Supercharger JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 545 of 3039

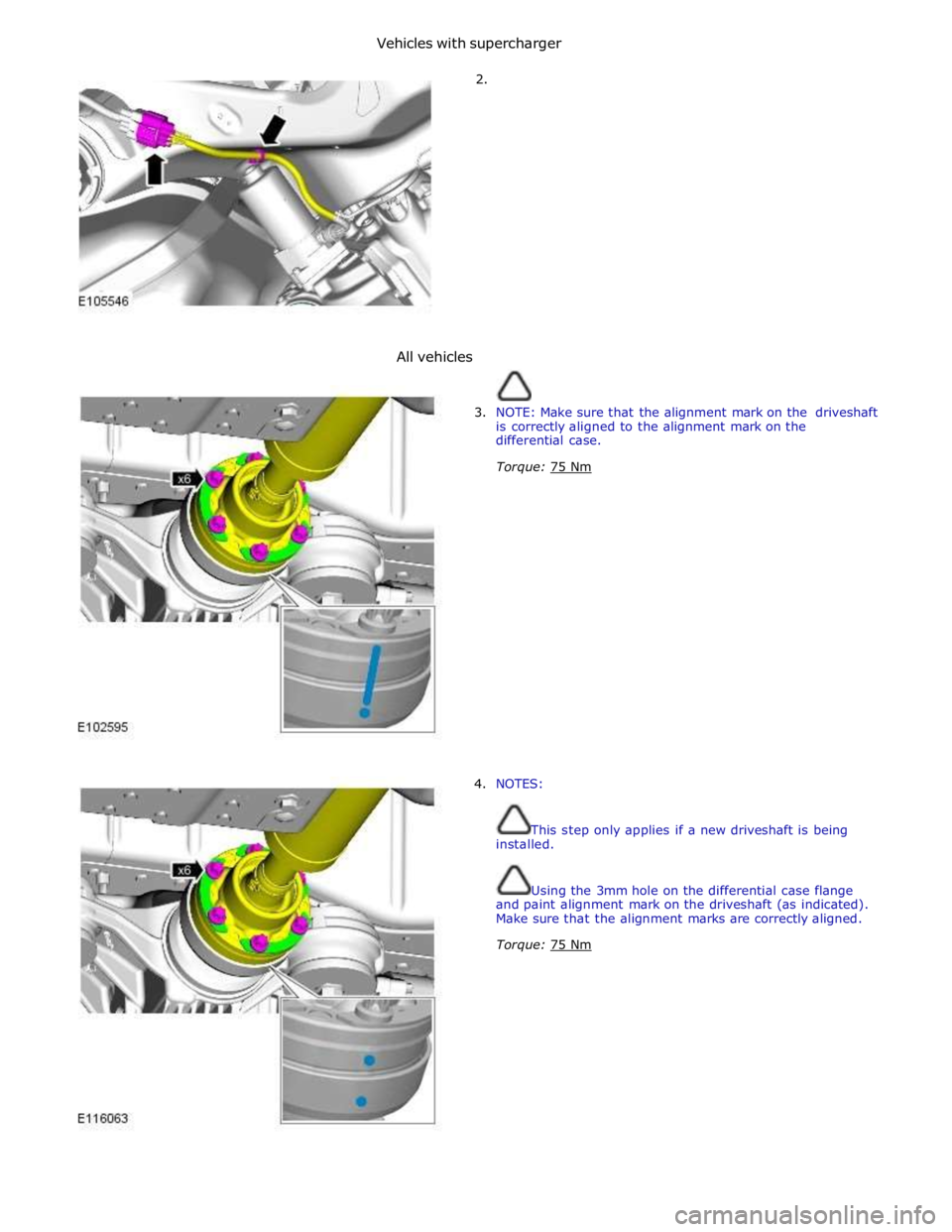

Vehicles with supercharger

2.

All vehicles

3. NOTE: Make sure that the alignment mark on the driveshaft

is correctly aligned to the alignment mark on the

differential case.

Torque: 75 Nm

4. NOTES:

This step only applies if a new driveshaft is being

installed.

Using the 3mm hole on the differential case flange

and paint alignment mark on the driveshaft (as indicated).

Make sure that the alignment marks are correctly aligned.

