suspension JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 114 of 3039

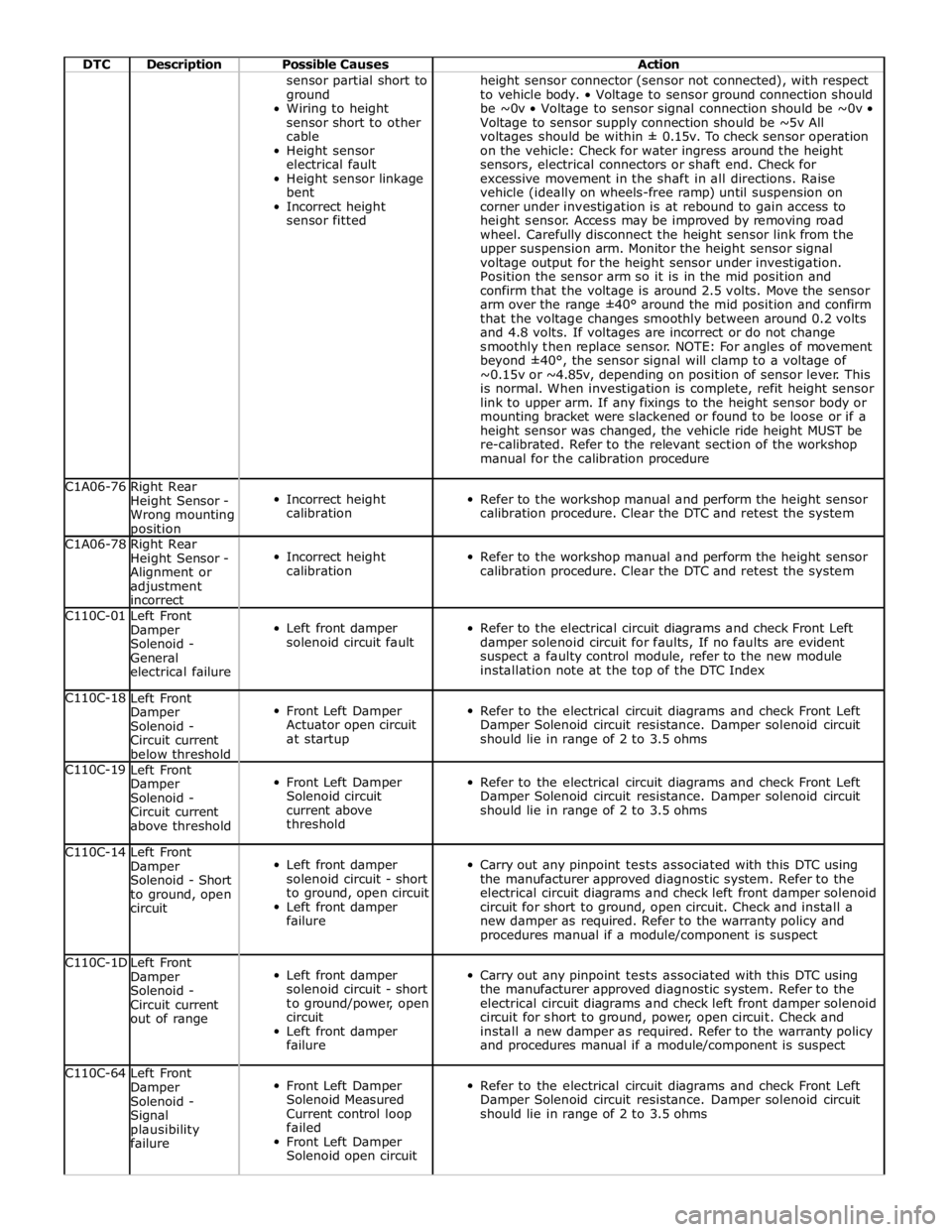

DTC Description Possible Causes Action sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor

electrical fault

Height sensor linkage

bent

Incorrect height

sensor fitted height sensor connector (sensor not connected), with respect

to vehicle body. • Voltage to sensor ground connection should

be ~0v • Voltage to sensor signal connection should be ~0v •

Voltage to sensor supply connection should be ~5v All

voltages should be within ± 0.15v. To check sensor operation

on the vehicle: Check for water ingress around the height

sensors, electrical connectors or shaft end. Check for

excessive movement in the shaft in all directions. Raise

vehicle (ideally on wheels-free ramp) until suspension on

corner under investigation is at rebound to gain access to

height sensor. Access may be improved by removing road

wheel. Carefully disconnect the height sensor link from the

upper suspension arm. Monitor the height sensor signal

voltage output for the height sensor under investigation.

Position the sensor arm so it is in the mid position and

confirm that the voltage is around 2.5 volts. Move the sensor

arm over the range ±40° around the mid position and confirm

that the voltage changes smoothly between around 0.2 volts

and 4.8 volts. If voltages are incorrect or do not change

smoothly then replace sensor. NOTE: For angles of movement

beyond ±40°, the sensor signal will clamp to a voltage of

~0.15v or ~4.85v, depending on position of sensor lever. This

is normal. When investigation is complete, refit height sensor

link to upper arm. If any fixings to the height sensor body or

mounting bracket were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Refer to the relevant section of the workshop

manual for the calibration procedure C1A06-76

Right Rear

Height Sensor -

Wrong mounting position

Incorrect height

calibration

Refer to the workshop manual and perform the height sensor

calibration procedure. Clear the DTC and retest the system C1A06-78

Right Rear

Height Sensor -

Alignment or

adjustment

incorrect

Incorrect height

calibration

Refer to the workshop manual and perform the height sensor

calibration procedure. Clear the DTC and retest the system C110C-01

Left Front

Damper

Solenoid -

General

electrical failure

Left front damper

solenoid circuit fault

Refer to the electrical circuit diagrams and check Front Left

damper solenoid circuit for faults, If no faults are evident

suspect a faulty control module, refer to the new module

installation note at the top of the DTC Index C110C-18

Left Front

Damper

Solenoid -

Circuit current

below threshold

Front Left Damper

Actuator open circuit

at startup

Refer to the electrical circuit diagrams and check Front Left

Damper Solenoid circuit resistance. Damper solenoid circuit

should lie in range of 2 to 3.5 ohms C110C-19

Left Front

Damper

Solenoid -

Circuit current

above threshold

Front Left Damper

Solenoid circuit

current above

threshold

Refer to the electrical circuit diagrams and check Front Left

Damper Solenoid circuit resistance. Damper solenoid circuit

should lie in range of 2 to 3.5 ohms C110C-14

Left Front

Damper

Solenoid - Short

to ground, open

circuit

Left front damper

solenoid circuit - short

to ground, open circuit

Left front damper

failure

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check left front damper solenoid

circuit for short to ground, open circuit. Check and install a

new damper as required. Refer to the warranty policy and

procedures manual if a module/component is suspect C110C-1D

Left Front

Damper

Solenoid -

Circuit current

out of range

Left front damper

solenoid circuit - short

to ground/power, open

circuit

Left front damper

failure

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check left front damper solenoid

