weight JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 401 of 3039

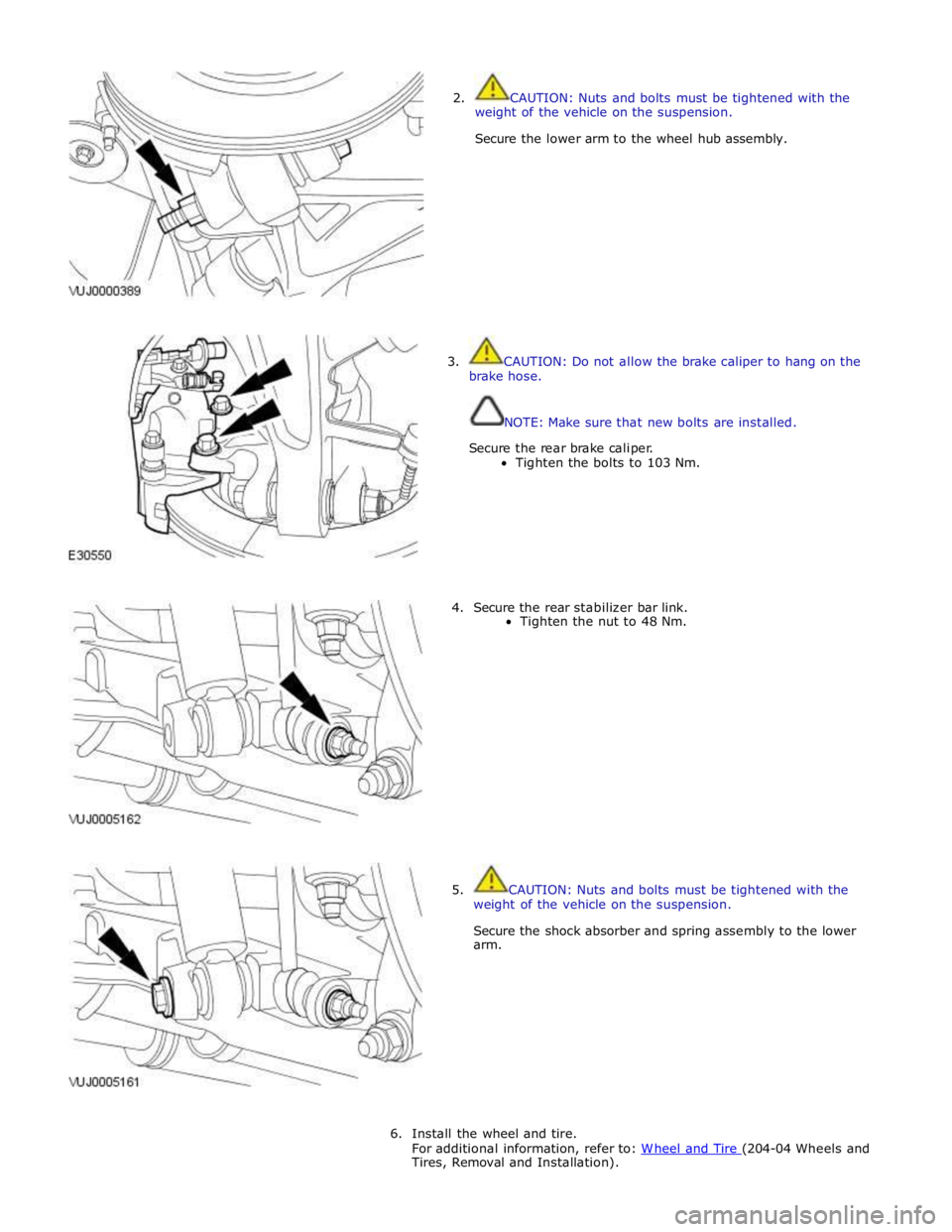

2. CAUTION: Nuts and bolts must be tightened with the

weight of the vehicle on the suspension.