Torque: 75 Nm

Page 606 of 3039

Published: 11-May-2011

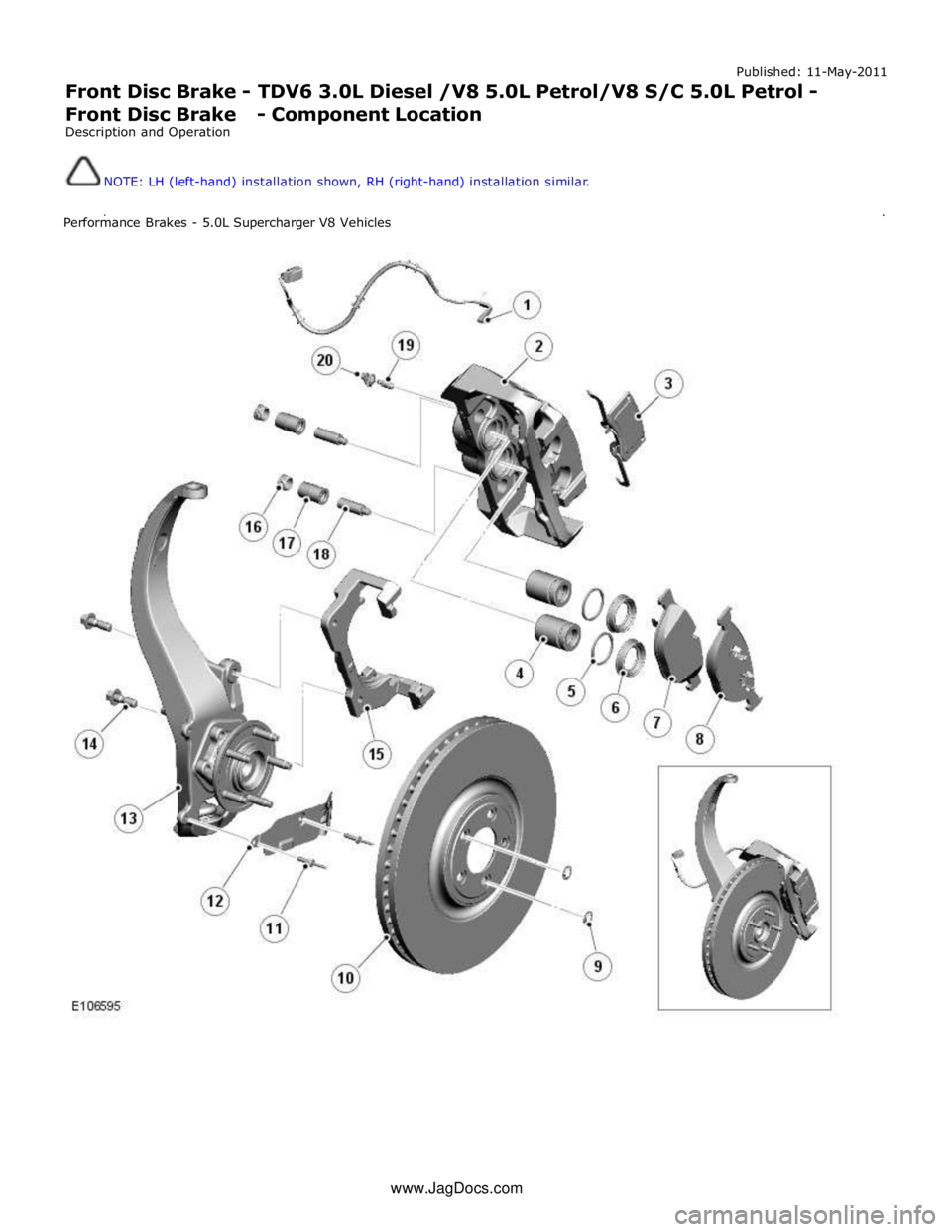

Front Disc Brake - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - Front Disc Brake - Component Location

Description and Operation

NOTE: LH (left-hand) installation shown, RH (right-hand) installation similar.

PerformanceBrakes-5.0LSuperchargerV8Vehicleswww.JagDocs.com

Page 608 of 3039

Published:

11-May-2011

Front Disc Brake - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol -

F

ront Disc Brake - Overview

Description and Operation

OVERVIEW

Performance Brakes - 5.0L Supercharger V8 Vehicles

The performance front braking system features ventilated brake discs with dual piston sliding calipers. The discs are 380 mm

(14.96 in.) diameter x 36 mm (1.42 in.) thick.

The brake disc is manufactured from cast iron. The disc is retained on the wheel hub by two retaining washers and the wheel

nuts.

A brake pads wear sensors is fitted to the LH front brake.