circuit for short to ground, power, open circuit. Check and

install a new damper as required. Refer to the warranty policy

and procedures manual if a module/component is suspect C110C-64

Left Front

Damper

Solenoid -

Signal

plausibility

failure

Front Left Damper

Solenoid Measured

Current control loop

failed

Front Left Damper

Solenoid open circuit

Refer to the electrical circuit diagrams and check Front Left

Damper Solenoid circuit resistance. Damper solenoid circuit

should lie in range of 2 to 3.5 ohms

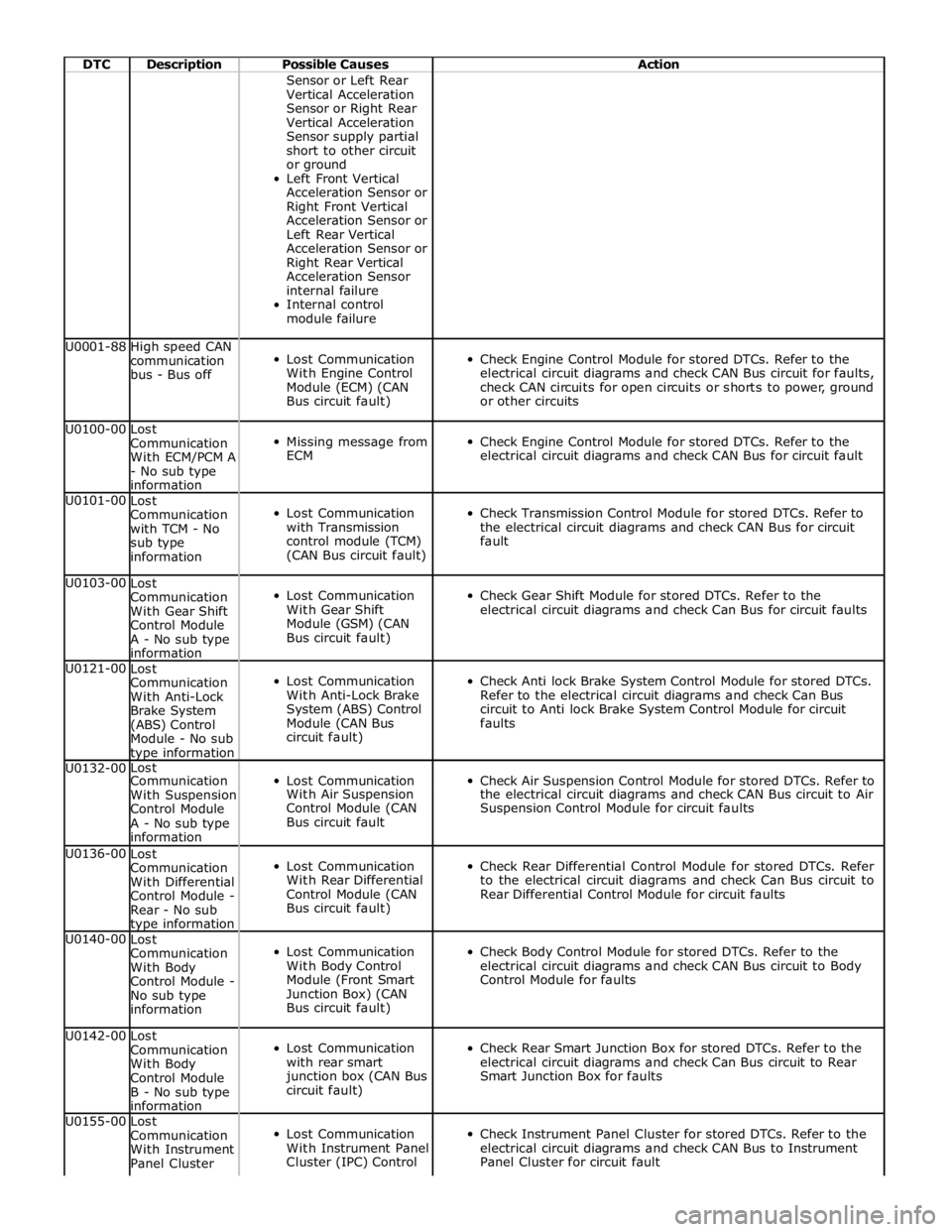

Page 117 of 3039

DTC Description Possible Causes Action Sensor or Left Rear

Vertical Acceleration

Sensor or Right Rear

Vertical Acceleration

Sensor supply partial

short to other circuit

or ground

Left Front Vertical

Acceleration Sensor or

Right Front Vertical

Acceleration Sensor or

Left Rear Vertical

Acceleration Sensor or

Right Rear Vertical

Acceleration Sensor

internal failure

Internal control

module failure U0001-88

High speed CAN

communication

bus - Bus off

Lost Communication

With Engine Control

Module (ECM) (CAN

Bus circuit fault)

Check Engine Control Module for stored DTCs. Refer to the

electrical circuit diagrams and check CAN Bus circuit for faults,

check CAN circuits for open circuits or shorts to power, ground

or other circuits U0100-00

Lost

Communication

With ECM/PCM A

- No sub type

information

Missing message from

ECM

Check Engine Control Module for stored DTCs. Refer to the

electrical circuit diagrams and check CAN Bus for circuit fault U0101-00

Lost

Communication

with TCM - No

sub type

information

Lost Communication

with Transmission

control module (TCM)

(CAN Bus circuit fault)

Check Transmission Control Module for stored DTCs. Refer to

the electrical circuit diagrams and check CAN Bus for circuit

fault U0103-00

Lost

Communication

With Gear Shift

Control Module

A - No sub type

information

Lost Communication

With Gear Shift

Module (GSM) (CAN

Bus circuit fault)

Check Gear Shift Module for stored DTCs. Refer to the

electrical circuit diagrams and check Can Bus for circuit faults U0121-00

Lost

Communication

With Anti-Lock

Brake System

(ABS) Control

Module - No sub type information

Lost Communication

With Anti-Lock Brake

System (ABS) Control

Module (CAN Bus

circuit fault)

Check Anti lock Brake System Control Module for stored DTCs.

Refer to the electrical circuit diagrams and check Can Bus

circuit to Anti lock Brake System Control Module for circuit

faults U0132-00 Lost

Lost Communication

Check Air Suspension Control Module for stored DTCs. Refer to Communication With Suspension With Air Suspension the electrical circuit diagrams and check CAN Bus circuit to Air Control Module Control Module (CAN Suspension Control Module for circuit faults A - No sub type Bus circuit fault information U0136-00

Lost

Communication

With Differential

Control Module -

Rear - No sub type information

Lost Communication

With Rear Differential

Control Module (CAN

Bus circuit fault)

Check Rear Differential Control Module for stored DTCs. Refer

to the electrical circuit diagrams and check Can Bus circuit to

Rear Differential Control Module for circuit faults U0140-00

Lost

Communication

With Body

Control Module -

No sub type

information

Lost Communication

With Body Control

Module (Front Smart

Junction Box) (CAN

Bus circuit fault)

Check Body Control Module for stored DTCs. Refer to the

electrical circuit diagrams and check CAN Bus circuit to Body

Control Module for faults U0142-00

Lost

Communication

With Body

Control Module

B - No sub type

information

Lost Communication

with rear smart

junction box (CAN Bus

circuit fault)