Secure the lower arm to the wheel hub assembly.

3. CAUTION: Do not allow the brake caliper to hang on the

brake hose.

NOTE: Make sure that new bolts are installed.

Secure the rear brake caliper.

Tighten the bolts to 103 Nm.

4. Secure the rear stabilizer bar link.

Tighten the nut to 48 Nm.

5. CAUTION: Nuts and bolts must be tightened with the

weight of the vehicle on the suspension.

Secure the shock absorber and spring assembly to the lower

arm.

6. Install the wheel and tire.

For additional information, refer to: W heel and Tire (204-04 Wheels and Tires, Removal and Installation).

Page 440 of 3039

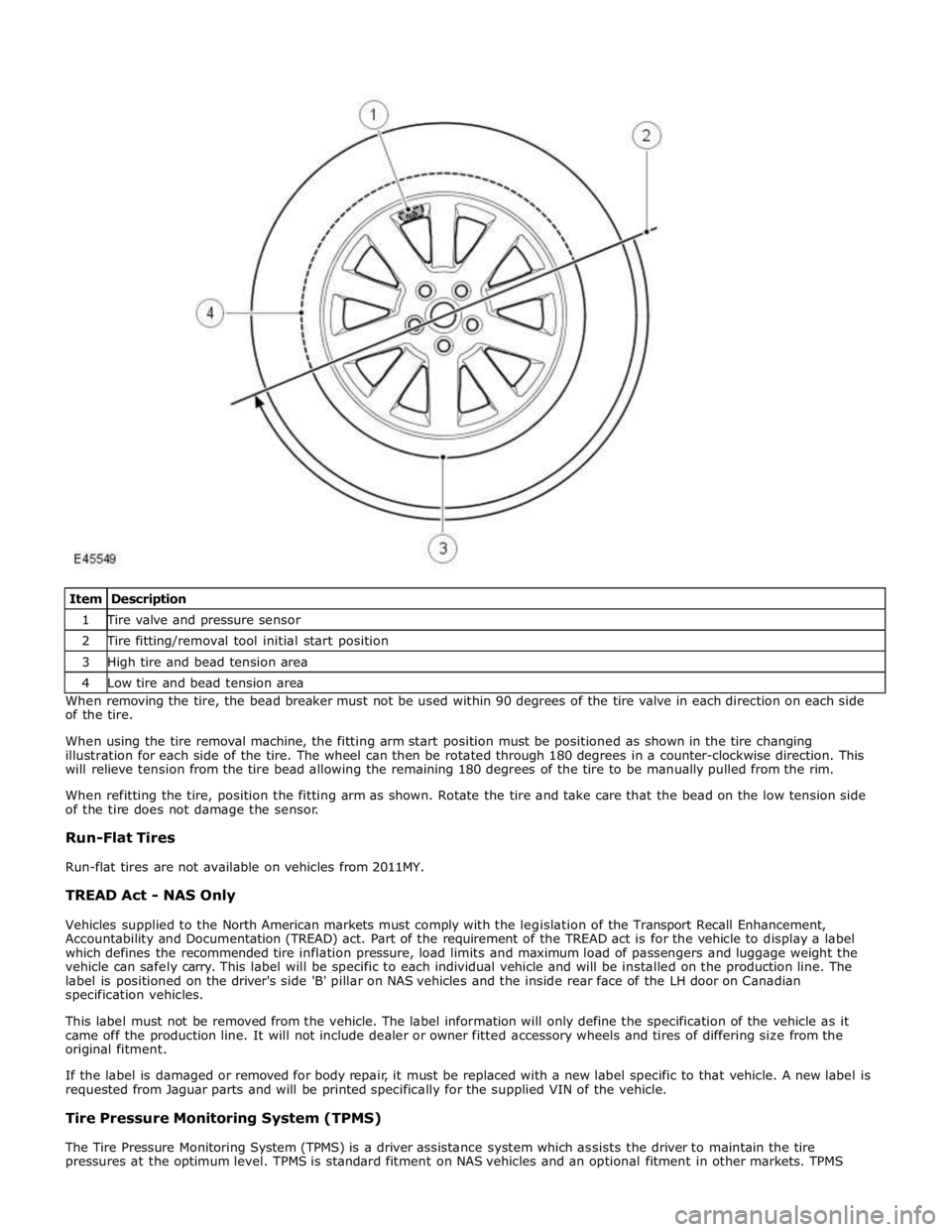

1 Tire valve and pressure sensor 2 Tire fitting/removal tool initial start position 3 High tire and bead tension area 4 Low tire and bead tension area When removing the tire, the bead breaker must not be used within 90 degrees of the tire valve in each direction on each side

of the tire.

When using the tire removal machine, the fitting arm start position must be positioned as shown in the tire changing

illustration for each side of the tire. The wheel can then be rotated through 180 degrees in a counter-clockwise direction. This

will relieve tension from the tire bead allowing the remaining 180 degrees of the tire to be manually pulled from the rim.

When refitting the tire, position the fitting arm as shown. Rotate the tire and take care that the bead on the low tension side

of the tire does not damage the sensor.

Run-Flat Tires

Run-flat tires are not available on vehicles from 2011MY.

TREAD Act - NAS Only

Vehicles supplied to the North American markets must comply with the legislation of the Transport Recall Enhancement,

Accountability and Documentation (TREAD) act. Part of the requirement of the TREAD act is for the vehicle to display a label

which defines the recommended tire inflation pressure, load limits and maximum load of passengers and luggage weight the

vehicle can safely carry. This label will be specific to each individual vehicle and will be installed on the production line. The

label is positioned on the driver's side 'B' pillar on NAS vehicles and the inside rear face of the LH door on Canadian

specification vehicles.