Page 610 of 3039

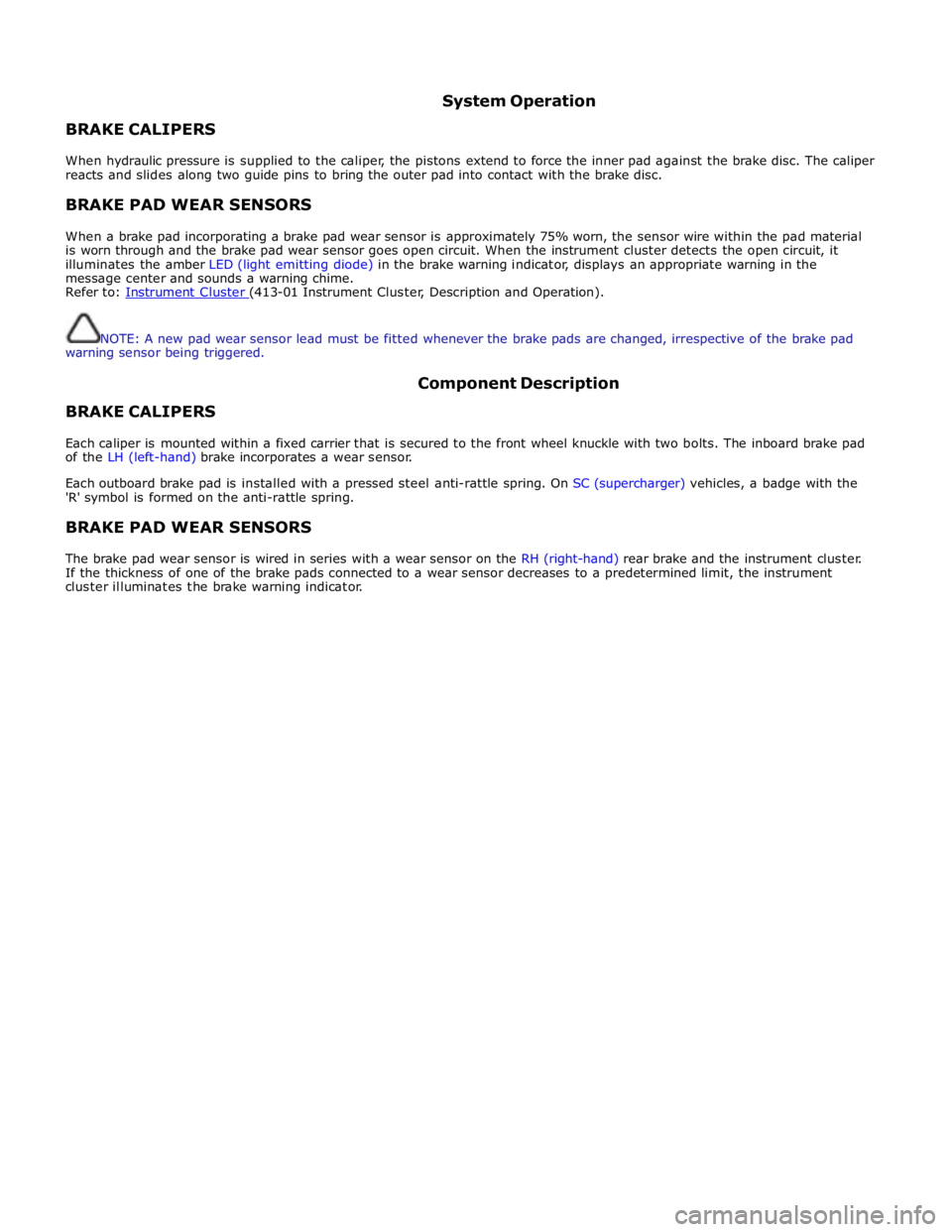

BRAKE CALIPERS System Operation

When hydraulic pressure is supplied to the caliper, the pistons extend to force the inner pad against the brake disc. The caliper

reacts and slides along two guide pins to bring the outer pad into contact with the brake disc.

BRAKE PAD WEAR SENSORS

When a brake pad incorporating a brake pad wear sensor is approximately 75% worn, the sensor wire within the pad material

is worn through and the brake pad wear sensor goes open circuit. When the instrument cluster detects the open circuit, it

illuminates the amber LED (light emitting diode) in the brake warning indicator, displays an appropriate warning in the

message center and sounds a warning chime.

Refer to: Instrument Cluster (413-01 Instrument Cluster, Description and Operation).

NOTE: A new pad wear sensor lead must be fitted whenever the brake pads are changed, irrespective of the brake pad

warning sensor being triggered.

BRAKE CALIPERS Component Description

Each caliper is mounted within a fixed carrier that is secured to the front wheel knuckle with two bolts. The inboard brake pad

of the LH (left-hand) brake incorporates a wear sensor.

Each outboard brake pad is installed with a pressed steel anti-rattle spring. On SC (supercharger) vehicles, a badge with the

'R' symbol is formed on the anti-rattle spring.

BRAKE PAD WEAR SENSORS

The brake pad wear sensor is wired in series with a wear sensor on the RH (right-hand) rear brake and the instrument cluster.

If the thickness of one of the brake pads connected to a wear sensor decreases to a predetermined limit, the instrument

cluster illuminates the brake warning indicator.

