ABS JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 63 of 3039

Highly flammable, flammable - observe No Smoking policy

Pressurized Equipment

See High Pressure Air, Lubrication and Oil Test Equipment.

Solder

Solders are a mixture of metals such that the melting point of the mixture is below that of the constituent metals (normally

lead and tin). Solder application does not normally give rise to toxic lead fumes, provided a gas/air flame is used.

Oxy-acetylene flames should not be used, as they are much hotter and will cause lead fumes to be produced.

Some fumes may be produced by the application of any flame to surfaces coated with grease etc. and inhalation of these

should be avoided.

Removal of excess solder should be undertaken with care, to make sure that fine lead dust is not produced, which can give

toxic effects if inhaled. Respiratory protection may be necessary.

Solder spillage and filings should be collected and removed promptly to prevent general air contamination by lead.

High standards of personal hygiene are necessary in order to avoid ingestion of lead or inhalation of solder dust from clothing.

Solvents

See also Chemical Materials, Fuels (Kerosene), Fire.

e.g. acetone, white spirit, toluene, xylene, trichloroethane.

Used in cleaning and de-waxing materials, paints, plastics, resins, thinners etc.

Some may be highly flammable or flammable.

Skin contact will degrease the skin and may result in irritation and dermatitis following repeated or prolonged contact. Some

can be absorbed through the skin in toxic or harmful quantities.

Splashes in the eye may cause severe irritation and could lead to loss of vision.

Brief exposure to high concentrations of vapors or mists will cause eye and throat irritation, drowsiness, dizziness, headaches

and, in the worst circumstances, unconsciousness.

Repeated or prolonged exposure to excessive but lower concentrations of vapors or mists, for which there might not be

adequate warning indications, can cause more serious toxic or harmful effects.

Aspiration into the lungs (e.g. through vomiting) is the most serious consequence of swallowing.

Avoid splashes to the skin, eyes and clothing. Wear protective gloves, goggles and clothing if necessary.

Ensure good ventilation when in use, avoid breathing fumes, vapors and spray mists and keep containers tightly sealed. Do not

use in confined spaces.

When spraying materials containing solvents, e.g. paints, adhesive, coatings, use extraction ventilation or personal respiratory

protection in the absence of adequate general ventilation.

Do not apply heat or flame except under specific and detailed manufacturer's instructions.

Sound Insulation

See Fibre Insulation, Foams.

Suspended Loads

CAUTION: Never improvise lifting tackle.

There is always a danger when loads are lifted or suspended. Never work under an unsupported, suspended or raised load e.g.

suspended engine, etc.

Always make sure that lifting equipment such as jacks, hoists, axle stands, slings, etc., are adequate and suitable for the job,

in good condition and regularly maintained.

Transmission Brake Bands

See Asbestos.

Underseal

See Corrosion Protection.

Page 64 of 3039

Viton

In common with many other manufacturers' vehicles, some components installed to the Jaguar range have 'O' rings, seals or

gaskets which contain a material known as 'Viton'.

Viton is a fluoroelastomer, that is a synthetic rubber type which contains Fluorine. It is commonly used for 'O' rings, gaskets

and seals of all types. Although Viton is the most well known fluoroelastomer, there are others, including Fluorel and

Tecmoflon.

When used under design conditions fluoroelastomers are perfectly safe. If, however, they are exposed to temperatures in

excess of 400º C, the material will not burn, but will decompose, and one of the products formed is hydrofluoric acid.

This acid is extremely corrosive and may be absorbed directly, through contact, into the body.

'O' rings, seals or gaskets which have been exposed to very high temperatures will appear charred or as a black sticky

substance.

DO NOT, under any circumstances touch them or the attached components.

Enquiries should be made to determine whether Viton or any other fluoroelastomer has been used in the affected 'O' ring, seal

or gasket. If they are of natural rubber or nitrile there is no hazard. If in doubt, be cautious and assume that the material may

be Viton or any fluoroelastomer.

If Viton or any other fluoroelastomers have been used, the affected area should be decontaminated before the commencement

of work.

Disposable heavy duty plastic gloves should be worn at all times, and the affected area washed down using wire wool and a

limewater (calcium hydroxide) solution to neutralize the acid before disposing of the decomposed Viton residue and final

cleaning of the area. After use, the plastic gloves should be discarded carefully and safely.

Welding

See also Fire, Electric Shock, Gas Cylinders.

Welding processes include Resistance Welding (Spot Welding), Arc Welding and Gas Welding (and cutting).

Resistance Welding (Spot Welding)

This process may cause particles of molten metal to be emitted at a high velocity, and the eyes and skin must be protected.

Arc Welding

This process emits a high level of ultraviolet radiation which may cause arc-eye and skin burns to the operator and to other

persons nearby. Gas-shielded welding processes are particularly hazardous in this respect. Personal protection must be worn,

and screens used to shield other people.

CONTACT LENS WEARERS ARE ADVISED TO REVERT TO ORDINARY SPECTACLES WHEN ARC WELDING as the arc spectrum is

believed to emit microwaves which dry out the fluid between the lens and the eye. This may result in blindness when the lens

is removed from the eye.

Metal spatter will also occur, and appropriate eye and skin protection is necessary.

The heat of the welding arc will produce fumes and gases from the metals being welded, the rods and from any applied

coatings or contamination on the surfaces being worked on. These gases and fumes may be toxic and inhalation of these

should be avoided. The use of extraction ventilation to remove the fumes from the working area may be necessary particularly

in cases where the general ventilation is poor, or where considerable welding work is anticipated. In extreme cases or confined

spaces where adequate ventilation cannot be provided, air-fed respirators may be necessary.

Gas Welding (and Cutting)

Oxy-acetylene torches may be used for welding and cutting, and special care must be taken to prevent leakage of these gases,

with consequent risk of fire and explosion.

The process will produce metal spatter and eye and skin protection is necessary.

The flame is bright, and eye protection should be used, but the ultraviolet emission is much less than that from arc welding,

and lighter filters may be used.

