatically reset once the applicable remote handset has been detected by the vehicle security systems.

STEERING WHEEL HEATER

On certain models the rim of the steering wheel contains a heater element. Operation of the heater is selected using the

Touch Screen Display (TSD).

The heater temperature is controlled by a heated steering wheel control module located within the steering wheel. Power for

the heater element is supplied to the steering wheel via 2 contacts on the clockspring and a slip ring mounted on the steering

wheel.

Page 1299 of 3039

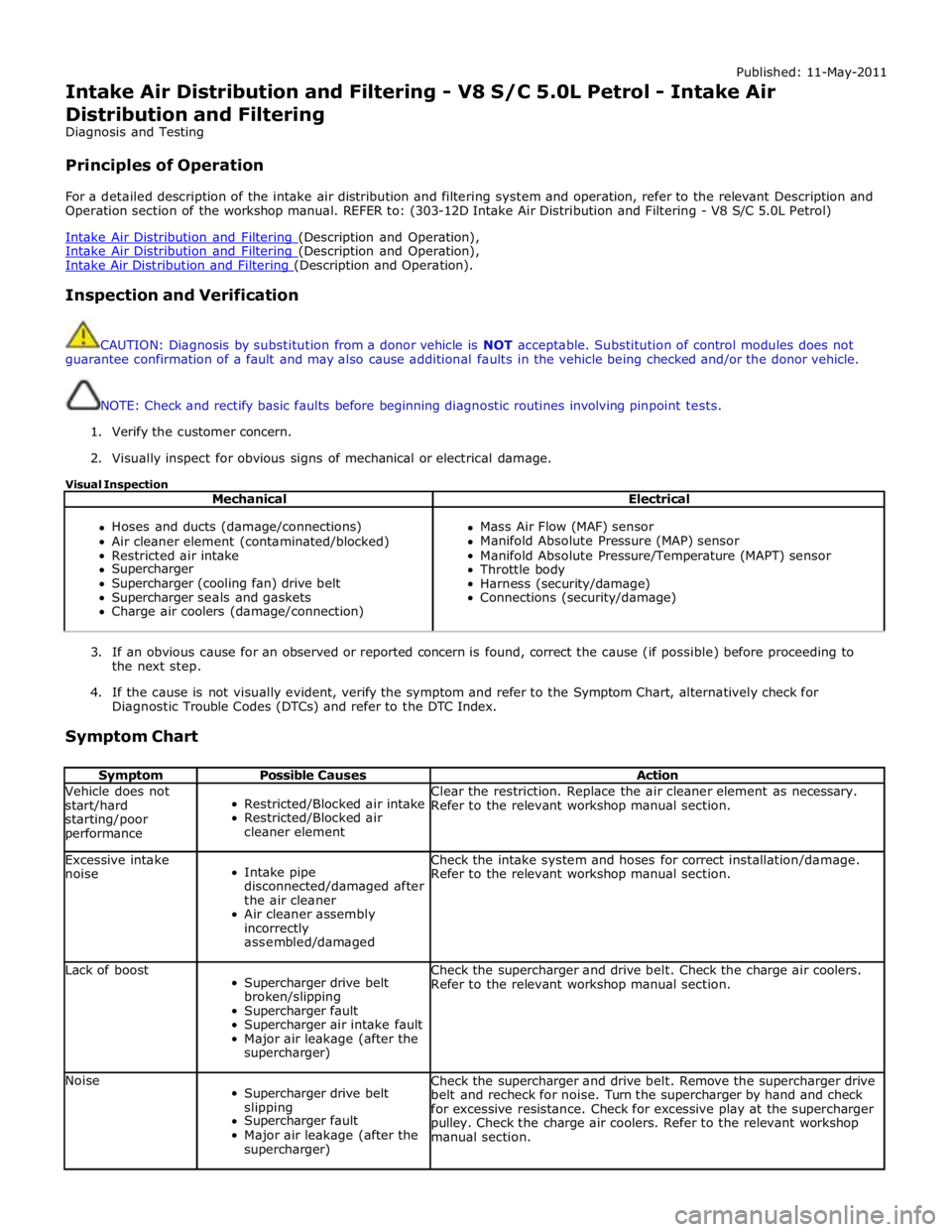

Published: 11-May-2011

Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol - Intake Air

Distribution and Filtering

Diagnosis and Testing

Principles of Operation

For a detailed description of the intake air distribution and filtering system and operation, refer to the relevant Description and