This label must not be removed from the vehicle. The label information will only define the specification of the vehicle as it

came off the production line. It will not include dealer or owner fitted accessory wheels and tires of differing size from the

original fitment.

If the label is damaged or removed for body repair, it must be replaced with a new label specific to that vehicle. A new label is

requested from Jaguar parts and will be printed specifically for the supplied VIN of the vehicle.

Tire Pressure Monitoring System (TPMS)

The Tire Pressure Monitoring System (TPMS) is a driver assistance system which assists the driver to maintain the tire

pressures at the optimum level. TPMS is standard fitment on NAS vehicles and an optional fitment in other markets. TPMS

Page 513 of 3039

Driveshaft - Driveshaft - Overview

Description and Operation

Driveshaft Overview Published: 11-May-2011

The two-piece driveshaft, manufactured from lightweight tubular steel, transmits drive from the engine, via the transmission,

to the differential. The driveshaft aligns with the centerline of the vehicle’s body and is supported by a center bearing.

Page 514 of 3039

Published: 11-May-2011

Driveshaft - Driveshaft - System Operation and Component Description

Description and Operation

Driveshaft System Operation

The two-piece driveshaft, manufactured from lightweight tubular steel, transmits drive from the engine, via the transmission,

to the differential. The driveshaft aligns with the centerline of the vehicle’s body and is supported by a center bearing.

The driveshaft's front tube is of swaged construction, which is a crash energy management feature, designed to collapse

progressively and predictably in the event of a severe frontal impact. A low-friction splined slip-joint at the center of the

driveshaft provide the driveshaft's plunge capability.

Flexible couplings connecting the driveshaft to both the transmission and the differential counteract the angular movement of

the driveshaft caused by the driveline's acceleration and braking forces.

The center universal joint is positioned at a specified angle using shims between the center bearing and the vehicle's body.