The process itself produces few toxic fumes, but such fumes and gases may be produced from coatings on the work,

particularly during cutting away of damaged body parts, and inhalation of the fumes should be avoided.

In brazing, toxic fumes may be produced from the metals in the brazing rod, and a severe hazard may arise if brazing rods

containing cadmium are used. In this event particular care must be taken to avoid inhalation of fumes and expert advice may

be required.

SPECIAL PRECAUTIONS MUST BE TAKEN BEFORE ANY WELDING OR CUTTING TAKES PLACE ON VESSELS WHICH HAVE

CONTAINED COMBUSTIBLE MATERIALS, E.G. BOILING OR STEAMING OUT OF FUEL TANKS.

Warning Symbols on Vehicles

Decals showing warning symbols will be found on various vehicle components.

Page 70 of 3039

Published: 11-May-2011

General Information - Petrol and Petrol-Ethanol Fuel Systems Health and

Safety Precautions

Description and Operation

WARNINGS:

Fuel may not give adequate warning before toxic or harmful effects arise.

Exposure to fuel can be harmful and can cause severe health damage or death.

Extreme care must be exercised when handling hot fluids. Always wash off spilled fluids from affected areas of skin

immediately.

Highly flammable mixtures are always present and may ignite when working on fuel systems. Do not allow naked flames,

sparks or lighted substances to come near fuel related components.

Fuel must not be used as a cleaning agent.

Keep fuel containers tightly closed, out of direct sunlight and in a cool area. Keep away from heat sources, ignition

sources and oxidizing agents.

SKIN CONTACT: Excessive or prolonged skin contact with diesel fuel may cause serious skin disorders including skin

cancer.

SKIN CONTACT: Fuel is mildly irritating to the skin and may cause dermatitis due to defatting effect. Remove

contaminated clothing. Wash affected areas of skin with soap and water. Seek medical attention for any persistent skin

irritation or abnormality. Wash contaminated clothing before reuse.

EYE CONTACT: Fuel is mildly irritating to the eyes. Flush with plenty of running water, blinking as often as possible. Do

not force the eyelid open. Seek medical attention for any persistent eye irritation or abnormality.

SWALLOWED: Fuel is moderately toxic and tends to foam on vomiting. If drawn into the lungs, inflammation may

develop. Do not induce vomiting. If spontaneous vomiting occurs place the victim in a forward position to reduce the risk of

fuel being drawn into the lungs. Give nothing by mouth. If breathing but unconscious, place in the recovery position. If

breathing has stopped, apply artificial respiration. Seek immediate medical attention.

INHALED: Fuel is toxic to the respiratory and other body systems. Exposure may result in various symptoms including

drowsiness, unconsciousness or severe health damage. Move a victim to fresh air. Keep a victim warm and at rest. If

unconscious, place in the recovery position. If not breathing, apply artificial respiration. Give cardiac massage if necessary.

Seek immediate medical attention.

CAUTIONS:

Fuel injection equipment is manufactured to very precise tolerances and fine clearances. It is essential that absolute

cleanliness is observed when working with these components.

Make sure that the workshop area in which the vehicle is being worked on is as clean and as dust free as possible.

www.JagDocs.com

Page 71 of 3039

General Information - Solvents, Sealants and Adhesives

Description and Operation Published: 11-May-2011

WARNING: Always handle all solvents, sealers and adhesives with extreme care. Some contain chemicals or give off

fumes which can be dangerous to health. Always follow the manufacturers instructions. If in doubt about any substance,

particularly a solvent, DO NOT use it.

CAUTION: If in doubt about the suitability of any proprietary solvent or sealer for a particular application, contact the

manufacturer of the product for information regarding storage, handling and application.

The Solvents, Sealers and Adhesives subsection refers to some commonly used chemicals and materials, hazards associated

with their use, and safety measures to be taken.

Adhesives and Sealers

Highly flammable, flammable, combustible – observe No Smoking policy.

Generally should be stored in No Smoking' areas. Cleanliness and tidiness in use should be observed e.g. disposable paper

covering benches; should be dispensed from applicators where possible; containers, including secondary containers, should be

labelled appropriately.

Solvent - based Adhesives/Sealers - See Solvents

Follow manufacturer's instructions.

Water - based Adhesives/Sealers

Those based on polymer emulsions and rubber latexes may contain small amounts of volatile toxic and harmful chemicals. Skin

and eye contact should be avoided and adequate ventilation provided during use.

Hot Melt Adhesives

In the solid state, they are safe. In the molten state they may cause burns and health hazards may arise from the inhalation

of toxic fumes.

Use appropriate protective clothing and a thermostatically controlled heater with a thermal cut - out and adequate extraction.

Resin - based Adhesives/Sealers e.g. Epoxide and Formaldehyde Resin - based

Mixing should be carried out in well ventilated areas, as harmful or toxic volatile chemicals may be released.

Skin contact with uncured resins and hardeners can result in irritation, dermatitis, and absorption of toxic or harmful chemicals

through the skin. Splashes can damage the eyes.

Provide adequate ventilation and avoid skin and eye contact.

Anaerobic, Cyanoacrylate (Super - glues) and other Acrylic Adhesives Many are irritant, sensitizing or harmful to the skin and/or respiratory tract. Some are eye irritants.

Skin and eye contact should be avoided and the manufacturer's instructions followed.

Cyanoacrylate adhesives (super-glues) MUST NOT contact the skin or eyes. If skin or eye tissue is bonded, cover with a clean

moist pad and seek immediate medical attention. Do not attempt to pull tissue apart. Use in well ventilated areas as vapors

can cause irritation to the nose and eyes.

For two - pack systems see Resin - based and Isocyanate Adhesives/Sealers.

Isocyanate (Polyurethane) Adhesives/Sealers

See also Resin - based Adhesives

Individuals suffering from asthma or respiratory allergies should not work with or near these materials as sensitivity reactions

can occur.