Operation section of the workshop manual. REFER to: (303-12D Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol)

Intake Air Distribution and Filtering (Description and Operation), Intake Air Distribution and Filtering (Description and Operation), Intake Air Distribution and Filtering (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTE: Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection

Mechanical Electrical

Hoses and ducts (damage/connections)

Air cleaner element (contaminated/blocked)

Restricted air intake

Supercharger

Supercharger (cooling fan) drive belt

Supercharger seals and gaskets

Charge air coolers (damage/connection)

Mass Air Flow (MAF) sensor

Manifold Absolute Pressure (MAP) sensor

Manifold Absolute Pressure/Temperature (MAPT) sensor

Throttle body

Harness (security/damage)

Connections (security/damage)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

Symptom Chart

Symptom Possible Causes Action Vehicle does not

start/hard

starting/poor

performance

Restricted/Blocked air intake

Restricted/Blocked air

cleaner element Clear the restriction. Replace the air cleaner element as necessary.

Refer to the relevant workshop manual section. Excessive intake

noise

Intake pipe

disconnected/damaged after

the air cleaner

Air cleaner assembly

incorrectly

assembled/damaged Check the intake system and hoses for correct installation/damage.

Refer to the relevant workshop manual section. Lack of boost

Supercharger drive belt

broken/slipping

Supercharger fault

Supercharger air intake fault

Major air leakage (after the

supercharger) Check the supercharger and drive belt. Check the charge air coolers.

Refer to the relevant workshop manual section. Noise

Supercharger drive belt

slipping

Supercharger fault

Major air leakage (after the

supercharger) Check the supercharger and drive belt. Remove the supercharger drive

belt and recheck for noise. Turn the supercharger by hand and check

for excessive resistance. Check for excessive play at the supercharger

pulley. Check the charge air coolers. Refer to the relevant workshop

manual section.

