ABS JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 171 of 3039

DTC Description Possible Causes Action

LR - Circuit UHEGO HEATER B -

Catalyst oxygen sensor heater

circuit control fuse failure

Post catalyst oxygen sensor-even

heater control circuit short circuit

to ground, short circuit to power,

open circuit, high resistance

Catalyst oxygen sensor heater

circuit control relay circuit short

circuit to ground, short circuit to

power, open circuit

Catalyst oxygen sensor heater

circuit control relay failure

Post catalyst oxygen sensor-even

failure Refer to the electrical circuit

diagrams and check post catalyst

oxygen sensor-even sensor fuse for

open circuit

Refer to the electrical circuit

diagrams and check post catalyst

oxygen sensor-even sensor circuit for

short circuit to ground, short circuit

to power, open circuit, high

resistance

Refer to the electrical circuit

diagrams and check catalyst oxygen

sensor heater circuit control relay

circuit for short circuit to ground,

short circuit to power, open circuit

Check and install a new catalyst

oxygen sensor heater control relay,

as required. Check and install a new

post catalyst oxygen sensor-even as

required. Refer to the warranty policy

and procedures manual, or determine

if any prior approval programme is in

operation, prior to the installation of

a new module/component P0069-29

MAP - Barometric Pressure

Correlation - Signal invalid

Manifold absolute pressure sensor

failure

Engine control module failure

Using the manufacturer approved

diagnostic system check datalogger

signal, Barometric Pressure Sensor

Voltage (0x035A). Check for related

manifold absolute pressure sensor

DTCs

Refer to the electrical circuit

diagrams and check manifold

absolute pressure sensor circuit for

short circuit to ground, short circuit

to power, open circuit

Check and install new manifold

absolute pressure sensor as

required. Check and install a new

engine control module as required.

Refer to the warranty policy and

procedures manual, or determine if

any prior approval programme is in

operation, prior to the installation of

a new module/component P0071-21

Ambient Air Temperature

Sensor Range/Performance -

Signal amplitude < minimum NOTES:

Jaguar - Circuit

AMBIENT_TEMP_SENSOR -

LR - Circuit TAMB TEMP -

Ambient air temperature sensor

circuit short circuit to ground, short

circuit to power, open circuit

Temperature and manifold absolute

pressure sensor circuit short circuit

to ground, short circuit to power,

open circuit

Ambient air temperature sensor

failure

Temperature and manifold absolute

pressure sensor failure

Using the manufacturer approved

diagnostic system check datalogger

signal, Ambient Air Temperature

Sensor Voltage (0x03BA)

Refer to the electrical circuit

diagrams and check ambient air

temperature sensor circuit for short

circuit to ground, short circuit to

power, open circuit

Refer to the electrical circuit

diagrams and check temperature and

manifold absolute pressure sensor

circuit for short circuit to ground,

short circuit to power, open circuit

Check and install a new ambient air

temperature sensor as required.

Check and install a new temperature

and manifold absolute pressure

sensor as required. Refer to the

warranty policy and procedures

manual, or determine if any prior

approval programme is in operation,

prior to the installation of a new

module/component P0071-22

Ambient Air Temperature

Sensor Range/Performance -

Signal amplitude > maximum NOTES:

- Circuit AMBIENT_TEMP_SENSOR -

Using the manufacturer approved

diagnostic system check datalogger

signal, Ambient Air Temperature

Sensor Voltage (0x03BA)

Refer to the electrical circuit www.JagDocs.com

Page 172 of 3039

DTC Description Possible Causes Action

LR - Circuit TAMB TEMP -

Ambient air temperature sensor

circuit short circuit to ground, short

circuit to power, open circuit

Temperature and manifold absolute

pressure sensor circuit short circuit

to ground, short circuit to power,

open circuit

Ambient air temperature sensor

failure

Temperature and manifold absolute

pressure sensor failure diagrams and check ambient air

temperature sensor circuit for short

circuit to ground, short circuit to

power, open circuit

Refer to the electrical circuit

diagrams and check temperature and

manifold absolute pressure sensor

circuit for short circuit to ground,

short circuit to power, open circuit

Check and install a new ambient air

temperature sensor as required.

Check and install a new temperature

and manifold absolute pressure

sensor as required. Refer to the

warranty policy and procedures

manual, or determine if any prior

approval programme is in operation,

prior to the installation of a new

module/component P0072-00

Ambient Air Temperature

Sensor Circuit Low - No sub

type information NOTES:

- Circuit AMBIENT_TEMP_SENSOR -

LR - Circuit TAMB TEMP -

Ambient air temperature sensor

circuit short circuit to ground, open

circuit, high resistance

Ambient air temperature sensor

failure

Using the manufacturer approved

diagnostic system check datalogger

signal, Ambient Air Temperature

Sensor Voltage (0x03BA)

Refer to the electrical circuit

diagrams and check ambient air

temperature sensor circuit for short

circuit to ground, open circuit, high

resistance

Check and install a new ambient air

temperature sensor as required.

Refer to the warranty policy and

procedures manual, or determine if

any prior approval programme is in

operation, prior to the installation of

a new module/component P0073-00

Ambient Air Temperature

Sensor Circuit High - No sub

type information NOTES:

- Circuit AMBIENT_TEMP_SENSOR -

LR - Circuit TAMB TEMP -

Ambient air temperature sensor

ground circuit high resistance,

open circuit

Ambient air temperature sensor

signal circuit short circuit to power

Ambient air temperature sensor

failure

Using the manufacturer approved

diagnostic system check datalogger

signals Ambient Air Temperature

Sensor Voltage (0x03BA)

Refer to the electrical circuit

diagrams and check ambient air

temperature sensor circuit for short

circuit to ground, high resistance,

short circuit to power. Check

connector terminals for corrosion or

damage

Check and install a new ambient air

temperature sensor as required.

Refer to the warranty policy and

procedures manual, or determine if

any prior approval programme is in

operation, prior to the installation of

a new module/component P007B-23

Charge Air Cooler

Temperature Sensor Circuit

Range/Performance (Bank 1)

- Signal stuck low

NOTE: - Circuit TMAP_TEMP_SENSOR

-

Charge air cooler temperature

sensor circuit poor / intermittent

connection

Charge air cooler temperature

sensor failure

Using the manufacturer approved

diagnostic system check datalogger

signal, Charge Air Temperature

Voltage (0x03EE)

Refer to the electrical circuit

diagrams and check charge air cooler

temperature sensor circuit for poor,

intermittent connection

Check and install a new charge air

cooler temperature sensor as

required. Refer to the warranty policy

and procedures manual, or determine

if any prior approval programme is in

operation, prior to the installation of

a new module/component

Page 173 of 3039

DTC Description Possible Causes Action P007B-24

Charge Air Cooler

Temperature Sensor Circuit

Range/Performance (Bank 1)