Page 628 of 3039

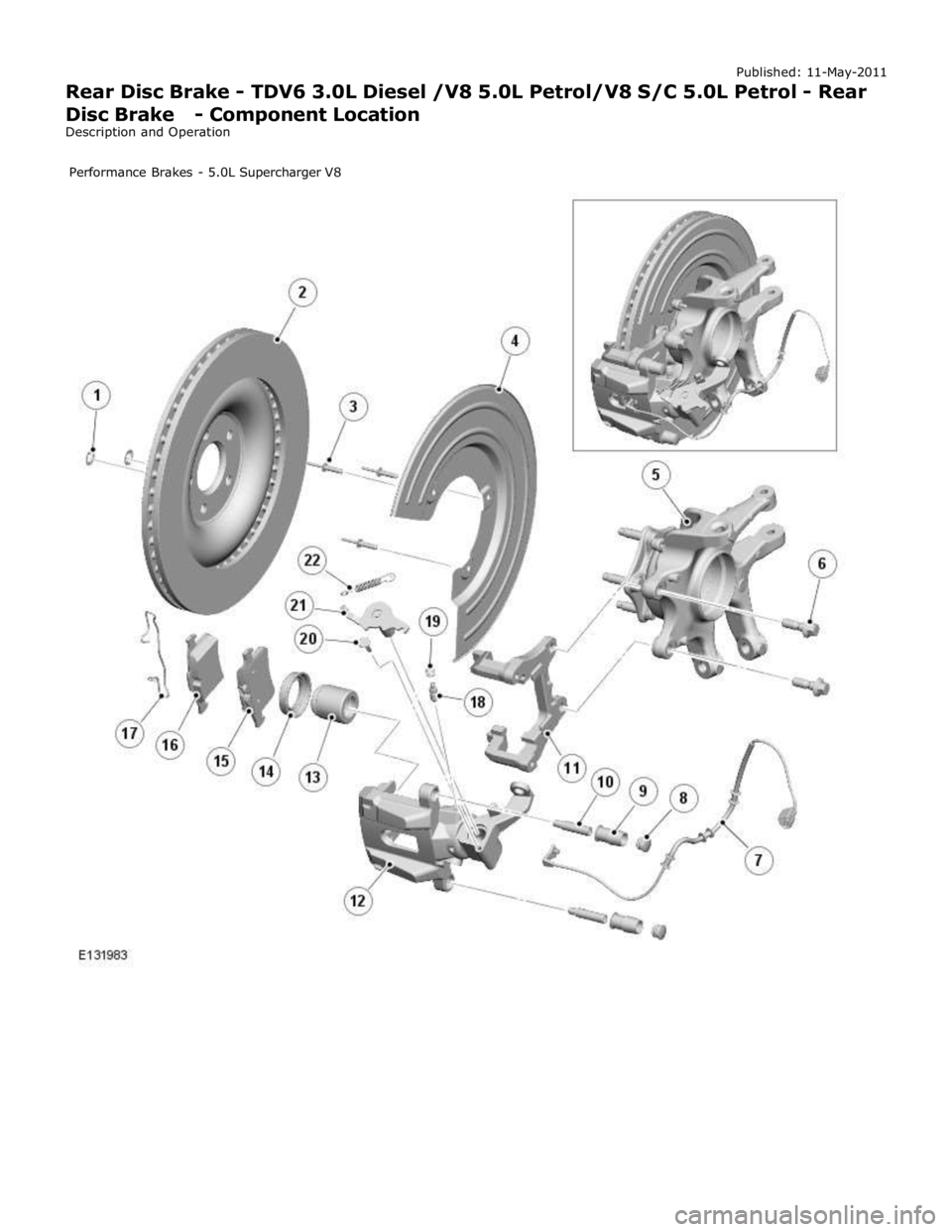

Published: 11-May-2011

Rear Disc Brake - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - Rear

Disc Brake - Component Location

Description and Operation

PerformanceBrakes-5.0LSuperchargerV8

Page 632 of 3039

BRAKE CALIPERS System Operation

When hydraulic pressure is supplied to the caliper, the pistons extend to force the inner pad against the brake disc. The caliper

reacts and slides along two guide pins to bring the outer pad into contact with the brake disc.

BRAKE PAD WEAR SENSORS

When a brake pad incorporating a brake pad wear sensor is approximately 75% worn, the sensor wire within the pad material

is worn through and the brake pad wear sensor goes open circuit. When the instrument cluster detects the open circuit, it

illuminates the amber LED (light emitting diode) in the brake warning indicator, displays an appropriate warning in the

message center and sounds a warning chime.

Refer to: Instrument Cluster (413-01 Instrument Cluster, Description and Operation).

NOTE: A new pad wear sensor lead must be fitted whenever the brake pads are changed, irrespective of the brake pad

warning sensor being triggered.

BRAKE CALIPERS Component Description

Each caliper is mounted within a fixed carrier that is secured to the rear wheel knuckle with two bolts. Each outboard brake pad

is installed with a wire anti-rattle spring.

The brake calipers on SC (supercharger) vehicles are painted and also include a logo badge, secured with two screws, which

must be removed in order to change the brake pads.