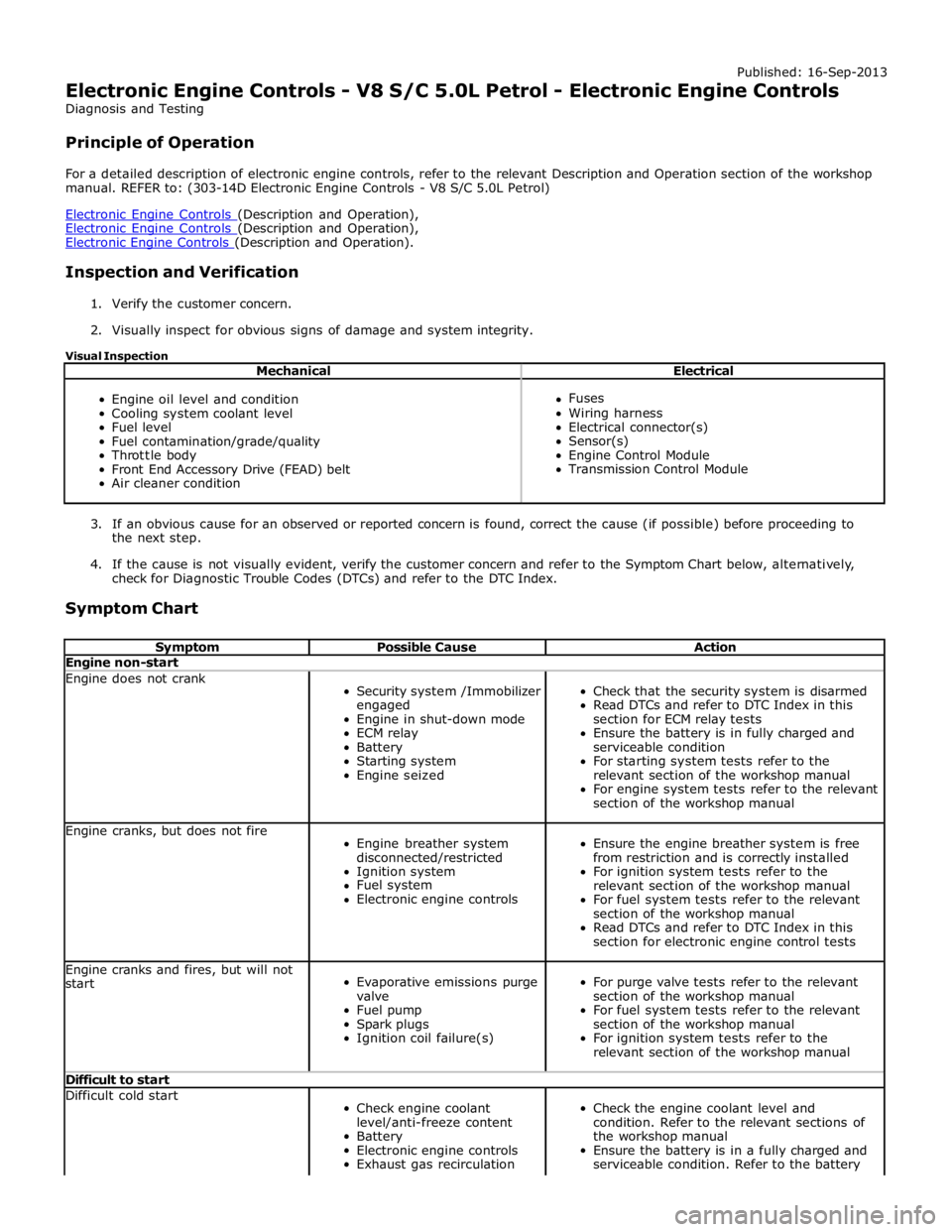

Page 1369 of 3039

Published: 16-Sep-2013

Electronic Engine Controls - V8 S/C 5.0L Petrol - Electronic Engine Controls

Diagnosis and Testing

Principle of Operation

For a detailed description of electronic engine controls, refer to the relevant Description and Operation section of the workshop

manual. REFER to: (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol)

Electronic Engine Controls (Description and Operation), Electronic Engine Controls (Description and Operation), Electronic Engine Controls (Description and Operation).

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Engine oil level and condition

Cooling system coolant level

Fuel level

Fuel contamination/grade/quality

Throttle body

Front End Accessory Drive (FEAD) belt

Air cleaner condition

Fuses

Wiring harness

Electrical connector(s)

Sensor(s)

Engine Control Module

Transmission Control Module

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the customer concern and refer to the Symptom Chart below, alternatively,

check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

Symptom Chart

Symptom Possible Cause Action Engine non-start Engine does not crank

Security system /Immobilizer

engaged

Engine in shut-down mode

ECM relay

Battery

Starting system

Engine seized

Check that the security system is disarmed

Read DTCs and refer to DTC Index in this

section for ECM relay tests

Ensure the battery is in fully charged and

serviceable condition

For starting system tests refer to the

relevant section of the workshop manual

For engine system tests refer to the relevant

section of the workshop manual Engine cranks, but does not fire

Engine breather system

disconnected/restricted

Ignition system

Fuel system

Electronic engine controls

Ensure the engine breather system is free

from restriction and is correctly installed

For ignition system tests refer to the

relevant section of the workshop manual

For fuel system tests refer to the relevant

section of the workshop manual

Read DTCs and refer to DTC Index in this

section for electronic engine control tests Engine cranks and fires, but will not

start

Evaporative emissions purge

valve

Fuel pump

Spark plugs

Ignition coil failure(s)

For purge valve tests refer to the relevant

section of the workshop manual

For fuel system tests refer to the relevant

section of the workshop manual

For ignition system tests refer to the

relevant section of the workshop manual Difficult to start Difficult cold start

Check engine coolant

level/anti-freeze content

Battery

Electronic engine controls

Exhaust gas recirculation

Check the engine coolant level and

condition. Refer to the relevant sections of

the workshop manual

Ensure the battery is in a fully charged and

serviceable condition. Refer to the battery