Check Rear Smart Junction Box for stored DTCs. Refer to the

electrical circuit diagrams and check Can Bus circuit to Rear

Smart Junction Box for faults U0155-00

Lost

Communication

With Instrument

Panel Cluster

Lost Communication

With Instrument Panel

Cluster (IPC) Control

Check Instrument Panel Cluster for stored DTCs. Refer to the

electrical circuit diagrams and check CAN Bus to Instrument

Panel Cluster for circuit fault

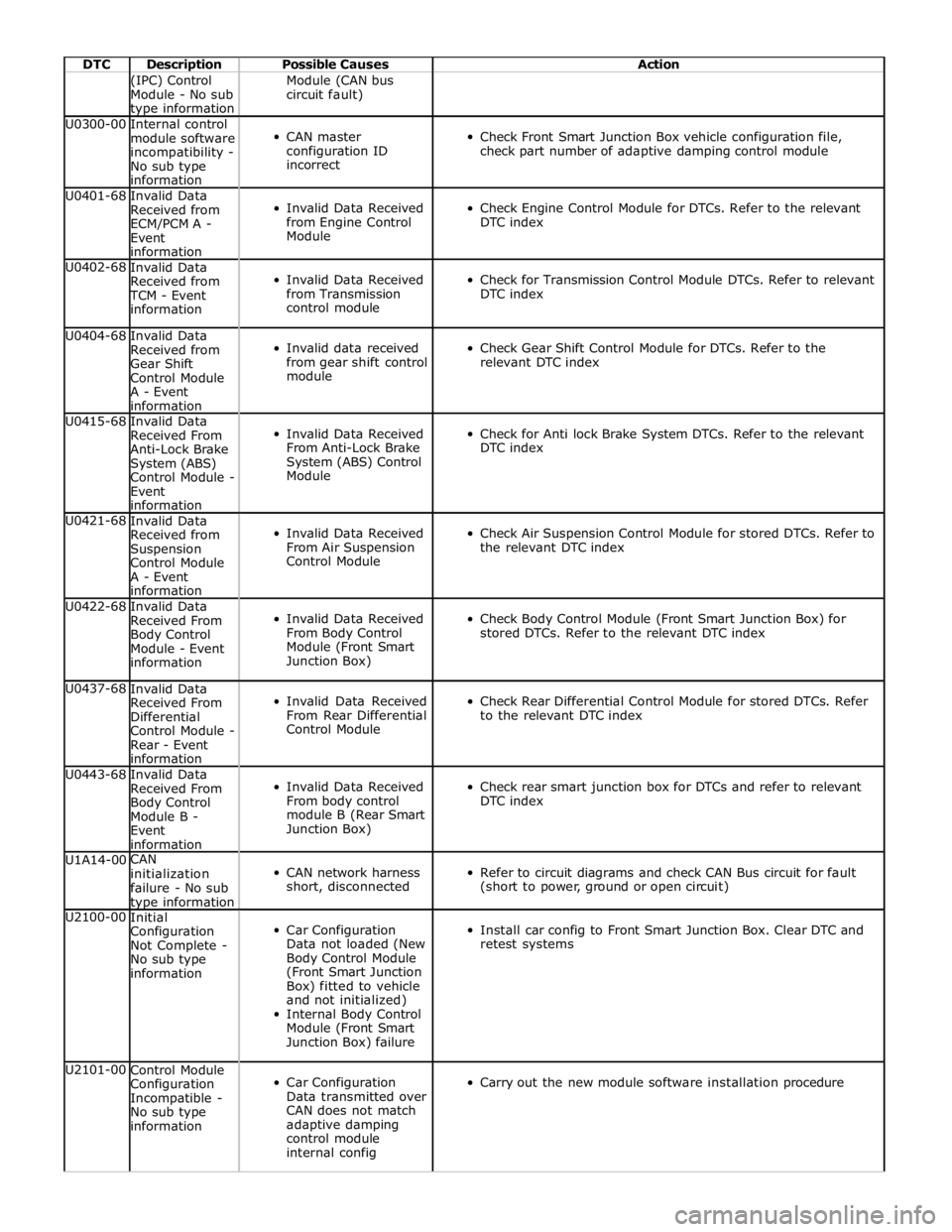

Page 118 of 3039

DTC Description Possible Causes Action (IPC) Control

Module - No sub

type information Module (CAN bus

circuit fault) U0300-00

Internal control

module software

incompatibility -

No sub type

information

CAN master

configuration ID

incorrect

Check Front Smart Junction Box vehicle configuration file,

check part number of adaptive damping control module U0401-68

Invalid Data

Received from

ECM/PCM A -

Event

information

Invalid Data Received

from Engine Control

Module

Check Engine Control Module for DTCs. Refer to the relevant

DTC index U0402-68

Invalid Data

Received from TCM - Event

information

Invalid Data Received

from Transmission

control module

Check for Transmission Control Module DTCs. Refer to relevant

DTC index U0404-68

Invalid Data

Received from

Gear Shift

Control Module

A - Event

information

Invalid data received

from gear shift control

module

Check Gear Shift Control Module for DTCs. Refer to the

relevant DTC index U0415-68

Invalid Data

Received From

Anti-Lock Brake

System (ABS)

Control Module -

Event

information

Invalid Data Received

From Anti-Lock Brake

System (ABS) Control

Module

Check for Anti lock Brake System DTCs. Refer to the relevant

DTC index U0421-68

Invalid Data

Received from

Suspension

Control Module

A - Event

information

Invalid Data Received

From Air Suspension

Control Module

Check Air Suspension Control Module for stored DTCs. Refer to

the relevant DTC index U0422-68

Invalid Data

Received From

Body Control

Module - Event

information

Invalid Data Received

From Body Control

Module (Front Smart

Junction Box)

Check Body Control Module (Front Smart Junction Box) for

stored DTCs. Refer to the relevant DTC index U0437-68

Invalid Data

Received From

Differential

Control Module -

Rear - Event

information

Invalid Data Received

From Rear Differential

Control Module

Check Rear Differential Control Module for stored DTCs. Refer

to the relevant DTC index U0443-68

Invalid Data

Received From

Body Control

Module B -

Event

information

Invalid Data Received

From body control

module B (Rear Smart

Junction Box)

Check rear smart junction box for DTCs and refer to relevant

DTC index U1A14-00 CAN

initialization

failure - No sub type information

CAN network harness

short, disconnected

Refer to circuit diagrams and check CAN Bus circuit for fault

(short to power, ground or open circuit) U2100-00

Initial

Configuration

Not Complete -

No sub type

information

Car Configuration

Data not loaded (New

Body Control Module

(Front Smart Junction

Box) fitted to vehicle

and not initialized)