- Signal stuck high

NOTE: Jaguar circuit reference

IC_COOLANT_PMP_CTRL &

BOOST_PRESS_SENSOR_TEMP_SIG. Land

Rover circuit reference O_S_CACWPR &

I_A_BTS

Connector is disconnected,

connector pin is backed out,

connector pin corrosion

Fuse failure

Temperature and manifold absolute

pressure sensor circuit, short

circuit to ground, short circuit to

power, open circuit, high resistance

Temperature and manifold absolute

pressure sensor failure

Air charge coolant pump and

control circuit, short circuit to

ground, short circuit to power, open

circuit, high resistance

Air charge coolant pump relay

failure

Air charge coolant pump failure

Inspect connectors for signs of water

ingress, and pins for damage and/or

corrosion

Refer to electrical circuit diagrams

and check for fuse failure, install

new fuse as required

Refer to electrical circuit diagrams

and check the temperature and

manifold absolute pressure sensor

circuit for short circuit to ground,

short circuit to power, open circuit,

high resistance

Check and install a new temperature

and manifold absolute pressure

sensor as required

Refer to electrical circuit diagrams

and check the air charge coolant

pump and control circuit for short

circuit to ground, short circuit to

power, open circuit, high resistance

Refer to electrical circuit diagrams

and check the air charge coolant

pump for open circuit, high

resistance

Refer to the relevant section of the

workshop manual and check the air

charge coolant pump for correct

operation. Check and install a new

air charge coolant pump as required

Clear DTC and retest P007B-29

Charge Air Cooler

Temperature Sensor Circuit

Range/Performance (Bank 1)

- Signal invalid

NOTE: Jaguar circuit reference

IC_COOLANT_PMP_CTRL &

BOOST_PRESS_SENSOR_TEMP_SIG. Land

Rover circuit reference O_S_CACWPR &

I_A_BTS

Connector is disconnected,

connector pin is backed out,

connector pin corrosion

Fuse failure

Temperature and manifold absolute

pressure sensor circuit, short

circuit to ground, short circuit to

power, open circuit, high resistance

Temperature and manifold absolute

pressure sensor failure

Air charge coolant pump and

control circuit, short circuit to

ground, short circuit to power, open

circuit, high resistance

Air charge coolant pump relay

failure

Air charge coolant pump failure

Inspect connectors for signs of water

ingress, and pins for damage and/or

corrosion

Refer to electrical circuit diagrams

and check for fuse failure, install

new fuse as required

Refer to electrical circuit diagrams

and check the temperature and

manifold absolute pressure sensor

circuit for short circuit to ground,

short circuit to power, open circuit,

high resistance

Check and install a new temperature

and manifold absolute pressure

sensor as required

Refer to electrical circuit diagrams

and check the air charge coolant

pump and control circuit for short

circuit to ground, short circuit to

power, open circuit, high resistance

Refer to electrical circuit diagrams

and check the air charge coolant

pump for open circuit, high

resistance

Refer to the relevant section of the

workshop manual and check the air

charge coolant pump for correct

operation. Check and install a new

air charge coolant pump as required

Clear DTC and retest P007C-00

Charge Air Cooler

Temperature Sensor Circuit

Low (Bank 1) - No sub type

information

NOTE: - Circuit TMAP_TEMP_SENSOR

-

Charge air cooler temperature

sensor (Bank 1) circuit short circuit

to ground, open circuit, high

resistance

Charge air cooler temperature

sensor (Bank 1) failure

Refer to the electrical circuit

diagrams and check charge air cooler

temperature sensor (Bank 1) circuit

for short circuit to ground, open

circuit, high resistance

Check and install a new charge air

cooler temperature sensor (Bank 1)

as required. Refer to the warranty

policy and procedures manual, or

determine if any prior approval

programme is in operation, prior to

the installation of a new

module/component

Page 184 of 3039

DTC Description Possible Causes Action B10AE-64

Headlamp Leveling

Motor - Signal

plausibility failure

Signal plausibility

failure voltage out of

range

Refer to the electrical circuit diagrams and check the

Headlamp Leveling Motor circuits for failure. Disconnect one

headlamp connector, clear DTC and re-test. If DTC cleared,

suspect Headlamp Leveling Module or circuits to the

disconnected side. If DTC remains, reconnect first

headlamp and disconnect second, clear DTC and re-test. If

DTC cleared, suspect Headlamp Leveling Module or circuits

to the disconnected side. If DTC remains, suspect common

circuits of the failure. Refer to the electrical circuit diagrams

and check as required B1A59-11

Sensor 5 Volt

Supply - Circuit

short to ground

Headlamp Leveling

Sensor 5 volt supply

circuit short to ground

Refer to electrical circuit diagrams and check Headlamp

Leveling Sensor 5 volt supply circuit for short to ground B1A59-12

Sensor 5 Volt

Supply - General

electrical failure

Headlamp Leveling

Sensor 5 volt supply

circuit short to power

Refer to electrical circuit diagrams and check Headlamp

Leveling Sensor 5 volt supply circuit for short to power C1A04-11

Right Front Height

Sensor - Circuit

short to ground

Right front Height

Sensor circuit short to

ground

Refer to the electrical circuit diagrams, and check Right

Front Height Sensor circuit for short to ground C1A04-15

Right Front Height

Sensor - Circuit

short to battery or

open

Right front Height

Sensor circuit short to

power or open circuit

Check Right Front Height Sensor connector for security.

Refer to the electrical circuit diagrams, and check Right

Front Height Sensor circuit for short to power or open circuit C1A04-64

Right Front Height

Sensor - Signal

plausibility failure

Sensor (PWM) Signal

out of range

NOTE: This DTC may be logged if the vehicles wheels have

been raised from the floor

Check the location, security and mechanical operation of

the Height Sensor. Refer to the electrical circuit diagrams,

and check Right Front Height Sensor signal circuit for fault C1A06-11

Right Rear Height

Sensor - Circuit

short to ground

Right rear Height

Sensor circuit short to

ground

Refer to the electrical circuit diagrams, and check Right

Rear Height Sensor circuit for short to ground C1A06-15

Right Rear Height

Sensor - Circuit

short to battery or

open

Right rear Height

Sensor circuit short to

power or open circuit

Check Right Rear Height Sensor connector for security. Refer

to the electrical circuit diagrams, and check Right Rear

Height Sensor circuit for short to power or open circuit C1A06-64

Right Rear Height

Sensor - Signal

plausibility failure

Sensor (PWM) Signal

out of range

NOTE: This DTC may be logged if the vehicles wheels have

been raised from the floor

Check the location, security and mechanical operation of

the Height Sensor. Refer to the electrical circuit diagrams,

and check Right Rear Height Sensor signal circuit for fault U0001-88

High Speed CAN

Communication Bus

- Bus off

CAN Bus Off

CAN Bus Circuit fault

Check other modules for stored DTCs. Carry out the CAN

Network Integrity test using the manufacturer approved

diagnostic system U0101-00

Lost Communication

with TCM - No sub

type information

Lost communication

with the Transmission

Control Module

CAN network fault

Check the Transmission Control Module for stored DTCs.