The inboard brake pad of the RH (right-hand) brake incorporates a wear sensor.

BRAKE PAD WEAR SENSORS

The brake pad wear sensor is wired in series with a wear sensor on the LH (left-hand) front brake and the instrument cluster. If

the thickness of one of the brake pads connected to a wear sensor decreases to a predetermined limit, the instrument cluster

illuminates the brake warning indicator.

Page 708 of 3039

Published: 11-May-2011

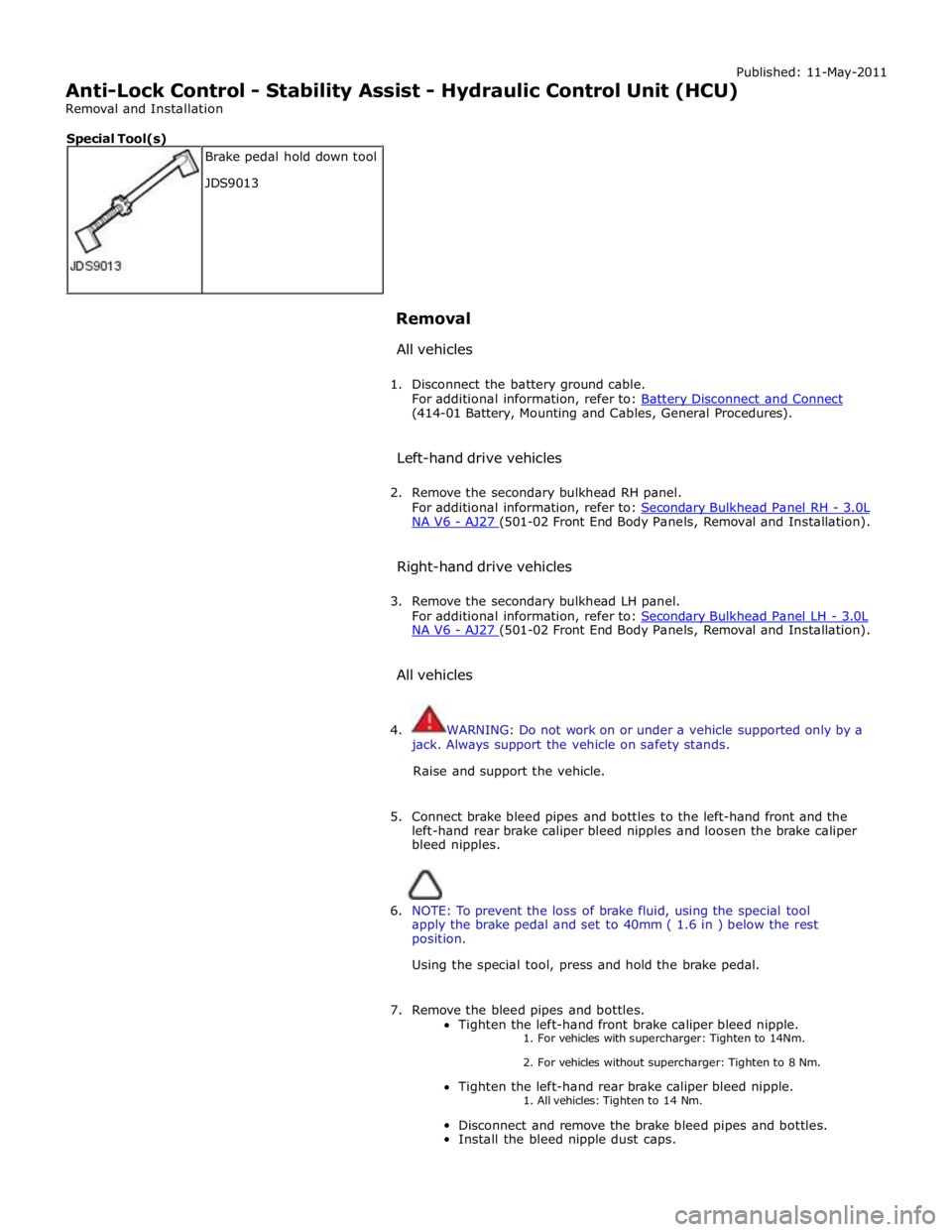

Anti-Lock Control - Stability Assist - Hydraulic Control Unit (HCU)

Removal and Installation

Removal

All vehicles

1. Disconnect the battery ground cable.

For additional information, refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

Left-hand drive vehicles

2. Remove the secondary bulkhead RH panel.

For additional information, refer to: Secondary Bulkhead Panel RH - 3.0L NA V6 - AJ27 (501-02 Front End Body Panels, Removal and Installation).

Right-hand drive vehicles

3. Remove the secondary bulkhead LH panel.

For additional information, refer to: Secondary Bulkhead Panel LH - 3.0L NA V6 - AJ27 (501-02 Front End Body Panels, Removal and Installation).