Internal Body Control

Module (Front Smart

Junction Box) failure

Install car config to Front Smart Junction Box. Clear DTC and

retest systems U2101-00

Control Module

Configuration

Incompatible -

No sub type

information

Car Configuration

Data transmitted over

CAN does not match

adaptive damping

control module

internal config

Carry out the new module software installation procedure

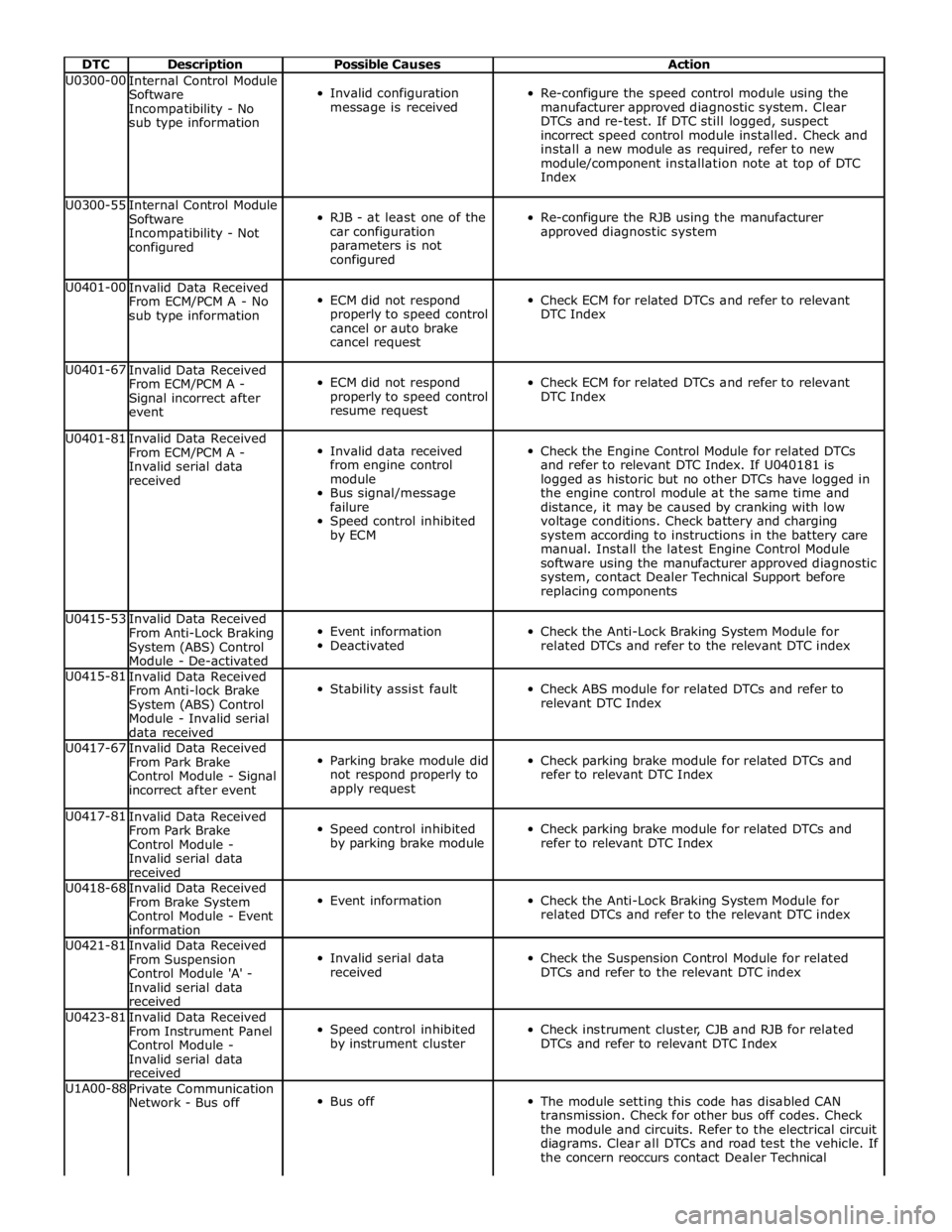

Page 240 of 3039

DTC Description Possible Causes Action U0300-00

Internal Control Module

Software

Incompatibility - No

sub type information

Invalid configuration

message is received

Re-configure the speed control module using the

manufacturer approved diagnostic system. Clear

DTCs and re-test. If DTC still logged, suspect

incorrect speed control module installed. Check and

install a new module as required, refer to new

module/component installation note at top of DTC

Index U0300-55

Internal Control Module

Software

Incompatibility - Not

configured

RJB - at least one of the

car configuration

parameters is not

configured

Re-configure the RJB using the manufacturer

approved diagnostic system U0401-00

Invalid Data Received

From ECM/PCM A - No

sub type information

ECM did not respond

properly to speed control

cancel or auto brake

cancel request

Check ECM for related DTCs and refer to relevant

DTC Index U0401-67

Invalid Data Received

From ECM/PCM A -

Signal incorrect after

event

ECM did not respond

properly to speed control

resume request

Check ECM for related DTCs and refer to relevant

DTC Index U0401-81

Invalid Data Received

From ECM/PCM A -

Invalid serial data

received

Invalid data received

from engine control

module

Bus signal/message

failure

Speed control inhibited

by ECM

Check the Engine Control Module for related DTCs

and refer to relevant DTC Index. If U040181 is

logged as historic but no other DTCs have logged in

the engine control module at the same time and

distance, it may be caused by cranking with low

voltage conditions. Check battery and charging

system according to instructions in the battery care

manual. Install the latest Engine Control Module

software using the manufacturer approved diagnostic

system, contact Dealer Technical Support before

replacing components U0415-53

Invalid Data Received

From Anti-Lock Braking

System (ABS) Control

Module - De-activated

Event information

Deactivated

Check the Anti-Lock Braking System Module for

related DTCs and refer to the relevant DTC index U0415-81

Invalid Data Received

From Anti-lock Brake

System (ABS) Control

Module - Invalid serial

data received

Stability assist fault

Check ABS module for related DTCs and refer to

relevant DTC Index U0417-67

Invalid Data Received

From Park Brake

Control Module - Signal

incorrect after event

Parking brake module did

not respond properly to

apply request

Check parking brake module for related DTCs and

refer to relevant DTC Index U0417-81

Invalid Data Received

From Park Brake

Control Module -

Invalid serial data

received

Speed control inhibited

by parking brake module

Check parking brake module for related DTCs and

refer to relevant DTC Index U0418-68

Invalid Data Received

From Brake System

Control Module - Event

information

Event information

Check the Anti-Lock Braking System Module for

related DTCs and refer to the relevant DTC index U0421-81

Invalid Data Received

From Suspension

Control Module 'A' -

Invalid serial data

received

Invalid serial data

received

Check the Suspension Control Module for related

DTCs and refer to the relevant DTC index U0423-81

Invalid Data Received

From Instrument Panel

Control Module -

Invalid serial data

received

Speed control inhibited

by instrument cluster

Check instrument cluster, CJB and RJB for related

DTCs and refer to relevant DTC Index U1A00-88

Private Communication

Network - Bus off

Bus off

The module setting this code has disabled CAN

transmission. Check for other bus off codes. Check

the module and circuits. Refer to the electrical circuit

diagrams. Clear all DTCs and road test the vehicle. If

the concern reoccurs contact Dealer Technical

Page 295 of 3039

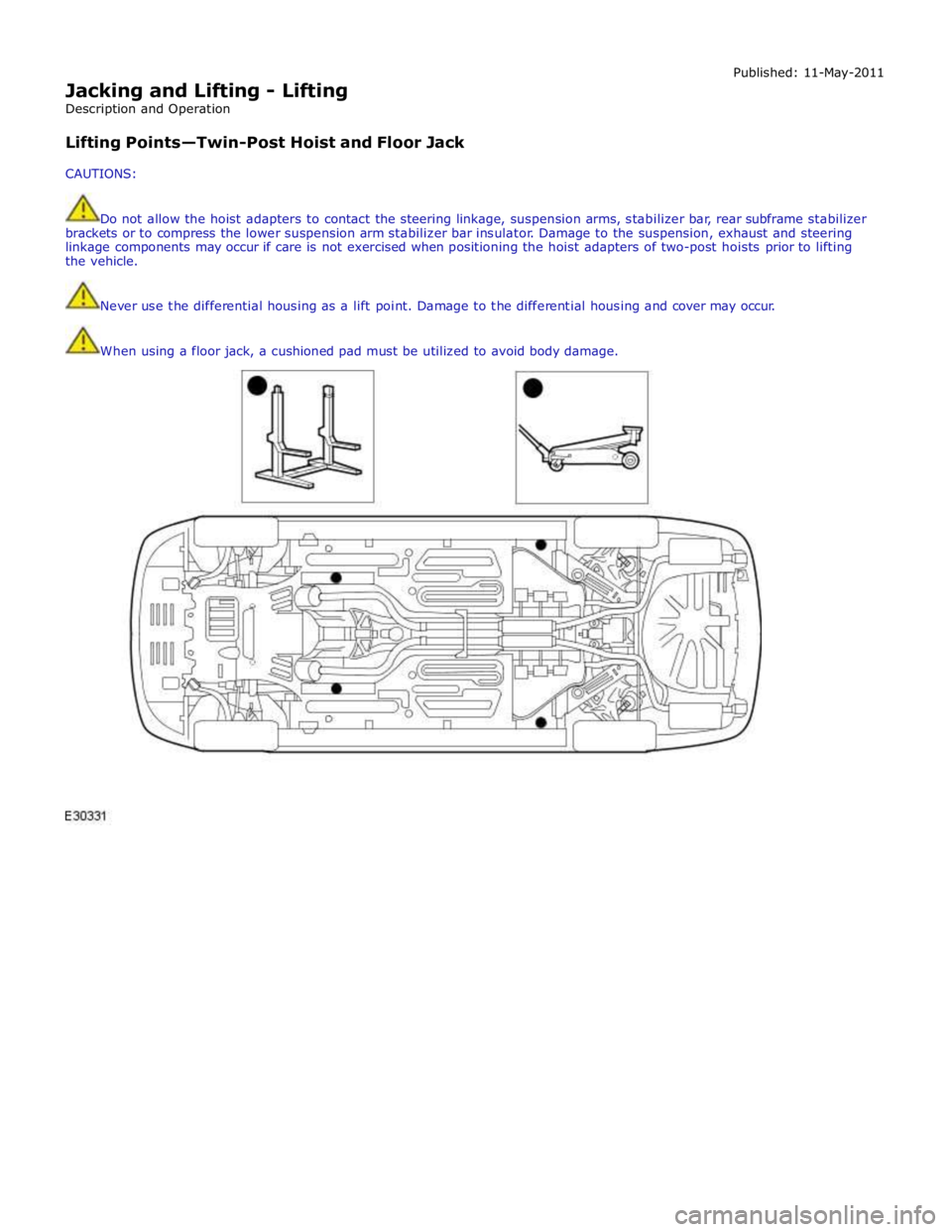

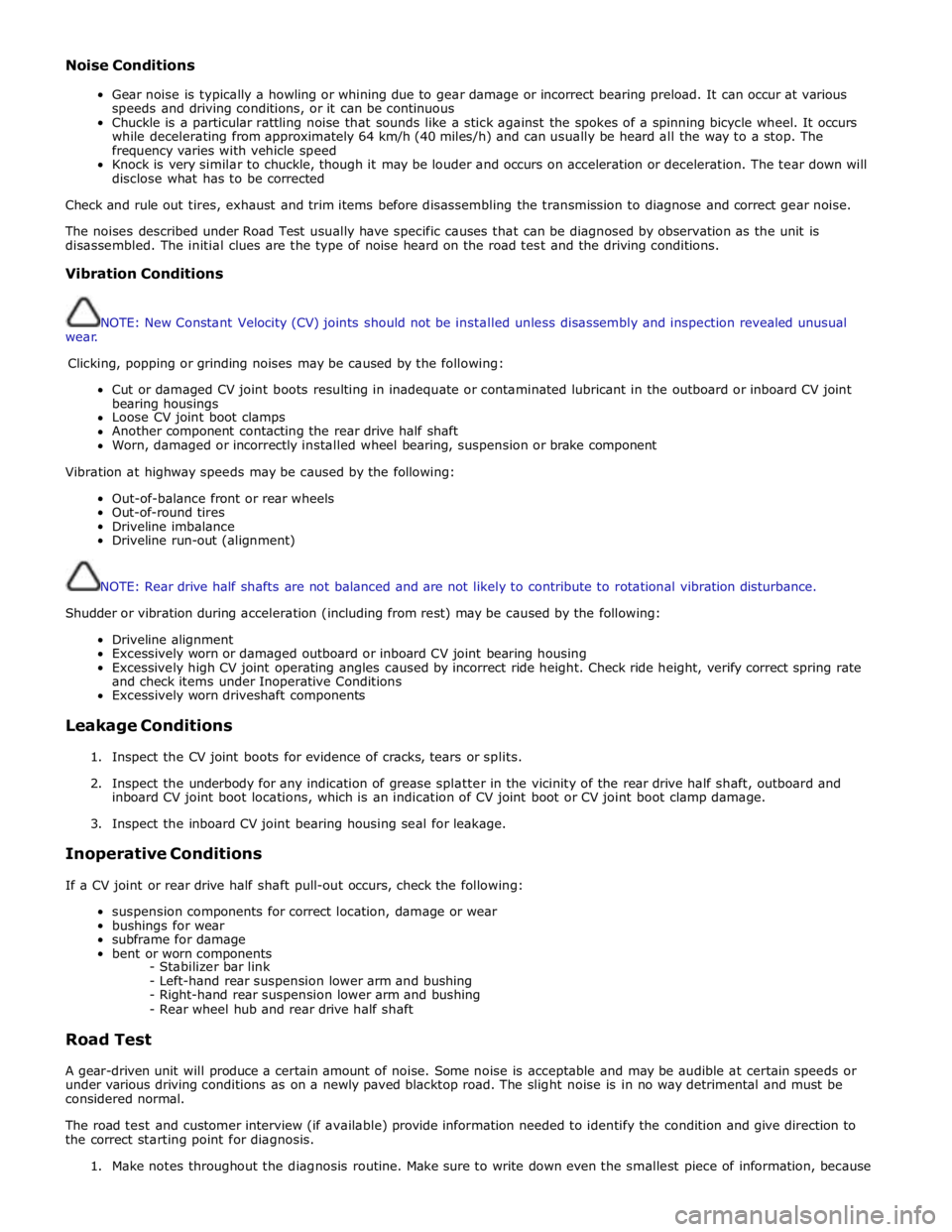

Jacking and Lifting - Lifting

Description and Operation

Lifting Points—Twin-Post Hoist and Floor Jack

CAUTIONS: Published: 11-May-2011

Do not allow the hoist adapters to contact the steering linkage, suspension arms, stabilizer bar, rear subframe stabilizer

brackets or to compress the lower suspension arm stabilizer bar insulator. Damage to the suspension, exhaust and steering