Using the manufacturer approved diagnostic system,

complete the CAN Network Integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the Headlamp Leveling Module and the

Transmission Control Module U0121-00

Lost Communication

With Anti-Lock

Brake System (ABS)

Control Module - No

sub type

information

Lost communication

with the Anti-lock

Brake System Module

CAN network fault

Check the Anti-lock Brake System Module for stored DTCs.

Using the manufacturer approved diagnostic system,

complete the CAN Network Integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the Headlamp Leveling Module and the Anti-lock

Brake System Module

Page 185 of 3039

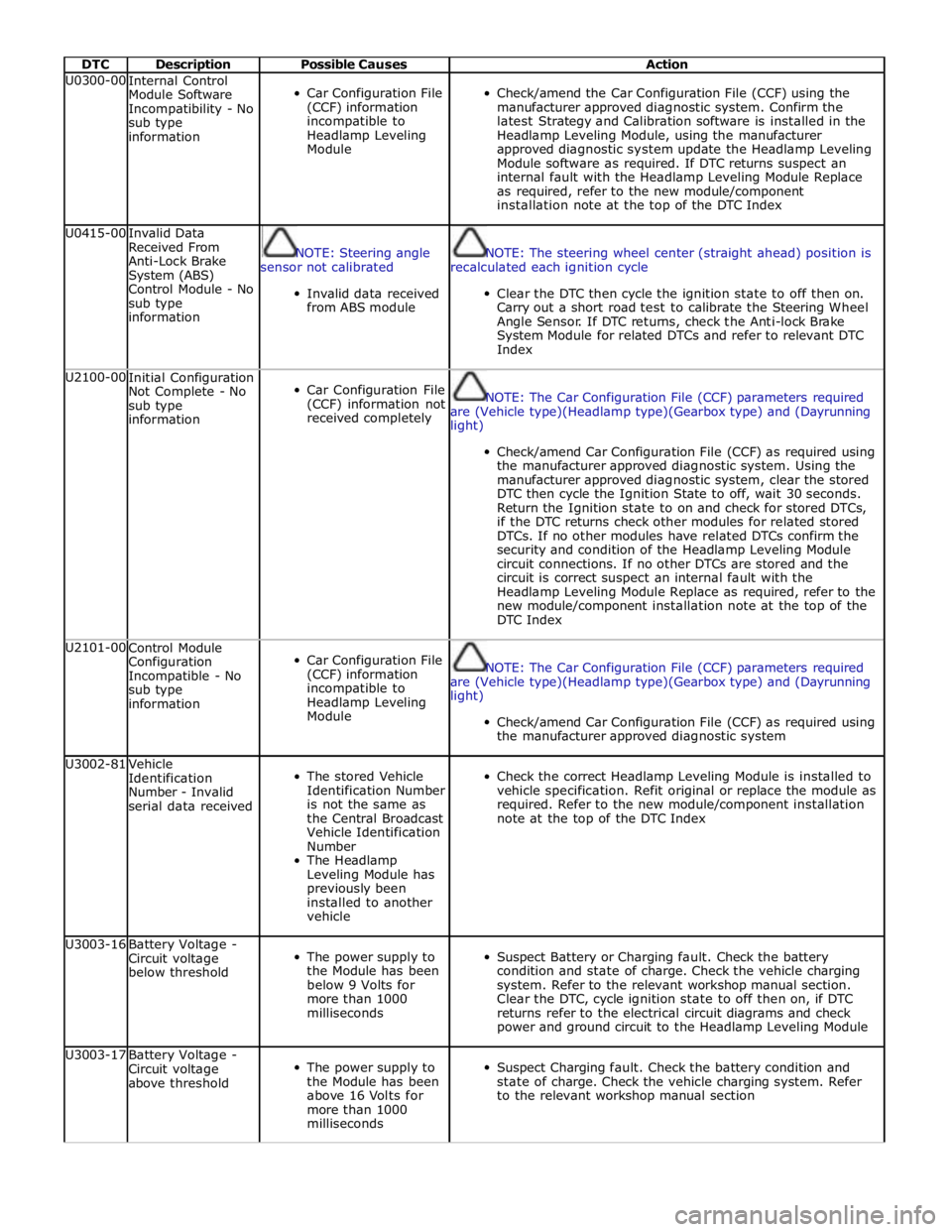

DTC Description Possible Causes Action U0300-00

Internal Control

Module Software

Incompatibility - No

sub type

information

Car Configuration File

(CCF) information

incompatible to

Headlamp Leveling

Module

Check/amend the Car Configuration File (CCF) using the

manufacturer approved diagnostic system. Confirm the

latest Strategy and Calibration software is installed in the

Headlamp Leveling Module, using the manufacturer

approved diagnostic system update the Headlamp Leveling

Module software as required. If DTC returns suspect an

internal fault with the Headlamp Leveling Module Replace

as required, refer to the new module/component

installation note at the top of the DTC Index U0415-00

Invalid Data

Received From

Anti-Lock Brake

System (ABS)

Control Module - No

sub type

information

NOTE: Steering angle

sensor not calibrated

Invalid data received

from ABS module

NOTE: The steering wheel center (straight ahead) position is

recalculated each ignition cycle

Clear the DTC then cycle the ignition state to off then on.

Carry out a short road test to calibrate the Steering Wheel

Angle Sensor. If DTC returns, check the Anti-lock Brake

System Module for related DTCs and refer to relevant DTC

Index U2100-00

Initial Configuration

Not Complete - No

sub type

information

Car Configuration File

(CCF) information not

received completely

NOTE: The Car Configuration File (CCF) parameters required

are (Vehicle type)(Headlamp type)(Gearbox type) and (Dayrunning

light)

Check/amend Car Configuration File (CCF) as required using

the manufacturer approved diagnostic system. Using the

manufacturer approved diagnostic system, clear the stored

DTC then cycle the Ignition State to off, wait 30 seconds.

Return the Ignition state to on and check for stored DTCs,

if the DTC returns check other modules for related stored

DTCs. If no other modules have related DTCs confirm the

security and condition of the Headlamp Leveling Module

circuit connections. If no other DTCs are stored and the

circuit is correct suspect an internal fault with the

Headlamp Leveling Module Replace as required, refer to the

new module/component installation note at the top of the

DTC Index U2101-00

Control Module

Configuration

Incompatible - No

sub type

information

Car Configuration File

(CCF) information

incompatible to

Headlamp Leveling

Module

NOTE: The Car Configuration File (CCF) parameters required

are (Vehicle type)(Headlamp type)(Gearbox type) and (Dayrunning

light)

Check/amend Car Configuration File (CCF) as required using

the manufacturer approved diagnostic system U3002-81

Vehicle

Identification

Number - Invalid

serial data received

The stored Vehicle

Identification Number

is not the same as

the Central Broadcast

Vehicle Identification

Number

The Headlamp

Leveling Module has

previously been

installed to another

vehicle

Check the correct Headlamp Leveling Module is installed to

vehicle specification. Refit original or replace the module as

required. Refer to the new module/component installation

note at the top of the DTC Index U3003-16

Battery Voltage -

Circuit voltage

below threshold

The power supply to

the Module has been

below 9 Volts for

more than 1000

milliseconds

Suspect Battery or Charging fault. Check the battery

condition and state of charge. Check the vehicle charging

system. Refer to the relevant workshop manual section.