All vehicles

4. WARNING: Do not work on or under a vehicle supported only by a

jack. Always support the vehicle on safety stands.

Raise and support the vehicle.

5. Connect brake bleed pipes and bottles to the left-hand front and the

left-hand rear brake caliper bleed nipples and loosen the brake caliper

bleed nipples.

6. NOTE: To prevent the loss of brake fluid, using the special tool

apply the brake pedal and set to 40mm ( 1.6 in ) below the rest

position.

Using the special tool, press and hold the brake pedal.

7. Remove the bleed pipes and bottles.

Tighten the left-hand front brake caliper bleed nipple. 1. For vehicles with supercharger: Tighten to 14Nm.

2. For vehicles without supercharger: Tighten to 8 Nm.

Tighten the left-hand rear brake caliper bleed nipple.

1. All vehicles: Tighten to 14 Nm.

Disconnect and remove the brake bleed pipes and bottles.

Install the bleed nipple dust caps. Brake pedal hold down tool

JDS9013 Special Tool(s)

Page 845 of 3039

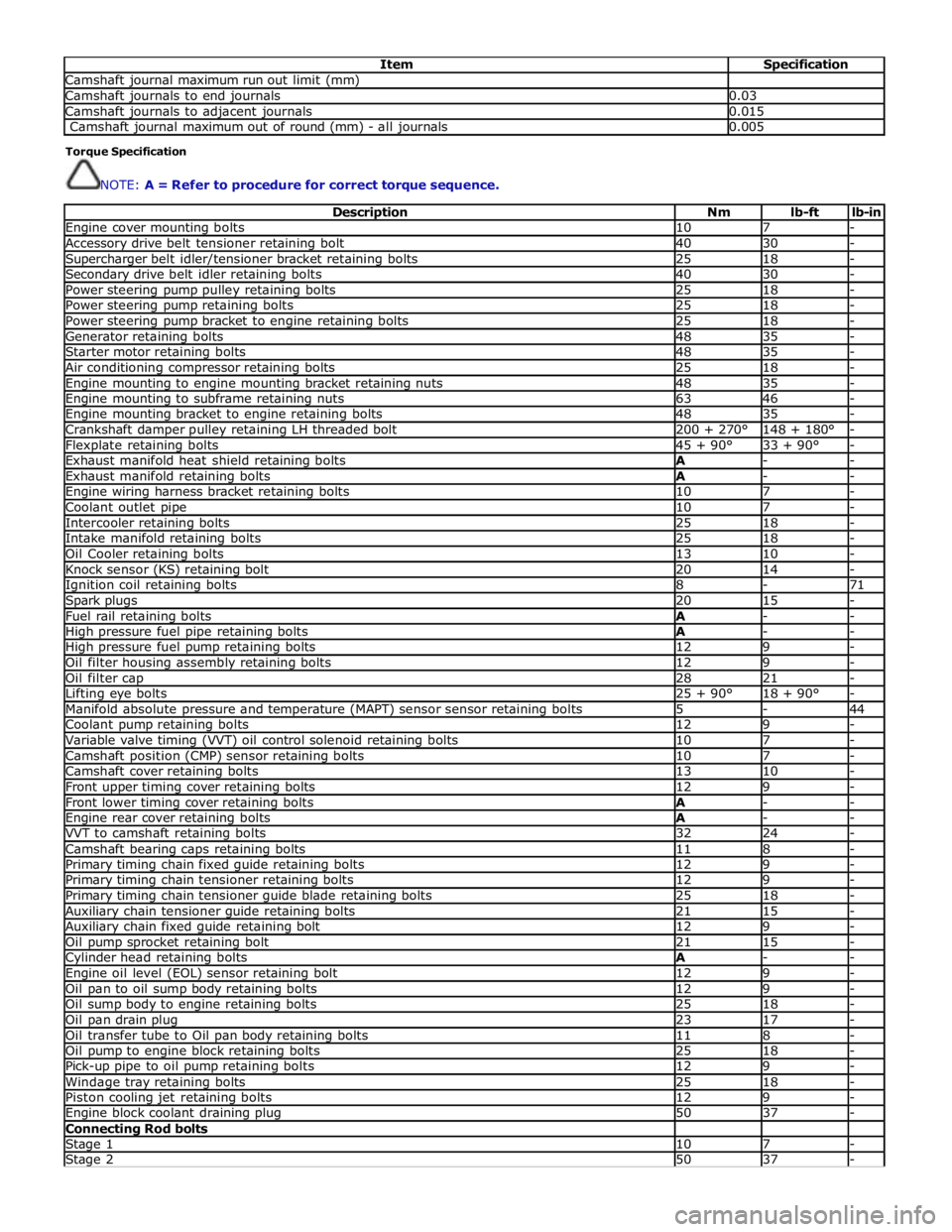

Item Specification Camshaft journal maximum run out limit (mm) Camshaft journals to end journals 0.03 Camshaft journals to adjacent journals 0.015 Camshaft journal maximum out of round (mm) - all journals 0.005 Torque Specification

NOTE: A = Refer to procedure for correct torque sequence.