linkage components may occur if care is not exercised when positioning the hoist adapters of two-post hoists prior to lifting

the vehicle.

Never use the differential housing as a lift point. Damage to the differential housing and cover may occur.

When using a floor jack, a cushioned pad must be utilized to avoid body damage.

Page 299 of 3039

Published: 16-Sep-2013

Noise, Vibration and Harshness - Noise, Vibration and Harshness (NVH)

Diagnosis and Testing

Principle of Operation

For a detailed description of Noise, Vibration and Harshness issues, refer to the Description and Operation section of the

workshop manual.

REFER to: Noise, Vibration and Harshness (NVH) (100-04 Noise, Vibration and Harshness, Description and Operation).

Inspection and Verification

1. Verify the customer's concerns by operating the vehicle to duplicate the condition.

2. Visually inspect the vehicle to determine any obvious cause(s) of the concern(s).

3. If the inspection reveals obvious causes that can be readily identified, repair as necessary.

4. If the concern(s) remains after the inspection, determine the symptom(s) and refer to the Symptom Chart.

How To Use This Diagnostic Procedure Section

Noise, vibration and harshness (NVH) concerns have become more important as vehicles have become more sensitive to

these vibrations. This section is designed as an aid to identifying these situations

The section provides diagnostic procedures based on symptoms. If the condition occurs at high speed, for instance, the

most likely place to start is under High Speed Shake

The road test procedure will tell how to sort the conditions into categories and how to tell a vibration from a shake

A series of Road Test Quick Checks is provided to make sure that a cause is either pinpointed or eliminated

Name the condition, proceed to the appropriate section and locate the correct diagnosis. When the condition is

identified, the job is partly done

Follow the diagnostic procedure as outlined

Quick Checks are described within the step, while more involved tests and adjustments are outlined in General

Procedures

Always follow each step exactly and make notes to recall important findings later

Customer Interview

The road test and customer interview (if available) provide information that will help identify the concerns and will provide

direction to the correct starting point for diagnosis.

Identify the Condition

NVH problems usually occur in a number of areas:

tires

engine accessories

suspension

driveline

air leakage (wind noise)

squeaks and rattles

heating ventilation and air conditioning (HVAC)

electrical (e.g. motor noise)

transmission

engine

It is important, therefore, that an NVH concern be isolated into its specific area(s) as soon as possible. The easiest and

quickest way to do this is to carry out the Road Test as outlined.

Noise Diagnostic Procedure

Non-Axle Noise

The five most important sources of non-axle noise are exhaust, tires, roof racks, trim and mouldings, and transmission.

Therefore, make sure that none of the following conditions are the cause of the noise before proceeding with a driveline tear

down and diagnosis.

Under certain conditions, the pitch of the exhaust may sound very much like gear noise. At other times, it can be

mistaken for a wheel bearing rumble

Tires, especially snow tires, can have a high pitched tread whine or roar, similar to gear noise. Radial tires, to some

degree, have this characteristic. Also, any non-standard tire with an unusual tread construction may emit a roar or

whine type noise

Trim and mouldings can also cause whistling or a whining noise

Clunk may be a metallic noise heard when the automatic transmission is engaged in reverse or drive, or it may occur

when the throttle is applied or released. It is caused by backlash somewhere in the driveline

Bearing rumble sounds like marbles being tumbled. This condition is usually caused by a damaged wheel bearing

Page 300 of 3039

Noise Conditions

Gear noise is typically a howling or whining due to gear damage or incorrect bearing preload. It can occur at various

speeds and driving conditions, or it can be continuous

Chuckle is a particular rattling noise that sounds like a stick against the spokes of a spinning bicycle wheel. It occurs

while decelerating from approximately 64 km/h (40 miles/h) and can usually be heard all the way to a stop. The

frequency varies with vehicle speed

Knock is very similar to chuckle, though it may be louder and occurs on acceleration or deceleration. The tear down will

disclose what has to be corrected

Check and rule out tires, exhaust and trim items before disassembling the transmission to diagnose and correct gear noise.