Clear the DTC, cycle ignition state to off then on, if DTC

returns refer to the electrical circuit diagrams and check

power and ground circuit to the Headlamp Leveling Module U3003-17

Battery Voltage -

Circuit voltage

above threshold

The power supply to

the Module has been

above 16 Volts for

more than 1000

milliseconds

Suspect Charging fault. Check the battery condition and

state of charge. Check the vehicle charging system. Refer

to the relevant workshop manual section

Page 188 of 3039

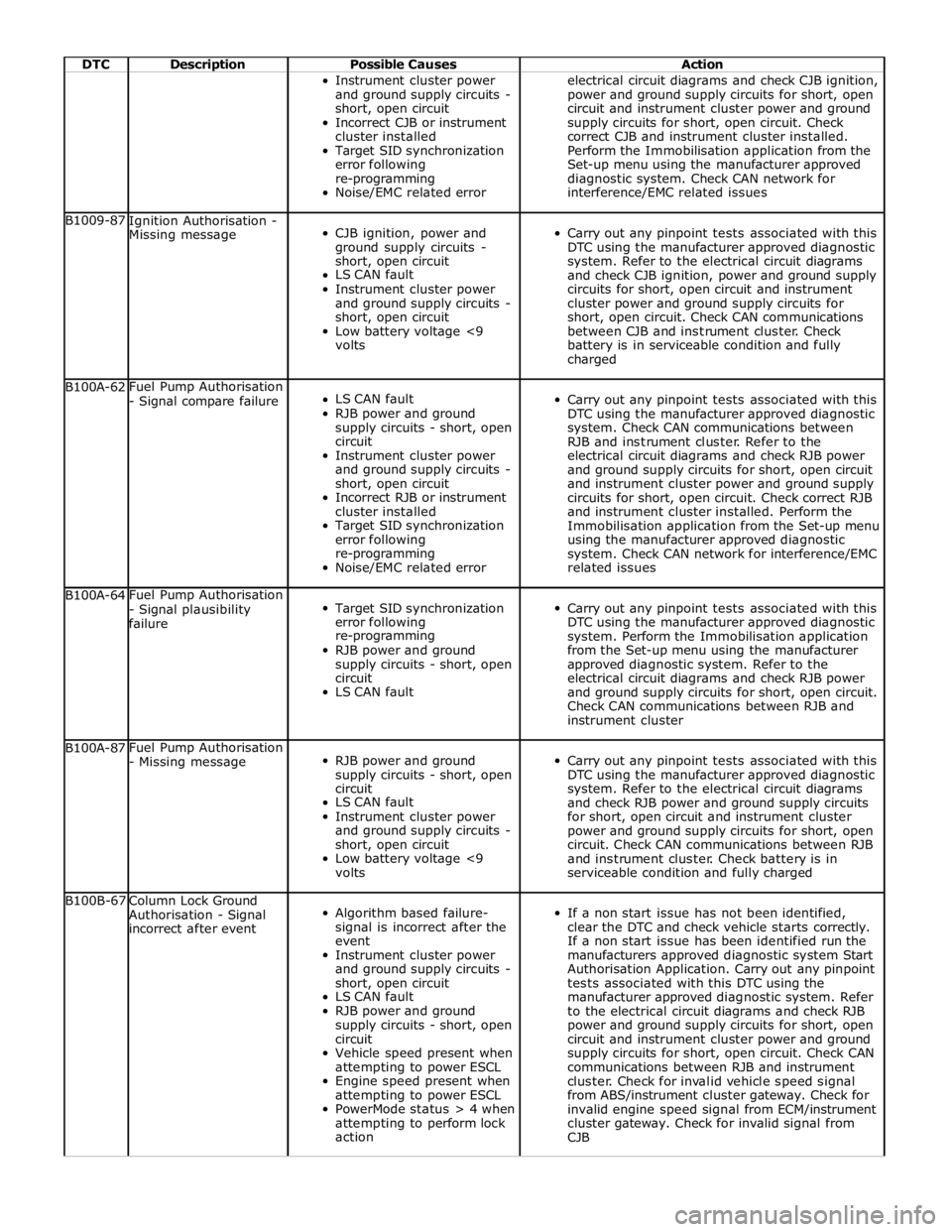

DTC Description Possible Causes Action Instrument cluster power

and ground supply circuits -

short, open circuit

Incorrect CJB or instrument

cluster installed

Target SID synchronization

error following

re-programming

Noise/EMC related error electrical circuit diagrams and check CJB ignition,

power and ground supply circuits for short, open

circuit and instrument cluster power and ground

supply circuits for short, open circuit. Check

correct CJB and instrument cluster installed.

Perform the Immobilisation application from the

Set-up menu using the manufacturer approved

diagnostic system. Check CAN network for

interference/EMC related issues B1009-87

Ignition Authorisation -

Missing message

CJB ignition, power and

ground supply circuits -

short, open circuit

LS CAN fault

Instrument cluster power

and ground supply circuits -

short, open circuit

Low battery voltage <9

volts

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check CJB ignition, power and ground supply

circuits for short, open circuit and instrument

cluster power and ground supply circuits for

short, open circuit. Check CAN communications

between CJB and instrument cluster. Check

battery is in serviceable condition and fully

charged B100A-62 Fuel Pump Authorisation

- Signal compare failure

LS CAN fault

RJB power and ground

supply circuits - short, open

circuit

Instrument cluster power

and ground supply circuits -

short, open circuit

Incorrect RJB or instrument

cluster installed

Target SID synchronization

error following

re-programming

Noise/EMC related error

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check CAN communications between

RJB and instrument cluster. Refer to the

electrical circuit diagrams and check RJB power

and ground supply circuits for short, open circuit

and instrument cluster power and ground supply

circuits for short, open circuit. Check correct RJB

and instrument cluster installed. Perform the

Immobilisation application from the Set-up menu

using the manufacturer approved diagnostic

system. Check CAN network for interference/EMC

related issues B100A-64 Fuel Pump Authorisation

- Signal plausibility

failure

Target SID synchronization

error following

re-programming

RJB power and ground

supply circuits - short, open

circuit

LS CAN fault

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Perform the Immobilisation application

from the Set-up menu using the manufacturer

approved diagnostic system. Refer to the

electrical circuit diagrams and check RJB power

and ground supply circuits for short, open circuit.

Check CAN communications between RJB and

instrument cluster B100A-87 Fuel Pump Authorisation

- Missing message

RJB power and ground

supply circuits - short, open

circuit

LS CAN fault

Instrument cluster power

and ground supply circuits -

short, open circuit

Low battery voltage <9

volts

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check RJB power and ground supply circuits

for short, open circuit and instrument cluster

power and ground supply circuits for short, open

circuit. Check CAN communications between RJB

and instrument cluster. Check battery is in

serviceable condition and fully charged B100B-67

Column Lock Ground

Authorisation - Signal

incorrect after event

Algorithm based failure-

signal is incorrect after the

event

Instrument cluster power

and ground supply circuits -

short, open circuit

LS CAN fault

RJB power and ground

supply circuits - short, open

circuit

Vehicle speed present when

attempting to power ESCL

Engine speed present when

attempting to power ESCL

PowerMode status > 4 when

attempting to perform lock

action

If a non start issue has not been identified,

clear the DTC and check vehicle starts correctly.