The driveline angles have been carefully configured to balance minimum power losses with excellent vibration and wear

characteristics. The universal joint is lubricated during manufacture and sealed for life.

www.JagDocs.com

Page 582 of 3039

Brake System - General Information - Brake System

Diagnosis and Testing

Principle of Operation Published: 11-May-2011

For a detailed description of the brake system, refer to the relevant Description and Operation sections in the workshop

manual. REFER to:

Front Disc Brake (206-03, Description and Operation),

Front Disc Brake (206-03, Description and Operation),

Front Disc Brake (206-03, Description and Operation),

Rear Disc Brake (206-04, Description and Operation),

Rear Disc Brake (206-04, Description and Operation),

Rear Disc Brake (206-04, Description and Operation),

Parking Brake (206-05 Parking Brake and Actuation, Description and Operation), Parking Brake (206-05 Parking Brake and Actuation, Description and Operation), Parking Brake (206-05 Parking Brake and Actuation, Description and Operation), Hydraulic Brake Actuation (206-06 Hydraulic Brake Actuation, Description and Operation), Hydraulic Brake Actuation (206-06 Hydraulic Brake Actuation, Description and Operation), Hydraulic Brake Actuation (206-06 Hydraulic Brake Actuation, Description and Operation), Brake Booster (206-07 Power Brake Actuation, Description and Operation), Brake Booster (206-07 Power Brake Actuation, Description and Operation), Brake Booster (206-07, Description and Operation).

Inspection and Verification

Visually examine the front and rear wheel and tire assemblies for damage such as uneven wear patterns, tread worn out or

sidewall damage. Verify the tires are the same size, type and, where possible, same manufacturer. Replace the damaged

wheel or excessively worn tire.

Wheels and tires must be cleared of any foreign matter and tire pressures adjusted to the correct specification.

If the tires exhibit uneven wear or feathering, the cause must be corrected. Check the steering and suspension components for

damage or wear and, if necessary, check and adjust front wheel alignment. REFER to: (204-00 Suspension System - General

Information)

Specifications (Specifications), Front Toe Adjustment (General Procedures).

Visual Inspection

Mechanical Electrical

Brake master cylinder

Brake caliper piston(s)

Brake discs

Wheel bearings

Brake pads

Power brake booster

Brake pedal linkage

Brake booster vacuum hose

Tires

Debris

Parking brake actuator

Parking brake module

Parking brake switch

Damaged or corroded wiring harness

Brake master cylinder fluid level switch Road Test

Carry out a road test to compare actual vehicle braking performance with the performance standards expected by the driver.

The ability of the test driver to make valid comparisons and detect performance deficiencies will depend on experience.

The driver should have a thorough knowledge of brake system operation and accepted general performance guidelines to make

good comparisons and detect performance concerns.

An experienced brake technician will always establish a route that will be used for all brake diagnosis road tests. The roads

selected will be reasonably smooth and level. Gravel or bumpy roads are not suitable because the surface does not allow the

tires to grip the road equally. Crowned roads should be avoided because of the large amount of weight shifted to the low set

of wheels on this type of road. Once the route is established and consistently used, the road surface variable can be

eliminated from the test results.

Before a road test, obtain a complete description of the customer concerns or suspected condition. From the description, the

technician's experience will allow the technician to match possible causes with symptoms. Certain components will be tagged

as possible suspects while others will be eliminated by the evidence. More importantly, the customer description can reveal

unsafe conditions which should be checked or corrected before the road test. The description will also help form the basic

approach to the road test by narrowing the concern to specific components, vehicle speed or conditions.

Begin the road test with a general brake performance check. Keeping the description of the concern in mind, test the brakes at

different vehicle speeds using both light and heavy pedal pressure. To determine if the concern is in the front or rear braking

system, use the brake pedal and then use the parking brake control. If the condition (pull, vibration, pulsation) occurs only

with the parking brake, the concern is in the rear brake system.

Page 695 of 3039

Press and hold the DSC switch for less than 10 seconds.

The message center will temporarily display either Trac DSC or DSC ON.

The warning indicator in the instrument panel will illuminate while Trac DSC is selected.

The warning indicator will flash when DSC or Trac DSC is active.

NOTE: If cruise control is engaged, it will automatically disengage if DSC activates.