The noises described under Road Test usually have specific causes that can be diagnosed by observation as the unit is

disassembled. The initial clues are the type of noise heard on the road test and the driving conditions.

Vibration Conditions

wear. NOTE: New Constant Velocity (CV) joints should not be installed unless disassembly and inspection revealed unusual

Clicking, popping or grinding noises may be caused by the following:

Cut or damaged CV joint boots resulting in inadequate or contaminated lubricant in the outboard or inboard CV joint

bearing housings

Loose CV joint boot clamps

Another component contacting the rear drive half shaft

Worn, damaged or incorrectly installed wheel bearing, suspension or brake component

Vibration at highway speeds may be caused by the following:

Out-of-balance front or rear wheels

Out-of-round tires

Driveline imbalance

Driveline run-out (alignment)

NOTE: Rear drive half shafts are not balanced and are not likely to contribute to rotational vibration disturbance.

Shudder or vibration during acceleration (including from rest) may be caused by the following:

Driveline alignment

Excessively worn or damaged outboard or inboard CV joint bearing housing

Excessively high CV joint operating angles caused by incorrect ride height. Check ride height, verify correct spring rate

and check items under Inoperative Conditions

Excessively worn driveshaft components

Leakage Conditions

1. Inspect the CV joint boots for evidence of cracks, tears or splits.

2. Inspect the underbody for any indication of grease splatter in the vicinity of the rear drive half shaft, outboard and

inboard CV joint boot locations, which is an indication of CV joint boot or CV joint boot clamp damage.

3. Inspect the inboard CV joint bearing housing seal for leakage.

Inoperative Conditions

If a CV joint or rear drive half shaft pull-out occurs, check the following:

suspension components for correct location, damage or wear

bushings for wear

subframe for damage

bent or worn components

- Stabilizer bar link

- Left-hand rear suspension lower arm and bushing

- Right-hand rear suspension lower arm and bushing

- Rear wheel hub and rear drive half shaft

Road Test

A gear-driven unit will produce a certain amount of noise. Some noise is acceptable and may be audible at certain speeds or

under various driving conditions as on a newly paved blacktop road. The slight noise is in no way detrimental and must be

considered normal.

The road test and customer interview (if available) provide information needed to identify the condition and give direction to

the correct starting point for diagnosis.

1. Make notes throughout the diagnosis routine. Make sure to write down even the smallest piece of information, because

Page 302 of 3039

and drive half shaft failure, which could cause serious personal injury and extensive vehicle damage. Failure to follow these

instructions may result in personal injury.

CAUTION: The suspension should not be allowed to hang free. When the CV joint is run at a very high angle, extra

vibration as well as damage to the seals and joints can occur.

The rear suspension lower arm should be supported as far outboard as possible. To bring the vehicle to its correct ride height,

the full weight of the vehicle should be supported in the rear by floor jacks. REFER to: (100-02 Jacking and Lifting)

Jacking (Description and Operation), Lifting (Description and Operation).

1. Raise and support the vehicle. REFER to: (100-02 Jacking and Lifting)

Jacking (Description and Operation), Lifting (Description and Operation).

2. Explore the speed range of interest using the Road Test Quick Checks as previously described.

3. Carry out a coast down in neutral. If the vehicle is free of vibration when operating at a steady indicated speed and

behaves very differently in drive and coast, a transmission concern is likely.

Note, however, that a test on the lift may produce different vibrations and noises than a road test because of the effect of the

lift. It is not unusual to find vibrations on the lift that were not found in the road test. If the condition found on the road can

be duplicated on the lift, carrying out experiments on the lift may save a great deal of time.

Exhaust Neutralization Procedure

1. Raise vehicle on lift and slacken all exhaust fixings.

2. With all fixings loose, neutralize the exhaust system.

3. Tighten all fixings to correct torque, starting at the rear-most point working towards the front of the vehicle.

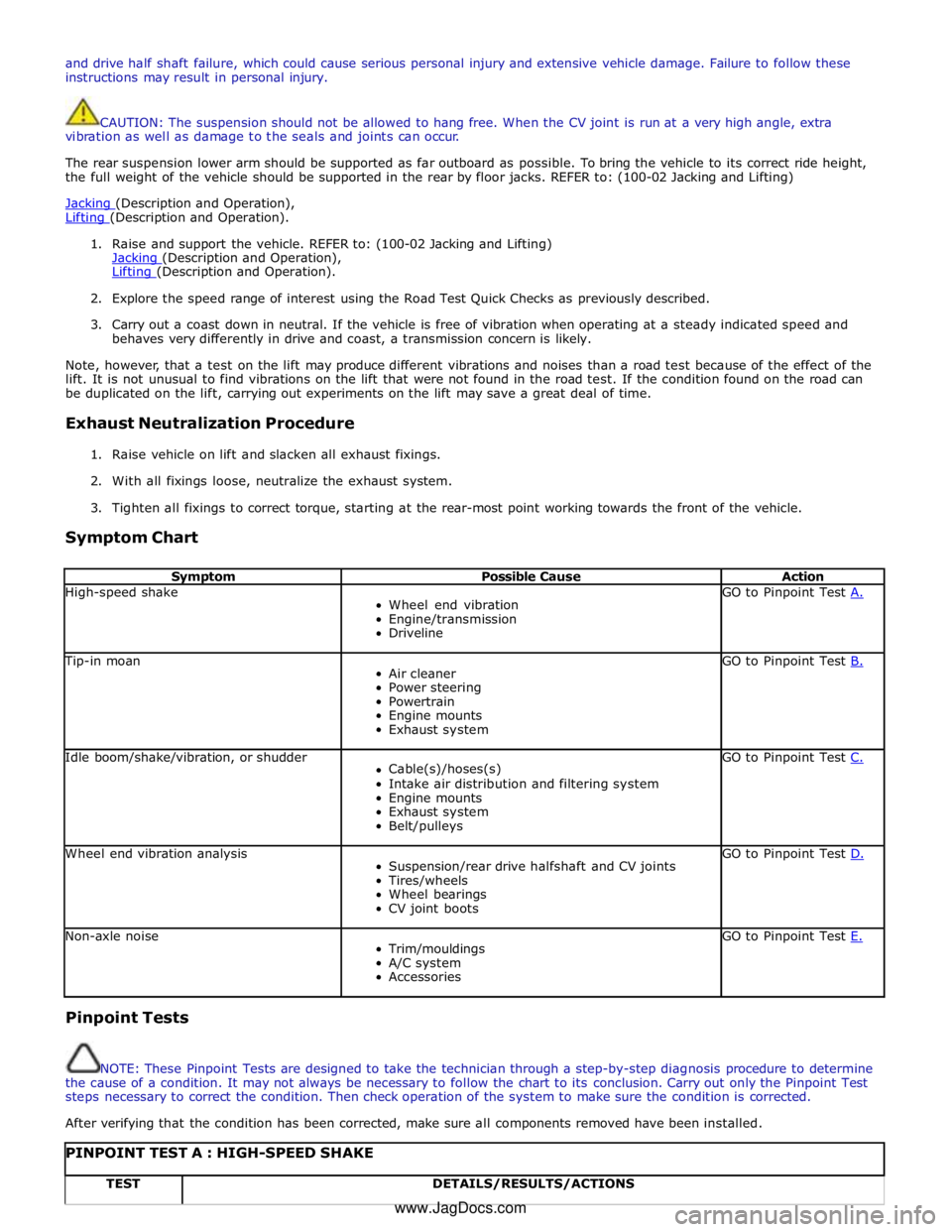

Symptom Chart

Symptom Possible Cause Action High-speed shake

Wheel end vibration

Engine/transmission

Driveline GO to Pinpoint Test A. Tip-in moan

Air cleaner

Power steering

Powertrain

Engine mounts

Exhaust system GO to Pinpoint Test B. Idle boom/shake/vibration, or shudder

Cable(s)/hoses(s)

Intake air distribution and filtering system

Engine mounts

Exhaust system

Belt/pulleys GO to Pinpoint Test C. Wheel end vibration analysis

Suspension/rear drive halfshaft and CV joints

Tires/wheels

Wheel bearings

CV joint boots GO to Pinpoint Test D. Non-axle noise

Trim/mouldings

A/C system

Accessories GO to Pinpoint Test E. Pinpoint Tests

NOTE: These Pinpoint Tests are designed to take the technician through a step-by-step diagnosis procedure to determine

the cause of a condition. It may not always be necessary to follow the chart to its conclusion. Carry out only the Pinpoint Test

steps necessary to correct the condition. Then check operation of the system to make sure the condition is corrected.