If a non start issue has been identified run the

manufacturers approved diagnostic system Start

Authorisation Application. Carry out any pinpoint

tests associated with this DTC using the

manufacturer approved diagnostic system. Refer

to the electrical circuit diagrams and check RJB

power and ground supply circuits for short, open

circuit and instrument cluster power and ground

supply circuits for short, open circuit. Check CAN

communications between RJB and instrument

cluster. Check for invalid vehicle speed signal

from ABS/instrument cluster gateway. Check for

invalid engine speed signal from ECM/instrument

cluster gateway. Check for invalid signal from

CJB

Page 189 of 3039

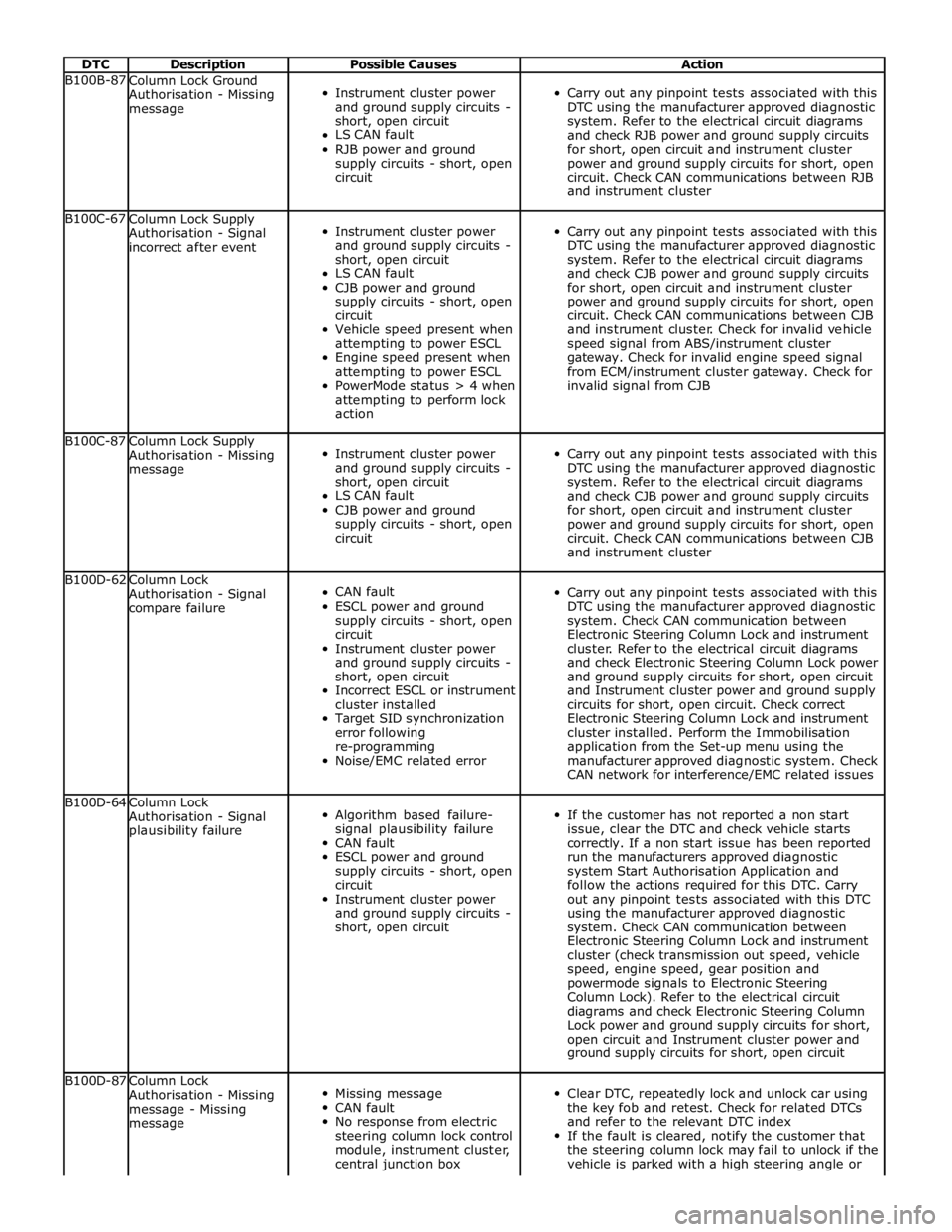

DTC Description Possible Causes Action B100B-87

Column Lock Ground

Authorisation - Missing

message

Instrument cluster power

and ground supply circuits -

short, open circuit

LS CAN fault

RJB power and ground

supply circuits - short, open

circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check RJB power and ground supply circuits

for short, open circuit and instrument cluster

power and ground supply circuits for short, open

circuit. Check CAN communications between RJB

and instrument cluster B100C-67

Column Lock Supply

Authorisation - Signal

incorrect after event

Instrument cluster power

and ground supply circuits -

short, open circuit

LS CAN fault

CJB power and ground

supply circuits - short, open

circuit

Vehicle speed present when

attempting to power ESCL

Engine speed present when

attempting to power ESCL

PowerMode status > 4 when

attempting to perform lock

action

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check CJB power and ground supply circuits

for short, open circuit and instrument cluster

power and ground supply circuits for short, open

circuit. Check CAN communications between CJB

and instrument cluster. Check for invalid vehicle

speed signal from ABS/instrument cluster

gateway. Check for invalid engine speed signal

from ECM/instrument cluster gateway. Check for

invalid signal from CJB B100C-87

Column Lock Supply

Authorisation - Missing

message

Instrument cluster power

and ground supply circuits -

short, open circuit

LS CAN fault

CJB power and ground

supply circuits - short, open

circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check CJB power and ground supply circuits

for short, open circuit and instrument cluster

power and ground supply circuits for short, open

circuit. Check CAN communications between CJB

and instrument cluster B100D-62

Column Lock

Authorisation - Signal

compare failure

CAN fault

ESCL power and ground

supply circuits - short, open

circuit

Instrument cluster power

and ground supply circuits -

short, open circuit

Incorrect ESCL or instrument

cluster installed

Target SID synchronization

error following

re-programming

Noise/EMC related error

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check CAN communication between