Refer to: Speed Control (310-03 Speed Control - 2.7L V6 - TdV6, Description and Operation).

Corner Brake Control

CBC (corner brake control) influences the brake pressures, below and within DSC and ABS thresholds, to counteract the yawing moment produced when braking in a corner. CBC produces a correction torque by limiting the brake pressure on one side of the

vehicle.

Electronic Brake Force Distribution

EBD (electronic brake force distribution) limits the brake pressure applied to the rear wheels. When the brakes are applied, the

weight of the vehicle transfers forwards, reducing the ability of the rear wheels to transfer braking effort to the road surface.

This may cause the rear wheels to slip and make the vehicle unstable.

EBD uses the ABS braking hardware to automatically optimize the pressure to the rear brakes, below the point where ABS is normally invoked.

NOTE: Only the rear brakes are controlled by the EBD function.

Electronic Traction Control

ETC (electronic traction control) attempts to optimize forward traction by reducing engine torque, or by applying the brake of a

spinning wheel until traction is regained.

ETC is activated if an individual wheel speed is above that of the vehicle reference speed (positive slip) and the brake pedal is

not pressed. The brake is applied to the spinning wheel, allowing the excess torque to be transmitted to the non-spinning

wheel through the drive line. If necessary, the ABS module also sends a high speed CAN bus message to the ECM to request a reduction in engine torque.

When the DSC function is selected off using the DSC switch, the braking and engine torque reduction features are both

disabled, except when the JaguarDrive control is in winter mode. When the JaguarDrive control is in winter mode, selecting the

DSC function off retains the braking and engine torque reduction features, but reduces intervention levels compared to DSC

and Trac DSC modes.

Emergency Brake Assist

EBA (emergency brake assist) assists the driver in emergency braking situations by automatically increasing the applied

braking effort. The ABS module invokes EBA when: The brake pedal is rapidly pressed.

The brake pedal is pressed hard enough to bring the front brakes into ABS operation.

When the brake pedal is rapidly pressed, the ABS module increases the hydraulic pressure to all of the brakes until the threshold for ABS operation is reached. This action applies the maximum braking effort for the available traction. The ABS module monitors for the sudden application of the brakes, using inputs from the brake pedal switch and from the pressure

sensor within the HCU (hydraulic control unit). With the brake pedal pressed, if the rate of increase of hydraulic pressure

exceeds the predetermined limit, the ABS module invokes emergency braking.

When the brake pedal is pressed hard enough to bring the front brakes into ABS operation, the ABS module increases the hydraulic pressure to the rear brakes up to the ABS threshold.

EBA operation continues until the driver releases the brake pedal, sufficiently for the hydraulic pressure in the HCU to drop below a threshold value stored in the ABS module.

Engine Drag-Torque Control

EDC (engine drag-torque control) prevents wheel slip caused by any of the following: A

sudden decrease in engine torque when the accelerator is suddenly released.

A downshift using the Jaguar sequential shift function on automatic transmission vehicles.

When the ABS module detects the onset of wheel slip without the brakes being applied, the ABS module signals the ECM via the high speed CAN bus to request a momentary increase in engine torque.

Understeer Control

Understeer Logic Control is a proactive system which monitors the vehicle for understeer by comparing signals from the yaw

rate and lateral acceleration sensor with signals from the steering angle sensor and wheel speed sensors. www.JagDocs.com