After verifying that the condition has been corrected, make sure all components removed have been installed.

PINPOINT TEST A : HIGH-SPEED SHAKE TEST DETAILS/RESULTS/ACTIONS www.JagDocs.com

Page 306 of 3039

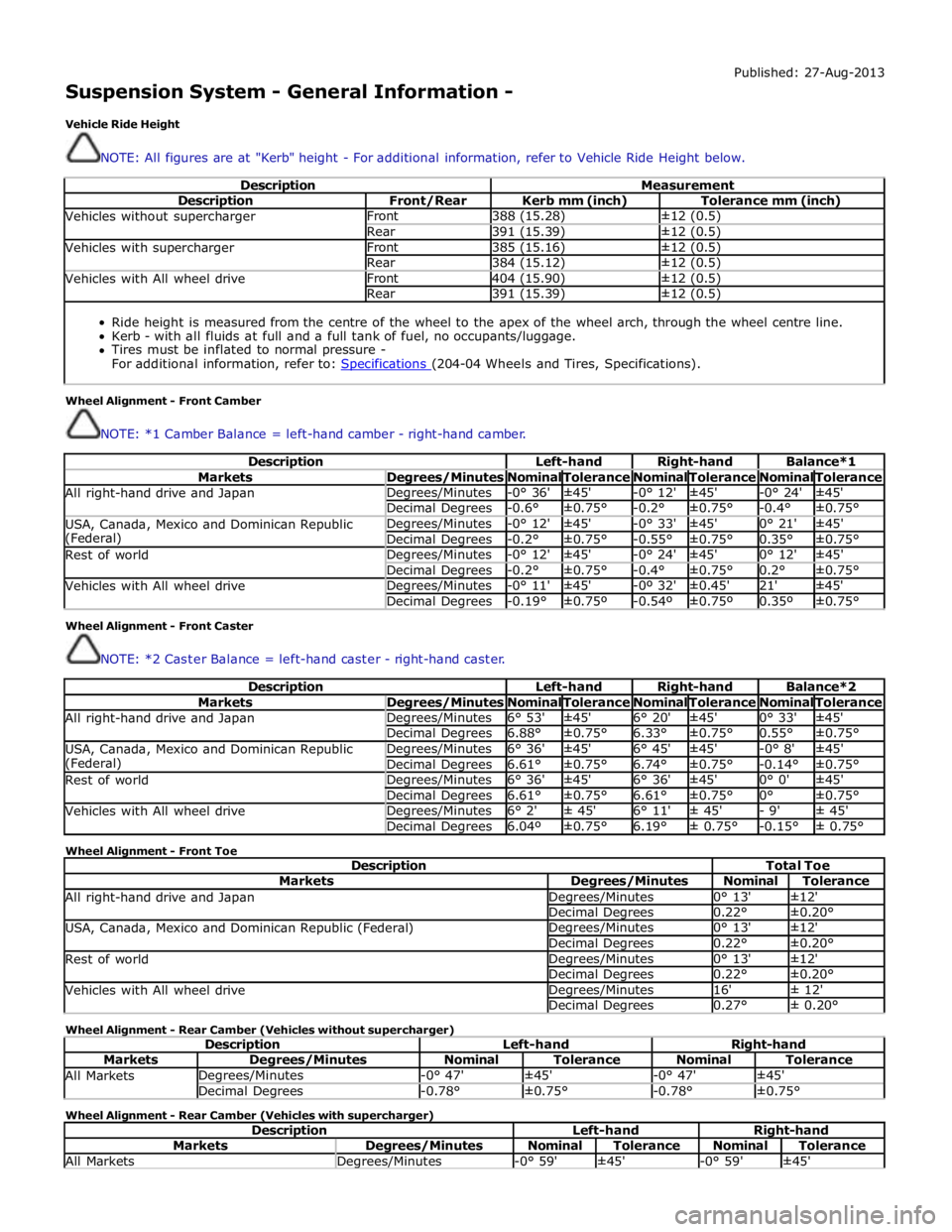

Suspension System - General Information -

Vehicle Ride Height Published: 27-Aug-2013

NOTE: All figures are at "Kerb" height - For additional information, refer to Vehicle Ride Height below.

Description Measurement Description Front/Rear Kerb mm (inch) Tolerance mm (inch) Vehicles without supercharger Front 388 (15.28) ±12 (0.5) Rear 391 (15.39) ±12 (0.5) Vehicles with supercharger Front 385 (15.16) ±12 (0.5) Rear 384 (15.12) ±12 (0.5) Vehicles with All wheel drive Front 404 (15.90) ±12 (0.5) Rear 391 (15.39) ±12 (0.5)

Ride height is measured from the centre of the wheel to the apex of the wheel arch, through the wheel centre line.

Kerb - with all fluids at full and a full tank of fuel, no occupants/luggage.

Tires must be inflated to normal pressure -

For additional information, refer to: Specifications (204-04 Wheels and Tires, Specifications). Wheel Alignment - Front Camber

NOTE: *1 Camber Balance = left-hand camber - right-hand camber.

Description Left-hand Right-hand Balance*1 Markets Degrees/Minutes Nominal Tolerance Nominal Tolerance Nominal Tolerance All right-hand drive and Japan Degrees/Minutes -0° 36' ±45' -0° 12' ±45' -0° 24' ±45' Decimal Degrees -0.6° ±0.75° -0.2° ±0.75° -0.4° ±0.75° USA, Canada, Mexico and Dominican Republic

(Federal) Degrees/Minutes -0° 12' ±45' -0° 33' ±45' 0° 21' ±45' Decimal Degrees -0.2° ±0.75° -0.55° ±0.75° 0.35° ±0.75° Rest of world Degrees/Minutes -0° 12' ±45' -0° 24' ±45' 0° 12' ±45' Decimal Degrees -0.2° ±0.75° -0.4° ±0.75° 0.2° ±0.75° Vehicles with All wheel drive Degrees/Minutes -0° 11' ±45' -0º 32' ±0.45' 21' ±45' Decimal Degrees -0.19° ±0.75º -0.54º ±0.75º 0.35º ±0.75° Wheel Alignment - Front Caster

NOTE: *2 Caster Balance = left-hand caster - right-hand caster.