Over exposure is irritating to the eyes and respiratory system. Excessive concentrations may produce effects on the nervous

system including drowsiness. In extreme cases, loss of consciousness may result. Long term exposure to vapor concentrations

may result in adverse health effects.

Prolonged contact with the skin may lead to skin irritation and, in some cases, dermatitis.

Splashes entering the eye will cause discomfort and possible damage.

Any spraying should preferably be carried out in exhaust ventilated booths removing vapors and spray droplets from the

breathing zone.

Wear appropriate gloves, eye and respiratory protection.

Page 101 of 3039

Published: 11-May-2011

General Information - Supplemental Restraint System (SRS) Health and

Safety Precautions

Description and Operation

WARNINGS:

Only qualified technicians are allowed to work on pyrotechnic components.

INHALED: Exposure to pyrotechnic residue may cause low blood pressure, severe headache, irritation of mucous

membranes, fainting, shortness of breath or rapid pulse. Move a victim to fresh air. Seek immediate medical attention.

EYE CONTACT: Exposure to unburned pyrotechnic residue may cause irritation, burning and etching of the eyes. Flush

immediately with plenty of cold running water for at least 15 minutes. Seek immediate medical attention.

EYE CONTACT: Exposure to burned pyrotechnic residue may cause irritation, burning and etching of the eyes. Flush

immediately with diluted boric acid solution. Seek immediate medical attention.

SKIN CONTACT: Unburned pyrotechnic residue may be rapidly absorbed through the skin in toxic quantities. Wash

immediately with plenty of soap and water. Seek medical attention.

SKIN CONTACT: Burned pyrotechnic residue may be rapidly absorbed through the skin in toxic quantities. Wash with

plenty of water. Do not use soap. Seek medical attention.

SWALLOWED: Unburned pyrotechnic residue is extremely toxic. If conscious drink plenty of water then induce vomiting.

Seek immediate medical attention. If unconscious, or in convulsions do not attempt to induce vomiting or give anything by

mouth. Seek immediate medical attention.

SWALLOWED: Burned pyrotechnic residue is extremely toxic. Drink plenty of water and seek immediate medical attention.

The deployment key must only be accessible to authorized personnel.

Make sure that the deployment key remains removed from the deployment equipment except during deployment.

If permenantly disabling or enabling the passenger air bag a new seat belt for vehicles without or with a passenger air

bag must be installed.

Undeployed pyrotechnic components must not be deployed in the vehicle.

Pyrotechnic components must be deployed following local regulations.

Check thoroughly that no loose objects can be spread during the deployment of pyrotechnic components.

Pyrotechnic components must be transported following local regulations.

Never carry out any electrical measurement on disconnected, undeployed pyrotechnic components.

Pyrotechnic components must not be disassembled.

Pyrotechnic components are not interchangeable between vehicles.

Always carry a live air bag module away from the body with the air bag or trim cover pointing upwards.