Page 858 of 3039

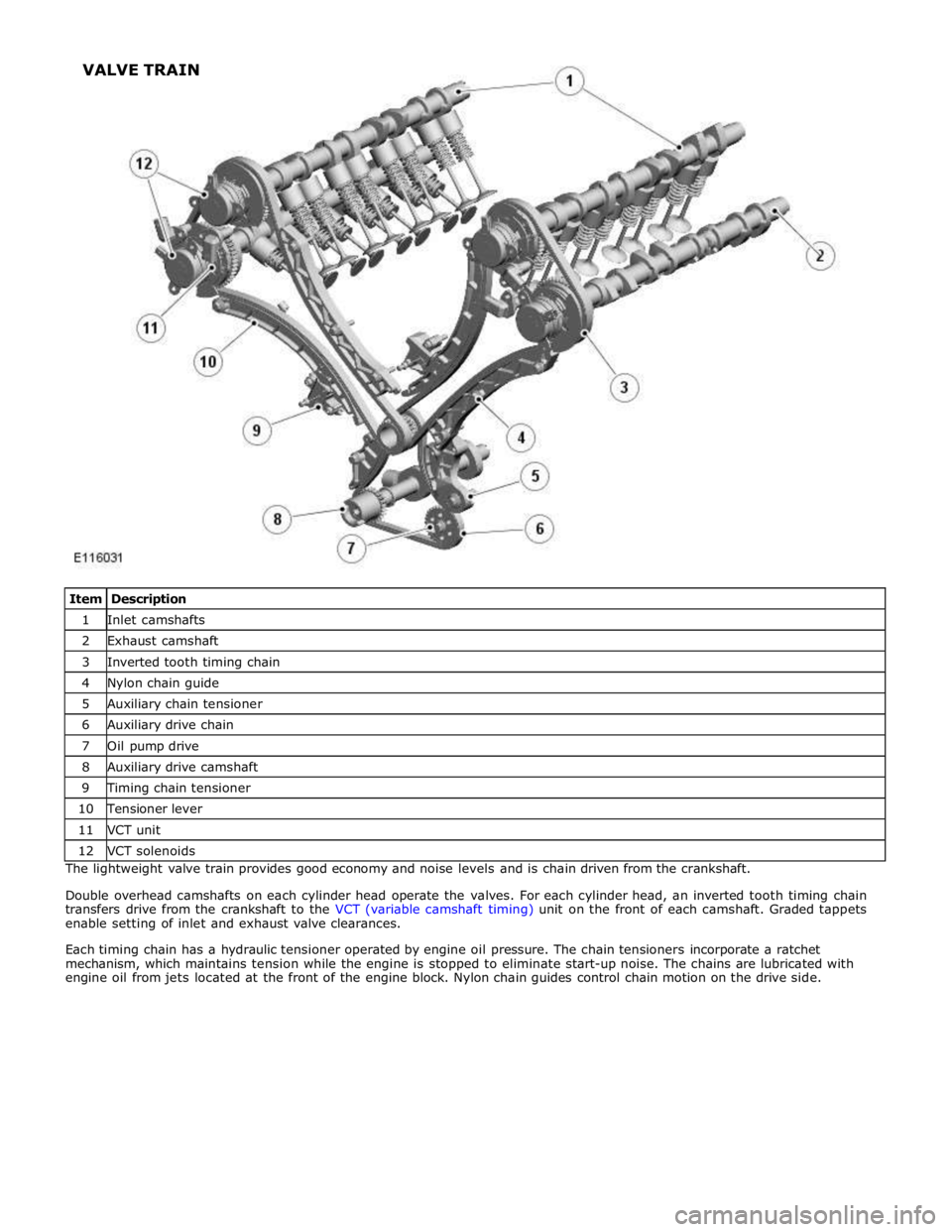

1 Inlet camshafts 2 Exhaust camshaft 3 Inverted tooth timing chain 4 Nylon chain guide 5 Auxiliary chain tensioner 6 Auxiliary drive chain 7 Oil pump drive 8 Auxiliary drive camshaft 9 Timing chain tensioner 10 Tensioner lever 11 VCT unit 12 VCT solenoids The lightweight valve train provides good economy and noise levels and is chain driven from the crankshaft.

Double overhead camshafts on each cylinder head operate the valves. For each cylinder head, an inverted tooth timing chain

transfers drive from the crankshaft to the VCT (variable camshaft timing) unit on the front of each camshaft. Graded tappets

enable setting of inlet and exhaust valve clearances.