Description Left-hand Right-hand Balance*2 Markets Degrees/Minutes Nominal Tolerance Nominal Tolerance Nominal Tolerance All right-hand drive and Japan Degrees/Minutes 6° 53' ±45' 6° 20' ±45' 0° 33' ±45' Decimal Degrees 6.88° ±0.75° 6.33° ±0.75° 0.55° ±0.75° USA, Canada, Mexico and Dominican Republic

(Federal) Degrees/Minutes 6° 36' ±45' 6° 45' ±45' -0° 8' ±45' Decimal Degrees 6.61° ±0.75° 6.74° ±0.75° -0.14° ±0.75° Rest of world Degrees/Minutes 6° 36' ±45' 6° 36' ±45' 0° 0' ±45' Decimal Degrees 6.61° ±0.75° 6.61° ±0.75° 0° ±0.75° Vehicles with All wheel drive Degrees/Minutes 6° 2' ± 45' 6° 11' ± 45' - 9' ± 45' Decimal Degrees 6.04º ±0.75° 6.19° ± 0.75° -0.15° ± 0.75° Wheel Alignment - Front Toe

Description Total Toe Markets Degrees/Minutes Nominal Tolerance All right-hand drive and Japan Degrees/Minutes 0° 13' ±12' Decimal Degrees 0.22° ±0.20° USA, Canada, Mexico and Dominican Republic (Federal) Degrees/Minutes 0° 13' ±12' Decimal Degrees 0.22° ±0.20° Rest of world Degrees/Minutes 0° 13' ±12' Decimal Degrees 0.22° ±0.20° Vehicles with All wheel drive Degrees/Minutes 16' ± 12' Decimal Degrees 0.27° ± 0.20° Wheel Alignment - Rear Camber (Vehicles without supercharger)

Description Left-hand Right-hand Markets Degrees/Minutes Nominal Tolerance Nominal Tolerance All Markets Degrees/Minutes -0° 47' ±45' -0° 47' ±45' Decimal Degrees -0.78° ±0.75° -0.78° ±0.75° Wheel Alignment - Rear Camber (Vehicles with supercharger)

Description Left-hand Right-hand Markets Degrees/Minutes Nominal Tolerance Nominal Tolerance All Markets Degrees/Minutes -0° 59' ±45' -0° 59' ±45'

Page 308 of 3039

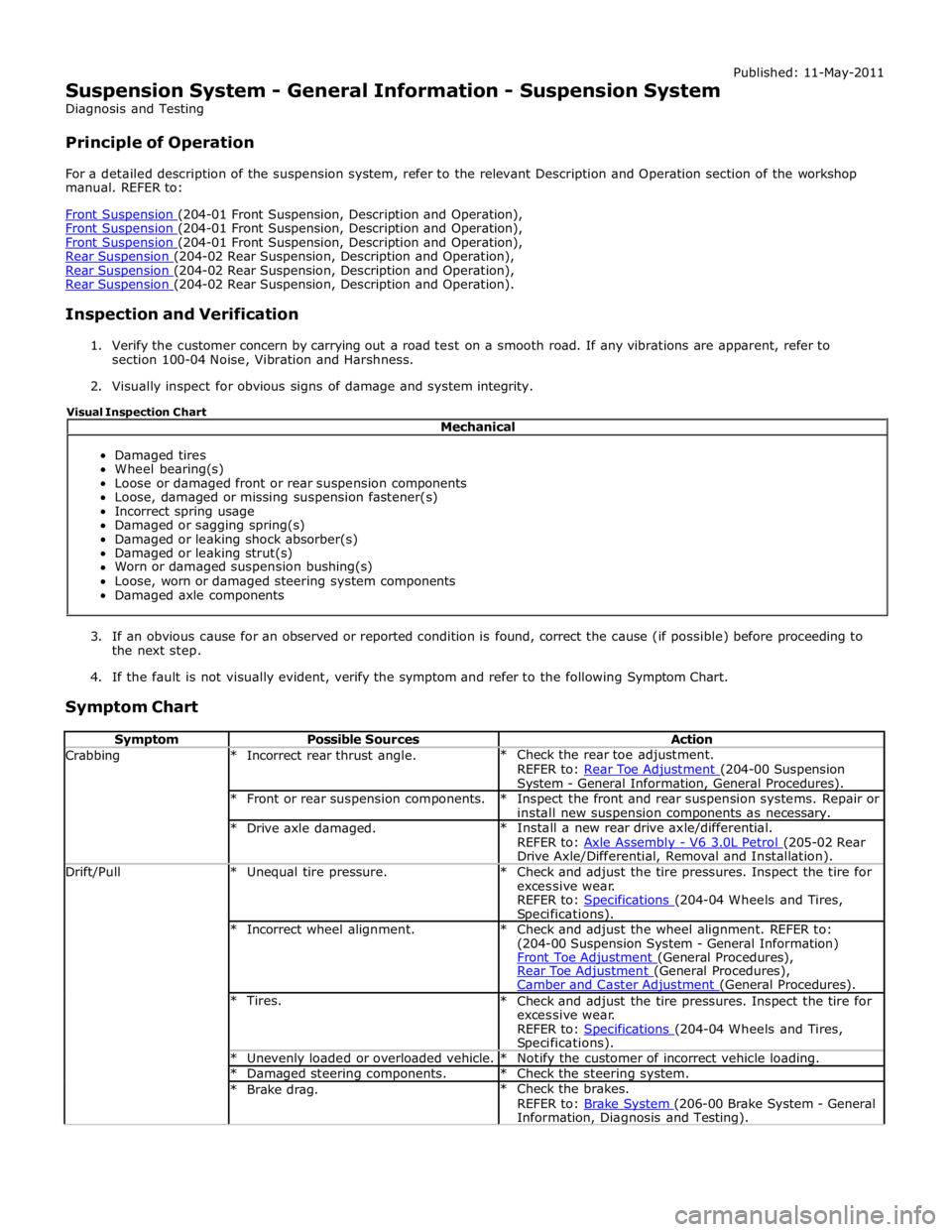

Front Suspension (204-01 Front Suspension, Description and Operation), Front Suspension (204-01 Front Suspension, Description and Operation), Rear Suspension (204-02 Rear Suspension, Description and Operation), Rear Suspension (204-02 Rear Suspension, Description and Operation), Rear Suspension (204-02 Rear Suspension, Description and Operation).

Inspection and Verification

1. Verify the customer concern by carrying out a road test on a smooth road. If any vibrations are apparent, refer to

section 100-04 Noise, Vibration and Harshness.

2. Visually inspect for obvious signs of damage and system integrity.

3. If an obvious cause for an observed or reported condition is found, correct the cause (if possible) before proceeding to

the next step.

4. If the fault is not visually evident, verify the symptom and refer to the following Symptom Chart.

Symptom Chart

Symptom Possible Sources Action Crabbing * Incorrect rear thrust angle. * Check the rear toe adjustment.

REFER to: Rear Toe Adjustment (204-00 Suspension System - General Information, General Procedures). * Front or rear suspension components.

* Inspect the front and rear suspension systems. Repair or

install new suspension components as necessary. * Drive axle damaged. * Install a new rear drive axle/differential.

REFER to: Axle Assembly - V6 3.0L Petrol (205-02 Rear Drive Axle/Differential, Removal and Installation). Drift/Pull * Unequal tire pressure.

* Check and adjust the tire pressures. Inspect the tire for

excessive wear.

REFER to: Specifications (204-04 Wheels and Tires, Specifications). * Incorrect wheel alignment.

* Check and adjust the wheel alignment. REFER to:

(204-00 Suspension System - General Information)

Front Toe Adjustment (General Procedures), Rear Toe Adjustment (General Procedures), Camber and Caster Adjustment (General Procedures). * Tires.

* Check and adjust the tire pressures. Inspect the tire for

excessive wear.

REFER to: Specifications (204-04 Wheels and Tires, Specifications). * Unevenly loaded or overloaded vehicle. * Notify the customer of incorrect vehicle loading. * Damaged steering components. * Check the steering system. * Brake drag. * Check the brakes.

REFER to: Brake System (206-00 Brake System - General Information, Diagnosis and Testing). Mechanical

Damaged tires

Wheel bearing(s)

Loose or damaged front or rear suspension components

Loose, damaged or missing suspension fastener(s)

Incorrect spring usage

Damaged or sagging spring(s)

Damaged or leaking shock absorber(s)

Damaged or leaking strut(s)

Worn or damaged suspension bushing(s)

Loose, worn or damaged steering system components

Damaged axle components Visual Inspection Chart