Page 117 of 3039

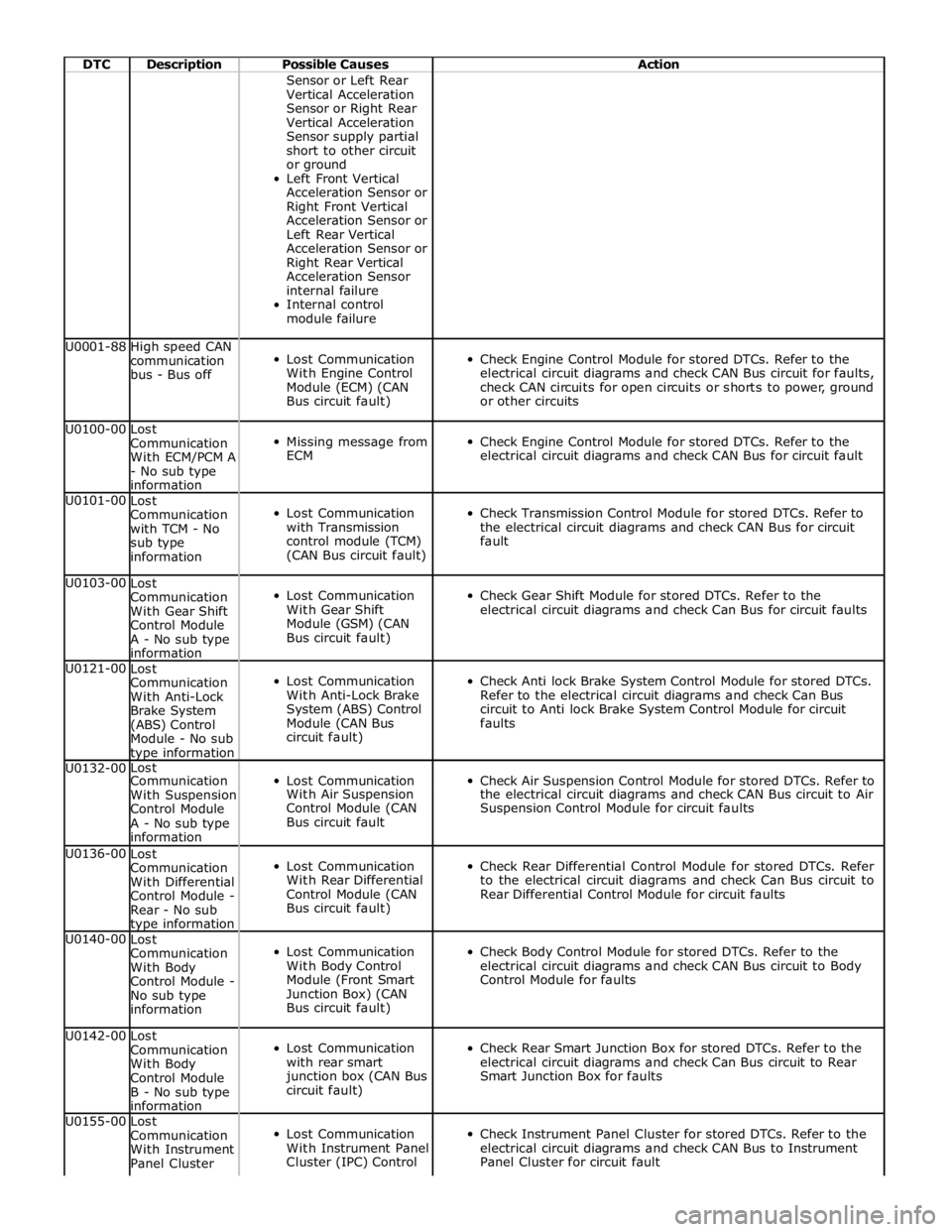

DTC Description Possible Causes Action Sensor or Left Rear

Vertical Acceleration

Sensor or Right Rear

Vertical Acceleration

Sensor supply partial

short to other circuit

or ground

Left Front Vertical

Acceleration Sensor or

Right Front Vertical

Acceleration Sensor or

Left Rear Vertical

Acceleration Sensor or

Right Rear Vertical

Acceleration Sensor

internal failure

Internal control

module failure U0001-88

High speed CAN

communication

bus - Bus off

Lost Communication

With Engine Control

Module (ECM) (CAN

Bus circuit fault)

Check Engine Control Module for stored DTCs. Refer to the

electrical circuit diagrams and check CAN Bus circuit for faults,

check CAN circuits for open circuits or shorts to power, ground

or other circuits U0100-00

Lost

Communication

With ECM/PCM A

- No sub type

information

Missing message from

ECM

Check Engine Control Module for stored DTCs. Refer to the

electrical circuit diagrams and check CAN Bus for circuit fault U0101-00

Lost

Communication

with TCM - No

sub type

information

Lost Communication

with Transmission

control module (TCM)

(CAN Bus circuit fault)

Check Transmission Control Module for stored DTCs. Refer to

the electrical circuit diagrams and check CAN Bus for circuit

fault U0103-00

Lost

Communication

With Gear Shift

Control Module

A - No sub type

information

Lost Communication

With Gear Shift

Module (GSM) (CAN

Bus circuit fault)

Check Gear Shift Module for stored DTCs. Refer to the

electrical circuit diagrams and check Can Bus for circuit faults U0121-00

Lost

Communication

With Anti-Lock

Brake System

(ABS) Control

Module - No sub type information

Lost Communication

With Anti-Lock Brake

System (ABS) Control

Module (CAN Bus

circuit fault)

Check Anti lock Brake System Control Module for stored DTCs.

Refer to the electrical circuit diagrams and check Can Bus

circuit to Anti lock Brake System Control Module for circuit

faults U0132-00 Lost

Lost Communication

Check Air Suspension Control Module for stored DTCs. Refer to Communication With Suspension With Air Suspension the electrical circuit diagrams and check CAN Bus circuit to Air Control Module Control Module (CAN Suspension Control Module for circuit faults A - No sub type Bus circuit fault information U0136-00

Lost

Communication

With Differential

Control Module -

Rear - No sub type information

Lost Communication

With Rear Differential

Control Module (CAN

Bus circuit fault)

Check Rear Differential Control Module for stored DTCs. Refer

to the electrical circuit diagrams and check Can Bus circuit to

Rear Differential Control Module for circuit faults U0140-00

Lost

Communication

With Body

Control Module -

No sub type

information

Lost Communication

With Body Control

Module (Front Smart

Junction Box) (CAN

Bus circuit fault)

Check Body Control Module for stored DTCs. Refer to the

electrical circuit diagrams and check CAN Bus circuit to Body

Control Module for faults U0142-00

Lost

Communication

With Body

Control Module

B - No sub type

information

Lost Communication

with rear smart

junction box (CAN Bus

circuit fault)