Electronic Steering Column Lock and instrument

cluster. Refer to the electrical circuit diagrams

and check Electronic Steering Column Lock power

and ground supply circuits for short, open circuit

and Instrument cluster power and ground supply

circuits for short, open circuit. Check correct

Electronic Steering Column Lock and instrument

cluster installed. Perform the Immobilisation

application from the Set-up menu using the

manufacturer approved diagnostic system. Check

CAN network for interference/EMC related issues B100D-64

Column Lock

Authorisation - Signal

plausibility failure

Algorithm based failure-

signal plausibility failure

CAN fault

ESCL power and ground

supply circuits - short, open

circuit

Instrument cluster power

and ground supply circuits -

short, open circuit

If the customer has not reported a non start

issue, clear the DTC and check vehicle starts

correctly. If a non start issue has been reported

run the manufacturers approved diagnostic

system Start Authorisation Application and

follow the actions required for this DTC. Carry

out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic

system. Check CAN communication between

Electronic Steering Column Lock and instrument

cluster (check transmission out speed, vehicle

speed, engine speed, gear position and

powermode signals to Electronic Steering

Column Lock). Refer to the electrical circuit

diagrams and check Electronic Steering Column

Lock power and ground supply circuits for short,

open circuit and Instrument cluster power and

ground supply circuits for short, open circuit B100D-87

Column Lock

Authorisation - Missing

message - Missing

message

Missing message

CAN fault

No response from electric

steering column lock control

module, instrument cluster,

central junction box

Clear DTC, repeatedly lock and unlock car using

the key fob and retest. Check for related DTCs

and refer to the relevant DTC index

If the fault is cleared, notify the customer that

the steering column lock may fail to unlock if the

vehicle is parked with a high steering angle or

Page 195 of 3039

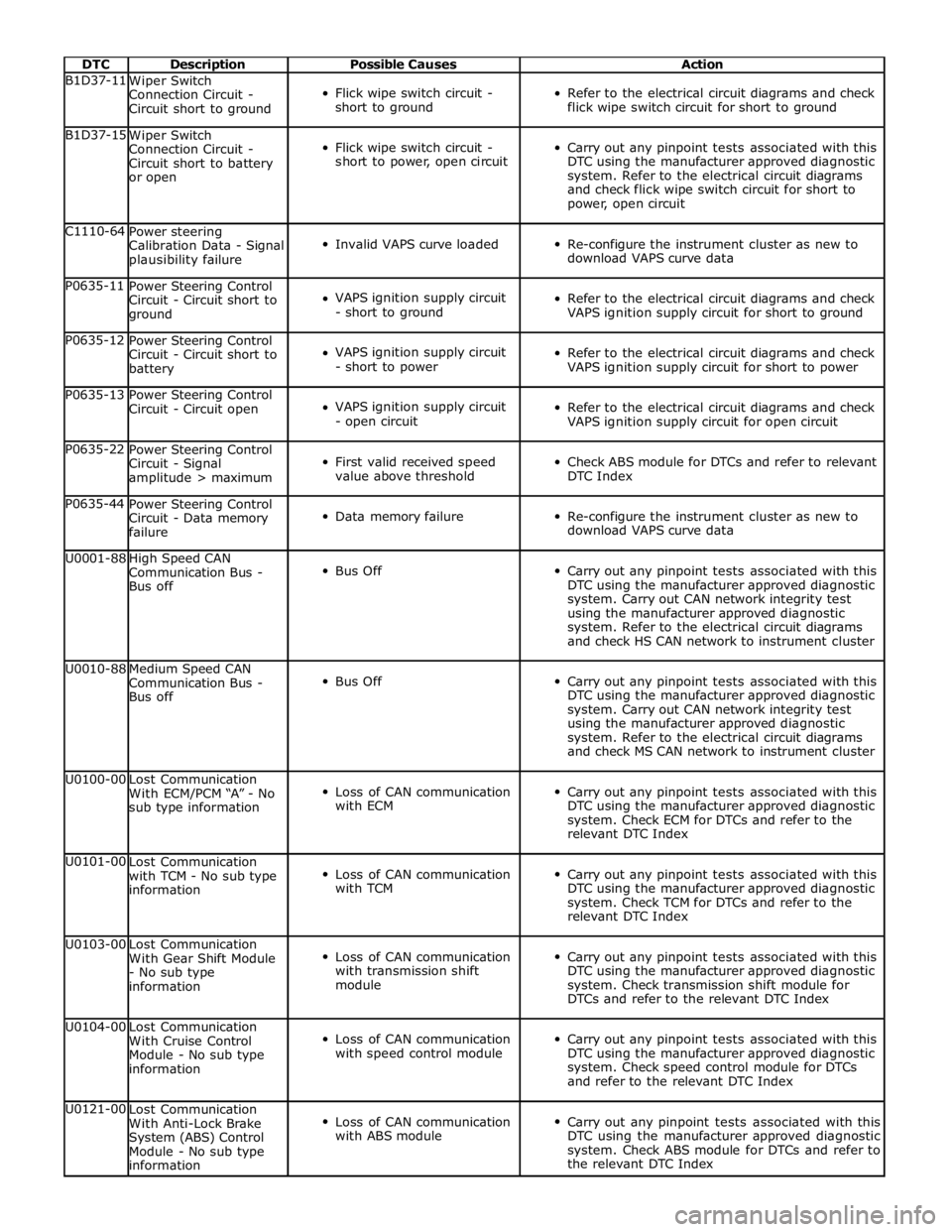

DTC Description Possible Causes Action B1D37-11

Wiper Switch

Connection Circuit -

Circuit short to ground

Flick wipe switch circuit -

short to ground

Refer to the electrical circuit diagrams and check

flick wipe switch circuit for short to ground B1D37-15

Wiper Switch

Connection Circuit -

Circuit short to battery

or open

Flick wipe switch circuit -

short to power, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check flick wipe switch circuit for short to

power, open circuit C1110-64

Power steering

Calibration Data - Signal

plausibility failure

Invalid VAPS curve loaded

Re-configure the instrument cluster as new to

download VAPS curve data P0635-11

Power Steering Control

Circuit - Circuit short to

ground

VAPS ignition supply circuit

- short to ground

Refer to the electrical circuit diagrams and check

VAPS ignition supply circuit for short to ground P0635-12

Power Steering Control

Circuit - Circuit short to

battery

VAPS ignition supply circuit

- short to power

Refer to the electrical circuit diagrams and check

VAPS ignition supply circuit for short to power P0635-13

Power Steering Control

Circuit - Circuit open

VAPS ignition supply circuit

- open circuit

Refer to the electrical circuit diagrams and check

VAPS ignition supply circuit for open circuit P0635-22

Power Steering Control

Circuit - Signal

amplitude > maximum

First valid received speed

value above threshold

Check ABS module for DTCs and refer to relevant

DTC Index P0635-44

Power Steering Control

Circuit - Data memory

failure

Data memory failure

Re-configure the instrument cluster as new to

download VAPS curve data U0001-88

High Speed CAN

Communication Bus -

Bus off

Bus Off

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Carry out CAN network integrity test

using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check HS CAN network to instrument cluster U0010-88

Medium Speed CAN

Communication Bus -

Bus off

Bus Off

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Carry out CAN network integrity test

using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check MS CAN network to instrument cluster U0100-00