Description Nm lb-ft lb-in Engine cover mounting bolts 10 7 - Accessory drive belt tensioner retaining bolt 40 30 - Supercharger belt idler/tensioner bracket retaining bolts 25 18 - Secondary drive belt idler retaining bolts 40 30 - Power steering pump pulley retaining bolts 25 18 - Power steering pump retaining bolts 25 18 - Power steering pump bracket to engine retaining bolts 25 18 - Generator retaining bolts 48 35 - Starter motor retaining bolts 48 35 - Air conditioning compressor retaining bolts 25 18 - Engine mounting to engine mounting bracket retaining nuts 48 35 - Engine mounting to subframe retaining nuts 63 46 - Engine mounting bracket to engine retaining bolts 48 35 - Crankshaft damper pulley retaining LH threaded bolt 200 + 270° 148 + 180° - Flexplate retaining bolts 45 + 90° 33 + 90° - Exhaust manifold heat shield retaining bolts A - - Exhaust manifold retaining bolts A - - Engine wiring harness bracket retaining bolts 10 7 - Coolant outlet pipe 10 7 - Intercooler retaining bolts 25 18 - Intake manifold retaining bolts 25 18 - Oil Cooler retaining bolts 13 10 - Knock sensor (KS) retaining bolt 20 14 - Ignition coil retaining bolts 8 - 71 Spark plugs 20 15 - Fuel rail retaining bolts A - - High pressure fuel pipe retaining bolts A - - High pressure fuel pump retaining bolts 12 9 - Oil filter housing assembly retaining bolts 12 9 - Oil filter cap 28 21 - Lifting eye bolts 25 + 90° 18 + 90° - Manifold absolute pressure and temperature (MAPT) sensor sensor retaining bolts 5 - 44 Coolant pump retaining bolts 12 9 - Variable valve timing (VVT) oil control solenoid retaining bolts 10 7 - Camshaft position (CMP) sensor retaining bolts 10 7 - Camshaft cover retaining bolts 13 10 - Front upper timing cover retaining bolts 12 9 - Front lower timing cover retaining bolts A - - Engine rear cover retaining bolts A - - VVT to camshaft retaining bolts 32 24 - Camshaft bearing caps retaining bolts 11 8 - Primary timing chain fixed guide retaining bolts 12 9 - Primary timing chain tensioner retaining bolts 12 9 - Primary timing chain tensioner guide blade retaining bolts 25 18 - Auxiliary chain tensioner guide retaining bolts 21 15 - Auxiliary chain fixed guide retaining bolt 12 9 - Oil pump sprocket retaining bolt 21 15 - Cylinder head retaining bolts A - - Engine oil level (EOL) sensor retaining bolt 12 9 - Oil pan to oil sump body retaining bolts 12 9 - Oil sump body to engine retaining bolts 25 18 - Oil pan drain plug 23 17 - Oil transfer tube to Oil pan body retaining bolts 11 8 - Oil pump to engine block retaining bolts 25 18 - Pick-up pipe to oil pump retaining bolts 12 9 - Windage tray retaining bolts 25 18 - Piston cooling jet retaining bolts 12 9 - Engine block coolant draining plug 50 37 - Connecting Rod bolts Stage 1 10 7 - Stage 2 50 37 -