Each timing chain has a hydraulic tensioner operated by engine oil pressure. The chain tensioners incorporate a ratchet

mechanism, which maintains tension while the engine is stopped to eliminate start-up noise. The chains are lubricated with

engine oil from jets located at the front of the engine block. Nylon chain guides control chain motion on the drive side. VALVE TRAIN

Page 1360 of 3039

4 Diagnostic socket 5 To other system control modules 6 ECM 7 Electronic throttle 8 APP sensor 9 AAT sensor 10 ECT sensor (ECT 1) 11 LH upstream HO2S 12 LH downstream HO2S 13 MAPT (manifold absolute pressure and temperature) sensor 14 RH downstream HO2S 15 RH upstream HO2S

ECM ADAPTIONS System Operation

The ECM (engine control module) has the ability to adapt the input values it uses to control certain outputs. This capability

maintains engine refinement and ensures the engine emissions remain within the legislated limits. The components which

have adaptions associated with them are:

The APP (accelerator pedal position) sensor

The heated oxygen sensors

The MAFT (mass air flow and temperature) sensors

The CKP (crankshaft position) sensor

Electronic throttle.

OXYGEN AND MAFT SENSORS

There are several adaptive maps associated with the fueling strategy. Within the fueling strategy the ECM calculates short-term adaptions and long term adaptions. The ECM will monitor the deterioration of the heated oxygen sensors over a period of time. It will also monitor the current correction associated with the sensors.

The ECM will store a fault code in circumstances where an adaption is forced to exceed its operating parameters. At the same time, the ECM will record the engine speed, engine load and intake air temperature.

CRANKSHAFT POSITION SENSOR

The characteristics of the signal supplied by the CKP sensor are learned by the ECM. This enables the ECM to set an adaption and support the engine misfire detection function. Due to the small variation between different drive plates and different CKP sensors, the adaption must be reset if either component is renewed, or removed and refitted. It is also necessary to reset the

drive plate adaption if the ECM is renewed or replaced. The ECM supports four drive plate adaptions for the CKP sensor. Each adaption relates to a specific engine speed range. The engine speed ranges are detailed in the table below:

Adaption Engine Speed, rev/min 1 1800 - 3000 2 3001 - 3800 3 3801 - 4600 4 4601 - 5400 MISFIRE DETECTION

Legislation requires that the ECM must be able to detect the presence of an engine misfire. It must be able to detect misfires at two separate levels. The first level is a misfire that could lead to the legislated emissions limit being exceeded by a given

amount. The second level is a misfire that may cause catalytic converter damage.

The ECM monitors the number of misfire occurrences within two engine speed ranges. If the ECM detects more than a predetermined number of misfire occurrences within either of these two ranges, over two consecutive journeys, it will record a

fault code and details of the engine speed, engine load and engine coolant temperature. In addition, the ECM monitors the number of misfire occurrences that happen in a 'window' of 200 engine revolutions. The misfire occurrences are assigned a

weighting according to their likely impact on the catalytic converters. If the number of misfires exceeds a given value, the ECM stores catalytic converter damage fault codes, along with the engine speed, engine load and engine coolant temperature.

The signal from the CKP sensor indicates how fast the poles on the drive plate are passing the sensor tip. A sine wave is generated each time a pole passes the sensor tip. The ECM can detect variations in drive plate speed by monitoring the sine wave signal supplied by the crankshaft position sensor. By assessing this signal, the ECM can detect the presence of an engine misfire. At this time, the ECM will assess the amount of variation in the signal received from the CKP sensor and assign a roughness value to it. This roughness value can be viewed within the real time monitoring feature using Jaguar approved

diagnostic equipment. TheECM will evaluate the signal against a number of factors and will decide whether to record the occurrence or ignore it. The ECM can assign a roughness and misfire signal for each cylinder.