Lost Communication

With ECM/PCM “A” - No

sub type information

Loss of CAN communication

with ECM

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check ECM for DTCs and refer to the

relevant DTC Index U0101-00

Lost Communication

with TCM - No sub type

information

Loss of CAN communication

with TCM

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check TCM for DTCs and refer to the

relevant DTC Index U0103-00

Lost Communication

With Gear Shift Module

- No sub type

information

Loss of CAN communication

with transmission shift

module

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check transmission shift module for

DTCs and refer to the relevant DTC Index U0104-00

Lost Communication

With Cruise Control

Module - No sub type

information

Loss of CAN communication

with speed control module

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check speed control module for DTCs

and refer to the relevant DTC Index U0121-00

Lost Communication

With Anti-Lock Brake

System (ABS) Control

Module - No sub type

information

Loss of CAN communication

with ABS module

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check ABS module for DTCs and refer to

the relevant DTC Index

Page 239 of 3039

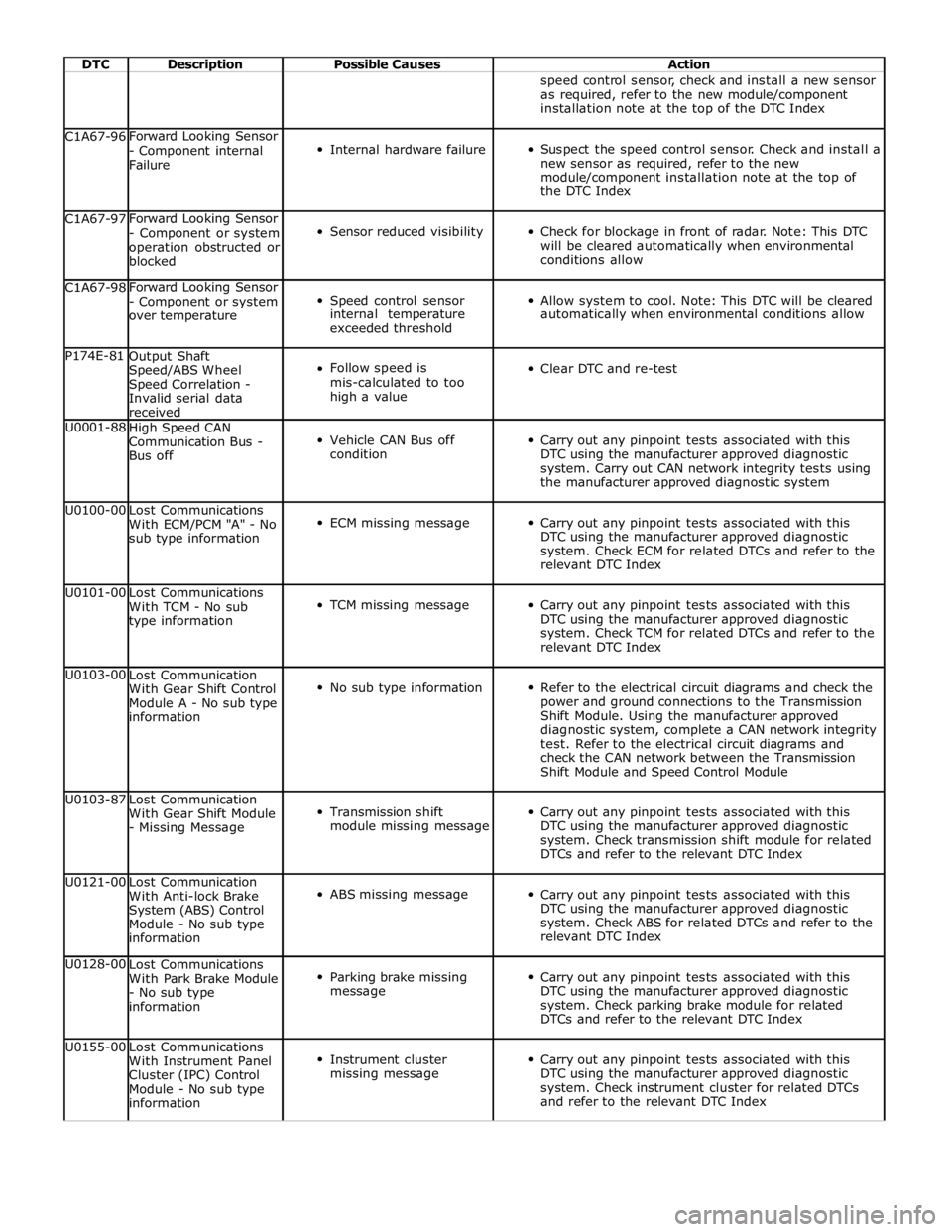

DTC Description Possible Causes Action speed control sensor, check and install a new sensor

as required, refer to the new module/component

installation note at the top of the DTC Index C1A67-96 Forward Looking Sensor

- Component internal

Failure

Internal hardware failure

Suspect the speed control sensor. Check and install a

new sensor as required, refer to the new

module/component installation note at the top of

the DTC Index C1A67-97 Forward Looking Sensor

- Component or system

operation obstructed or

blocked

Sensor reduced visibility

Check for blockage in front of radar. Note: This DTC

will be cleared automatically when environmental

conditions allow C1A67-98 Forward Looking Sensor

- Component or system

over temperature

Speed control sensor

internal temperature

exceeded threshold

Allow system to cool. Note: This DTC will be cleared

automatically when environmental conditions allow P174E-81

Output Shaft

Speed/ABS Wheel

Speed Correlation -

Invalid serial data

received

Follow speed is

mis-calculated to too

high a value

Clear DTC and re-test U0001-88

High Speed CAN

Communication Bus -

Bus off

Vehicle CAN Bus off

condition

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Carry out CAN network integrity tests using

the manufacturer approved diagnostic system U0100-00

Lost Communications

With ECM/PCM "A" - No

sub type information

ECM missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check ECM for related DTCs and refer to the

relevant DTC Index U0101-00

Lost Communications

With TCM - No sub

type information

TCM missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check TCM for related DTCs and refer to the

relevant DTC Index U0103-00

Lost Communication

With Gear Shift Control

Module A - No sub type

information

No sub type information

Refer to the electrical circuit diagrams and check the

power and ground connections to the Transmission

Shift Module. Using the manufacturer approved

diagnostic system, complete a CAN network integrity

test. Refer to the electrical circuit diagrams and

check the CAN network between the Transmission

Shift Module and Speed Control Module U0103-87

Lost Communication

With Gear Shift Module

- Missing Message

Transmission shift

module missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check transmission shift module for related

DTCs and refer to the relevant DTC Index U0121-00

Lost Communication

With Anti-lock Brake

System (ABS) Control

Module - No sub type

information

ABS missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check ABS for related DTCs and refer to the

relevant DTC Index U0128-00

Lost Communications

With Park Brake Module

- No sub type

information

Parking brake missing

message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check parking brake module for related