Check Rear Smart Junction Box for stored DTCs. Refer to the

electrical circuit diagrams and check Can Bus circuit to Rear

Smart Junction Box for faults U0155-00

Lost

Communication

With Instrument

Panel Cluster

Lost Communication

With Instrument Panel

Cluster (IPC) Control

Check Instrument Panel Cluster for stored DTCs. Refer to the

electrical circuit diagrams and check CAN Bus to Instrument

Panel Cluster for circuit fault

Page 118 of 3039

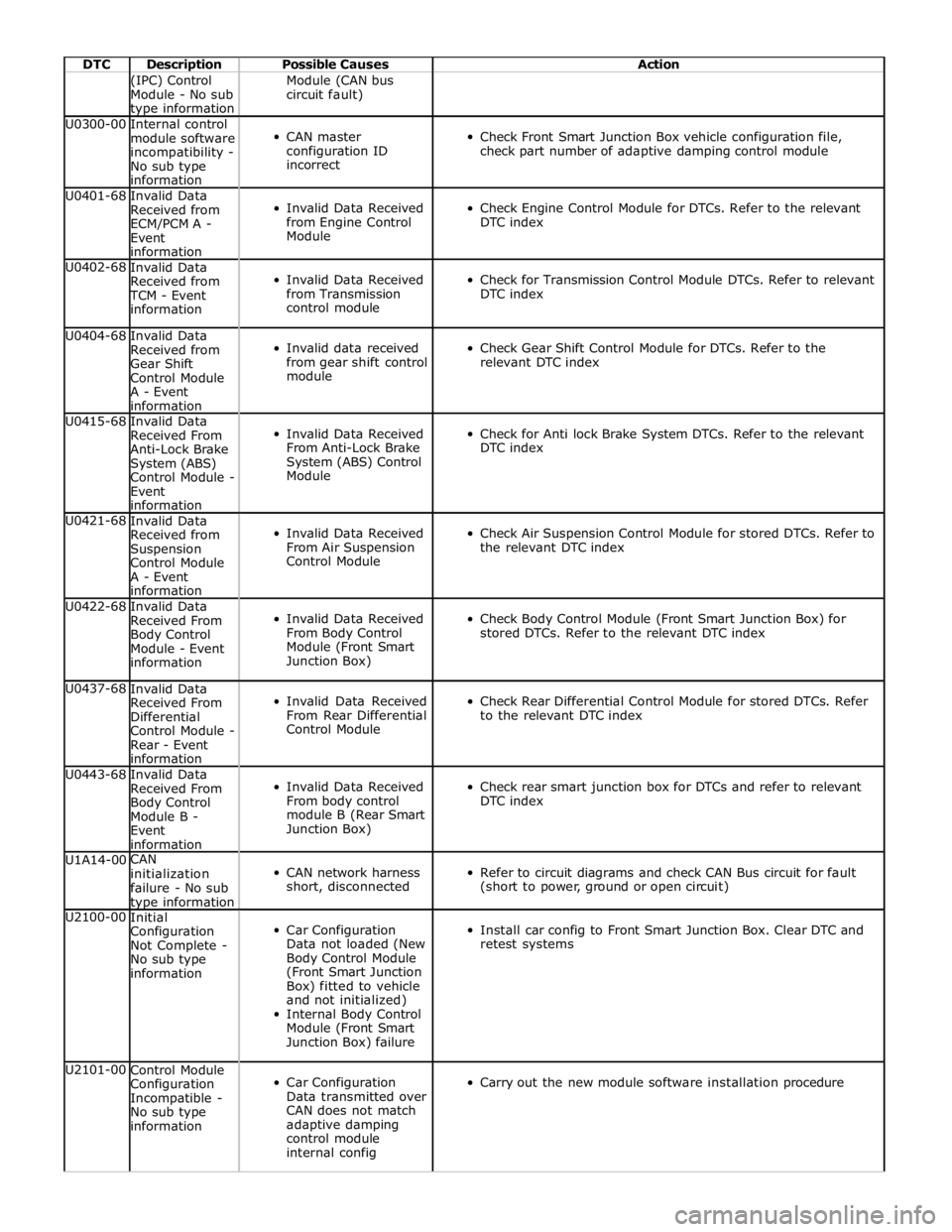

DTC Description Possible Causes Action (IPC) Control

Module - No sub

type information Module (CAN bus

circuit fault) U0300-00

Internal control

module software

incompatibility -

No sub type

information

CAN master

configuration ID

incorrect

Check Front Smart Junction Box vehicle configuration file,

check part number of adaptive damping control module U0401-68

Invalid Data

Received from

ECM/PCM A -

Event

information

Invalid Data Received

from Engine Control

Module

Check Engine Control Module for DTCs. Refer to the relevant

DTC index U0402-68

Invalid Data

Received from TCM - Event

information

Invalid Data Received

from Transmission

control module

Check for Transmission Control Module DTCs. Refer to relevant

DTC index U0404-68

Invalid Data

Received from

Gear Shift

Control Module

A - Event

information

Invalid data received

from gear shift control

module

Check Gear Shift Control Module for DTCs. Refer to the

relevant DTC index U0415-68

Invalid Data

Received From

Anti-Lock Brake

System (ABS)

Control Module -

Event

information

Invalid Data Received

From Anti-Lock Brake

System (ABS) Control

Module

Check for Anti lock Brake System DTCs. Refer to the relevant

DTC index U0421-68

Invalid Data

Received from

Suspension

Control Module

A - Event

information

Invalid Data Received

From Air Suspension

Control Module

Check Air Suspension Control Module for stored DTCs. Refer to

the relevant DTC index U0422-68

Invalid Data

Received From

Body Control

Module - Event

information

Invalid Data Received

From Body Control

Module (Front Smart

Junction Box)

Check Body Control Module (Front Smart Junction Box) for

stored DTCs. Refer to the relevant DTC index U0437-68

Invalid Data

Received From

Differential

Control Module -

Rear - Event

information

Invalid Data Received

From Rear Differential

Control Module

Check Rear Differential Control Module for stored DTCs. Refer

to the relevant DTC index U0443-68

Invalid Data

Received From

Body Control

Module B -

Event

information

Invalid Data Received

From body control

module B (Rear Smart

Junction Box)

Check rear smart junction box for DTCs and refer to relevant

DTC index U1A14-00 CAN

initialization

failure - No sub type information

CAN network harness

short, disconnected

Refer to circuit diagrams and check CAN Bus circuit for fault

(short to power, ground or open circuit) U2100-00

Initial

Configuration

Not Complete -

No sub type

information

Car Configuration

Data not loaded (New

Body Control Module

(Front Smart Junction

Box) fitted to vehicle

and not initialized)