Page 1666 of 3039

TEST

CONDITIONS DETAILS/RESULTS/ACTIONS C1: GAUGE TEST 1

NOTE: This test is performed with the engine running and the air conditioning set to on. 1 Check the pressure values Did the gauges register a change in pressure when the air conditioning was switched on? Yes

GO to C2. No

Using the manufacturer approved diagnostic system, check the Automatic Temperature Control Module (ATCM) for related DTCs and refer to the relevant DTC index C2: GAUGE TEST 2

NOTE: This test is performed with the engine running and the air conditioning set to on. 1 Check the pressure values Are the pressure gauge readings fluctuating? Yes

Moisture present in the air conditioning system. Recover the refrigerant. Install a new receiver drier.

Refer to the relevant section of the workshop manual and evacuate and recharge the air conditioning

system. GO to Pinpoint Test B. No

GO to C3. C3: GAUGE TEST 3 NOTES:

This test is performed with the engine running and the air conditioning set to on.

Normal pressures for a correctly charged and working system are 1.0 bar to 2.0 bar (low) and 11.0 bar to 15.0 bar (high). 1 Check the pressure values Are the pressure gauge readings too low? Yes

GO to C4. No

GO to C6. C4: GAUGE TEST 4

NOTE: This test is performed with the engine not running. 1 Stop the engine 2 Using the manufacturer approved refrigerant leak detector, check for a refrigerant leak Was a refrigerant leak detected? Yes

Refer to the relevant section of the workshop manual and recover the refrigerant. Repair as necessary.

Evacuate and recharge the air conditioning system. GO to Pinpoint Test B. No

GO to C5. C5: GAUGE TEST 5

NOTE: This test is performed with the engine not running. 1 Refer to the relevant section of the workshop manual and recover the refrigerant Was the weight of the recovered refrigerant less than specified for the air conditioning system? Yes

Refer to the relevant section of the workshop manual and evacuate and recharge the air conditioning

system. GO to Pinpoint Test B. No

Install a new receiver drier. Refer to the relevant section of the workshop manual and evacuate and recharge the air conditioning system. GO to Pinpoint Test B. C6: GAUGE TEST 6 NOTES:

This test is performed with the engine running and the air conditioning set to on.

Normal pressures for a correctly charged and working system are 1.0 bar to 2.0 bar (low) and 11.0 bar to 15.0 bar (high).

Page 1667 of 3039

1 Check the pressure values Are the pressure gauge readings too high? Yes

GO to C7. No

Test inconclusive. GO to Pinpoint Test B. C7: GAUGE TEST 7

NOTE: This test is performed with the engine not running. 1 Stop the engine 2 Refer to the relevant section of the workshop manual and recover the refrigerant Was the weight of the recovered refrigerant more than specified for the air conditioning system? Yes

Refer to the relevant section of the workshop manual and evacuate and recharge the air conditioning

system. GO to Pinpoint Test B. No

Install a new thermal expansion valve. Refer to the relevant section of the workshop manual and

evacuate and recharge the air conditioning system. GO to Pinpoint Test B.

PINPOINT TEST D : NITROGEN LEAK TESTS TEST

CONDITIONS DETAILS/RESULTS/ACTIONS D1: NITROGEN LEAK TEST

CAUTION: When charging the system with nitrogen, the pressure should be regulated to 7.0 bar.

NOTE: This test is performed with the engine not running. 1 Charge the air conditioning system with nitrogen 2 Isolate the nitrogen supply 3 Monitor the pressure gauge and check for leaks Has the source of the leak been identified?

Yes

Rectify the leak as necessary. Install a new receiver drier. Refer to the relevant section of the workshop

manual and evacuate and recharge the air conditioning system. GO to Pinpoint Test B. No

Refer to the relevant section of the workshop manual and evacuate and recharge the air conditioning system. GO to Pinpoint Test B.

DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00.

REFER to: Diagnostic Trouble Code (DTC) Index - DTC: Climate Control Module (HVAC) (100-00 General Information, Description and Operation).