Page 852 of 3039

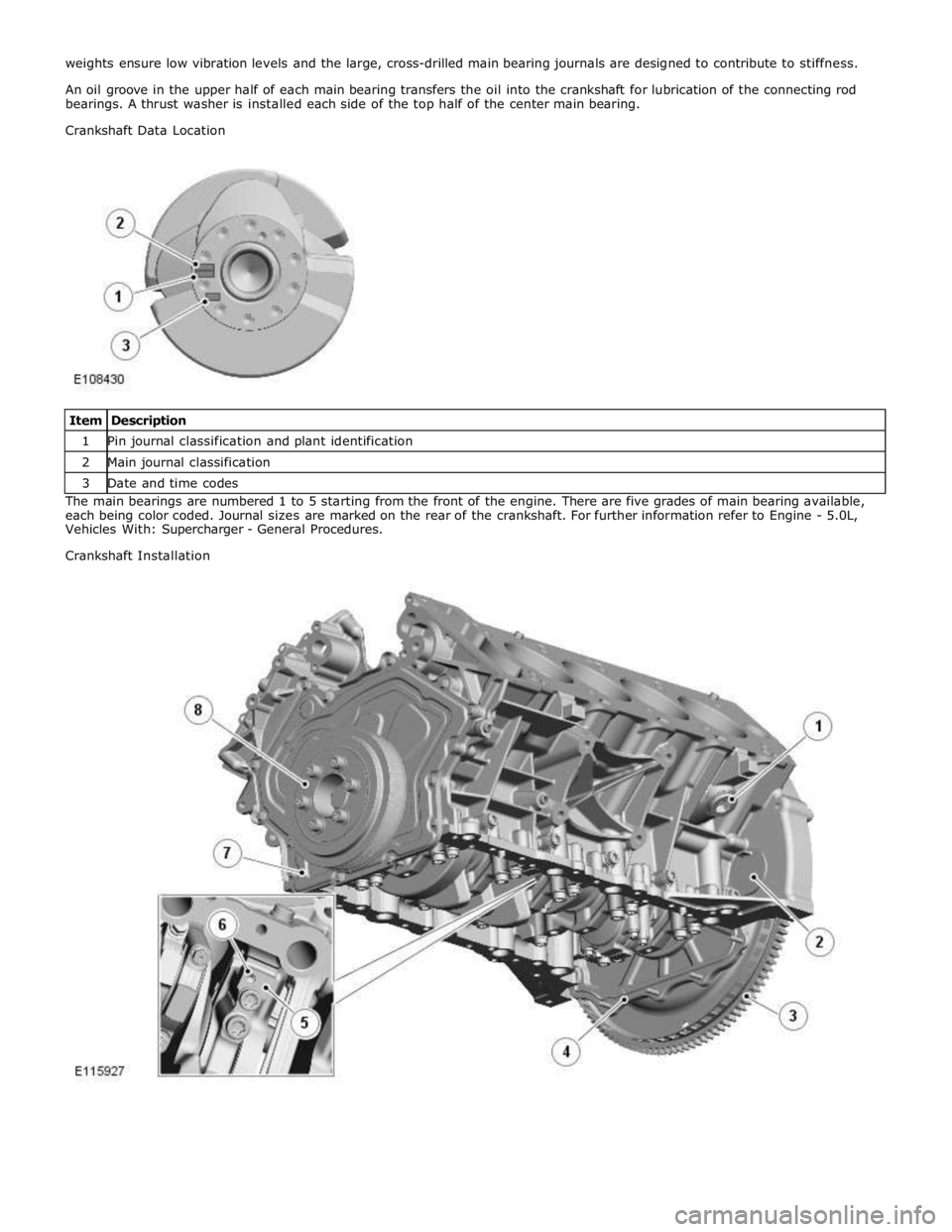

1 Pin journal classification and plant identification 2 Main journal classification 3 Date and time codes The main bearings are numbered 1 to 5 starting from the front of the engine. There are five grades of main bearing available,

each being color coded. Journal sizes are marked on the rear of the crankshaft. For further information refer to Engine - 5.0L,

Vehicles With: Supercharger - General Procedures.

Crankshaft Installation

Page 853 of 3039

1 Coolant drain plug 2 Torque converter access plug 3 Drive plate 4 Rear cover 5 Main bearing cap 6 Identification mark 7 Front cover 8 Front pulley The main bearing caps are made from cast iron and are cross bolted to increase rigidity. An identification mark on the bearing

cap faces the front of the engine.

At the front of the crankshaft, a tuned torsional vibration damper is incorporated into the crankshaft front pulley. At the rear of

the crankshaft a pressed steel drive plate, with a steel starter ring gear, is installed to transfer drive from the engine to the

transmission. The reluctor ring for the CKP (crankshaft position) sensor is integrated into the perimeter of the drive plate.

The crankshaft seals are located in the front and rear covers.

PISTONS AND CONNECTING RODS

The diameter of each piston is graded and precisely matched to each cylinder bore to help reduce noise. In the vertical plane,

the pistons have a slight barrel form, which helps to ensure a reliable oil film is maintained between the piston and the

cylinder bore. A solid film lubricant coating is applied to both reaction faces of the piston to reduce wear and improve fuel

economy.

A three-ring piston-sealing system is used. The steel top ring is treated with a PVD (physical vapor deposition) peripheral

coating. PVD is a coating technique where material can be deposited with improved properties to ensure good cylinder bore

compatibility and wear resistance. A Napier center ring helps cylinder pressure and oil management, while the three-piece oil

control lower ring is produced from nitrided steel.

The pistons are cooled with engine oil from four piston cooling jets installed under the valley of the cylinder block. Each piston

cooling jet sprays oil onto the underside of the two adjacent pistons, one from each cylinder bank.

The connecting rods are forged from high strength steel. The cap is fracture-split from the rod to ensure precision re-assembly

for bearing shell alignment. There are three grades of large end bearing available, each being color coded. For further

information refer to Engine - 5.0L, Vehicles Without: Supercharger - General Procedures.