Internal Body Control

Module (Front Smart

Junction Box) failure

Install car config to Front Smart Junction Box. Clear DTC and

retest systems U2101-00

Control Module

Configuration

Incompatible -

No sub type

information

Car Configuration

Data transmitted over

CAN does not match

adaptive damping

control module

internal config

Carry out the new module software installation procedure

Page 120 of 3039

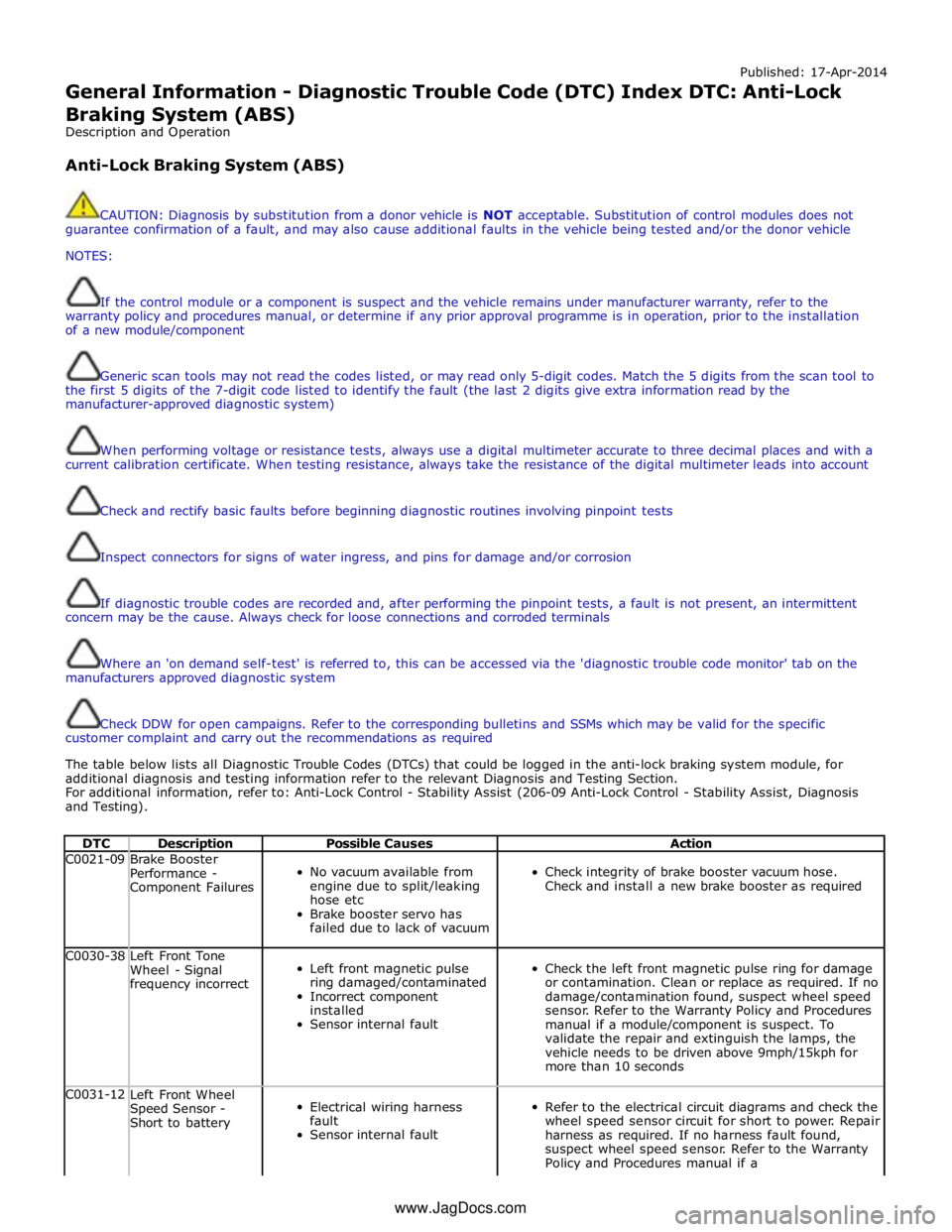

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Anti-Lock Braking System (ABS)

Description and Operation

Anti-Lock Braking System (ABS)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system)

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places and with a

current calibration certificate. When testing resistance, always take the resistance of the digital multimeter leads into account

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

If diagnostic trouble codes are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent

concern may be the cause. Always check for loose connections and corroded terminals

Where an 'on demand self-test' is referred to, this can be accessed via the 'diagnostic trouble code monitor' tab on the

manufacturers approved diagnostic system

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the anti-lock braking system module, for

additional diagnosis and testing information refer to the relevant Diagnosis and Testing Section.

For additional information, refer to: Anti-Lock Control - Stability Assist (206-09 Anti-Lock Control - Stability Assist, Diagnosis

and Testing).

DTC Description Possible Causes Action C0021-09

Brake Booster

Performance -

Component Failures

No vacuum available from

engine due to split/leaking

hose etc

Brake booster servo has

failed due to lack of vacuum

Check integrity of brake booster vacuum hose.