DTCs and refer to the relevant DTC Index U0155-00

Lost Communications

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

Instrument cluster

missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check instrument cluster for related DTCs

and refer to the relevant DTC Index

Page 240 of 3039

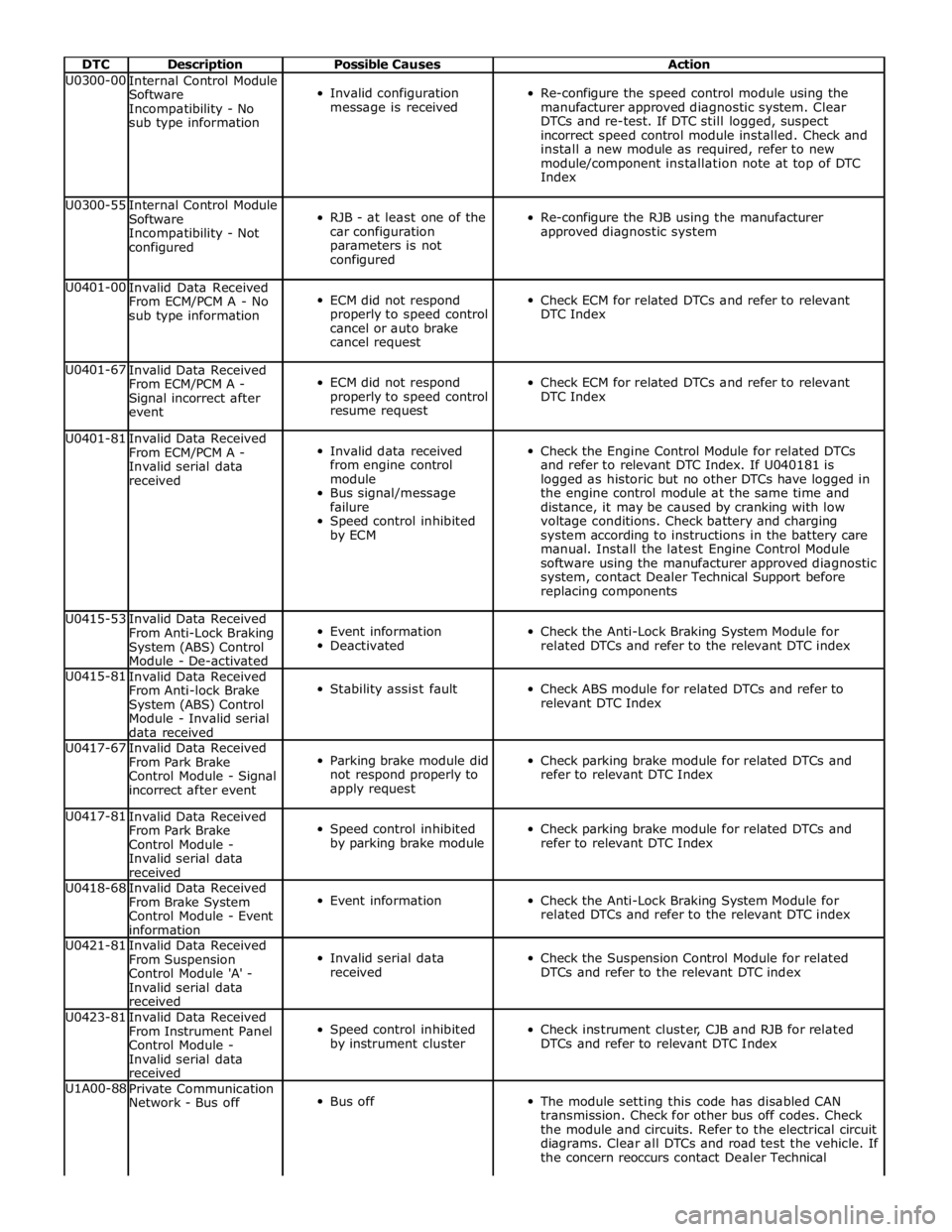

DTC Description Possible Causes Action U0300-00

Internal Control Module

Software

Incompatibility - No

sub type information

Invalid configuration

message is received

Re-configure the speed control module using the

manufacturer approved diagnostic system. Clear

DTCs and re-test. If DTC still logged, suspect

incorrect speed control module installed. Check and

install a new module as required, refer to new

module/component installation note at top of DTC

Index U0300-55

Internal Control Module

Software

Incompatibility - Not

configured

RJB - at least one of the

car configuration

parameters is not

configured

Re-configure the RJB using the manufacturer

approved diagnostic system U0401-00

Invalid Data Received

From ECM/PCM A - No

sub type information

ECM did not respond

properly to speed control

cancel or auto brake

cancel request

Check ECM for related DTCs and refer to relevant

DTC Index U0401-67

Invalid Data Received

From ECM/PCM A -

Signal incorrect after

event

ECM did not respond

properly to speed control

resume request

Check ECM for related DTCs and refer to relevant

DTC Index U0401-81

Invalid Data Received

From ECM/PCM A -

Invalid serial data

received

Invalid data received

from engine control

module

Bus signal/message

failure

Speed control inhibited

by ECM

Check the Engine Control Module for related DTCs

and refer to relevant DTC Index. If U040181 is

logged as historic but no other DTCs have logged in

the engine control module at the same time and

distance, it may be caused by cranking with low

voltage conditions. Check battery and charging

system according to instructions in the battery care

manual. Install the latest Engine Control Module

software using the manufacturer approved diagnostic

system, contact Dealer Technical Support before

replacing components U0415-53

Invalid Data Received

From Anti-Lock Braking

System (ABS) Control

Module - De-activated

Event information

Deactivated

Check the Anti-Lock Braking System Module for

related DTCs and refer to the relevant DTC index U0415-81

Invalid Data Received

From Anti-lock Brake

System (ABS) Control

Module - Invalid serial

data received

Stability assist fault

Check ABS module for related DTCs and refer to

relevant DTC Index U0417-67

Invalid Data Received

From Park Brake

Control Module - Signal

incorrect after event

Parking brake module did

not respond properly to

apply request

Check parking brake module for related DTCs and

refer to relevant DTC Index U0417-81

Invalid Data Received

From Park Brake

Control Module -

Invalid serial data

received

Speed control inhibited

by parking brake module

Check parking brake module for related DTCs and

refer to relevant DTC Index U0418-68

Invalid Data Received

From Brake System

Control Module - Event

information

Event information

Check the Anti-Lock Braking System Module for

related DTCs and refer to the relevant DTC index U0421-81

Invalid Data Received

From Suspension

Control Module 'A' -

Invalid serial data

received

Invalid serial data

received

Check the Suspension Control Module for related

DTCs and refer to the relevant DTC index U0423-81

Invalid Data Received

From Instrument Panel

Control Module -

Invalid serial data

received

Speed control inhibited

by instrument cluster

Check instrument cluster, CJB and RJB for related

DTCs and refer to relevant DTC Index U1A00-88

Private Communication

Network - Bus off

Bus off

The module setting this code has disabled CAN

transmission. Check for other bus off codes. Check

the module and circuits. Refer to the electrical circuit

diagrams. Clear all DTCs and road test the vehicle. If

the concern reoccurs contact Dealer Technical