Check and install a new brake booster as required C0030-38

Left Front Tone

Wheel - Signal

frequency incorrect

Left front magnetic pulse

ring damaged/contaminated

Incorrect component

installed

Sensor internal fault

Check the left front magnetic pulse ring for damage

or contamination. Clean or replace as required. If no

damage/contamination found, suspect wheel speed

sensor. Refer to the Warranty Policy and Procedures

manual if a module/component is suspect. To

validate the repair and extinguish the lamps, the

vehicle needs to be driven above 9mph/15kph for

more than 10 seconds C0031-12

Left Front Wheel

Speed Sensor -

Short to battery

Electrical wiring harness

fault

Sensor internal fault

Refer to the electrical circuit diagrams and check the

wheel speed sensor circuit for short to power. Repair

harness as required. If no harness fault found,

suspect wheel speed sensor. Refer to the Warranty

Policy and Procedures manual if a www.JagDocs.com

Page 132 of 3039

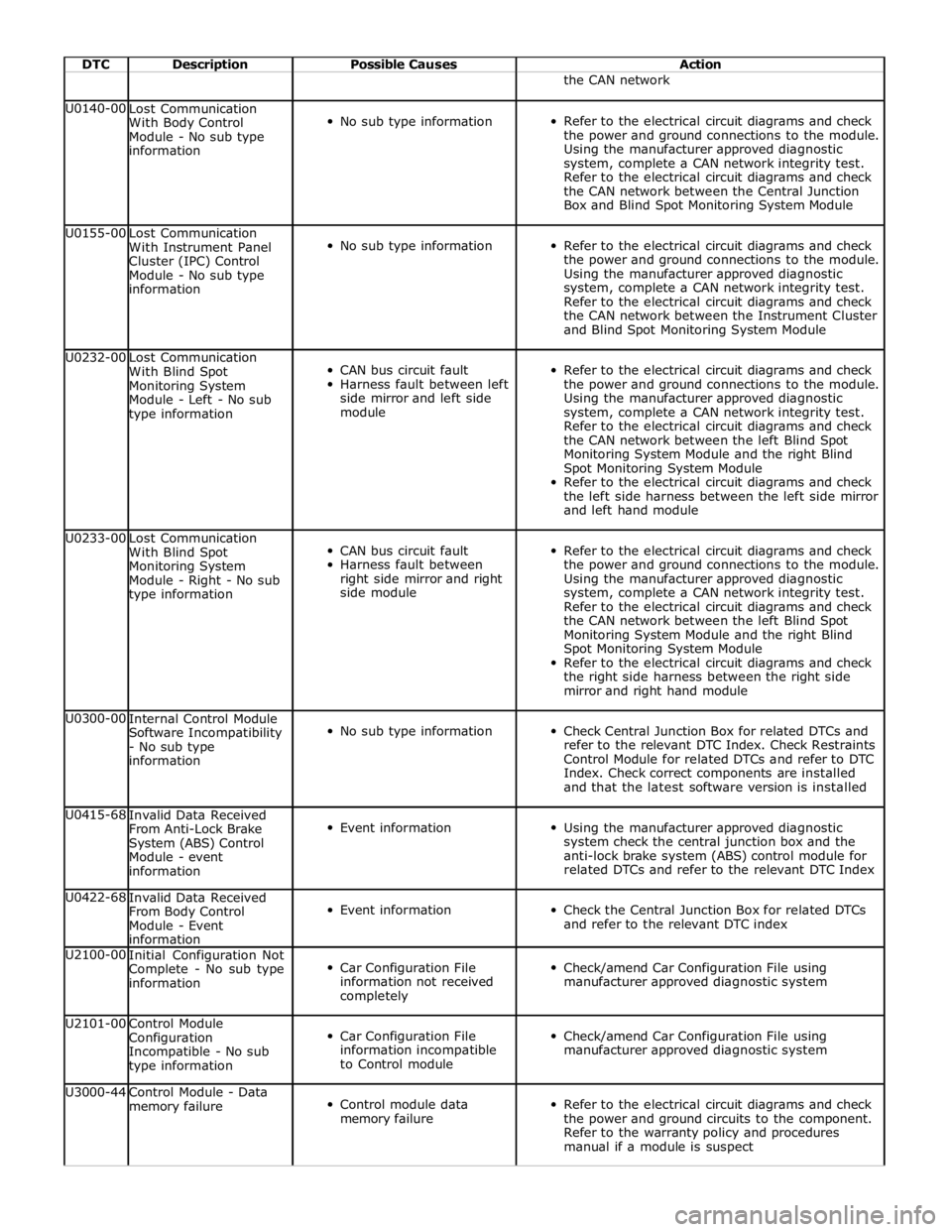

DTC Description Possible Causes Action the CAN network U0140-00

Lost Communication

With Body Control

Module - No sub type

information

No sub type information

Refer to the electrical circuit diagrams and check

the power and ground connections to the module.

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test.

Refer to the electrical circuit diagrams and check

the CAN network between the Central Junction

Box and Blind Spot Monitoring System Module U0155-00

Lost Communication

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

No sub type information

Refer to the electrical circuit diagrams and check

the power and ground connections to the module.

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test.

Refer to the electrical circuit diagrams and check

the CAN network between the Instrument Cluster

and Blind Spot Monitoring System Module U0232-00

Lost Communication

With Blind Spot

Monitoring System

Module - Left - No sub

type information

CAN bus circuit fault

Harness fault between left

side mirror and left side

module

Refer to the electrical circuit diagrams and check

the power and ground connections to the module.

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test.

Refer to the electrical circuit diagrams and check

the CAN network between the left Blind Spot

Monitoring System Module and the right Blind

Spot Monitoring System Module

Refer to the electrical circuit diagrams and check

the left side harness between the left side mirror

and left hand module U0233-00

Lost Communication

With Blind Spot

Monitoring System

Module - Right - No sub

type information

CAN bus circuit fault

Harness fault between

right side mirror and right

side module

Refer to the electrical circuit diagrams and check

the power and ground connections to the module.

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test.

Refer to the electrical circuit diagrams and check

the CAN network between the left Blind Spot

Monitoring System Module and the right Blind

Spot Monitoring System Module

Refer to the electrical circuit diagrams and check

the right side harness between the right side

mirror and right hand module U0300-00

Internal Control Module

Software Incompatibility

- No sub type

information

No sub type information

Check Central Junction Box for related DTCs and

refer to the relevant DTC Index. Check Restraints

Control Module for related DTCs and refer to DTC

Index. Check correct components are installed

and that the latest software version is installed U0415-68

Invalid Data Received

From Anti-Lock Brake

System (ABS) Control

Module - event

information

Event information

Using the manufacturer approved diagnostic

system check the central junction box and the

anti-lock brake system (ABS) control module for

related DTCs and refer to the relevant DTC Index U0422-68

Invalid Data Received

From Body Control

Module - Event

information

Event information

Check the Central Junction Box for related DTCs

and refer to the relevant DTC index U2100-00

Initial Configuration Not

Complete - No sub type

information

Car Configuration File

information not received

completely

Check/amend Car Configuration File using

manufacturer approved diagnostic system U2101-00

Control Module

Configuration

Incompatible - No sub

type information

Car Configuration File

information incompatible

to Control module

Check/amend Car Configuration File using

manufacturer approved diagnostic system U3000-44

Control Module - Data

memory failure

Control module data

memory failure

Refer to the electrical circuit diagrams and check

the power and ground circuits to the component.

Refer to the warranty policy and procedures

manual if a module is suspect

Page 161 of 3039

DTC Description Possible Causes Action system, complete a CAN network integrity test.

Refer to the electrical circuit diagrams and check

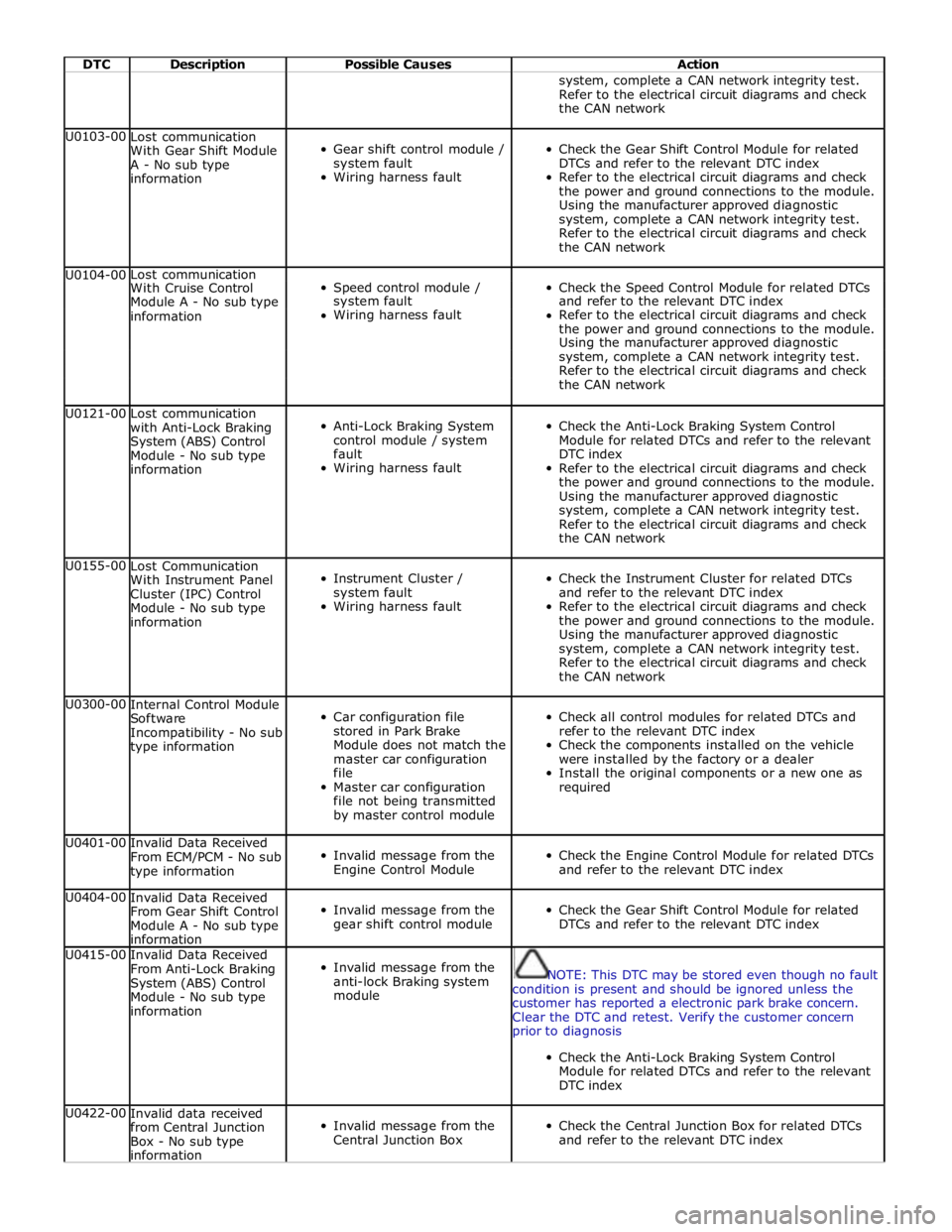

the CAN network U0103-00

Lost communication

With Gear Shift Module

A - No sub type

information

Gear shift control module /

system fault

Wiring harness fault

Check the Gear Shift Control Module for related

DTCs and refer to the relevant DTC index

Refer to the electrical circuit diagrams and check

the power and ground connections to the module.

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test.

Refer to the electrical circuit diagrams and check

the CAN network U0104-00 Lost communication

Speed control module /

Check the Speed Control Module for related DTCs With Cruise Control Module A - No sub type system fault and refer to the relevant DTC index information Wiring harness fault Refer to the electrical circuit diagrams and check the power and ground connections to the module. Using the manufacturer approved diagnostic system, complete a CAN network integrity test. Refer to the electrical circuit diagrams and check the CAN network U0121-00

Lost communication

with Anti-Lock Braking

System (ABS) Control

Module - No sub type

information

Anti-Lock Braking System

control module / system

fault

Wiring harness fault

Check the Anti-Lock Braking System Control

Module for related DTCs and refer to the relevant

DTC index

Refer to the electrical circuit diagrams and check

the power and ground connections to the module.

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test.

Refer to the electrical circuit diagrams and check

the CAN network U0155-00

Lost Communication

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

Instrument Cluster /

system fault

Wiring harness fault

Check the Instrument Cluster for related DTCs

and refer to the relevant DTC index

Refer to the electrical circuit diagrams and check

the power and ground connections to the module.

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test.

Refer to the electrical circuit diagrams and check

the CAN network U0300-00

Internal Control Module

Software

Incompatibility - No sub

type information

Car configuration file

stored in Park Brake

Module does not match the

master car configuration

file

Master car configuration

file not being transmitted

by master control module

Check all control modules for related DTCs and

refer to the relevant DTC index

Check the components installed on the vehicle

were installed by the factory or a dealer

Install the original components or a new one as

required U0401-00

Invalid Data Received

From ECM/PCM - No sub

type information

Invalid message from the

Engine Control Module

Check the Engine Control Module for related DTCs

and refer to the relevant DTC index U0404-00

Invalid Data Received

From Gear Shift Control

Module A - No sub type

information

Invalid message from the

gear shift control module

Check the Gear Shift Control Module for related

DTCs and refer to the relevant DTC index U0415-00

Invalid Data Received

From Anti-Lock Braking

System (ABS) Control

Module - No sub type

information

Invalid message from the

anti-lock Braking system

module

NOTE: This DTC may be stored even though no fault

condition is present and should be ignored unless the

customer has reported a electronic park brake concern.

Clear the DTC and retest. Verify the customer concern

prior to diagnosis

Check the Anti-Lock Braking System Control

Module for related DTCs and refer to the relevant

DTC index U0422-00

Invalid data received

from Central Junction

Box - No sub type

information

Invalid message from the

Central Junction Box

Check the Central Junction Box for related DTCs

and refer to the relevant DTC index